Hydrolysis evolution in a codigestion reactor at various hydraulic residence times

Evolución de la hidrólisis en un reactor de codigestión, empleando diferentes tiempos de residencia hidráulica

G. González1, E. Rustrián2, C. Carreón-Diazconti3 and E. Houbron4

1Gloria González. Ingeniera bioquímica, Tecnológico de Veracruz. Master en Ing. Ambiental, UNAM, México. Doctorante de la Universidad Autónoma de Baja California, México.

E-mail: giglzlzy@yahoo.com.mx

2Elena Rustrián. Master en Biotecnología, Tecnológico de Veracruz, México. Dra. en Ecología Microbiana, Universidad Claude Bernand, Lyon I, Francia. Affiliation: Universidad Veracruzana, México.

E-mail: erustrian@uv.mx

3Concepción Carreón-Diazconti. M. Sc., Brigham Young University, USA. Dra. en Hidrología de contaminantes, Universidad de Arizona, USA. Affiliation: Universidad Autónoma de Baja California, México.

E-mail: ccarreond@uabc.edu.mx

4Eric Houbron. Dr. en tratamiento biológico de aguas, Instituto Nacional de Ciencias Aplicadas de Toulouse, Francia. Posdoctorado, Universidad de ciencias de Valladolid, España. Affiliation: Universidad Veracruzana, México.

E-mail: ehoubron@uv.mx

How to cite: González, G., Rustrián, E., Carreón-Diazconti, C., Houbron, E., Hydrolysis evolution in a codigestion reactor at various hydraulic residence times., Ingeniería e Investigación, Vol. 34, No. 1, April, 2014, pp. 48 – 52.

ABSTRACT

The aim of this research is to study the influence of two different hydraulic residence times (HRT's), 5 and 10 days, on the process of hydrolysis-solubilization in a codigestion reactor. Tap water was used to simulate recirculation of a treated leachate. Organic solid waste (OSW) from urban solid waste (USW) and excess sludge from an urban wastewater treatment plant were first characterized and then treated together by anaerobic codigestion. This was done using a 27.2-L total volume pilot scale bioreactor, which was loaded with equal amounts (w/w) of OSW and sludge to a total useful volume of 13-L. The bioreactor was filled with tap water to ensure high humidity. In order to assure suitable mixing and good microbial-substrate contact in the reactor, recirculation of treated effluent was maintained by continuous water flow. The influence of HRT on the process performance was determined through physicochemical characterization of the effluent. Results indicate that HRT is a determinant factor in the efficiency of the system. Reducing HRT increases hydrodynamics and solubilization kinetic rate of organic matter in the bioreactor. Stabilization time of solids is reduced from 20 to 10 days when HRT is shortened from 10 to 5 days.

Keywords: Bioreactor, codigestion, hydraulic residence time, leachate, solid waste.

RESUMEN

El objetivo de este trabajo, fue estudiar la influencia de dos tiempos de residencia hidráulica (TRH) diferentes, durante 5 y 10 días, en el proceso de hidrólisis-solubilización en un reactor de codigestión. Se empleó agua de la llave para simular la recirculación de lixiviado tratado, se mezclaron residuos sólidos orgánicos (RSO), seleccionados de residuos sólidos urbanos (RSU), y lodos de una planta de tratamiento de aguas residuales urbanas, se caracterizaron y luego se trataron mediante codigestión anaerobia. A su vez, se empleó un biorreactor piloto, con volumen total de 27.2 L, el cual se cargó con cantidades iguales (peso/peso) de RSO y lodos, que ocuparon un volumen útil de 13 L. El biorreactor se llenó totalmente con agua de la llave, con el fin de asegurar una humedad elevada. Como estrategia para favorecer el mezclado y mantener el contacto biomasa-sustrato, se recirculó agua de manera continua, que simulaba el efluente tratado. La influencia de los TRH en el desempeño del proceso se determinó a través de la caracterización fisicoquímica del efluente. Finalmente, los resultados indican que el TRH es un factor determinante en la eficiencia del sistema; reduciendo el TRH se incrementó la hidrodinámica y la velocidad de la cinética de solubilización de la materia orgánica en el biorreactor. El tiempo de estabilización de los sólidos se redujo de 20 a 10 días, cuando el TRH disminuyó de 10 a 5 días.

Palabras clave: biorreactor, codigestión, lixiviado, residuos sólidos, tiempo de residencia hidráulica.

Received: May 20th 2013 Accepted: February 03th 2014

Introduction

In México, approximately 50% of the garbage carried away to final disposal sites is comprised of easily putrescible organic matter such as food leftovers, garden waste, paper and cardboard. Only 65% of the 42.2 millions of tons of urban solid waste generated in 2012 were disposed in landfills (SEMARNAT 2012). The crisis created by the scarcity of final waste disposal sites is exacerbated by the generation of sludge from wastewater treatment plants (Nelson et al., 2004). Both residues are considered a problem for final disposition sites due to their high content of organic matter and humidity, in addition to their potential as greenhouse gas emitters given their prospective biodegradability (Bouallagui et al., 2005).

Anaerobic digestion (AD) has emerged as an attractive option for treatment organic solid waste given that it can use a great variety of substrates (such as those previously mentioned), it produces renewable energy, does not require a supply of oxygen and its final product can be used as soil enhancer by means of a simple treatment (Bouallagui et al., 2005; Khalid et al., 2011). AD of complex organic materials is a sequential process that involves four steps: hydrolysis, acidogenesis, acetogenesis and methanogenesis. Throughout the first step, organic matter such as cellulose, hemicellulose, lignin and pectin, become part of the liquid phase given the action of acidogenic bacteria that provide extracellular enzymes. The rate of hydrolysis is a function of pH, particle size, temperature, composition and concentration of intermediate products like volatile fatty acids (VFAs) (Veeken et al., 2000). Comprehensive studies have aimed to improve the efficiency of AD of solid wastes (Hartmann and Ahring, 2006). Though hydrolysis has been traditionally considered the rate limiting step in AD, some authors affirm that it is instead the less well defined step (Gavala et al., 2003). Hence, more thorough studies are essential in order to better understand the processes involved and to acutely describe hydrolysis.

Anaerobic codigestion of organic fractions from USW and sludge offers many advantages over separate treatments (Stroot et al., 2001; Gómez et al., 2006). Mixing solids with a more diluted waste, such as sludge, facilitates handling and degradability. In addition, it increases the humidity ratio, reduces and counteracts the effects of inhibitors and adds specific nutrients that might be absent. Codigestion by itself has other advantages, for instance, higher performance of biogas production compared to digestion of each individual waste and the generation of a stable product, which can be used to improve soil qualities and productivity. Hence, it is a method that provides an added value to the process of anaerobic digestion. Furthermore, it offers an alternative for disposal of excess sludge generated by urban wastewater treatment plants (Mata-Alvarez et al., 2011).

Codigestion offers other advantages over the typical system of an-aerobic digestion of solid waste. For example, it allows the reduction of solid residence times, which gives a bioreactor a higher degradation capacity in terms of digested mass per unit of volume. Therefore, it is possible to work with a higher organic load. Codigestion experiments carried out elsewhere have been performed using different organic loads, HRT's, substrates, substrate combinations, temperatures and bioreactor designs (e.g., Sosnowski et al., 2003; Alatriste-Mondragón et al., 2006; Corti and Lombardi, 2007). In general, results show the benefits of this technology. Experiments on coffee pulp indicate that, when only solid residence time in a hydrolysis-solubilization reactor is considered, the system itself shows limitations of diffusion and hydrodynamics, exhibiting an optimal solid residence time of 20 days. Increasing the humidity ratio and applying recirculation of treated leachate, resulted in a significant increment in the hydrolysis-solubilization kinetics with values of 32,000mg COD d-1 (Houbron et al., 2003).

The intention of this work is to evaluate the influence of two different hydraulic residence times (HRT), 5 and 10 days, on the hydrolysis-solubilization rate in a codigestion reactor fed by a mixture of sludge and OSW, using tap water recirculation in a codigestion reactor. The bioreactor was operated under mesophilic conditions.

Methodology

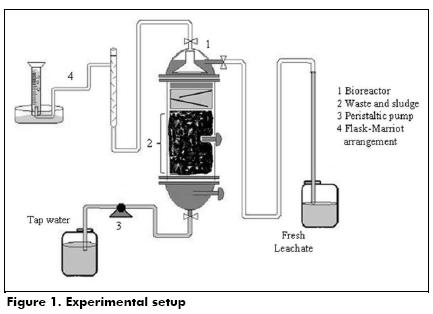

Experimental setup. The bioreactor used in this work had a total volume of 27.2-L with a useful volume of 13-L. It is comprised of four parts: a 6.9-L homogenization chamber, a 13-L solid waste chamber, a 7.3-L triphasic liquid-solidgas separator constituted by a solids trap and a gas recovering funnel and finally a headspace of 3.5 L. This reactor was built with schedule 80 PVC measuring a total length of 94 cm and an internal diameter of 19.2 cm (see Fig. 1).

To discriminate solid residence time (SRT) from liquid residence time (HRT) we decided to use a cell filled with solid waste wherein the liquid is introduced by a continuous flow. This assembly ensures that the solids are retained for a long time, while the liquid's HRT is being controlled in order to determine its effect on the hydrolyis-solubilization rate of organic matter contained in the solid fraction. This effect was measured by means of Chemical Oxygen Demand (COD) in the liquid phase. All of these were routinely analyzed following the procedures of Standard Methods (1998). A continuous tap water flow was introduced at the bottom of the cell by means of a peristaltic pump to produce feeding flows of 226.7 and 113.3 ml h-1 that render HRT of 5 and 10 days, respectively. Hence, matter liquefaction was observed without the interference of additional non-controlled organic matter or other types of inhibitors.

A perforated plate of 80 PVC material with 0.8 cm holes was installed between the homogenization and the solid waste chambers to enable the uniform and ascendant distribution of the liquid that favors good contact between liquid, solid substrate and microorganisms. Outflow of produced leachate was located at the upper side of the bioreactor. A Marriot-flask type system was placed at the top center to determine volume of biogas produced. The reactor operated at room temperature (22-28°C) during the entire experiment.

Solid Substrate. A standard OSW sample was prepared in accordance with the national composition (%) reported by INEGI (2011). It consisted of pineapple, potato, tomato, carrot, orange, banana, chayote and corn peels mixed with lettuce and tree leaves, coriander, newspaper and cardboard. These residues were manually cut in square pieces of 3 cm on average.

Sludge Substrate. Secondary treatment of activated sludge from a 25 L s-1 urban wastewater treatment plant was used in this research. Physical characteristics of sludge included black color, nauseating odor and humid and adhesive consistency in addition to presence of hair, leaves, rubbish, etc.

Reactor's start up. A 13 kg substrate comprised of a mixture of 6.5 kg OSW and 6.5 kg fresh sludge, was prepared for codigestion. Substrate was introduced into the bioreactor and compacted until it reached the useful volume of 13 L with a density of approximately 1 kg L-1. Subsequently, 14.2 L of tap water were used to completely fill up the reactor obtaining a humidity ratio higher than 90%. In both HRTs, tap water was used to completely fill the reactor and to reach a humidity ratio of more than 90%. Both experiments were performed using only one load of solid waste and a continuous water inflow to ensure an exhaustive extraction of solubilized organic matter. These experiments were performed in batch mode.

Selective pressure. The experimental setup was designed with the specific idea of favoring the hydrolysis-solubilization processes and to inhibit the process of methanization. Transfer of organic matter from solid to liquid phase was prioritized to preserve the soluble form of COD. Incidentally, this soluble COD enriched leachate, has the potential to serve as a feedstock for a high performance methanogenic reactor. Two variables were used as parameters of selective pressure, pH and organic load. Acidic environments inhibit the activity of methanogenic bacteria, thus preserving the soluble form of COD in leachate, consequently, no attempts were made to increase the low pH resulting from the acidification process. In addition, the rate limiting step of methanization in the presence of a high content of solids is hydrolysis. For this reason, a high organic load for inhibiting the digestion was maintained for this experiment. Accordingly, under the described experimental scheme, our anaerobic bioreactor is mainly designed for hydrolysis-solubilization of solid waste that incorporates recirculation of tap water simulating recirculation of treated leachate from a methanogenic reactor.

Physicochemical Analysis. Characterization of OSW was performed at the beginning and at the end of the experiments. Fresh residues for both experiments were prepared separately and contained more than 80% humidity. The obtained leachate was analyzed on a daily basis. Mass evolution was monitored through the quantification of the solid fraction in its different forms: COD, nitrogen and wet weight. Organic matter content was determined by means of total and soluble chemical oxygen demand (CODt and CODs, respectively). Other measured parameters were total and volatile solids (TS and VS, respectively), Kjeldhal Total and ammoniacal Nitrogen (N-NTK and N-NH4, respectively), pH and total phosphorus. All of these were routinely analyzed following the procedures of Standard Methods (1998).

Results and discussion

Even though equivalent wet masses of OSW and sludge were introduced into the bioreactor for a total of 13 kg for an HRT 5 and 10 days, the proportion of organic matter drawn from sludge is much larger. This fact strengthens the interest in codigestion using sludge as one of the substrates, given that it largely increases the contribution of organic matter (Stroot et al., 2001; Fernández et al., 2001; Sosnowski et al., 2003). Besides that, the addition of active microorganisms naturally enhances the biological processes of hydrolysis, solubilization and even methanization. One of the purposes for using solid waste in a two-phase anaerobic digestion process is to optimize each stage. The favorable conditions to improve hydrolysis and solubilization of organic matter are created during the first step. A second high efficiency methanogenic reactor dedicated to the treatment of leachate, which is rich in soluble organic matter, would efficiently transform these solubilized products to methane. A disadvantage of a onestep anaerobic reactor that operates on a continuous basis is the accumulation of solids, which prevents methanization (Houbron et al., 2003).

A two-stage biodigestor has been recommended when dealing with loads rich in highly putrescible residues, such as fruit, vegetables and other organics (Mata-Alvarez et al., 2000; Bouallagui et al., 2005). However, the long SRT imposed under this scheme are not favorable for the process and the kinetics of methanization. As already mentioned, to disassociate the solid from the liquid phase, rich in soluble COD and to control HRT, it is proposed that a cell that contains an immobile solid substrate be worked on and a continuous liquid flow be applied. This configuration allows control of the humidity ratio and favors the contact between substrate and microorganisms.

Organic matter is observed in the effluent as total and soluble COD immediately after starting reactor's operation (see Figure 2). As expected, the dominant form of COD in the liquid phase of both experiments is the soluble one. Maximum concentrations were reached at the beginning of each experiment with values of 15,000 and 12,000 mg L-1 for HRT of 5 and 10 days, respectively.

The presence of active anaerobic microorganisms in secondary sludge used for codigestion, favors the achievement of high reaction kinetics. For instance, when sludge was added into the digestion process of coffee pulp, the total time for hydrolysis was reduced from 500 to 300 days (Houbron et al., 2003). This is due to the sequence that the hydrolytic process follows. During the first step, organic matter is disintegrated releasing polymers such as carbohydrates, lipids and proteins. These, in turn, are hydrolyzed as result of the action of cellulase, lipase and protease enzymes, respectively, which are produced by microorganisms contained in the added biomass (Vavilin et al., 2008). In our codigestion experiments however, the amount and source of the added biomass were constant varying only the flow velocity of recirculated leachate.

In our case, 90% of the organic matter was hydrolysis-solubilized within a period of 10 days when HRT was 5 days, though for an HRT of 10 days, the same process required for as long as 20 days. A reduction in residence time increases turbulences and consequently, promotes contact between the solid substrate and microorganisms, which in turn, favors the hydrolysis-solubilization stage. This behavior fit well with that reported by Veeken (2000) under similar conditions. At the beginning of our experiment, there is access to organic matter with the highest potential for hydrolysis and latter solubilization. Once this substrate is exhausted, a period of little variable COD values is observed, which means the process is acting on more complex organic fractions, such as lignocellulose materials (Khalid et al., 2011). Mesophylic conditions (22–28°C) were maintained throughout the duration of the experiments.

On the other hand, concentrations of solids from extracted leachate were consistent with the evolution of COD for both experiments. This means that the amount of solids in the liquid phase is relatively low and consequently, indicates a good hydrolysis process in which all of the organic matter is dissolved. For an HRT of 5 days, 10 days were required to reach the steady state with a solid content of 10 mg L-1 while a little more than 20 days were needed in the case of the HRT of 10 days with a solid content of 20 mg L-1.

Maximum kinetic rate was observed at the beginning of the process with values of 2,700 and 1,200 mgCOD L-1 for an HRT of 5 and 10 days, respectively (see Fig. 3). Increasing the reactor's flow by a factor of two makes more than double the kinetics of hydrolysis possible. These results are very similar to those obtained by Houbron et al. (2008), applying comparable HRT in the hydrolysis of coffee pulp. In addition, it has been shown that optimal residence time of solids in a continuous flow treatment is 20 days, although the kinetics is relatively lower (Banks and Wang 1999, Mata-Alvarez et al., 2000).

By maintaining a reactor's high humidity ratio and a continuous inflow, it is possible to dissociate HRT from SRT and to significantly optimize the kinetics process. Conversely, it is important to emphasize that recirculation of nontreated leachate may generate an accumulation of toxic or inhibiting compounds, such as ammonia in the liquid phase (Benabdallah et al., 2009). Hence, only recirculation of treated leachate has the potential to elevate the kinetics of reaction up to 2,700 mg L-1 d-1.

Acidic pHs with values between 5 and 6, which are considered optimal for an efficient hydrolysis process (Kim et al., 2003) were dominant in both experiments (see Fig. 4). It was observed that at an HRT of 5 days, the pH is close to 6 for the hydrolysis phase (the first 10 days). It drops down to approximately 5 during acidification and begins to increase again after day 28. Once this last phase ended, the pH raised to values near 6 as a result of continuous extraction of generated acids. The acidification phenomenon was even more significant while working at an HRT of 10 days, due to low flows and slow acid extraction rates (see Fig. 4). Even though the liquid phase showed an acidic pH along the entire hydrolysis-acidification process, slight and intermittent generation of methane was observed in both experiments. At an HRT of 5 days, methane accumulation summed 43 L in 79 days, representing approximately 12.5% of total COD while, at an HRT of 10 days, only 5.3 L of methane were generated in 106 days. This last experiment shows a low pH of 4.6 in combination with a low presence of methane, which seems to indicate that pH controls and inhibits the production of methane.

The main interest in this kind of reactors is to hydrolyze and solubilize organic matter in the codigestion cell and consequently, to generate an effluent rich in soluble COD and volatile fatty acid (VFA), which can easily be transformed into methane. Subse-quently, leachate obtained at the end of the process can be treated in a high efficiency methanogenic reactor. In our case, pH as a selection parameter did not suffice to completely inhibit methanization. Nitrogen and phosphorus were also detected in leachate showing a behavior very similar to a COD profile. Initial concentrations of nitrogen and phosphorus were 150 and 40 mg L-1 at HRT of 5 days, and 340 and 40 mg L-1 at an HRT of 10 days, respectively (date not shown).

Table 1 shows the results obtained from analyses performed on initial and final solid mass from substrates loaded into the bioreactors for codigestion experiments (mixing of sludge and OSW). It illustrates that both HRTs allow for an effective reduction in masses of COD and solids from substrates. An HRT of 5 days permitted a reduction of 49.4% of total wet weight of solid waste, of 12.3% of total solids and of 51% of COD. Meanwhile, an HRT of 10 days achieved the removal of 46.2%, 23.4% and 62% of wet weight, total solids and COD, respectively. The larger removals of total solids and COD observed at HRT 10 are explained by the longer experiment period.

At the end of experimentation, the liquid phase showed a relatively light color and low contents of COD and solids, however, the solid phase still revealed the presence of fiber and paper. Regardless, under these conditions it is possible to generate easily degradable leachate that has the potential to be treated in high efficiency methanogenic reactors, which may give OSW an added value as energy producers.

Conclusions

The experiment design used in our research offered the best operational conditions for the adequate transport of organic matter particles from substrates. Continuous flow of recirculated liquid favored the interaction between microorganisms and polymers which, in turn, promoted production of the appropriate hydrolytic enzymes. Fixing the amount and source of biomass (inoculum) for all experiments helped to verify that the hydrolysis rate depends on the surface interaction between the available organic matter and the enzymes present within the reactor. HRT was the only variable parameter used throughout the experiments.

Under the described conditions, the highest hydrolysis rate was obtained when using the lowest HRT, which results in an expedited process. The same behavior is observed for the kinetics of hydrolysis-solubilization, i.e., the lower HRT lead to the maximum reaction kinetics. Maximum hydrolysis-solubilization kinetics of 2,700 and 1,200 mgCOD L-1 d-1 were observed for HRTs of 5 and 10 days, respectively.

Continuous extraction of leachate, by means of flow from the bed of bioresidues to the effluent, prevented massive accumulation of the several inhibitors of hydrolysis besides pH, such as amino acids, sugars, ammonia and VFAs in the hydrolytic reactor; hence, inhibition was not present. Acidic conditions were developed for both experiments. At the highest HRT, pH reached the lowest value of 4.6 causing almost total inhibition of methane production. At a lower HRT inhibition was lower as well.

The selected reactor's configuration, including dissociation of HRT and SRT through continuous liquid flow, allowed considerable acceleration of the time needed to stabilize OSW. Subsequently, leachate rich in VFAs is available to be treated in a high efficiency methanogenic reactor.

References

Alatriste-Mondragón, F., Samar, P., Cox, H., Ahring, B. K., Iranpour, R., Anaerobic codigestion of municipal, farm, and industrial organic wastes: A survey of recent literature., Water Environ. Research, Vol. 78, No. 6, Jun., 2006, pp. 607-636.

Banks, C. J., Wang, Z., Development of a two phase anaerobic digester for the treatment of mixed abattoir wastes., Water Science and Technology, Vol. 40, No. 1, Jan., 1999, pp. 69-76.

Benabdallah El-Hadj, T., Astals, S., Galí, A., Mace, S., Mata-Alvarez, J., Ammonia influence in anaerobic digestion of OFMSW., Water Science and Technology, Vol. 59, No. 6, March, 2009, pp. 1153-1158.

Bouallagui, H., Touhami, Y., Cheikh, R. B., Hamdi, M., Bioreactor performance in anaerobic digestion of fruit and vegetable wastes., Process Biochemistry, Vol. 40, No. 3/4, March, 2005, pp. 989-995.

Corti, A., Lombardi, L., Anaerobic Codigestión of source selected organic waste and sewage sludge., Memoirs from 11th International Waste Management and Landfill Symposium, Sardinia, Italy, October, 2007, pp. 599-600.

Fernandez, B., Porrier, P., Chamy, R., Effect of inoculum-substrate ratio on the startup of solid waste anaerobic digesters., Water Sci. Technol., Vol. 44, No. 4, March, 2001, pp. 103-108.

Gavala, H. N., Angelidaki, I., Ahring, B. K., Kinetics and modeling of anaerobic digestion process., Adv. Biochem. Eng. Biotechnol., Vol. 81, 2003, pp. 57-93.

Gómez, X., Cuetos, M. J., Cara, J., Morán, A., García, A. I., Anaerobic codigestion of primary sludge and the fruit and vegetable fraction of the municipal solid wastes. Conditions for mixing and evaluation of the organic loading rate., Renewable energy, Vol. 31, No. 12, Oct., 2006, pp. 2017-2024.

Hartmann, H., Ahring, B. K., Strategies for the anaerobic digestion of the organic fraction of municipal solid waste: an overview., Water Science & Technology, Vol. 53, No. 8, Aug., 2006, pp. 7-22.

Houbron, E., Larrinaga, A., Rustrián, E., Liquefaction and methanization of solid and liquid coffee wastes by two phase anaerobic digestion process., Water science and technology, Vol. 48, No. 6, Jun., 2003, pp. 255-262.

Houbron, E., González-López, G., Cano-Lozano, V., Rustrián, E., Hydraulic retention time impact of treated recirculated leachate on the hydrolytic kinetic rate of coffee pulp in an acidogenic reactor., Water Science and Technology, Vol. 58, No. 7, July, 2008, pp. 1415-1421.

INEGI, Censo general de población y vivienda, Estadísticas por tema, en estadísticas ambientales: residuos., México, Instituto Nacional de Estadística Geografía e Informática, 2011.

Khalid, A., Arshad, M., Anjum, M., Mahmood, T., Dawson, L., The anaerobic digestion of solid organic waste., Waste Management, Vol. 31, No. 8, May, 2011, pp. 1737-1744.

Kim, J., Park, C., Kim, T. H., Lee, M., Kim, S., Kim, S. W., Lee, J., Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge., J. Biosci. Bioeng., Vol. 95, No. 3, Jun, 2003, pp. 271-275.

Mata-Alvarez, J., Macé, S., Llabrés, P., Anaerobic digestion of organic solid waste. An overview of research achievements and perpectives., Bioresources Technology, Vol. 74, No. 1, Aug., 2000, pp. 3-16.

Mata-Alvarez, J., Dosta, J., Macé, S., Astals, S., Codigestion of solid wastes: a review of its uses and perspectives including modeling., Critical Reviews in Biotechnology, Vol. 31, No. 2, June, 2011, pp. 99-111.

Nelson, K. L., Jiménez, C. B., Tchobanoglous, G., Darby, J. L., Sludge accumulation, characteristics, and pathogen inactivation in four primary waste stabilization ponds in central Mexico., Water Research, Vol. 38, No. 1, Jan., 2004, pp. 111-127.

SEMARNAT, Sistema nacional de información ambiental y de recursos naturales, Base de datos estadísticos: Consulta temática, Residuos sólidos urbanos., México, Secretaría de medio ambiente y recursos naturales, 2012.

Sosnowski, P., Wieczorek, A., Ledakowicz, S., Anaerobic codigestion of sewage sludge and organic fraction of municipal solid wastes., Advances in Environmental Research, Vol. 7, No. 3, May, 2003, pp. 609-616.

American Public Health Association/American Water Works Association/Water Environment Federation (ed.), Standard Methods for the Examination of Water and Wastewater., Washington DC, USA, 1998.

Stroot, P. G., McMahon, K. D., Mackie, R. I., Raskin, L., Anaerobic codigestion of MSW and biosolids under various mixing conditions-I. Digester performance., Water Research, Vol. 35, No. 7, May, 2001, pp. 1804-1816.

Vavilin, V. A., Fernandez, B., Palatsi, J., Flotats, X., Hydrolysis kinetics in anaerobic degradation of particulate organic material: an overview., Waste Manage., Vol. 28, No. 6, May, 2008, pp. 939-53.

Veeken, A., Kalyuzhnyi, S., Scharff, H., Hamelers, B., Effect of pH and VFA on hydrolysis of organic solid waste., Journal of Environmental Engineering, Vol. 126, No. 12, Dec., 2000, pp. 1076-1081.