Publicado

Influence of input variables on the unitary deformation experienced in pipes subjected to the action of lateral loads

Influencia de las variables de entrada en la deformación unitaria evidenciada en tuberías sometidas a la acción de cargas laterales

DOI:

https://doi.org/10.15446/dyna.v91n232.111471Palabras clave:

pipelines; bending moment; risk assessment; integrity pipeline (en)tuberías de transporte; momento flector; evaluación de riesgo; integridad de tuberías (es)

Descargas

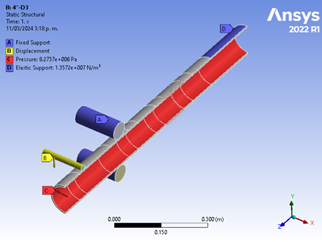

The hydrocarbon transportation industry uses extensive pipeline networks subject to complex loading conditions. The finite element analysis (FEA) has proven to be effective in simulating the deformation behavior in these pipelines, which assists in the assessment of their integrity and risks. In this work, a model developed using finite elements is proposed to analyze the behavior of API 5L Gr B carbon steel pipes, subject to internal pressure and lateral loads. The model is validated through uniaxial tensile and four-point bending tests. In addition, parametric analysis is carried out considering variables such as diameter, lateral load, and distance between supports. The objective is to identify which one of these variables has the most influence in the unit strain. The results indicate that the unit strain obtained from the numerical model agrees with the experimental tests. Furthermore, it is concluded that the diameter is the influential parameter.

La industria del transporte de hidrocarburos utiliza extensas redes de tuberías sometidas a condiciones de carga complejas. El análisis por elementos finitos ha demostrado ser efectivo para simular el comportamiento de deformación en estas tuberías, lo que ayuda en la evaluación de su integridad y riesgos. En este trabajo, se propone un modelo desarrollado mediante elementos finitos para analizar el comportamiento de tuberías de acero al carbono API 5L Gr B, sujetas a presión interna y cargas laterales. El modelo se valida mediante pruebas experimentales de tensión y flexión de cuatro puntos. Además, se realiza análisis paramétrico considerando variables como diámetro, la carga lateral y distancia entre soportes. El objetivo es identificar cuál de estas variables influye más en la deformación unitaria. Los resultados indican que la deformación unitaria obtenida del modelo numérico concuerda con las pruebas experimentales. Además, se concluye que el diámetro es el parámetro influyente.

Referencias

ASME, Pipeline Integrity Assurance-A Practical Approach, [Online]. 2010. Available at: https://www.copyright.com

Phillip, J., Ellenberger, Piping and pipeline calculations manual: construction, design, fabrication, and examination. Butterworth-Heinemann/Elsevier, 2010.

Ozkan, I.F., Mohareb, M. and Asce, M., Testing and Analysis of Steel Pipes under Bending, Tension, and Internal Pressure, Journal of Structural Engineering, 135(2), art. 9445, 2009. DOI: https://doi.org/10.1061/(ASCE)0733-9445(2009)135:2(187). DOI: https://doi.org/10.1061/(ASCE)0733-9445(2009)135:2(187)

Ahn, K., Lim, I.G., Yoon, J., and Huh, H., A simplified prediction method for the local buckling load of cylindrical tubes, International Journal of Precision Engineering and Manufacturing, 17(9), pp. 1149–1156, 2016. DOI: https://doi.org/10.1007/s12541-016-0139-0. DOI: https://doi.org/10.1007/s12541-016-0139-0

Bazhenov, V.A., Luk’yanchenko, O.O., Kostina, O.V., and Gerashchenko, O.V., Nonlinear bending stability of a long flexible cylindrical shell with geometrical imperfections. Strength of Materials, 48(2), pp. 308–314, 2016, DOI: https://doi.org/10.1007/s11223-016-9766-z. DOI: https://doi.org/10.1007/s11223-016-9766-z

Antaki, G.A., Fitness-for-service and integrity of piping, vessels, and tanks: ASME code simplifed. McGraw-Hill, USA, 2005.

Cai, J., Jiang, X., Lodewijks, G., Pei, Z., and Wu, W., Residual ultimate strength of seamless metallic pipelines under a bending moment-a numerical investigation, Ocean Engineering, 164, pp. 148–159, 2018. DOI: https://doi.org/10.1016/j.oceaneng.2018.06.044. DOI: https://doi.org/10.1016/j.oceaneng.2018.06.044

Nazemi, N., Behavior of X60 Line Pipe under Combined Axial and Transverse Loads with Internal Pressure, 2009. [Online]. Available at: https://scholar.uwindsor.ca/etd DOI: https://doi.org/10.1115/1.4001426

ANSYS, Element Reference, 2022. [Online]. Available at: http://www.ansys.com

Li, Y., Shuai, J., Jin, Z.L., Zhao, Y.T., and Xu, K., Local buckling failure analysis of high-strength pipelines, Pet Sci, 14(3), pp. 549–559, 2017. DOI: https://doi.org/10.1007/s12182-017-0172-3. DOI: https://doi.org/10.1007/s12182-017-0172-3

Wang, J., Shuai, Y., He, R., Dou, X., Zhang, P., and Feng, C., Ultimate strain capacity assessment of local buckling of pipelines with kinked dents subjected to bending loads. Thin-Walled Structures, 169, 2021. DOI: https://doi.org/10.1016/j.tws.2021.108369.

ANSYS, Basic Analysis Guide, 2022. [Online]. Available at: http://www.ansys.com

Shuai, Y. et al., Local buckling failure analysis of high strength pipelines containing a plain dent under bending moment, J Nat Gas Sci Eng, 77, 2020, DOI: https://doi.org/10.1016/j.jngse.2020.103266. DOI: https://doi.org/10.1016/j.jngse.2020.103266

Kamaya, M., Ramberg-Osgood type stress-strain curve estimation using yield and ultimate strengths for failure assessments, International Journal of Pressure Vessels and Piping, 137, pp. 1–12, 2014. DOI: https://doi.org/10.1016/j.ijpvp.2015.04.001. DOI: https://doi.org/10.1016/j.ijpvp.2015.04.001

Tee, K.F., and Wordu, A.H., Burst strength analysis of pressurized steel pipelines with corrosion and gouge defects, Eng Fail Anal, 108, 2020 DOI: https://doi.org/10.1016/j.engfailanal.2019.104347. DOI: https://doi.org/10.1016/j.engfailanal.2019.104347

NACE, Standard Test Method - Four-Point Bend Testing of Materials for Oil and Gas Applications, 2016.

ASTM E 8M, Standard Test Methods for Tension Testing of Metallic Materials, 2001.

Han, J., Lu, Ch., Wu, B., Li, J., Li, H., Lu, Y., and Gao, Q., Innovative analysis of Luders band behaviour in X80 pipeline steel Materials Science & Engineering A, A683, pp. 123-128, 2017. DOI: https://doi.org/10.1016/j.msea.2016.12.008 DOI: https://doi.org/10.1016/j.msea.2016.12.008

Urriolagoitia-Sosa, G., Durodola, J.F., Lopez-Castro, A., and Fellows, N.A., A method for the simultaneous derivation of tensile and compressive behaviour of materials under Bauschinger effect using bend tests, Journal of Mechanical Engineering Science, 220(10), pp. 1509-1518, 2006. DOI: https://doi.org/10.1243/09544062JMES180 DOI: https://doi.org/10.1243/09544062JMES180

API Specification 5L, Specification for line pipe, 2013.

Keil, S., Technology and practical use of strain gages, Publisher: Ernst & Sohn a Wiley Brand, 2017.

Montgomery, D.C., Design and analysis of experiments, Wiley, USA, 2020.

Shuai, Y. Wang, X-H., Cheng, Y.F., Buckling resistance of an X80 steel pipeline at corrosion defect under bending moment. J. Nat Gas Sci Eng, 93, art. 104016, 2021. DOI: https://doi.org/10.1016/j.jngse.2021.104016 DOI: https://doi.org/10.1016/j.jngse.2021.104016

Wang, J. et al., Ultimate strain capacity assessment of local buckling of pipelines with kinked dents subjected to bending loads. J. Thin-Walled Structures, 169, art. 108369, 2021. DOI: https://doi.org/10.1016/j.tws.2021.108369 DOI: https://doi.org/10.1016/j.tws.2021.108369

Jindra, D. et al., Experimental and numerical simulation of a three-point bending test of a stainless-steel beam. J. Transportation Research Procedia, 55, pp. 1114-1121 2021. DOI: https://doi.org/10.1016/j.trpro.2021.07.183 DOI: https://doi.org/10.1016/j.trpro.2021.07.183

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.