Publicado

Rheological modeling of cellulose gum, xanthan gum, and guar gum mixtures in aqueous solutions

Modelamiento reológico de mezclas de goma de celulosa, goma xantana y goma guar en soluciones acuosas

DOI:

https://doi.org/10.15446/dyna.v90n229.109644Palabras clave:

synergy; ternary gum mixture; viscoelasticity (en)sinergia; mezcla ternaria de gomas; viscoelasticidad (es)

Descargas

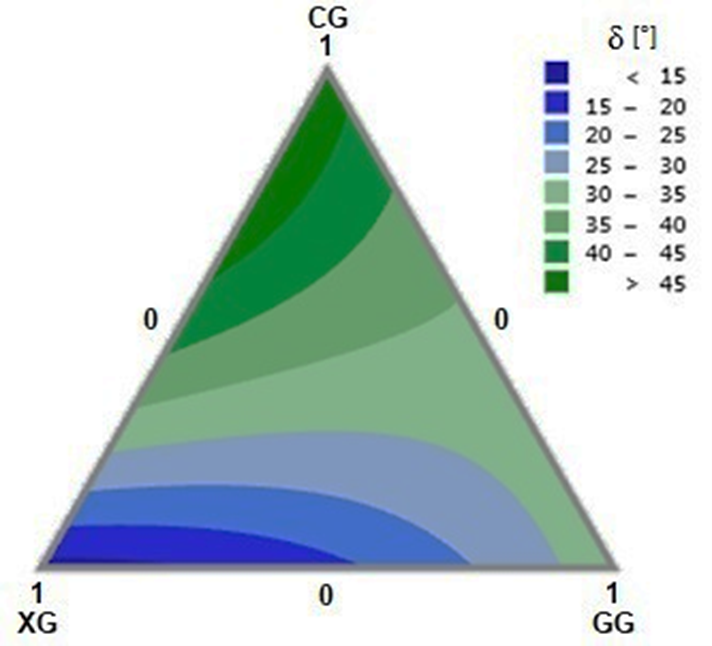

The synergistic effects observed in hydrocolloid mixtures hold significant potential for the discovery of new industrial products and compounds. Through an examination of the rheological behavior of mixtures of cellulose gum, xanthan gum, and guar gum, synergistic viscosity patterns were observed in binary mixtures. Notably, the viscosity of these mixtures exceeded that of the individual components. Binary and ternary systems with high elasticity and minimal temporal variation exhibited low levels of thixotropy and demonstrated stable elastic modulus values across various frequencies. Ternary mixtures containing a high proportion of xanthan gum exhibit enhanced stability in response to temperature fluctuations. This underscores the potential of hydrocolloid mixtures to yield novel functionalities by capitalizing on the distinct rheological behaviors arising from their interactions.

El efecto sinérgico entre las mezclas de hidrocoloides es de gran interés, puesto que se pueden encontrar nuevos productos y compuestos de uso industrial. Mediante el estudio del comportamiento reológico de mezclas de goma de celulosa, goma xantana y goma guar se encontraron comportamientos sinérgicos de viscosidad en mezclas binarias, observando que el valor de la viscosidad de las mezclas es mayor a la viscosidad de los componentes individuales. Se encontraron sistemas binarios y ternarios con alto comportamiento elástico y menor variación en el tiempo, con bajos valores de tixotropía y estabilidad del módulo elástico a diferentes frecuencias. Las mezclas ternarias con altos contenidos de goma xantana presentan un comportamiento más estable frente a cambios de temperatura. Se evidencia que la mezcla de hidrocoloides es una posibilidad de obtención de nuevas funcionalidades a partir de las diferencias en el comportamiento reológico dado por la interacción entre ellas.

Referencias

Yaseen, E., Herald, T., Aramouni, F. and Alavi, S., Rheological properties of selected gum solutions. Food Research International, 38, pp. 111-119, 2005. DOI: https://doi.org/10.1016/j.foodres.2004.01.013.6/j.hydromet.2018.05.022

Lapasin, R. and Pricl, S., Rheology of Industrial Polysaccharides: Theory and Applications, Glasgow: Blackie Academic and Professional. Springer New York, 1995. DOI: https://doi.org/10.1007/978-1-4615-2185-3

Philips, G. and Williams, P., Handbook of Hydrocolloids. Cambridge: Woodhead Publishing, CRP Press [Online]. 2009. Available at: https://www.sciencedirect.com/book/9781845694142/handbook-of-hydrocolloids DOI: https://doi.org/10.1533/9781845695873

Haleema, N., Arshada, M., Shahidb, M. and Tahir, M.A., Synthesis of carboxymethyl cellulose from waste of cotton ginning industry. Carbohydrate Polymers, 113, pp. 249-255, 2014. DOI: http://dx.doi.org/10.1016/j.carbpol.2014.07.023

Salmi, T., Damlin, P., Mikkola, J.P. and Kangas, M., Modelling and experimental verification of cellulose substitution kinetics. Chemical Engineering Science, 66(2), pp. 171-182, 2011. https://doi.org/10.1016/j.ces.2010.10.013

Katzbauer, B., Properties and applications of xanthan gum. Polymer Degradation and Stability, 59(1-3) pp. 81-84, 1998. DOI: https://doi.org/10.1016/S0141-3910(97)00180-8

Song, K., Kim, Y. and Chang, G., Rheology of concentrated xanthan gum solutions: steady shear flow behavior. Fibers and Polymers, 7(2), pp. 129-138, 2006. DOI: https://doi.org/10.1007/BF02908257

Jeanes, A., Pittsley, J. and Senti, F., Polysaccharide B‐1459: A new hydrocolloid polyelectrolyte produced from glucose by bacterial fermentation. Journal of Applied Polymer Science, 5(17), pp. 519-526, 1961. DOI: https://doi.org/10.1002/app.1961.070051704

Tipvarakarnkoon, T. and Senge, B., Rheological behaviour of gum solutions and their interactions after mixing. Annual Transactions of the Nordic Rheology Society [Online]. 16, pp. 1-8, 2008. Available at: https://nordicrheologysociety.org/Content/Transactions/2008/Oral%20presentations/Rheology%20of%20Food%20Hydrocolloids/Tipvarakarnkoon.pdf

Nikaedo, P., Amaral, F. and Penna, A.L., Caracterização tecnológica de sobremesas lácteas achocolatadas cremosas elaboradas com concentrado protéico de soro e misturas de gomas carragena e guar. Revista Brasileira de Ciências Farmacêuticas, 40(3), pp. 397-404, 2004. DOI: https://doi.org/10.1590/S1516-93322004000300016

BeMiller, J., Carbohydrate Chemistry for Food Scientists. Woodhead Publishing and AACC International Press, 2019. DOI: https://doi.org/10.1016/C2016-0-01960-5

Ospina, K., Estudio de la interacción de hidrocoloides empleados en alimentos y su efecto en las propiedades reológicas y de textura sensorial e instrumental. Bogotá: Universidad Nacional de Colombia, Tesis de Maestría [Online]. 2016. Available at: https://repositorio.unal.edu.co/handle/unal/59273

Ospina, M., Sepúlveda, J., Restrepo, D., Cabrera, K. and Suarez, H., Influencia de goma xantan y goma guar sobre las propiedades reológicas de leche saborizada con cocoa. Biotecnología en el Sector Agropecuario y Agroindustrial [Online]. 10(1), pp. 51-59, 2012. Available at: http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S1692-35612012000100007

Gómez, D. and Navaza, J., Rheology of aqueous solutions of food additives: Effect of concentration, temperature and blending. Journal of Food Engineering, 56(4), pp. 387-392, 2003. DOI: https://doi.org/10.1016/S0260-8774(02)00211-X

Hayati, I., Ching, C. and Helmi, M., Flow properties of o/w emulsions as affected by xanthan gum, guar gum and carboxymethyl cellulose interactions studied by a mixture regression modelling. Food Hydrocolloids, 53, pp. 199-208, 2016. DOI: https://doi.org/10.1016/j.foodhyd.2015.04.032

Fagioli, L., Pavoni, L., Logrippo, S., Pelucchini, C., Rampoldi, L., Cespi, M., Bonacucina, G. and Casettari, L., Linear viscoelastic properties of selected polysaccharide gums as function of concentration, pH, and temperature. Journal of Food Science, 84(1), pp. 65-72, 2018. DOI: https://doi.org/10.1111/1750-3841.14407

Brookfield Engineering Laboratories Inc., More solutions to sticky problems. Middleboro, MA: Brookfield [Online]. 2017. Available at: https://www.brookfieldengineering.com/-/media/ametekbrookfield/tech%20sheets/more%20solutions%202017.pdf?la=en

ASTM International, D1439-15: Standard Test Methods for sodium carboxymethylcellulose. West Conshohocken: ASTM [Online]. 2015. Available at: https://celluloseether.com/wp-content/uploads/2018/04/ASTM-D1439-03.pdf

Razavi, S.M.A. and Irani, M., Rheology of Food Gum. Bioactive Molecules in Food. Reference Series in Phytochemistry, Springer, Cham, 2019. DOI: https://doi.org/10.1007/978-3-319-78030-6_20

Razavi, S., Emerging Natural Hydrocolloids: Rheology and Functions. John Wiley & Sons, Inc. [Online]. 1, 2019. Available at: https://www.wiley.com/en-us/Emerging+Natural+Hydrocolloids%3A+Rheology+and+Functions-p-9781119418542 DOI: https://doi.org/10.1002/9781119418511.ch1

Moraes, I., Fasolin, L., Cuhna, R. and Menegalli, F., Dynamic and steady-shear rheological propertiesof xanthan and guar gums dispersed in yellow passion fruit pulps. Brazilian Journal of Chemical Engineering, 28(3), pp. 483-494, 2011. DOI: https://doi.org/10.1590/S0104-66322011000300014

Minitab® Support. Models, the terms that they fit, and the type of blending that they model. Minitab® Support [Online]. 2020. Available at: https://support.minitab.com/en-us/minitab/20/help-and-how-to/statistical-modeling/doe/supporting-topics/mixture-designs/models-terms-and-blending/

Montgomery, D.C., Design and analysis of experiments. John Wiley & Sons, Inc. [Online]. 8, 2005. Available at: https://mip.faperta.unri.ac.id/file/bahanajar/58219-2013-8ed-Montgomery-Design-and-Analysis-of-Experiments.pdf

U.S. Food and Drugs Administration. Code of Federal Regulations Title 21: 21CFR182.1745 [Online]. 2019. Available at: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.1745

Food and Agriculture Organization of the United Nations. Xanthan Gum [Online]. 1999. Available at: http://www.fao.org/fileadmin/user_upload/jecfa_additives/docs/Monograph1/Additive-487.pdf

Food and Agriculture Organization of the United Nations. Guar Gum, chemical and technical assessment [Online]. 2008. Available at: http://www.fao.org/fileadmin/templates/agns/pdf/jecfa/cta/69/Guar_gum.pdf

Escudier, M.P., Gouldson, I.W., Pereira, A.S., Pinho, F.T. and Poole, R.J., On the reproducibility of the rheology of shear-thinning liquids. Journal of Non-Newtonian Fluid Mechanics, 97(2–3), pp. 99-124, 2001. DOI: https://doi.org/10.1016/S0377-0257(00)00178-6

Choi, S.J., Chun, S.Y. and Yoo, B., Dynamic rheological comparison of selected gum solutions. Food Science and Biotechnology [Online]. 15(3), pp. 474-477, 2006. Available at: https://koreascience.kr/article/JAKO200609905843557.pdf

Gunasekaran, S. and Ak, M.M., Dynamic oscillatory shear testing of foods selected applications. Trends in Food Science & Technology, 11, pp. 115-127, 2000. DOI: https://doi.org/10.1016/S0924-2244(00)00058-3

Miao, Q., Jiang, H., Gao, L., Cheng, Y., Xu, J., Fu, X. and Gao, X., Rheological properties of five plant gums. American Journal of Analytical Chemistry, 9, pp. 210-223, 2018. DOI: https://doi.org/10.4236/ajac.2018

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Nick W. Johnson, Sheng Yan Jiang, Samuel B. H. Patterson, Trevor Hinchcliffe, Filipe Vilela, Humphrey H. P. Yiu. (2025). Nanomaterial scaffolds for enzymatic polymer degradation: a tool to advance current biodegradation assessments of polymers in liquid formulation. Bioscience Nanotechnology, 1(1) https://doi.org/10.1186/s44331-025-00004-4.

2. Samin Rafi Azari, Mohammad Hojjatoleslamy, Zeinab E. Mousavi, Hossein Kiani, Sayed Mohammad Ali Jalali. (2025). Investigating the impact of sodium alginate and xanthan hydrocolloids on the rheological Doogh properties (Iranian dairy drink). Food Hydrocolloids for Health, 7, p.100206. https://doi.org/10.1016/j.fhfh.2025.100206.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2023 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.