Implementing condition-based maintenance using modeling and simulation: a case study of a permanent magnet synchronous motor

Jabid Quiroga Méndez1, Silvia Oviedo Castillo2

1 Mechanical Engineer, Universidad Industrial de Santander, Colombia. Master of Mechanical Engineering, Florida State University, USA. Associate Professor, Universidad Industrial de Santander. jabib@uis.edu.co

2 Electronic Engineering, Universidad Industrial de Santander. Candidate for Masters in Mechanical Engineering, Universidad Industrial de Santander, Colombia. siljuovi@uis.edu.co

ABSTRACT

This paper introduces condition-based maintenance (CBM) architecture regarding an electrical application. Appropriate and efficient fault detection constitutes one of the major challenges associated with CBM and a modelbased approach constitutes the way to achieve it. A case study using a permanent magnet synchronous motor (PMSM) is presented to illustrate implementing CBM using a neural network motor model. CBM may be implemented in real time using Matlab and dSpace. The difference between line currents' negative sequence components, predicted by a multilayer neural network, and the current values acquired from the motor is used as fault indicator. Experimental results have shown the efficiency of the proposed model in detecting several stator winding short faults in differing load conditions and fault severity, obtaining up to 95% reliability.

Keywords: condition-based maintenance, fault detection, neuronal networks, permanent magnet synchronous motor.

Received: January 20th 2010

Accepted: May 31th 2011

Introduction

Technological progress has encouraged system complexity. Highly-automated systems highlight the need for developing intelligent maintenance strategies that can optimise monitoring tasks' reliability.

Maintenance management aims to minimise operational costs, particularly reduced man-hours and repair costs. Various technologies have been pursued to achieve the above objectives, such as total productive maintenance (TPM), root cause analysis (RCA), preventative maintenance, etc.

Conventionally, maintenance has been implemented using corrective, reactive or preventative approaches. Maintenance is carried out in the reactive mode only after the obvious functional failure of a component or complete system breakdown. An alternative method is time-based maintenance where maintenance is based on accumulated operation hours. Time-based maintenance assumes that mean time between functional failures is statistically or experientially known when the equipment or machinery is running in normal usage. Obviously, time-based maintenance involves planned system shutdowns and scheduled repair activities on some still functioning equipment, meaning that system integrity may become compromised when corrective action is not necessary.

On the other hand, condition-based maintenance (CBM) avoids unnecessary stoppages. System condition is assessed in real time in a CBM approach. CBM methods are classified as being model -based, knowledge-based and signal-based. In this work redundant model-based maintenance is used instead of hardware redundancy (Kim and Parlos, 2002).The main benefit of a model -based approach lies in simplification of the information being assessed. This approach involves greater system diagnostic ability; however, this method has its own drawbacks. One of the most important ones concerns modelling error robustness (Liu, 2006). Therefore, modelling is a priority in CBM implementation. Embedded models in CBM usually correspond to a system model running in normal conditions.

This paper presents fundamental concepts and technical scope associated with CBM. It also shows the importance of CBM model-based modelling. An example of CBM for stator winding short fault detection is provided using a PMSM.

The conceptual structure for a CBM system

An effective maintenance system should be able to provide specific information about such system and its abnormal conditions. Maintenance tasks need to monitor system conditions through online monitoring and assure updated equipment information to accurately determine actual conditions for ascertaining a system’s actual overall condition and ultimately its required maintenance. A system captures and analyses machine signals to perform the previous task; these are compared to simulated information for such system in normal operation and predicts system's future condition based on trends associated with fault condition trends. The scope of a typical CBM model-based system is illustrated in Figure 1.

Real-time monitoring uses current performance data to produce fault indicators and continuously evaluate operating conditions. The predictive stage uses the information provided by real-time monitoring to predict a particular need for corrective action. CBM should contain the following parts (Figure 1):

- Sensor module to capture signals (vibration, current, temperature) in real-time;

- Data acquisition where measured signals are processed to produce fault features for fault detection and diagnosis purposes;

- Analytical model of the system to predict monitoring compared to measured values to produce residual basis for fault detection and diagnosis; and

- Fault detection module where residuals are compared to a statistically established threshold to determine a system’s condition.

Modelling and simulation

The key to the success of CBM is effective condition assessment based on an accurate analytical model (Figure 1)). Early detection of the fault condition allows maintenance personnel to schedule repairs prior to catastrophic failure or even human casualties. PMSM is investigated in this case study. PMSMs are a type of electric motor having increasing popularity because the armature ield is provided by permanent magnets mounted on rotor surface instead of the induced field. This characteristic provides the PMSM with high power density compared to induction motors (i.e. the most popular electromechanical torque applicator).

Methodology

PMSM faults

The number of PMSM applications is steadily increasing as a result of the advantages attributed to this type of motor. PMSM motors are found in both high- and low-power applications such as ship propulsion systems, robotics and machine tools. The main reason PMSM is so attractive is due to its efficiency and performance. PMSM presents several advantages when compared to induction motors, such as high power density, low weight, less copper loss and a small rotor for the same power output. These qualities are derived from the fact that the armature field is provided by permanent magnets mounted on rotor surface and the subsequent lack of armature windings and winding frame. The armature can thus provide higher flux density for similar air gaps, resulting in higher torque for less volume and current. PMSMs are referred to as "synchronous" because their rotor magnetic fields rotate at the same speed (synchronous speed) as their stator magnetic fields.

PMSMs are generally robust; they are frequently exposed to severe circumstances so that they are inclined to certain fault conditions after long periods of continuous operation. The statistics show that stator winding faults account for the largest percentage of electric motor failures (Ojo et al., 2002). The interturn fault in stator windings usually starts as an undetected insulation failure between adjacent turns and then develops into a shortcircuit isolating a number of turns. Single stator coil winding faults may have relatively little effect on motor performance but may affect overall motor reliability, availability and longevity (Awadallah and Morcos, 2004). Though starting with incipient turn-to-turn short-circuits, undetected small insulation failures can deteriorate and accumulate rapidly. The resulting high current may eventually lead to loss of phase winding, phase to phase or phase to ground faults.

Causes of stator winding faults can be summarised as follows (Bonnet and Soukup, 1992; Nandy et al., 2005):

- Interturn insulation suffers from transient overvoltage during motor start-up;

- Lack of balance and overvoltage cause increases in winding temperature and deterioration of the insulation;

- Loose bracing for end winding;

- Short-circuits and electrical discharges; and

- Aggressive environments weaken the insulation i.e. contamination, moisture, chemicals and high temperatures.

Fault model development

One of the most challenging tasks in modelling for CBM purposes is the development of robust and accurate fault models. The previous characteristics are intended to attenuate, or in the best cases, eliminate monitoring misdetections. The fault is explicit in line current asymmetry in the specific case of a stator winding short in a PMSM. A CBM-based model thus requires a healthy model simulating the currents of the system in normal conditions. The predicted currents are compared with actual current values producing residuals which form the basis of fault detection. A nonlinear empirical model using neural networks was developed for determining line currents using line voltages and motor speed because of the complexity of the dynamic behaviour associated with the PMSM in normal condition and load fluctuation and due to the difficulties associated with establishing exact mathematical PMSM models with conventional methods (Quiroga et al., 2009).The architecture for the problem being addressed was a neural network having a structure corresponding to a multi-layer dynamic recurrent NN with local and global feedback (as shown in Figure 2).

Local feedback was achieved in the proposed network by introducing feedback within the hidden layer, whereas global feedback was produced by connecting network output to network input.

The implemented NN consisted of an input layer, a hidden layer and an output layer. The tansig function was used in this study in the hidden layer and purelin was used in the output layer. Input vector was defined as U(t), consisting of the actual and past normalised values for the three phase line voltages (Vab, Vbc, Vca), the three normalised predicted phase currents and the rotor’s normalised rotational speed (see Figure 2)).

Figure 2) shows that the hidden layer was composed of six neurons having delayed local feedback used in each neuron. The output layer, with global feedback, had three nodes, corresponding to three-phase current predictions.

The Nguyen-Widrow method was used for initialisation (Nguyen and Widrow, 1990).Network performance during the training stage was evaluated in terms of MSE. The training function used updated weighting and bias by applying Bayesian regulation, in combination with the Levenberg-Marquardt optimisation approach. This combination minimised squared errors and weighting and then determined the correct combination so as to produce a well generalised network (Foresee and Hagan, 1997).

Residual generation

Residuals are the basis of the fault detection strategy and are produced by comparing three-phase current predictions and actual three-phase current values. Theoretically, residuals are small values during normal operation even under load fluctuation. However, residuals generated under a fault condition deviate from nominal value. The residual for phase A (phases B and C were similar) was expressed as:

| [1] |

where  was the actual value of current in phase A at time t and

was the actual value of current in phase A at time t and  was the predicted value of current in phase A at time

t.

was the predicted value of current in phase A at time

t.

Figure 3 gives an overview of fault detection and diagnosis (FFD) implemented as a part of the CBM described. The proposed fault indicator was based on observation of the residuals’ negative sequence component magnitude. This indicator rising above some previously established baseline by observation of the motor in normal conditions would result from the presence of a fault condition. The system was able to locate and evaluate the severity of the fault monitored

Negative sequence component

The fault studied was reflected by an imbalance (asymmetry) in motor line currents. This condition produced an increase in negative sequence component magnitude. Both analytical and experimental results have demonstrated an increase in negative sequence current regarding stator winding short-circuits (Williamson and Mirzoian, 1985). Negative sequence current magnitude was determined by:

| [2] |

where la,f , lb,f and lc,f were current signal fundamental component magnitude for three-phase currents and α was a phase rotation operator equivalent to ei 2π/3 or 120°.

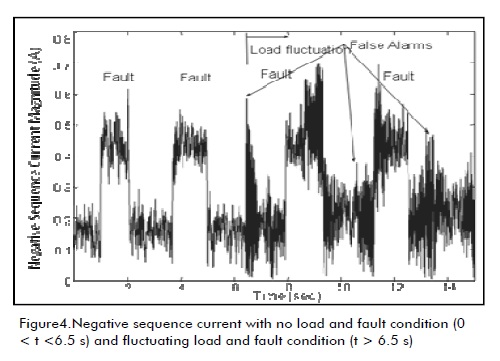

Experiments showed that load fluctuation produced onstationary asymmetry which could generate a significant increase in high frequency component magnitude in negative sequence current. A false alarm could thus have resulted in the monitoring system(see Figure 4).

A robust fault detection scheme was obtained using a model which provided current prediction under normal and load fluca genetuations. The model may reproduce current behaviour under load fluctuations, so, theoretically, the residuals were small values during normal operation, even under load fluctuation. However, the residuals generated under a fault condition deviated from nominal value. The negative component of the residuals ra,2 (3) was thus used as a fault indicator to produce robust fault detection in the proposed CBM:

Experimental results

The proposed CBM was experimentally validated using a system consisting of an 11.25 kW, 640 V, 60 Hz, Y-connected 8-pole PMSM. A DC motor was mechanically coupled to the PMSM to serve as load (see Figure 4)). Load was changed during the experiments by varying DC motorarmature resistance to emulate load fluctuation.

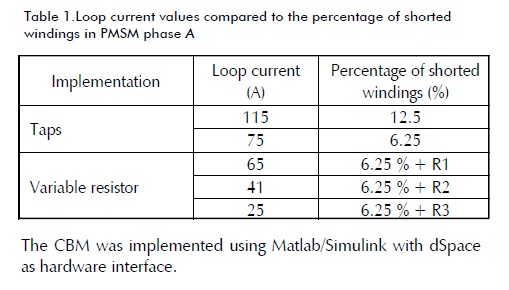

The test bench was specifically designed to emulate different stator winding fault severity levels in this proposed experimental setup. The stator windings were reconstructed, as shown in Figure 5. Different severity levels were simulated by closing different pairs of taps, which could also be observed by monitoring the fault current generated in the short-circuit loop. Only two distintaps were placed in phase A, having6.25% and 12.5%shorted windings.

An adjustable resistor was used to emulate a less severe fault (incipient fault), as shown in Figure 5. Change in stator winding fault severity level were emulated by adjusting this resistor’s value, reflected in the variation of the loop current and the magnitude of current asymmetry, as shown in Table 1

The CBM was implemented using Matlab/Simulink with dSpace as hardware interface.

A series of case studies were performed, attempting to cover a wide variety of operating conditions at different fault and load levels. However, due to space limitations, only two typical cases are presented here for each approach. The first case was performed to demonstrate incipient fault detectability (less than 6.25% of winding short in phase A) with 25 A loop current under 0%-30% fluctuating load conditions of rated torque. The fault was applied twice and the residuals' negative sequence component was obtained, as shown in Figure 6.

Figure6 shows that the system was effective in distinguishing between normal and fault conditions under load fluctuation. Residuals’ negative sequence component magnitude under fault conditions had slight changes in magnitude, mainly caused by deviations in current prediction in the neural network. Nevertheless, variations were not significant and the system performed satisfactorily in detecting the fault. A second case was performed under no-load load fluctuation of to 45% of rated torque at 41.5 A loop current in the fault. In this case the fault was applied three times (see Figure 7). An increase in residuals’ negative sequence component magnitude of was observed in the second case as a result of a more severe fault condition when comparing the experimental results obtained for the two cases studied.

The proposed indicator had a strong correlation between its magnitude and fault severity level in successive tests. This is illustrated in Table 2 and Figure 8 where it can be observed that residuals’ negative sequence current increased with loop current and fault severity.

The increase in negative ra,2 in Table2 was calculated using:

| [8] |

Where x was the actual value and x0 was normal condition value.

Conclusions

The early detection of faults in electric machines is of great significance for industry. Early, reliable and accurate machine monitoring and fault detection schemes are the object of interest and research. The CBM provides early fault detection using indicators revealed in current signals' dynamic characteristics.

In this PMSM case study, the CBM method was implemented using the negative sequence current of the difference between current actual and predicted values as a fault indicator for stator winding short-circuit faults. An NN multilayer was used to produce the residuals. A successful model was implemented for detecting fault conditions under changing load condition. The experiments showed a strong correlation between fault indicator magnitude and fault severity level.

The stator winding short fault was only considered in this case study. However, many other types of faults should be considered, such as bearing faults, air gap eccentricity, shaft faults, etc. Faults should be considered to the maximum extent possible for a comprehensive fault detection system.

References

Awadallah, M.A., Morcos, M. M., ANFIS-based diagnosis and location of stator interturn faults in PM brushless DC motors., IEEE Trans. Energy Conversion, Vol. 19, No. 4, 2004, pp. 795–796.

Bonnett, A.H., Soukup, G.C., Cause and analysis of stator and rotor failures in three-phase squirrel-cage induction motors., IEEE Transactions on Industry Applications, Vol.28, No.4, Jul/Aug 1992, pp.921-937.

Foresee, F.D., Hagan, M.T., Gauss-Newton approximation to Bayesian regularization., Proceedings of the 1997 International Joint Conference on Neural Networks, 1997, pp. 1930–1935.

Kim, K., Parlos, A., G., Induction Motor Fault Diagnosis Based on Neuropredictors and Wavelet Signal Processing., IEEE/ASME Transactions on Mechatronics, Vol. 7, No 2, June 2002, pp 201-219.

Liu, L., Robust fault detection and diagnosis for permanent magnet synchronous motors., Ph.D. dissertation, Dept. Mech. Eng., Florida State University, Tallahassee, FL, 2006.

Nandi, S., Toliyat, H.A., Xiaodong, L., Condition monitoring and fault diagnosis of electrical motors-a review., IEEE Transaction on Energy Conversion, vol.20, no.4, pp. 719-729, Dec.2005

Nguyen, D., Widrow, B., Improving the learning speed of 2-layer neural networks by choosing initial values of the adaptive weights., Proceedings of the International Joint Conference on Neural Networks, Vol. 3, 1990, pp. 21–26.

Ojo, O., Osaloni O., Kshirsagar P., Models for the control and simulation of synchronous type machine drives under various fault conditions., in 2002 Conference Record Ind. Applicat, 2002.

Quiroga, J., Cartes, D., Edrington, C., Neural Network Based System Identification of a PMSM Under Load Fluctuation., Revista DYNA, vol 76, no. 160, pp. 273-283, Dec. 2009.

Williamson, S., Mirzoian, K., Analysis of cage induction motors with stator windings faults., IEEE Transactions Power App. Systems, Vol. 104, No. 7, Julio, 1985, pp.1832-1842.