Publicado

Probabilistic Weibull reliability of a shaft design subjected to bending and torsion stress

Confiabilidad probabilística Weibull en el diseño de un eje sometido a esfuerzos de flexión y torsión

DOI:

https://doi.org/10.15446/dyna.v91n232.111361Palabras clave:

probabilistic design; Weibull distribution; reliability; stress-strength (en)diseño probabilístico; distribución de Weibull; fiabilidad; tensión-resistencia (es)

Descargas

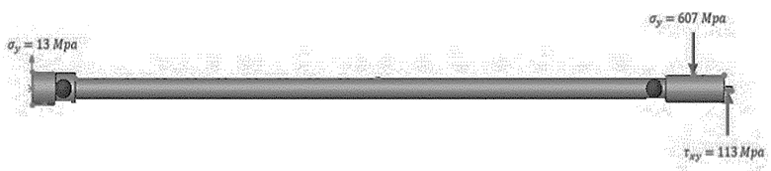

The circular shaft serves as the axis of rotation for the components. It is subjected to flexion and tearing, indicating that fatigue is the mode of failure. The range of stresses resulting from the mean and alternating loads determines the occurrence of fatigue failure. The deterministic fatigue analysis, calculated using the stress average obtained from SN curves, can only represent the mean life. This is because the stress range is not a single number, and therefore it cannot provide the reliability level for the stress. The study employs the Weibull distribution to estimate loads and parameters for a probabilistic shaft design under bending and torsion. The minimum strength is assessed using corresponding stress analysis to determine the reliability index for the designed shaft.

El eje circular sirve de eje de rotación de los componentes. Está sometido a flexión y desgarro, lo que indica que el modo de fallo es la fatiga. El rango de tensiones resultante de las cargas medias y alternas determina la aparición del fallo por fatiga. El análisis determinista de la fatiga, calculado a partir de la tensión media obtenida de las curvas SN, sólo puede representar la vida media. Esto se debe a que el rango de tensiones no es un número único y, por lo tanto, no puede proporcionar el nivel de fiabilidad de la tensión. El estudio emplea la distribución de Weibull para estimar las cargas y los parámetros de un diseño probabilístico de un eje sometido a flexión y torsión. La resistencia mínima se evalúa mediante el correspondiente análisis de tensiones para determinar el índice de fiabilidad del eje diseñado.

Referencias

Khan, A., Das, A., and Bhaskar, A.S., Prediction of fatigue life of glass-vinyl-ester-polyurethane sandwich structure using mathematical model. In: Pal, S., Roy, D., Sinha, S.K. (eds), Processing and Characterization of Materials. Springer Proceedings in Materials, 13, Springer, Singapore. 2021. DOI: https://doi.org/10.1007/978-981-16-3937-1_24 DOI: https://doi.org/10.1007/978-981-16-3937-1_24

Ebrahimi, A., Effect analysis of RAMS parameter in design & operation of DP system in floating offshroe structure, Royal Institute of Technology, October, 2010.

Rao, B.C., Revisiting classical design in engineering from a perspective of frugality, Heliyon, 3(5), art. e00299, 2017. DOI: https://doi.org/10.1016/j.heliyon.2017.e00299. DOI: https://doi.org/10.1016/j.heliyon.2017.e00299

Xu, Z., Cui, Y., Li, B., Liu, K., Shi, F., and Cao, P., Impact analysis of initial cracks angle on fatigue failure of flange shafts. Coatings, 12(2), 2022. DOI: https://doi.org/10.3390/coatings12020276 DOI: https://doi.org/10.3390/coatings12020276

Rexnord Industries G.G., LLC, Gears-Shafts-Bearings-Seals, Failure Analysis Installation & Maintenance, 2(August), 1978, 20 P.

Korczewski, Z. and Marszałkowski, K., Energy analysis of the propulsion shaft fatigue process in a rotating mechanical system. Part III dimensional analysis. Polish Maritime Research, 28(2), pp. 72–77, 2021. DOI: https://doi.org/10.2478/pomr-2021-0023. DOI: https://doi.org/10.2478/pomr-2021-0023

Barraza-Contreras, J.M., Piña-Monarrez, M.R., and Molina, A., Fatigue-life prediction of mechanical element by using the Weibull distribution, Applied Sciences (Switzerland), 10(18), art. 6384, 2020. DOI: https://doi.org/10.3390/APP10186384. DOI: https://doi.org/10.3390/app10186384

Zhao, Y.X., and Liu, H.B., Weibull modeling of the probabilistic S-N curves for rolling contact fatigue, Int J Fatigue, 66, pp. 47–54, 2014. DOI: https://doi.org/10.1016/j.ijfatigue.2014.03.008. DOI: https://doi.org/10.1016/j.ijfatigue.2014.03.008

Taketomi, N., Yamamoto, K., Chesneau, C., and Emura, T., Parametric distributions for survival and reliability analyses, a review and historical sketch, Mathematics, 10(20),art. 10203907, 2022. DOI: https://doi.org/10.3390/math10203907. DOI: https://doi.org/10.3390/math10203907

Matsuda, S. and Ogi, K., Effect analysis of loading rate on relationship between strength and flaw size of ceramics using probabilistic model on the basis of SCG concept, Transactions of the JSME (in Japanese), 83(847), pp. 16-00369-16–00369, 2017. DOI: https://doi.org/10.1299/transjsme.16-00369. DOI: https://doi.org/10.1299/transjsme.16-00369

Baro-Tijerina, M., Piña-Monárrez, M.R., and Villa-Covarrubias, B., Stress-strength weibull analysis with different shape parameter β and probabilistic safety factor, DYNA (Colombia), 87(215), pp. 28–33, 2020. DOI: https://doi.org/10.15446/dyna.v87n215.84909. DOI: https://doi.org/10.15446/dyna.v87n215.84909

Aaronson, L.S., Defining and measuring fatigue. Journal of Nursing Scholarship, 31(1), pp. 45–50, 1999. DOI: https://doi.org/10.1111/j.1547-5069.1999.tb00420.x. DOI: https://doi.org/10.1111/j.1547-5069.1999.tb00420.x

Ma, X., Yang, F., Li, J., Xue, Y., and Guan, Z., Fatigue life assessment method of in-service mechanical structure. Advances in Mechanical Engineering, 13(2), pp. 1–9, 2021. DOI: https://doi.org/10.1177/1687814021996524. DOI: https://doi.org/10.1177/1687814021996524

Khalaf, M.R. and Al-Ahmed, A.H.A., Effect of large openings on the behavior of reinforced concrete continuous deep beams under static and repeated load. E3S Web of Conferences, 318, pp. 3–10, 2021. DOI: https://doi.org/10.1051/e3sconf/202131803012. DOI: https://doi.org/10.1051/e3sconf/202131803012

Hosseini, S.M., Azadi, M., Ghasemi-Ghalebahman, A., and Jafari, S.M., Data analysis of striation spacing, lifetime, and crack length in crankshaft ductile cast iron under cyclic bending loading through high-cycle fatigue regime, Data Brief, 45(December), art. 108666, 2022. DOI: https://doi.org/10.1016/j.dib.2022.108666. DOI: https://doi.org/10.1016/j.dib.2022.108666

Kashyzadeh, K.R., Souri, K., Bayat, A.G., Jabalbarez, R.S, and Ahmad, M., Fatigue life analysis of automotive cast iron knuckle under constant and variable amplitude loading conditions. Applied Mechanics, 3(2), pp. 517–532, 2022. DOI: https://doi.org/10.3390/applmech3020030. DOI: https://doi.org/10.3390/applmech3020030

Liu, B., Sun, Y., Wang, J., and Zhang, G., Characteristic analysis of crack initiation and crack damage stress of sandstone and mudstone under low-temperature condition. Journal of Cold Regions Engineering, 34(3), art. 0225, 2020. DOI: https://doi.org/10.1061/(asce)cr.1943-5495.0000225. DOI: https://doi.org/10.1061/(ASCE)CR.1943-5495.0000225

Kim, H.S., A practical procedure for predicting the remaining fatigue life at an arbitrary stress ratio, Journal of Composites Science, 6(6), art. 60170, 2022. DOI: https://doi.org/10.3390/jcs6060170. DOI: https://doi.org/10.3390/jcs6060170

Kim, J., Anterior cruciate ligament microfatigue damage detected by collagen autofluorescence in situ. J Exp Orthop, 9(1), art. 74, 2022. DOI: https://doi.org/10.1186/s40634-022-00507-6. DOI: https://doi.org/10.1186/s40634-022-00507-6

Chen, M., Xiong, X., Zhuang, W., and Zeng, F., Fatigue life analysis of automotive glass regulator based on ABAQUS and FE-SAFE. IOP Conf Ser Earth Environ Sci, 571(1), art. 012109, 2020. DOI: https://doi.org/10.1088/1755-1315/571/1/012109. DOI: https://doi.org/10.1088/1755-1315/571/1/012109

Alamnie, M.M., and Endalemaw, Y., Fatigue life analysis of rail-welds using linear elastic fracture mechanics, ISEC 2019 - 10th International Structural Engineering and Construction Conference (July), 2019. DOI: https://doi.org/10.14455/isec.res.2019.197. DOI: https://doi.org/10.14455/ISEC.res.2019.197

Wang, S., Tang, S., He, C., and Wang, Q., Cyclic deformation and fatigue failure mechanisms of thermoplastic polyurethane in high cycle fatigue, Polymers (Basel), 15(4), art. 5040899, 2023. DOI: https://doi.org/10.3390/polym15040899. DOI: https://doi.org/10.3390/polym15040899

Chai, Y., Gao, W., Ankay, B., Li, F., and Zhang, C., Aeroelastic analysis and flutter control of wings and panels: a review. International Journal of Mechanical System Dynamics, 1(1), pp. 5–34, 2021. DOI: https://doi.org/10.1002/msd2.12015. DOI: https://doi.org/10.1002/msd2.12015

Guo, F., Hu, F., Wu, S., He, F., Liu, J., and Wu, X., System dynamics in structural strength and vibration fatigue life assessment of the swing bar for high‐speed maglev train. International Journal of Mechanical System Dynamics, 2(2), pp. 178–189, 2022. DOI: https://doi.org/10.1002/msd2.12045. DOI: https://doi.org/10.1002/msd2.12045

Schneider, J., and Haindl, H., Mechanic treatment of fastener holes: the influence of compressive residual stress on the corrosion behaviour of aluminium alloys, Materials and Corrosion, 59(9), pp. 753–761, 2008. DOI: https://doi.org/10.1002/maco.200804149. DOI: https://doi.org/10.1002/maco.200804149

Hirschberg, V., Wilhelm, M., and Rodriguez, D., Cumulative nonlinearity as a parameter to quantify mechanical fatigue. Fatigue Fract Eng Mater Struct, 43(2), pp. 265–276, 2020. DOI: https://doi.org/10.1111/ffe.13120. DOI: https://doi.org/10.1111/ffe.13120

Hahn, S., Feldmeth, S., and Bauer, F., Assessment of the lubricity of grease-sealing rotary shaft seals based on grease properties. Chem Eng Technol, 46(1), pp. 53–60, 2023. DOI: https://doi.org/10.1002/ceat.202200382. DOI: https://doi.org/10.1002/ceat.202200382

Patel, N., Mohebbi, A., Jan, C.D., and Guo, J., Maximum shear-stress method for stable channel design. Guo, 146(12), art. 01827, 2020. DOI: https://doi.org/10.1061/(asce)hy.1943-7900.0001827. DOI: https://doi.org/10.1061/(ASCE)HY.1943-7900.0001827

Turbucz, M., and Fayad, J., Can semirigid fixation of the rostral instrumented segments prevent proximal junctional kyphosis in the case of long thoracolumbar fusions? A finite element study, SPIN (March), art. 22931, 2023. DOI: https://doi.org/10.3171/2023.1.SPINE22931. DOI: https://doi.org/10.3171/2023.1.SPINE22931

Joun, M.S., Ji, S.M., Chung, W.J., Cho, G.S., and Lee, K.H., A new general fatigue limit diagram and its application of predicting die fatigue life during cold forging, Materials, 15(79, pp. 1–17, 2022. DOI: https://doi.org/10.3390/ma15072351. DOI: https://doi.org/10.3390/ma15072351

Wang, Y., and Peng, Z., Fatigue life prediction method of mechanical parts based on Weibull distribution. IOP Conf Ser Mater Sci Eng, 782(2), art. 022068, 2020, DOI: https://doi.org/10.1088/1757-899X/782/2/022068. DOI: https://doi.org/10.1088/1757-899X/782/2/022068

Pawliczek, R., and Rozumek, D., Limited stress surface model for bending and torsion fatigue loading with the mean load value, Materials, 14(22), art. 227023, 2021. DOI: https://doi.org/10.3390/ma14227023. DOI: https://doi.org/10.3390/ma14227023

Parry, Mohr’s Circles, Stress Paths, and Geotechnics. New York, USA, 2004. DOI: https://doi.org/10.1201/9781482264982

Stresses, P., Stress, Strain, Mohr’ s Circle, 2014, pp. 1–7.

Narayan, K., Behdinan, K., and Vanderpol, P., An equivalent uniaxial fatigue stress model for analyzing landing gear fuse pins, Strength of Materials, 38(3), pp. 278–288, 2006. DOI: https://doi.org/10.1007/s11223-006-0041-6. DOI: https://doi.org/10.1007/s11223-006-0041-6

Pelleg, J., Mechanical Properties of Materials, Vol. 190, Springer, 2012, 645 P. DOI: https://doi.org/10.1007/978-94-007-4342-7. DOI: https://doi.org/10.1007/978-94-007-4342-7

Wang, Z., Sun, G., Wang, W., and Zhang, M., Application for surveillance video with tensor factorization in machine learning. SSRN Electronic Journal (February), art. 4218404, 2022. DOI: https://doi.org/10.2139/ssrn.4218404. DOI: https://doi.org/10.2139/ssrn.4218404

Taniguchi, Y., Takizawa, K., Otoguro, Y., and Tezduyar, T.E., A hyperelastic extended Kirchhoff–Love shell model with out-of-plane normal stress: I. Out-of-plane deformation, Comput Mech, 70(2), pp. 247–280, 2022. DOI: https://doi.org/10.1007/s00466-022-02166-x. DOI: https://doi.org/10.1007/s00466-022-02166-x

Piña-Monarrez, M.R., Weibull stress distribution for static mechanical stress and its stress/strength analysis. Qual Reliab Eng Int, 34(May), pp. 229–244, 2017. DOI: https://doi.org/10.1002/qre.2251. DOI: https://doi.org/10.1002/qre.2251

Li, L., Cao, H., Guan, J., He, S., Niu, L., and Liu, H., A three-parameter Weibull distribution method to determine the fracture property of PMMA Bone Cement, Polymers (Basel), 14(17), pp. 1–17, 2022. DOI: https://doi.org/10.3390/polym14173589. DOI: https://doi.org/10.3390/polym14173589

Menan, F., P-a A., and François, M., The stress-strength interference method applied to fatigue design: the independence of the random variables, Procedia Eng., 133(December), pp. 746–757, 2015. DOI: https://doi.org/10.1016/j.proeng.2015.12.656. DOI: https://doi.org/10.1016/j.proeng.2015.12.656

Sugito, P M.A., Ispriyanti, D., and Dewi, L.N., Analysis of geometric and Weibull queuing model. Case study: customer service and electronic ID card recording counters at Dispendukcapil of Semarang City. Journal of Physics: Conference Series, 1943(1), art. 012151, 2021. DOI: https://doi.org/10.1088/1742-6596/1943/1/012151. DOI: https://doi.org/10.1088/1742-6596/1943/1/012151

Khan, M.G.M. and Ahmed, M.R., Bayesian method for estimating Weibull parameters for wind resource assessment in the Equatorial region: a comparison between two-parameter and three-parameter Weibull distributions, Wind Energy Science, 8, pp. 1277–1298, 2023. DOI: https://doi.org/10.5194/wes-8-1277-2023 DOI: https://doi.org/10.5194/wes-8-1277-2023

Piña-Monarrez, M.R. and Ortiz-Yañez, J.F., Weibull and lognormal Taguchi analysis using multiple linear regression. Reliability Engineering & System Safety, 144, pp. 244–253, 2015. DOI: https://doi.org/10.1016/j.ress.2015.08.004. DOI: https://doi.org/10.1016/j.ress.2015.08.004

Juvinall, R.C., and Saunders, H., Fundamentals of Machine Component Design. J. Mech., Trans., and Automation, 105(4), pp. 607-607, 2012. DOI: https://doi.org/10.1115/1.3258522. DOI: https://doi.org/10.1115/1.3258522

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.