Doi: https://doi.org/10.15446/rev.colomb.quim.v45n3.58085

Analytical method validation of GC-FID for the simultaneous measurement of hydrocarbons (C2-C4) in their gas mixture

Validación de un método analítico GC-FID para la medida simultánea de hidrocarburos (C2-C4) en una mezcla gaseosa

Validação de uma metodologia analítica GC-FID para a medida simultánea de hidrocarbonetos (C2-C4) em uma mistura gasosa

Oman Zúas1*, Muhammad R. Mulyana1, Harry Budiman1

1 Gas Analysis Laboratory, Metrology in Chemistry Research Group, Research Centre for Metrology, Indonesian Institute of Sciences (Pusat Penelitian Metrologi-LIPI), Building 456, Kawasan PUSPIPTEK Serpong 15314, Tangerang, Banten, Indonesia.

* Corresponding author: : oman.zuas@lipi.go.id

Article citation:

Zuas, O.; Mulyana, M. R.; Budiman, H. Analytical method validation of GC-FID for the simultaneous measurement of hydrocarbons (C2-C4) in their gas mixture. Rev. Colomb. Quim. 2016, 45 (3), 22-27. DOI: https://doi.org/10.15446/rev.colomb.quim.v45n3.58085.

Recibido: 14 de Julio de 2016. Aceptado: 23 de Agosto de 2016.

Abstract

An accurate gas chromatography coupled to a flame ionization detector (GC-FID) method was validated for the simultaneous analysis of light hydrocarbons (C2-C4) in their gas mixture. The validation parameters were evaluated based on the ISO/TEC 17025 definition including method selectivity, repeatability, accuracy, linearity, limit of detection (LOD), limit of quantitation (LOQ), and ruggedness. Under the optimum analytical conditions, the analysis of a gas mixture revealed that each target component was well-separated with high selectivity property. The method was also found to be precise and accurate. The method linearity was found to be high with good correlation coefficient values (R2 ≥ 0.999) for all target components. It can be concluded that the GC-FID developed method is reliable and suitable for determination of light C2-C4 hydrocarbons in their gas mixture. The validated method was successfully applied to the estimation of light C2-C4 hydrocarbons in natural gas samples, showing high performance repeatability with relative standard deviation (RSD) less than 1.0% and good selectivity with no interference from other possible components.

Keywords: Method validation, hydrocarbons, GC-FID, ISO/IEC 17025.

Resumen

Se validó una cromatrografía de gases precisa, acoplada con un detector de ionización de llama (GC-FID) para el análisis simultáneo de hidrocarburos ligeros (C2-C4) en su mezcla gaseosa. Los parámetros de validación se evaluaron con base en la definición de la ISO/ IEC 17025, que incluye selectividad del método, precisión y repetibilidad, exactitud, linealidad, limite de detección (LOD), limite de cuantificación (LOQ) y robustez. Bajo las condiciones analiticas óptimas, el análisis de la mezcla gaseosa mostró que cada analito de interés fue separado adecuadamente con alta selectividad. Se encontró también que el método fue preciso y exacto; la linealidad fue alta y con buen coeficiente de correlación lineal (R2 ≥ 0.999) para todos los analitos. Se puede concluir que el método GC-FID es confiable y apropiado para la determinación de hidrocarburos ligeros C2-C 4 en una mezcla gaseosa. El método validado ha sido exitosamente aplicado a la valoración de hidrocarburos ligeros C2-C4 en muestras de gas natural, mostrando alta repetibilidad con desviación estándar relativa (RDS) menor al 1% y buena selectividad sin interferencias de otros posibles componentes.

Palabras clave: Validación de método analítico, hidrocarburos, GC-FID, ISO/IEC 17025.

Resumo

Foi avaliada uma cromatografia gasosa precisa, equipada com um detector de ionização de chama (CG-FID) para a análise simultâneo de hidrocarbonetos ligeiros (C2-C4) em uma mistura gasosa. Os parâmetros de validação foram avaliados baseados na definição da ISO/IEC 17025, que inclui seletividade do método, precisão e repetibilidade, exatidão, linearidade, limite de detecção (LOD), limite de quantificação (LOQ) e robustez. Baixo as condições analiticas ótimas, a análise da mistura gasosa mostrou que cada analito foi separado adequadamente com alta seletividade. Também foi encontrado que o método foi preciso e exato; a linearidade foi alta e com bom coeficiente de correlação linear (R2 ≥0.999) para todos os analitos. Pode-se concluir que o método GC-FID é confiável e apropriado para a determinação de hidrocarbonetos ligeiros C2-C4 em uma mistura gasosa. O método avaliado têm sido exitosamente aplicado à valoração de hidrocarbonetos ligeiros C2-C4 em amostras de gás natural mostrando alta repetibilidade com desvio-padrão relativo menor funcionais. ao 1% e boa seletividade sem interferências de outros possiveis componentes.

Palavras-Chave: Validação do método analitico, hidrocarbonetos, CG-FID, ISO/IEC 17025.

Introduction

Non-methane hydrocarbons (NMHCs in short) are typically low molecular weight (C1-C10) species in the hydrocarbon chain. The NMHCs have become important in industry and environment. In chemical industries, some natural sources of NMHCs (such as methane, propane, and butane) have more popular feedstock and their trading supply are highly demanded (1). Furthermore, NMHCs, generated by anthropogenic activities, (fuel and biomass burning, vehicles, solvent usage, and oil refineries) have been detected in the atmosphere and they have grown environmental and public health concern (2, 3). Regardless of their importance, it is necessary to reassess measurement practice in order to provide accurate and reliable data of the NMHCs concentration. This necessity is related to the fact that accurate and reliable data are used as the basis for decision making related to both for market price in industrial purpose and regulatory enforcement for the environmental monitoring program.

According to ISO/IEC 17025, a reliable and accurate result can only be obtained by using a validated method. In any testing laboratory, method validation is a part of quality assurances to declare that a high quality of analytical result is provided (4). In general, method validation refers to a documented procedure used by a laboratory to assure that the method performance for the determination of a particular analyte meets the required criteria (5-7). This paper presents results on the validation of a GC-FID method for the measurement of five components of light hydrocarbons (C2-C4) including ethylene, propane, propylene, isobutane, and n-butane in their gas mixture. The evaluation was based on the ISO/IEC 17025 definition (8, 9) and it was emphasized on the following validation parameters: method selectivity, repeatability, accuracy, linearity, limit of detection (LOD), limit of quantification (LOQ), and ruggedness. The validated method was successfully employed in the assay of light C2-C4 hydrocarbons in natural gas samples.

Materials and methods

Materials

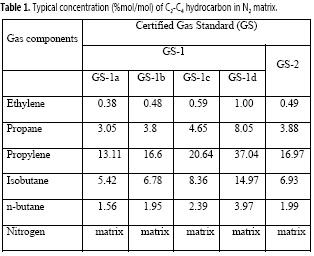

Certified gas standards for C2-C4 hydrocarbon mixture (GS-1 in short) were purchased from Mesa Specialty Gases and Equipment (CA, USA). A series of GS-1 (denoted as GS-1a to GS-1d), having concentration as listed in Table 1, was used as test standard in all experimental runs. Another GS (denoted as GS-2) was only used for method accuracy assessment. Both certified GS-1 and GS-2 with relative uncertainty +2% are traceable to National Institute of Standards and Technology (NIST), USA.

Instrumentation

Separation of C2-C4 hydrocarbons from their mixture was performed on a packed-column (Coated GC Packing 23% SP-1700, 80/100 Chromosorb PAW, 30 ft x 1/8 inch SS from Supelco) installed on a GC system Model 6890 (Hewlett Packard Agilent, CA, USA), equipped with a flame ionization detector (FID). The optimized analytical conditions for the GC-FID method are tabulated (Table 2).

Gas chromatography analysis

A certain volume of gas standard was injected into a GC system under optimized analytical conditions (Table 2). The output signal was monitored using GC ChemStation version Rev. A.10.02 (1757), which was installed on a LG personal computer (Processor AMD Richland A4-7300-HD 8470D, LG International Corp.). The data was estimated by automated integration of the area under the resolved chromatographic profile.

Procedure for method validation

All data obtained from the GC-FID measurement were used for the method validation. The assessment parameters (selectivity, repeatability, linearity, LOD, LOQ, and ruggedness) were calculated by adopting some procedures, as they can be found everywhere in published literature (4, 5, 10-16). In a typical experiment, the calculation procedure is described as follows: selectivity of the method was determined by injecting the gas standard (GS-1) and it was evaluated in term of retention time (tR) and selectivity factor (a); repeatability was established by measuring the response of the GS-1 standard and expressed as percentage relative standard deviation (% RSD) of seven replications injection under the same operating condition over a short time interval (in the same day); accuracy was evaluated by comparing the concentration of GS-1 standard against another independent gas standard (GS-2).

Furthermore, to investigate the linearity, a series of GS-1 standard (GS-1a to GS-1d as listed in Table 1) was used. The injection of each gas standard was conducted in seven replications and then the linearity was estimated from the calibration curve. The calibration curve was constructed by plotting peak area of each component in the GS-1 standard (GS-1a to GS-1d) as a function of their concentration. The LOD and LOQ were established at a signal-to-noise ratio (S/N) of 3 and 10, respectively, of the chromatogram at the lowest concentration point of each component. Ruggedness was evaluated by small changing in flow rate of carrier gas during analysis (from 6.5 to 7.5 mL/min with 0.5 mL/min flow rate different as listed in Table 7).

Selectivity, repeatability, accuracy, linearity, LOD and LOQ, and ruggedness were defined as follows:

Selectivity

The selectivity refers to the capability of GC method to discriminate and quantify the response of target component in the presence of other components as interference (5, 10). The selectivity is the relative retention of two adjacent peaks; hence, it is highly dependent on the change of the tR values of the two corresponding target gas components.

Repeatability

The repeatability precision of method refers to the closeness between measured values resulting from an independent measurement using the same equipment, under the same analytical condition, by the same operator and within short intervals of time (5, 10). Theoretically, the determination of the repeatability was conducted by the prediction of relative standard deviation (%RSD) of precision using Horwitz function [1] (14):

where C is the concentration of gas component stated in decimal fraction. The requirement of %RSD for repeatability is between 0.5 and 0.75 of a theoretical value determined by Horwitz function. In a word, the repeatability of the method is categorized acceptable when the %RSD is less than 0.67 of the %CV- Horwitz (0.67CV-Horwitz) (7).

Accuracy

Method accuracy refers to the closeness of agreement between measured and accepted (true) concentration of target component. The accuracy value is dependent on two factors i.e., the bias and precision. The bias of a method is the difference between the measured value and the value from certificate of reference standard, which was calculated using an expression below [2] (4, 6, 7):

where  is the average of measured reference standard value, and Y is value from certificate of reference standard. For assessing the method accuracy, precision of an analytical method (σ) from repeatability and reproducibility is included. In addition, the uncertainty value from certificate of reference standard is also included for estimating the a value. Thus, the value of a is obtained by combining those three components by using the following expression [3] (6, 7):

is the average of measured reference standard value, and Y is value from certificate of reference standard. For assessing the method accuracy, precision of an analytical method (σ) from repeatability and reproducibility is included. In addition, the uncertainty value from certificate of reference standard is also included for estimating the a value. Thus, the value of a is obtained by combining those three components by using the following expression [3] (6, 7):

where Sb is the standard deviation from reproducibility (inter day precision); Sw is the standard deviation from repeatability (intra day precision), and μRM is the uncertainty of standard GS-2 as stated in the certificate. The acceptance criteria is set according to the ISO Guide 33:2000 (15). In such ISO Guide, no bias is found if the observed bias (CΔ) value falls within ±2 σ at confidence level 95% [4]:

Linearity

Method linearity is defined as the ability of the method to demonstrate that the test results are proportional to the concentration of sample (5, 7, 10). Investigation of method linearity for C2-C4 measurement was conducted by generating a calibration curve using different concentration levels of C2-C4 gas standards. Each concentration level was analyzed using GC-FID in six replications (n =6).

LOD and LOQ

LOD of an analytical method refers to the lowest amount of analyte that can be detected which is not necessarily quantified as an exact value. Meanwhile, LOQ is the lowest concentration of an analyte that can be quantitatively determined with appropriate precision (5, 10). In a GC measurement, both LOD and LOQ are important. The LOD and LOQ were calculated based on signal to noise ratio, which are 3:1 and 10:1, respectively.

Ruggedness

The ruggedness of an analytical method is the method capacity to generate some results which remains unaffected by minor changes of the experimental conditions during analysis (5, 10). In this study, the ruggedness of the method was assessed by investigating the effect of small change on the flow rate of the carrier gas used as the mobile phase for gas component separation in the column of GC-FID system.

Assay of hydrocarbon in natural gas samples

Two natural gas samples were obtained commercially from Indonesian State Oil and Natural Gas Mining Company (PERTAMINA) located in North of Jakarta. The natural gas samples were analyzed by the validated method without any special treatment.

Results and discussion

Practically, in every method validation process for a GC technique, performing development of the method is the initial step, which can be carried out by optimizing the conditions of the GC for the measurement of the target component. Figure 1 depicts a typical chromatogram of C2-C4 gas component obtained under optimum analytical conditions of the GC-FID instrument (Table 2). As can be seen from Figure 1, all gas components were well separated with their retention times (tR) as listed in Table 3. No other interference peaks could be found, indicating that the development of the GC method was achieved successfully (12). Thus, the method validation process could be conducted.

Selectivity

As discussed above, no interfering peak of one gas component relative to others could be observed (Figure 1), resulting in excellent selectivity factor (α) (Table 3) with a values larger than 1.0 (15).

Repeatability

From the calculation result, the % of CV- Horwitz for each individual gas component as found to be less than 0.67 CV-Horwitz as listed in Table 4, indicating that the method is repeatable.

Accuracy

From the Table 5, it can be observed that the measured values of all C2-C4 hydrocarbons fall within ± 2σ; thus, it can be concluded that no evidence of bias can be found in the analytical method used under this study.

Linearity

The linearity data of the method are listed in Table 6. As it can be seen from Table 6, excellent linearity was obtained for all gas components with correlation coefficient values (R2) equal or greater than 0.999. Thus, the method may fit for purpose for the determination of C2-C4 gas in their mixture.

LOD and LOQ

For any quantification process producing a value below the LOD and LOQ level may lead to yield in a high measurement uncertainty; thus an unreliable measurement would occur. In addition, practically, the LOD and LOQ assessment are equally important in comparison to other method validation parameters. At a LOD level, only qualitative analysis is possible to be evaluated, while at a LOQ level, both quantitative and qualitative analysis are possible. However, at the LOQ level, the quantitative analysis performed may produce inaccuracy and imprecise result, leading to a high uncertainty contribution on the final analytical results (4). Table 6 tabulates the LOD and LOQ values for all gas components. As it can be seen in Table 6, the lowest LOD value was found to be 270 μmol/mol for ethylene, and the highest LOD values was found to be 770 μmol/mol for propylene. Correspondingly, the LOQ of ethylene (910 μmol/ mol) and propylene (2560 μmol/mol) were found to have the same trend as the lowest and the highest LOQ value, respectively.

This is a reasonably accepted finding because the concentration of ethylene (0.38 9 mol/mol) and propylene (13.11 9 mol/mol), as the lowest and the highest concentration among all other components (Table 6), respectively, were used as the basis for calculating the LOD/LOQ. Since the value of LOD/LOQ obtained from an analytical measurement is generally concentration dependent; therefore, the value of LOD/LOQ could be decreased by decreasing the concentration of the component used for LOD/LOQ calculation.

Ruggedness

As can be seen in Table 7, in all flow rate levels, both retention time and percentage peak area were found to be within acceptable limit with very low standard deviation (SD). Thus, small changes on the GC-FID experimental conditions in term of flow rate variation did not have any effect on the results of analytical measurement. Although, a massive change on the flow rate level of carrier gas has been reported to significantly affect theresults of a GC measurement (16).

Assay of natural gas samples

The validated method was applied for the analysis of light hydrocarbons (C2-C4) in two natural gas samples. The primary analysis results indicated that the concentration of the target components (C2-C4) in the natural gas sample was higher than the linear concentration range of the standard gas mixture (Table 6). This implies that a dilution step is required. Therefore, the natural gas samples were then properly diluted by using ultra high pure helium (99.9999 purity) with a dilution factor of 6, and the final concentration is shown in Table 8. It can be seen from Table 8 that all the target components (C2-C4) in the natural gas samples were detected and found at high concentration, except for propylene. Propylene may also exist in the natural gas sample but it cannot be detected by the GC-FID system under the experimental condition of this study. In addition, Figure 2 displays a typical chromatogram of a natural gas sample after the analysis using the validated method. Chromatogram in Figure 2 indicates that the method was selective for the analysis of C2-C4, and no interference from other components could be observed.

Conclusions

In this study, the developed GC-FID method for the analysis of the C2-C4 hydrocarbons (including ethylene, propane, propylene, isobutane, and n-butane) provides good selectivity toward separation of individual gas components from their mixture. Moreover, the results of each validation parameter, based on the ISO/IEC 17025, indicated that the validated method provides a sufficient evidence for proving a reliable GC-FID method for the measurement of C2-C4 hydrocarbon in their gas mixture. The developed and validated method could also be extended to the analysis of real natural gas samples. Hence, the use of such validated method may keep the degree of user confidence regarding their analytical data.

Acknowledgement

The authors gratefully acknowledged the Indonesian Government for financially supporting this study within the scope of LIPI's project "Strengthening Chemical Metrology Competency and Infrastructure" under Project No. SP.DIPA-079.01.2.664833/2016. The authors are also very much thankful to anonymous reviewers for their valuable comments, which helped the authors to improve the manuscript.

References

1. Zyryanova, M.M.; Badmaev, S.D.; Belyaev, V.D.; Amosov, Y.I.; Snitnikov, P.V.; Kirillov, V.A. et al. Catalytic reforming of hydrocarbon feedstocks into fuel for power generations units. Catal. Ind.. 2013, 5, 312-317. DOI: https://doi.org/10.1134/S2070050413040107.

2. Williams, J. Organic trace gases: an overview. Environ. Chem. 2014, 1, 125-136. DOI: https://doi.org/10.1071/EN04057.

3. Thompson, C.R.; Hueber, J.; Helmig, D. Influence of oil and gas emissions on ambient atmospheric non-methane hydrocarbons in residential areas of Northeastern Colorado. Elem. Sci. Anth. 2014, 2, 000035. DOI: https://doi.org/10.12952/journal.elementa.000035.

4. Budiman, H.; Zuas, O. Validation of analytical method for determination of high level carbon dioxide (CO2) in nitrogen gas (N2) matrix using gas chromatography thermal conductivity detector. Periódico Tchê Química. 2015, 12, 7-16.

5. European Guide: The Fitness for Purpose of Analytical Methods A Laboratory Guide to Method Validation and Related Topics. 1998. Available at https://www.eurachem.org/.

6. Taverniers, I.; Loose, M.D.; Van Bockstaele, E. Trends in quality in the analytical laboratory, II: Analytical method validation and quality assurance. Trac-Trend Anal. Chem. 2004, 23, 535-552. DOI: https://doi.org/10.1016/j.trac.2004.04.001.

7. Taverniers, I.; Van Bockstaele, E.; Loose, M.D. Trends in quality in the analytical laboratory I Traceability and measurement uncertainty of analytical results Trends in Anal. Chem. 2004, 23, 480-490 DOI: https://doi.org/10.1016/S0165-9936(04)00733-2.

8. ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories. 2nd Edition, Switzerland. 2005.

9. ALACC Guide 3: How to Meet ISO 17025 Requirements for Method Verification. The Analytical Laboratory Accreditation Criteria Committee. 2007.

10. NATA: Guidelines for the validation and verification of quantitative and qualitative test methods. The National Association of Testing Authorities (NATA). 2013. Available at http://www.nata.com.au/.

11. Styarini, D.; Zuas, O.; Hamim, N. Validation and uncertainty estimation of analytical method for determination of benzene in beverages. Eurasian. J. Anal. Chem. 2011, 6, 159-172.

12. Di Marco, G.; de Andrade, M.; Felipe, C.; Alfieri, F.; Gooding, A.; Silva, H. T. J.; et al. Determination of sirolimus blood concentration using high-performance liquid chromatography with ultraviolet detection. Ther. Drug Monit. 2003, 25, 558-264. PMID: 14508378.

13. Guaratini, T.; Cardozo, K. H. M.; Pinto, E.; Colepicolo, P. Comparison of diode array and electrochemical detection in the C30 reverse phase HPLC analysis of algae carotenoids, J. Braz. Chem. Soc. 2003, 20, 1609-1616. DOI: https://doi.org/10.1590/S0103-50532009000900007.

14. Linsinger, T. P. J.; Josephs, R. D. Limitations of the application of the Horwitz equation. Trac. Trends in Anal. Chem. 2006, 25, 1125-1130. DOI:https://doi.org/10.1016/j.trac.2006.11.002.

15. ISO Guide 33: Guide 33: Uses of certified reference materials. The International Organization for Standardization. 2000.

16. Zuas, O.; Budiman, H. Estimating precision and accuracy of GC-TCD method for carbon dioxide, propane and carbon monoxide determination at different flow rate of carrier gas. Hem. Ind. 2016, 4, 451-459. DOI:https://doi.org/10.2298/HEMIND150315051Z.