Publicado

A reliability model for non-isothermal isotropic damages

Un modelo de confiabilidad para daños isotrópicos no isotérmicos

DOI:

https://doi.org/10.15446/dyna.v91n232.111320Palabras clave:

reliability; Neyman type A distribution; accelerated life tests (en)confiabilidad; distribución de Neyman tipo A; pruebas de vida aceleradas (es)

Descargas

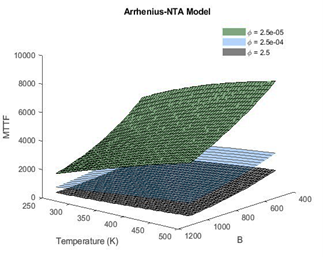

This study introduces a novel lifetime distribution originating from the Neyman Type A distribution. We built a Neyman Type A counting process and developed a survival function. Some statistical properties of the new distribution were presented, such as the resulting humped hazard function and its convergence. An accelerated test model structure with Arrhenius law was specified, and the effects of different accelerating stresses were analyzed. The hazard function implied by the model is inversely proportional to the stress, which results in interesting features and provides an efficient approach to describe the lifespan phenomena of some engineering metals and bulbs under low temperatures. The estimation of parameters of the accelerated model by maximum likelihood, mean time to failure, and expected number of failures are discussed in the numerical experiments.

Este artículo presenta una nueva distribución de vida útil que se origina a partir de la distribución de Neyman Tipo A. Construimos el proceso de conteo de Neyman Tipo A y desarrollamos la función de supervivencia. Se presentan algunas propiedades estadísticas de la nueva distribución, como la función de riesgo resultante en forma de joroba y su convergencia. Se especifica una estructura de modelo de prueba acelerada con la ley de Arrhenius, y se analizan los efectos de diferentes tensiones acelerantes. La función de riesgo implicada por el modelo es inversamente proporcional al estrés, lo que resulta en características interesantes: el modelo proporciona un enfoque eficiente para describir los fenómenos de vida útil de algunos metales de ingeniería y bombillas a bajas temperaturas. Se discute la estimación de parámetros del modelo acelerado mediante máxima verosimilitud, el tiempo medio hasta la falla y el número esperado de fallas en experimentos numéricos.

Referencias

Elsayed, E.A., Reliability Engineering, Wiley Series in Systems Engineering and Management, 3rd Ed., Wiley. 2021. DOI: https://doi.org/10.1002/9781119665946. DOI: https://doi.org/10.1002/9781119665946

Deshpande, J.V. and Purohit, S.G., Lifetime data: statistical models and methods, Series on quality, reliability and engineering statistics, World Scientific. 2005. DOI: https://doi.org/10.1142/5988. DOI: https://doi.org/10.1142/5988

Nelson, W., Accelerated testing: statistical models, test plans, and data analyses, 2nd Ed., John Wiley & Sons, 2004.

Wallace, R., Blischke, M., Rezau-Karim, D.N.P.M., Warranty data collection and analysis, Springer Series in Reliability Engineering, Springer, 2011. DOI: https://doi.org/10.1007/978-0-85729-647-4. DOI: https://doi.org/10.1007/978-0-85729-647-4

Rahman, A., and Chattopadhyay, G., Long term warranty and after sales: service concept, policies and cost models, Springer Briefs in Applied Sciences and Technology, Springer, 2015. DOI: https://doi.org/10.1007/978-3-319-16271-3. DOI: https://doi.org/10.1007/978-3-319-16271-3

Murthy, D.N.P., and Jack, N., Extended warranties, maintenance Service and lease contracts: modeling and analysis for decision-making, Springer Series in Reliability Engineering, Springer, 2014. DOI: https://doi.org/10.1007/978-1-4471-6440-1. DOI: https://doi.org/10.1007/978-1-4471-6440-1

Smith, R., and Mobley, R.K., Rules of thumb for maintenance and reliability engineers, Elsevier, 2008. DOI: https://doi.org/10.1016/B978-075067862-9.50002-2

da Silva, A.J., Maintenance policy costs considering imperfect repairs. Reliability: Theory & Applications. 1(72), pp. 564-574, 2023. DOI: https://doi.org/10.24412/1932-2321-2023-172-564-574

de Souza, F.L.C., da Silva, A.J., Statistical learning for maintenance optimization: modeling the hazard function with variable recovery factors. Revista de Gestão e Secretariado, 15(2), art. e3478, 2024. DOI: https://doi.org/10.7769/gesec.v15i2.3478 DOI: https://doi.org/10.7769/gesec.v15i2.3478

Lee, J.M., Special issue: Low-temperature behavior of metals, Metals 12(4), 2022.

Xi, X., Zhao, D.Q., Pan, M.X., Wang, W., Wu, Y., and Lewandowski, J.J., Fracture of brittle metallic glasses: Brittleness or plasticity. 2005. DOI: https://doi.org/10.1103/PhysRevLett.94.125510 DOI: https://doi.org/10.1103/PhysRevLett.94.125510

Lancaster, J., Chapter 4 - The technical background, in: Lancaster, J., ed., Engineering Catastrophes, 3rd Ed., Woodhead Publishing, 2005, pp. 139-189. DOI: https://doi.org/10.1533/9781845690816. DOI: https://doi.org/10.1533/9781845690816.139

Chernov, V., Kardashev, B., and Moroz, K., Low-temperature embrittlement and fracture of metals with different crystal lattices dislocation mechanisms, Nuclear Materials and Energy 9, 496-501. 2016. DOI: https://doi.org/10.1016/j.nme.2016.02.002. DOI: https://doi.org/10.1016/j.nme.2016.02.002

Sallaba, F., Rolof, F., Ehlers, S., Walters, C.L., and Braun, M., Relation between the fatigue and fracture ductile-brittle transition in s500 welded steel joints, Metals 12(3), art. 305, 2022. DOI: https://doi.org/10.3390/met12030385 DOI: https://doi.org/10.3390/met12030385

Park, J.Y., Kim, B.K., Nam, D.G., and Kim, M.H., Effect of nickel contents on fatigue crack growth rate and fracture toughness for nickel alloy steels, Metals 12(2), art. 173, 2022. DOI: https://doi.org/10.3390/met12020173 DOI: https://doi.org/10.3390/met12020173

Mulford, R.A., Grain-boundary embrittlement of ni and ni alloys, in C. Briant and Banerji, S., Ed., Embrittlement of Engineering Alloys, Vol. 25 of Treatise on Materials Science & Technology, Elsevier, pp. 1-19. 1983. DOI: https://doi.org/10.1557/S0883769400069001. DOI: https://doi.org/10.1016/B978-0-12-341825-8.50007-6

Lepov, V., Grigoriev, A., Achikasova, V., and Lepova, K., Cold resistance of materials as an integrity factor of railway transport in the extreme environment, in Procedia Structural Integrity: 1st International Conference on Integrity and Lifetime in Extreme Environment, Vol. 20, 2019, pp. 57-62. DOI: https://doi.org/10.1016/j.prostr.2019.12.116. DOI: https://doi.org/10.1016/j.prostr.2019.12.116

Li, Y., Fu, G., Wan, B., Jiang, M., Zhang, W., and Yan, X., Failure analysis of sac305 ball grid array solder joint at extremely cryogenic temperature, Applied Sciencies 10, 2020. DOI: https://doi.org/10.3390/app10061951. DOI: https://doi.org/10.3390/app10061951

Bo-Bonning, C., Blackburn, J., Stretz, H.A., Wilson, C.D., Johnson, W.R., Superposition-based predictions of creep for polymer films at cryogenic temperatures, Cryogenics, 104, art. 102979, 2019. DOI: https://doi.org/10.1016/j.cryogenics.2019.102979. DOI: https://doi.org/10.1016/j.cryogenics.2019.102979

Soares, G.C., Rodrigues, M.C.M., and Santos, L.deA., Influence of temperature on mechanical properties, fracture morphology and strain hardening behavior of a 304 stainless steel. Materials Research, 20, pp. 141–151, 2017. DOI: https://doi.org/10.1590/1980-5373-MR-2016-0932 DOI: https://doi.org/10.1590/1980-5373-mr-2016-0932

Mohsin-Sattar, A.R., Othman, S., Kamaruddin, M.A., and Rashid, K., Limitations on the computational analysis of creep failure models: a review. Engineering Failure Analysis, 134, art. 105968 2022. DOI: https://doi.org/10.1016/j.engfailanal.2021.105968. DOI: https://doi.org/10.1016/j.engfailanal.2021.105968

Hossain, M.A., and Stewart, C.M., A probabilistic creep model incorporating test condition, initial damage, and material property uncertainty. International Journal of Pressure Vessels and Piping. 193, art. 104446, 2021. DOI: https://doi.org/10.1016/j.ijpvp.2021.104446. DOI: https://doi.org/10.1016/j.ijpvp.2021.104446

Chandra, K., Kain, V., Bhutani, V., Raja, V.S., Tewari, R., Dey, G.K., and Chakravartty, J.K., Low temperature thermal aging of austenitic stainless-steel welds: kinetics and effects on mechanical properties. DOI: https://doi.org/10.1016/j.msea.2011.11.055 DOI: https://doi.org/10.1016/j.msea.2011.11.055

Run-Zi, W., Hang-Hang G., Shun-Peng Z., Kai-Shang L., Ji W., Xiao-Wei W., Miura, H., Xian-Cheng Z., and Shan-Tung T., A data-driven roadmap for creep-fatigue reliability assessment and its implementation in low-pressure turbine disk at elevated temperatures. Reliability Engineering & System Safety, 225, art. 108523, 2022. DOI: https://doi.org/10.1016/j.ress.2022.108523. DOI: https://doi.org/10.1016/j.ress.2022.108523

Neyman, J., On a new class of contagious distributions applicable in entomology and bacteriology, Ann. Math. Stat 10, pp. 35-57, 1939. DOI: https://doi.org/10.1214/aoms/1177732245. DOI: https://doi.org/10.1214/aoms/1177732245

Martin, D.C., and Katti, S.K., Approximations to the neyman type a distribution for practical problems, Biometrics 18(3), pp. 354-364, 1962. DOI: https://doi.org/10.2307/2527477. DOI: https://doi.org/10.2307/2527477

Ozel, G., and Turkan, S., Neyman type a distribution for the natural disasters and related casualties in Turkey, Journal of Data Science 13(3), pp. 533-550, 2022. DOI: https://doi.org/10.6339/JDS.201507_13(3).0007. DOI: https://doi.org/10.6339/JDS.201507_13(3).0007

Johnson, N.L., Kemp, A.W., and Kotz, S., Univariate discrete distributions, Wiley Series in Probability and Statistics, 3rd Ed., Wiley. 2005. DOI: https://doi.org/10.1002/0471715816. DOI: https://doi.org/10.1002/0471715816

Fang, F., and Oosterlee, C.W., A novel pricing method for European options based on Fourier-cosine series expansions, SIAM Journal on Scientific Computing 31(2), pp. 826-848, 2009. DOI: https://doi.org/10.1137/080718061. DOI: https://doi.org/10.1137/080718061

da Silva, A.J., Baczynski, J., and Vicente, J.V.M., Recovering probability functions with Fourier series. Pesquisa Operacional, 43, art. 7882 2023. DOI: https://doi.org/10.1590/0101-7438.2023.043.00267882 DOI: https://doi.org/10.1590/0101-7438.2023.043.00267882

Shenton, L.R. and Bowman, K.O., Remarks on large sample estimators for some discrete distributions, technometrics, Technometrics 9(4), pp. 587-598,1967. DOI: https://doi.org/10.2307/1266197. DOI: https://doi.org/10.1080/00401706.1967.10490507

Fisher, R.A., On the mathematical foundations of theoretical statistics, Philosophical Transactions of the Royal Society of London 222, pp. 309-368, 1922. DOI: https://doi.org/10.1098/rsta.1922.0009. DOI: https://doi.org/10.1098/rsta.1922.0009

Sasongko, L. and Mahatma, T., The estimation of renewal functions using the mean value theorem for integrals (mevti) method. d'CARTESIAN 5, pp. 111-120, 2016. DOI: https://doi.org/10.35799/dc.5.2.2016.14984. DOI: https://doi.org/10.35799/dc.5.2.2016.14984

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.