Assessment of the processing profile of six “creole potato” genotypes (Solanum tuberosum Phureja Group)

Downloads

Six diploid potato (“creole potato”, Solanum tuberosum PhurejaGroup) genotypes were grown at the localities of Soacha, Duitama and Mosquera (Colombia) and were assessed for their suitability for industrial processing using Individual Quick Freezing (IQF) as pickled and dehydrated (flakes) potatoes. The following variables were assessed: Percentage of defective tubers, dry weight, specific gravity, “eye” depth, skin type, shape, appearance, color, aroma, flavor and texture. Cultivar Criolla Colombia and clone 98-71.26 showed the best behavior for precooking processing. The best characteristics for IQF and pickling corresponded to tubers with yellow colored peel, round shape, shallow “eyes”, 16 to 20.5% dry weight, 2.5 to 3.5 cm diameter and less than 0.1% reducing sugars. For dehydrated flakes the tubers with 21-25% dry weight, large size and reducing sugars below 0.1% exhibited the best processing behavior. In addition, it was observed that the cultivar’s environmental conditions affect tuber quality and processing type to be performed.

Assessment of the processing profile of six "creole potato" genotypes (Solanum tuberosum Phureja Group)

Evaluación de la aptitud de procesamiento en seis genotipos de papa criolla (Solanum tuberosum Grupo Phureja)

Jesús Elías Rivera1, Anibal Orlando Herrera1, and Luis Ernesto Rodríguez1,2

1 Agronomy Department, Agronomy Faculty, Universidad Nacional de Colombia. Bogotá (Colombia).

2 Corresponding author: aoherreraa@unal.edu.co

Received for publication: 27 August, 2010. Accepted for publication: 2 February, 2011.

ABSTRACT

Six diploid potato ("creole potato", Solanum tuberosum Phureja Group) genotypes were grown at the localities of Soacha, Duitama and Mosquera (Colombia) and were assessed for their suitability for industrial processing using Individual Quick Freezing (IQF) as pickled and dehydrated (flakes) potatoes. The following variables were assessed: Percentage of defective tubers, dry weight, specific gravity, "eye" depth, skin type, shape, appearance, color, aroma, flavor and texture. Cultivar Criolla Colombia and clone 98-71.26 showed the best behavior for precooking processing. The best characteristics for IQF and pickling corresponded to tubers with yellow colored peel, round shape, shallow "eyes", 16 to 20.5% dry weight, 2.5 to 3.5 cm diameter and less than 0.1% reducing sugars. For dehydrated flakes the tubers with 21-25% dry weight, large size and reducing sugars below 0.1% exhibited the best processing behavior. In addition, it was observed that the cultivar's environmental conditions affect tuber quality and processing type to be performed.

Key words: diploid potato, industrial processing, precooked potato, frozen potato.

RESUMEN

Se sembraron seis genotipos diploides de papa criolla (Solanum tuberosum Grupo Phureja) en los municipios colombianos de Soacha, Duitama y Mosquera a fin de obtener información acerca de su aptitud para el procesamiento industrial mediante los métodos de Congelamiento Rápido Individual (CRI), papas en encurtido y hojuelas deshidratadas. Se evaluaron las variables siguientes: porcentaje de tubérculos defectuosos, peso seco, gravedad específica, profundidad de "ojos", tipo de piel, forma, apariencia, color, aroma, sabor y textura. El cultivar Criolla Colombia y el clon 98-71.26 mostraron el mejor comportamiento para el procesamiento previo a la cocción. Las características principales para CRI y encurtido correspondieron a tubérculos con piel de color amarillo, forma redondeada, "ojos" poco profundos, entre 16 y 20,5% de peso seco, 2,5 a 3,5 cm de diámetro y menos de 0,1% de azúcares reductores. Con relación a las hojuelas de papa deshidratadas los mejores tubérculos para procesamiento presentaron entre 21 y 25% de peso seco, tamaño grande y pocos azúcares reductores (bajo 0,1%). Además, se observó que las condiciones ambientales de los cultivares afectan la calidad del tubérculo y el tipo de procesamiento que se debe implementar.

Palabras clave: papa diploide, procesamiento industrial, papa precocida, papa congelada.

Introduction

In Colombia the name "creole potato" corresponds to morphotypes that develop tubers with yellow skin color and pulp ("yema de huevo" or egg yolk phenotype) (Rodríguez et al., 2009). It has been classified as Solanum phureja (Hawkes, 1990); Solanum tuberosum Phureja group (Huamán and Spooner, 2002) and recently as Solanum tuberosum Andigenum group (Spooner et al., 2007; Rodríguez et al., 2010). This group is conformed by a number of native potato varieties extensively grown in The Andes from the west part of Venezuela to the center of Bolivia (Ghislain et al., 2006). Creole potatoes are grown between 2.000 and 3.000 m.a.s.l. being the optimal growing height between 2.300 and 2.800 m.a.s.l. (Becerra et al., 2007), temperature values ranging between 10 and 20° C and loamy soils with pH between 5,2 and 5,9 (Pérez et al., 2008). It's been estimated that in 2010, 136,664 ha potato year-1 were sown of which creole potato represented approximately 6% with about 8,000 ha year-1 located in the Colombian departments of Cundinamarca, Boyacá and Nariño (Ministry of Agriculture and Rural Development, 2011). The total exportations ascended to about 1.000 t year-1 (Fedepapa, 2010).

The creole potato stands out for its culinary properties having pleasant flavor and texture, easy cooking, good market acceptance and high exportation potential under various forms of processing (Rivera et al., 2006). It is equally worth to highlight as well its nutritional value because there are several genotypes with high contents of protein and dry matter (DM) (Rodríguez et al., 2006) which provide carbohydrates, proteins of high biological value, vitamins (C and B complex), minerals (Fe, Zn, Cu and Ca) and carotenoids (Bonierbale et al., 2004). The creole potato is considered a functional foodstuff due to the presence of secondary metabolites like phenolic compounds, carotenoids and alkaloids (Cisneros-Cevallos, 2008).

According to the Ministry of Agriculture and Rural Development (2006) the creole potato has awaken interest due to its potential as an exportation product, it's considered promissory for its eventual positioning on international markets which confirms the necessity of promoting research on it. The industry of creole potato is a recent activity in expansion although this is not yet evident in the international statistics (Bonilla et al., 2009). Colombia's economical opening has generated opportunities for its commercialization as processed product, in presentations ranging from frozen potatoes packed in plastic bags to canned potatoes, contained using high standards. However, one of the processing constraints is the fact of not having rest period which makes it a very perishable product (Rivera et al., 2006). The consumption of processed potato has increased in the last decades due to changes in markets, the adoption of new dietary patterns, the trend of using precooked food products or of easy preparation and the incorporation of women to the labor market (Bonierbale et al., 2004).

Culture is done on small land extensions generating a variable market in volumes and prices which affects the availability of raw material for the industry and to satisfy the potential international demand (Fedepapa, 2009).

Parameters for processing

Quality is a concept associated with the form in which a product satisfies the requirements imposed by a specific use. Potato processing requires that quality has certain attributes related to external and internal quality of the tubers (Bonierbale et al., 2001; Gould, 1999), two complementary aspects that constitute key factors for processing companies (Borruey et al., 2001). The demands of consumers and industry are crucial for researching the population demands in relation to the characteristics of the type of potato that has to be produced and its quality requirements (Moreno, 2000).

Among the attributes characterize the culinary quality of potato texture, aroma, taste and color are considered (Trinchero et al., 2008). Texture is one of the most important parameters for determining sensory quality (Ross and Scanlon, 2004).

External quality

It is defined by the color of skin and pulp, form and size of the tuber, eye depth and absence of greening and physical defects. Tubers that are deformed, with holes, hollow core, rots or cracks caused by drought are undesirable (Storey, 2007). Size is also important and varies according to the type of product (Andrade, 2002; Bonierbale et al., 2001; Rivera et al., 2006). In creole potatoes the brightness and intense yellow color of the skin and pulp together with absence of defects are the main attributes for both the market of fresh products and processing; sizes may vary from 2 to 6 cm in diameter.

In precooked and frozen potatoes the absence of defects, taste and color of skin and pulp are the attributes that determine the sensory quality of the product while in pickle preparation these are the absence of defects, appearance and color of tuber as well as a translucent brine and in the processing for mashed potatoes the most important one is the texture of the final product (Rivera et al., 2006).

Gómez and Wong (2000) indicate that tubers with a diameter from 2,5 to 4,5 cm must be used for the elaboration of precooked and frozen creole potato. For pickling and preserved food a mean diameter of 2,5 cm and tubers of round and compressed shape are preferred (IICA, 1999). Potatoes for industrial use must possess good flavor, low levels of glycoalkaloids, without darkening and low levels of reducing sugars (RS) (Bonierbale et al., 2001).

Internal quality

It depends on the chemical composition. Dry matter (DM) has influence on consistency, texture and mealiness and at the same time it determines the value of specific gravity (SG). High contents of DM and low levels of RS are important factors for fresh consumption and constitute an important quality criterion for the majority of processed products (Bonierbale et al., 2001). RS are responsible for the darkening and bitterness of potato, not only when newly harvested but also during postharvest.

According to Moreno (2000) and Rodríguez et al. (2006) potatoes of Phureja Group that are found in Colombia's Central Collection have a DM content oscillating between 16% and 27.26 %. In the majority of cases the DM determines the efficiency of the finished product (Moreno, 2000).

Due to the diversity of options for processing and culinary preparation it is very difficult that a sole cultivar can be absolutely suitable for a specific type of use (Borruey et al., 2001). For the industry of potato chips DM contents of maximum 25% are required (Moreno, 2000) while Estrada (2000), Guerra (1989) and Gould (1999) mutually agree to state that potato for canning has to contain less than 18,10% (1,070 SG) being 16.84% the ideal value (1.060 SG). On the other hand Guerra (1989) and Borruey et al. (2001) conclude that for elaboration of precooked frozen potato the amount of solids has to be lower than 20.50% (1.070 SG).

Glycoalkaloid levels have to be lower than 13 mg/100 g fresh weight; higher levels produce a bitter taste being chaconine and solanine the most frequent glycoalkaloids (Gómez and Wong, 2002). Phenolic compounds work on the browning of fresh potatoes and in the blackening after cooking or during dehydration. This blackening is caused by the presence of thyroxine and chlorogenic acid in the tuber reacting with iron ions (Estrada, 2000), the immersion of peeled creole potato in a water solution with citric acid avoids this blackening without altering product quality (Fano et al, 1998).

In cooked potatoes the internal quality is determined by consistency, mealiness, humidity, color, aroma, taste and discoloration (Moreno, 2000). Disintegration, consistency and mealiness are related with starch content and separation of cells when cooking the product (Andrade, 2002). Potatoes suitable for cooking have been classified into four types: firm (for potato salad), mealy, very mealy (for soups, consommés and mashed potatoes) and for various purposes (Estrada, 2000).

Products elaborated from dehydrated potatoes comprise flakes, flour, granules, slices and cubes among others. These products can be used as thickeners, cohesive agents, bakery ingredients, as central ingredient of certain dishes or as a secondary ingredient in main dishes. Dehydrated flakes can be used in culinary recipes that require mashed potatoes; they are useful as a base for products such as instant mashed potatoes, croquettes, pasta dishes and processed appetizers.

Moreover, they are a convenient ingredient to include in bakery products as well as in the snack industry (Potatoes. com, 2000). Some companies use mashed potatoes in the fabrication of pies or "empanadas", a product offered in the principal cities of the country (Corporación Colombia Internacional, 2000).

However, there is still need for getting deeper into aspects related with quality parameters both internal and external and in the different processing options taking into account the demands of both national and international markets.

The objective of this study was to assess the physicochemical and morphological characteristics of six creole potato clones originating from three localities to determine the potential of use in the production of precooked potato (frozen or vacuum packed), pickled potato, in stripes and in dehydrated flakes for mashed potatoes.

Materials and methods

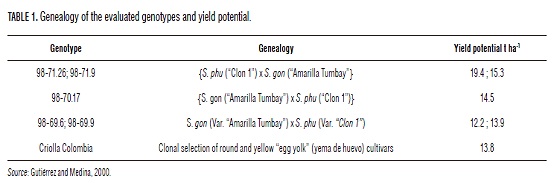

Six round yellow genotypes originating from the program for genetic improvement of Colombia's National University were used (Tab. 1); they were cultivated in the localities of Mosquera and Soacha (Cundinamarca) and Duitama (Boyacá) and were previously selected by their skin color and pulp, shape and eye depth and by yield potential (Gutiérrez and Medina, 2000).

Assessed variables

A physicochemical and morphological characterization was made for each material by taking 20 representative tubers by genotype and locality. The following parameters were determined on them: Dry Matter (DM), Specific Gravity (SG), tuber shape, skin type, eye depth, and color of skin and pulp.

Dry weight was measured by means of drying at 105 °C during two days. On the other hand, SG was determined by the use of the following relationship:

SG= Weight in air / Weight in water – Weight in air The morphological description scales proposed by Huamán (1994) were used to define parameters as tuber shape, skin type and eye depth. The methodology for evaluating color is described by Rivera (2002).

Data on eye shape and depth was converted to the numerical ranking system and analyzed by Friedman's test. Variables such as specific gravity, fresh weight and dry weight were studied with a completely randomized design with factorial arrangement 3x6 (three localities and six genotypes). In addition, Tukey's test was carried out and a correlation analysis was made.

Results and discussion

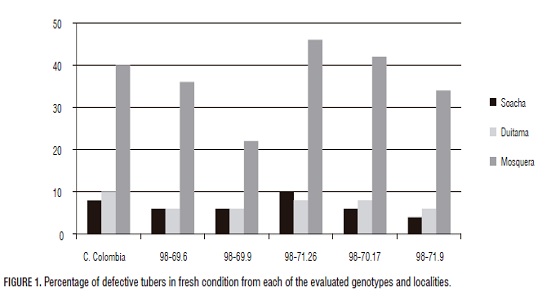

Tuber shape and size, eye depth and absence of damage and physical defects were assessed. Results on the assessment of color of skin and pulp are reported by Rivera (2002). Despite the pre-selection made on the field, percentage differences in external quality of the materials were found. Fig. 1 shows that the tubers originating from Duitama and Soacha are more suitable for processing. The tubers originating from Mosquera showed lower quality possibly due to poor management of insect pests and higher soil compactation. This induced a higher deformation of tubers with malformations and damage caused by insects.The tubers originating from Duitama showed a larger diameter while those from Soacha were smaller and uniform which agrees with the reports of Rodríguez et al. (2006) on this last locality. The tubers originating from Mosquera showed elliptical, oblong, oval and elongated shapes which could have been caused by an extended drought period and/or clay soil.

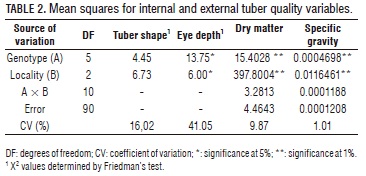

Although statistical differences weren't found between the different tuber shapes (Tab. 2) round tubers were predominant (Tab. 3). Genotypes 98-70.17 and 98-69.9 showed compressed shapes as a consequence of the sustained pulp loss which is inconvenient for the peeling process. In contrast, genotypes 98-71.9, 98-71.26 and 98-69.6 produced round tubers, a characteristic that favors their use for precooked and frozen or pickled potatoes as well as a good acceptance for fresh consumption. Kirkman (2007), referring to white potatoes, states that in order to process them as chips they have to show a relationship near 1.25 between their longitudinal and transverse axis.

Eye depth varied statistically between genotypes and localities (Tab. 2) indicating that this character, despite being dependant on genotype as indicated by Li et al. (2005), is influenced by environment. Genotypes 98-71.9 and 98-69.6 showed superficial eyes, a characteristic favoring cleaning and peeling while 98-69.9 and 98-70.17 showed medium to deep eyes. The materials originating from Soacha showed more superficial eyes than those from Duitama, a condition that probably is determined by differences in soil texture, taking into account that soils of Soacha are silt loamy, which generates more tension to tubers when there are changes in soil humidity content (Gómez, 2005).

According to Tab. 3 all genotypes showed smooth skin, a favorable characteristic for processing. Summarizing, genotypes 98-71.9, 98-69.6, 98-71.26 and Criolla Colombia offer the best conditions for peeling processes which are natural in the preparation of chips and mashed potatoes.

Internal quality

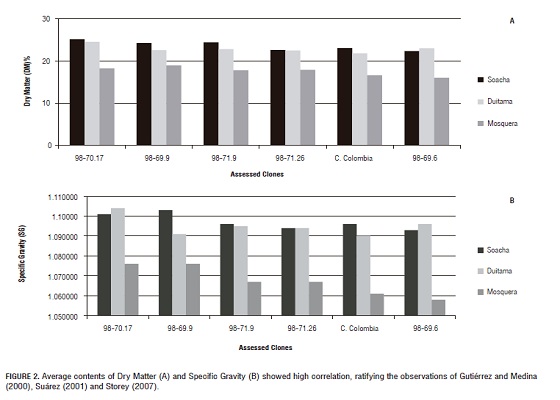

Highly significant differences were observed in the analysis of variance between genotypes and localities for DM and SG (Tab. 3). The differences found at genotype level suggest that the materials have different DM accumulation potential which are probably caused by the origin of the parents with different photoassimilate accumulation capacity. That is how genotypes 98-98-70.17 and 98-71.9 originating from the parental S. goniocalyx with high DM content (Fano et al. 1998), showed the highest values for this variable as well as for SG. Meanwhile, the control and genotype 98-69.6 showed the lowest levels (Fig. 2). These results, while confirming the findings of Gutiérrez and Medina (2000) and Monroy and Reynales (2001) who tested and initially selected these genotypes in the field, agree with the DM data reported for potatoes for industrial use, this is, between 18% and 26%.

The genotypes from Soacha and Duitama where statistically similar unlike those from Mosquera which showed the lowest levels for these two variables probably due to a higher content of nitrates in soil. This factor stimulates growth of vegetative organs and affects photoassimilate translocation to the tubers preventing their maturation (Monroy and Reynales, 2001). Exempting genotypes 98-69.6 and Criolla Colombia which were cultivated in Mosquera the other genotypes coincide with the SG range (between 1.060 and 1.110) found by Lulai and Orr (1979) in Norchip potatoes for industrial use.

Fig. 3 shows the differences in DM and SG contents between localities. The tuber growth in the localities of Duitama and Soacha produced more DM than those from Mosquera. The results suggest that under the actual experimental conditions the genotypes produced in the regions of Duitama and Soacha would be more suitable for dehydrated products such as mashed potatoes, chips and snacks. In turn, the genotypes produced in Mosquera would be suitable for canning or other processes involving cooking. As stated by Storey (2007) these variations in DM content between localities can be the result of the action of environmental factors such as intercepted solar radiation, soil temperature, water availability and agricultural practices.

Potential use for the tested genotypes

Taking into account the different sources consulted and the observations of the present study (Tab. 4) as well as the characteristics of external quality, values of SG and contents of DM, starch and RS reported for these genotypes by Gutiérrez and Medina (2000)5 the following potential uses are proposed.

The materials growth in Duitama and Soacha, according to the analysis performed, are suggested to be the most suitable for elaboration of dehydrated products, vacuum packed potato, flakes and French fries due to SG values being higher than 1,080. In turn, the tubers originating from Mosquera showed an average value of 1,066 which makes them suitable for elaboration of pickles or precooked frozen potatoes because of presenting SG values lower than 1,080.

Genotypes 98-71.26, 98-69.6, 98-69.9 and Criolla Colombia are considered suitable for elaboration of refrigerated and vacuum packed potatoes due to their SG of 1,100 (25 % DM). Genotype 98-70.17 is considered suitable for dehydration as long as it is peeled chemically since its eye depth and compressed shape determine considerable pulp losses. All genotypes can develop the characteristics necessary for elaboration of precooked frozen potatoes if they are cultivated under height and soil conditions similar to those of Mosquera so that a product which SG is lower than 1,080 (21,05 % DM) can be obtained.

Genotype 98-71.26 is not considered suitable for the industry of chips or French Fries because it exceeds 0,1 % RS (Moreno, 2000) although internationally it is accepted 0,2% to 0,3% for chips and from 0,3% to 0,5% for French Fries (Storey, 2007). For the elaboration of dehydrated products and French Fries it wouldn't be convenient to use genotype 98-69.9 because of its compressed shape and medium depth eyes which causes losses in peeling besides of its pale yellow color.

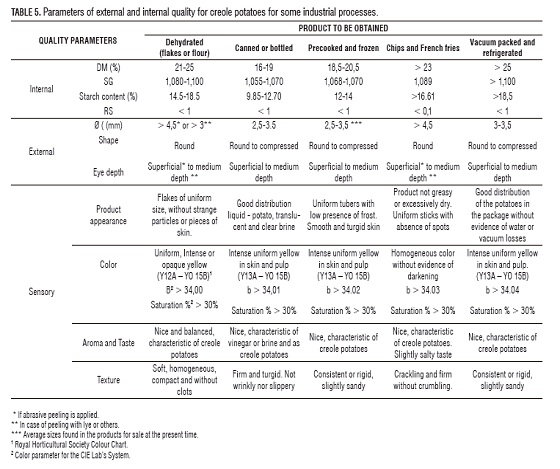

Quality parameters for different processing options Because of the possibilities of industrialization shown by creole potato, of the niches that are being established on the internal and external market of processed products and the necessity of establishing parameters able to define product quality (which at the present time are very scarce or have been defined in independently) the following requirements for external and internal quality that creole potatoes have to meet for elaboration of the products presented in Tab. 5 are suggested. This suggestion is sustained by the results obtained in the present study, by the sources consulted for its development and by the experienced acquired by the authors through the processing of these materials in ways of precooked, pickled and dehydrated potatoes, which results are presented in detail by Rivera (2002).

Conclusions and recommendations

Raw material for processing purpose has to be selected according to specifications of size and physicochemical characteristics of the product that is going to be elaborated in order to optimize yield and avoid cost overruns in labor at the factory.

The majority of variables, despite being determined by genotype, are affected by environmental conditions. Because of producing tubers with low dry mat-ter contents the locality of Mosquera turned out to be the most suitable for producing tubers destined to the elaboration of precooked potatoes which is the reason why the culture locality had a marked effect on the characteristics and quality of the processed tubers.

On the other hand, genotypes Criolla Colombia and 98-71.26 show high potential for being processed as precooked-frozen or pickled potato because of presenting low precooking loss and good organoleptic characteristics.

For the producer it is important to know the characteristics of the cultivar he is going to sow as well as the adequate culture techniques for obtaining a product that meets market demands. In turn, the industry must know if the tuber acquired is adequate for the process that is going to be performed.

Different quality parameters are proposed for creole potatoes which should be taken into account in the different transformation processes in order to obtain higher yields and quality.

5 0% for genotypes 71.9, 69.9 and 69.6; 0.1% for 70.17 and 0.25% for 71.26.

Acknowledgements

The authors express their thanks to engineer Rolando Mendoza, to the Institute of Science and Food Technology of Colombia's National University, to the Ministry of Agriculture and Rural Development and to Asohofrucol for the support given to this study.

Literature cited

Andrade, B.H. 2002. Requerimientos cualitativos para la industrialización de la papa. Instituto Nacional Autónomo de Investigaciones Agropecuarias-INIAP, Ecuador. In: http://www.redepapa.org/culinaria.pdf; recovered: June, 2010.

Becerra, L., S. Navia and C. Ñustez, 2007. Efecto de niveles de fosforo y potasio sobre el rendimiento del cultivar "Criolla Guaneña" en el departamento de Nariño. Revista de la Asociación Latinoamericana de la Papa 14(1), 51-60.

Bonierbale, M., W. Amoros, J. Espinoza, E. Mihovilovich, W. Roca, and R. Gómez. 2004. Recursos genéticos de la papa, don del pasado, legado para el futuro. pp. 3-14. In: Suplemento Revista Latinoamericana de la Papa, Valdivia, Chile.

Bonierbale, M., W. Amoros, J. Espinoza, X.Q. Li, and T. Walker. 2001. Estrategias y desafíos para el mejoramiento de papa para procesamiento. In: Centro Internacional de la Papa, http:// www.redepapa.org/boletindieciseis.html; recovered: July, 2010.

Bonilla, M.E., F. Cardozo, and A. Morales. 2009. Agenda prospectiva de investigación y desarrollo tecnológico para la cadena productiva de la papa en Colombia con énfasis en papa criolla. Ministerio de Agricultura y Desarrollo Rural. Bogota.

Borruey, A., F. Cotrina, J. Mula and C. Vega. 2001. Calidad industrial y culinaria de las variedades de patata. In: http://www. redepapa.org/culinaria.pdf; recovered: July, 2010.

Cisneros-Cevallos, L. 2008. Las papas como alimentos funcionales. In: Memorias XXIII Congreso de la Asociación Latinoamericana de la Papa. Mar de Plata, 2008. pp. 52.

Corporación Colombia Internacional, CCI. 2000. Exportaciones de chontaduro y papa criolla congelada a Japón. In: Inteligencia de Mercados, No. 26. Corporación Colombia Internacional. Bogota.

Estrada, N. 2000. La biodiversidad en el mejoramiento genético de la papa. CIP, IPGRI, PRACIPA, IBTA, PROINPA, COSUDE and CID.

Fano, H., G. Carmona, M. Ordinola and G. Scott. 1998. Experiencias de exportación de la papa amarilla peruana. CIP. Lima.

Fedepapa. 2010. Recopilación de la investigación del sistema productivo de papa criolla. Bogota.

Ghislain, M., D. Andrade, F. Rodriguez, R.J. Hijmans and D.M. Spooner. 2006. Genetic analysis of the cultivated potato Solanum tuberosum L. Phureja Group using rapds and nuclear ssrs. Theor. Appl. Genet. 113, 1515-1527.

Gómez, M. 2005. Guía técnica para el manejo nutricional de los cultivos: Diagnostico, interpretación y recomendación de planes de fertilización. Microfertisa. Bogota. 52p.

Gómez, R. and D. Wong. 2002. Procesamiento de la papa. Revista INDOAGRO (1) 5 In: http://www.redepapa.org/culinaria.pdf; recovered: July, 2010.

Gould, W. A. 1999. Potato Processing, and Technology. CTI publications, INC. Oakway Road, Timonium, Maryland, USA.

Guerra, L.P. 1989. Análisis de algunos componentes químicos y tecnológicos relacionados con la calidad de la papa (Solanum tuberosum, L.). o letin No.5. Instituto Nacional de Ciencias Agrícolas (INCA). La Habana, Cuba.

Gutiérrez, B.A. and R.J. Medina 2000. Ensayos preliminares de rendimiento en veintiseis clones F1 provenientes de hibridación interespecífica en papa. Tesis de Grado, Facultad de Agronomía, Universidad Nacional de Colombia. Bogota.

Hawkes, J.G. 1990. The potato: evolution, biodiversity and genetic resources. Belhaven Press, Washington DC.

Huaman, Z. 1994. Descriptores de papa para la caracterización básica de colecciones nacionales. CIP, Lima.

Huaman, Z. and D. Spooner. 2002. Reclassification of landrace populations of cultivated potatoes (Solanum sect. Petota). Am. J. Bot. 89,947-965.

IICA. 1999. Acuerdo de competitividad de la cadena agroalimentaria de la papa. Folleto No. 14. Bogota.

Kirkman, M. 2007. Global markets for processed potato products. In: Potato biology and biotechnology advances and perspectives. Edited por Dick Vreugdenhil. Amsterdam. pp. 39-42.

Li, X.Q., H. de Jong, D.M. de Jong and W.S. de Jong, 2005. Inheritance and genetic mapping of tuber eye depth in cultivated diploid potatoes. Theor. Appl. Genet . 110 (6), 1068-73.

Lulai, E. and P. Orr. 1979. Influence of potato specific gravity on yield and oil content of chips. Amer. J. Potato Research. 56, 8.

Martínez, H., N. Pinzón and C. Barrios. 2006. La cadena de la papa en Colombia. Una mirada global de su estructura y dinámica 1991-2005. Documento de trabajo N° 100. Ministerio de Agricultura y Desarrollo Rural-MADR. Observatorio Agrocadenas Colombia e Instituto Interamericano de Cooperación Agropecuaria-IICA. Bogota. 37p.

Ministry of Agriculture and Rural Development. 2006. I Censo Departamental del Cultivo de Papa - Nariño, IV Separata de Resultados, Producción y Rendimiento, semestre A de 2006. Ministerio de Agricultura y Desarrollo Rural; Gobernación Departamental de Nariño, Centro Virtual de Investigación de la Cadena Agroalimentaria de la Papa (Cevipapa), Bogota.

Monroy, L.P. and S.D. Reynales 2001. Evaluación de variables agronómicas y fisiológicas de mejoramiento de papas diploides en dos localidades de Cundinamarca. Tesis de Grado, Facultad de Agronomía, Universidad Nacional de Colombia. Bogota.

Moreno, J.D. 2000. Calidad de la papa para usos industriales. In: Papas colombianas 2000 con el mejor entorno ambiental, 2a ed. pp. 44-47.

Pérez, L., L.E. Rodríguez and M. Gómez. 2008. Efecto del fraccionamiento de la fertilización con N, P, K y Mg y la aplicación de los micronutrientes B, Mn y Zn en el rendimiento y calidad de papa criolla (Solanum phureja) variedad "Criolla Colombia". Agronomía Colombiana 26(3), 477-485.

Potatoes.com. (2001). In: http://www.potatoes.com; recovered: June, 2010.

Rivera, J.E. 2002. Evaluación de diferentes opciones de procesamiento industrial de seis colones de papa diploide. Tesis de grado, Facultad de Agronomía, Universidad Nacional de Colombia. Bogota.

Rivera, J.E., A. Herrera and L.E. Rodriguez. 2006. Evaluación sensorial en productos procesados de papa criolla (Solanum phureja) y su importancia para el fitomejoramiento. Fitotecnia Colombiana 6(2), 9-25.

Rodríguez, D., L.E. Rodríguez and C.E. Ñustez. 2006. Heredabilidad y evaluación del contenido de proteínas totales de la colección de papa criolla (Solanum phureja juz. et buk.) de la Universidad Nacional de Colombia. pp 71. In: Memorias del XXII Congreso de la Asociación Latinoamericana de la Papa (ALAP). 30 July - 4 August. Toluca, Mexico.

Rodríguez, F., M. Ghislain , A.M. Clausen, S.H. Jansky and D.M. Spooner. 2010. Hybrid origins of cultivated potatoes. Theor Appl Genet 121:1187-1198.

Rodríguez, L.E., C.E. Ñustez and N. Estrada. 2009. Criolla Latina, Criolla Paisa y Criolla Colombia: nuevos cultivares de papa criolla para el departamento de Antioquia (Colombia). Agronomía Colombiana 27(3), 289-303.

Ross, K.A. and M.G. Scanlon. 2004. A fracture mechanics analysis of the texture of fried potato crust. J. Food Engineering 62, 417 -423.

Spooner, D., J. Nuñez, G. Trujillo, M. del R. Herrera, F. Guzmán, and M. Ghislain. 2007. Extensive simple sequence repeat genotyping of potato landraces supports a major reevaluation of their gene pool structure and classification. PNAS 104(49), 19398-19403.

Storey, M. 2007. The Harvested Crop. In: potato biology and biotechnology advances and perspectives. Edited by Dick Vreugdenhil. Amsterdam. pp. 421-448.

Suarez, C.M. 2001. Evaluación de la calidad industrial de 50 accesiones de papa criolla (Solanum phureja) de la Colección Central de Colombiana. Tesis de grado, Facultad de Ciencias Técnicas de Ingeniería de Alimentos; Universidad INCCA de Colombia, Bogota (Colombia).

Trinchero J., P. Ceroli, M.C. Monti, P. Daniel, M. Huarte. 2008. Memorias XXIII Congreso de la Asociación Latinoamericana de la Papa. Mar de Plata, Argentina.

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Article abstract page views

Downloads

License

Copyright (c) 2011 Agronomía Colombiana

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

© Centro Editorial de la Facultad de Ciencias Agrarias, Universidad Nacional de Colombia

Reproduction and quotation of material appearing in the journal is authorized provided the following are explicitly indicated: journal name, author(s) name, year, volume, issue and pages of the source. The ideas and observations recorded by the authors are their own and do not necessarily represent the views and policies of the Universidad Nacional de Colombia. Mention of products or commercial firms in the journal does not constitute a recommendation or endorsement on the part of the Universidad Nacional de Colombia; furthermore, the use of such products should comply with the product label recommendations.

The Creative Commons license used by Agronomia Colombiana journal is: Attribution - NonCommercial - ShareAlike (by-nc-sa)

Agronomia Colombiana by Centro Editorial of Facultad de Ciencias Agrarias, Universidad Nacional de Colombia is licensed under a Creative Commons Reconocimiento-NoComercial-CompartirIgual 4.0 Internacional License.

Creado a partir de la obra en http://revistas.unal.edu.co/index.php/agrocol/.