Publicado

CEMPRI, a primary cementing software for vertical onshore wells as a tool for petroleum engineering education

CEMPRI, un software de cementación primaria para pozos verticales terrestres como herramienta para la educación en ingeniería petrolera

DOI:

https://doi.org/10.15446/dyna.v91n233.112977Palabras clave:

onshore oil well, primary cementing, software, wellbore diagram, casing (en)pozos petroleros terrestres, cementación primaria, software, estado mecánico, tubería de revestimiento (es)

Descargas

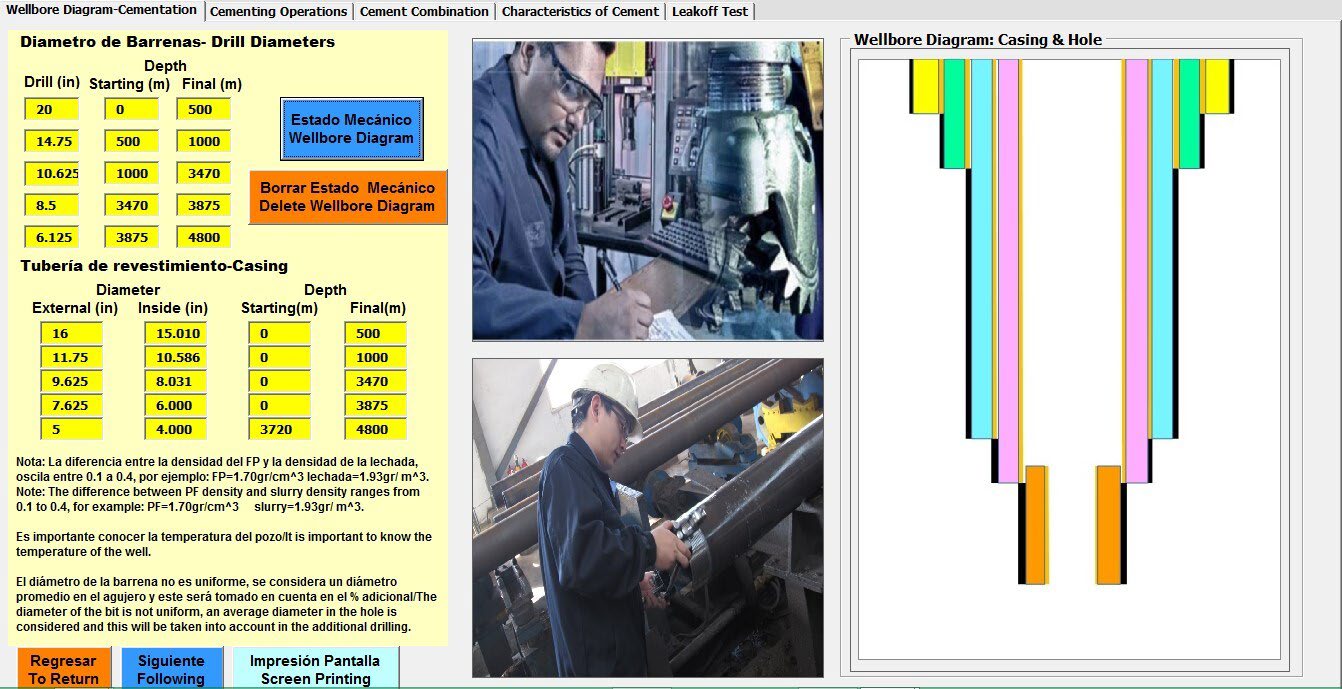

The use of simulation software applicable to the various stages of petroleum engineering facilitates decision-making and, at the same time, minimizes possible failures, problems, and incidents during each well intervention. In addition, a computer tool provides the user with instant and accurate results that can be used during personnel training and higher education. The objective of the present work was to develop an open-source computational tool with a graphical, numerical, and schematic interface to facilitate the teaching and learning of operations related to primary cementing. The tool considers four sections: (a) wellbore diagram, (b) identification of the relation between volumetry and the geometric design of the well, (c) integration of the mechanical state with the number of intervals, slurry design, and operating characteristics of the pumps, and (d) the wellbore diagram integrated by drilling, displacement and slurry fluids, according to each of the cementing stages. Among the results, it was combined programming with specialized technical and scientific material, considering academic and field experience characteristics. The program is a versatile tool that integrates the general mechanical state and each of the five stages with a maximum depth of 5,000 m.

El uso de software de simulación aplicable a las distintas etapas de la ingeniería petrolera facilita la toma de decisiones y, al mismo tiempo, minimiza posibles fallas, problemas e incidentes durante cada intervención en el pozo. Además, una herramienta informática proporciona al usuario resultados instantáneos y precisos que pueden utilizarse durante la formación del personal y la educación superior. El objetivo del presente trabajo fue desarrollar una herramienta computacional de código abierto con una interfaz gráfica, numérica y esquemática para facilitar la enseñanza y el aprendizaje de operaciones relacionadas con la cementación primaria. La herramienta considera cuatro secciones: (a) diagrama de pozo, (b) identificación de la relación entre volumetría y diseño geométrico del pozo, (c) integración del estado mecánico con el número de intervalos, diseño de lechada y características operativas del pozo. las bombas, y (d) el diagrama de pozo integrado por los fluidos de perforación, desplazamiento y lodo, según cada una de las etapas de cementación. Entre los resultados, se combinó programación con material técnico y científico especializado, considerando características académicas y de experiencia de campo. El programa es una herramienta versátil que integra el estado mecánico general y cada una de las cinco etapas con una profundidad máxima de 5.000 m.

Referencias

[1] McLean, R.H., Manry, C.W., and Whitaker, W.W., Displacement mechanics in primary cementing. Journal of Petroleum Technology. 19, pp. 251–260, 1967. DOI: https://doi.org/10.2118/1488-PA.

[2] Clark, C.R., and Carter, G.L., Mud displacement with cement slurries. Journal of Petroleum Technology. 25, pp. 775–783, 1973. DOI: https://doi.org/10.2118/4090-PA.

[3] Haut, R.C., Collins, R.E., and Graves, W.G., Applications of a computer simulator to primary cementing. All Days, Houston, Texas, SPE-7588-MS, 1978. DOI: https://doi.org/10.2118/7588-MS.

[4] Tardy, P.M., Flamant, N.C., Lac, E., Parry, A., Sutama, C.S., and Almagro, S.P., New generation 3D simulator predicts realistic mud displacement in highly deviated and horizontal wells. Day 2 Wed, March 15, 2017, The Hague, The Netherlands, SPE, D021S011R004. 2017. DOI: https://doi.org/10.2118/184677-MS.

[5] Smith, R.C., Successful primary cementing can be a reality. Journal of Petroleum Technology. 36, pp. 1851-1858, 1984. DOI: https://doi.org/10.2118/13498-PA.

[6] Tardy, P.M.J., A 3D model for annular displacements of wellbore completion fluids with casing movement. Journal of Petroleum Science and Engineering 162, pp. 114–136, 2018. DOI: https://doi.org/10.1016/j.petrol.2017.11.071.

[7] Foroushan, H.K., Lund, B., Ytrehus, J.D., and Saasen, A., Cement placement: An overview of fluid displacement techniques and modelling. Energies 14(3), art. 573, 2021. DOI: https://doi.org/10.3390/en14030573.

[8] Wu, X., Liu, J., Li, Z., Song, W., Liu, Y., Shi, Q., et al., Failure analysis of cement sheath mechanical integrity based on the statistical damage variable. ACS Omega 8, pp. 2128–2142, 2023. DOI: https://doi.org/10.1021/acsomega.2c06164.

[9] Lavrov, A., Effect of eccentric annulus, washouts, and breakouts on well cementing quality: laminar regime. Energy Procedia 86, pp. 391–400, 2016. DOI: https://doi.org/10.1016/j.egypro.2016.01.040

[10] Al-Maskary, S., Halim, A.A., and Al-Menhali, S., Curing losses while drilling & cementing, Abu Dhabi, UAE: SPE, 2014, D041S065R002. DOI: https://doi.org/10.2118/171910-MS.

[11] Beirute, R.M., The phenomenon of free fall during primary cementing. All Days, Houston, Texas: 1984, SPE-13045-MS. DOI: https://doi.org/10.2118/13045-MS.

[12] Hartog, J.J., Davies, D.R., and Stewart, R.B., An integrated approach for successful primary cementations. Journal of Petroleum Technology, 35, pp. 1600–1610, 1983. DOI: https://doi.org/10.2118/9599-PA.

[13] Wang, C., Meng, R., Chen, Z., Yang, S., Chen, S., Yu, Y., et al., Study on the key issue in the application of nanoemulsions in preflush spacer: contamination of cement slurry by nanoemulsions. SPE Journal, (28), pp. 64–79, 2023. DOI: https://doi.org/10.2118/212278-PA.

[14] Kulakofsky, D.S., Henry, S.R., and Porter, D., PC-based cement job design system improves primary cement jobs. All Days, New Orleans, Louisiana, SPE, 1993, pp. SPE-26261-MS. DOI: https://doi.org/10.2118/26261-MS.

[15] Villegas-Javier, M.I., Análisis y propuesta del plan de estudios de la carrera de ingeniería petrolera, MSc. Thesis, Universidad Autónoma de México. [online]. 2014. Available at: https://hdl.handle.net/20.500.14330/TES01000719758

[16] Zhang, H., Guo, J., Yang, L., Wu, P., Xue, H., and Yang, M., Optimization of cementing displacement efficiency based on circulation pressure of a shale gas horizontal well in low pressure and leakage formations. Energy Reports 8, pp. 11695–11706, 2022. DOI: https://doi.org/10.1016/j.egyr.2022.08.253.

[17] Torres, D.E., and Anders, J.L., Using MS Visual Basic to write engineering applications. All Days, SPE, Houston, Texas, 1995, pp. SPE-30215-MS. DOI: https://doi.org/10.2118/30215-MS.

[18] Akpan, H.O., and Kwelle, S.O., Efficient computational method for casing string design. All Days, SPE, Abuja, Nigeria, 2005, pp. SPE-98790-MS. DOI: https://doi.org/10.2118/98790-MS.

[19] Bell, M.R.G., Davies, J.B., and Simonian, S., Optimized perforation—from black art to engineering software tool. All Days, SPE, Adelaide, Australia, 2006, pp. SPE-101082-MS. DOI: https://doi.org/10.2118/101082-MS.

[20] Utsalo, O., Olamigoke, O., and Adekuajo, C.O., An excel based casing design application. All Days, SPE, Lagos, Nigeria, 2014, pp. SPE-172466-MS. DOI: https://doi.org/10.2118/172466-MS.

[21] Comisión Nacional de Hidrocarburos. Lineamientos de Perforación de Pozos. Gobierno de México. Diario Oficial de la Federación, [online]. 2017. Available at: https://www.dof.gob.mx/nota_detalle.php?codigo=5505865

[22] Maleki, A., and Frigaard, I.A., Tracking fluid interfaces in primary cementing of surface casing. Physics of Fluids 30, art. 093104, 2018. DOI: https://doi.org/10.1063/1.5042260.

[23] Nelson, E.B., Guillot, D., eds. Well Cementing. 2nd ed. Sugar Land, Schlumberger. Texas, [online]. 2006. Available at: https://www.slb.com/resource-library/book/well-cementing

[24] Cammarata, N., and Rosero, I., CEM 2 Primary cementing. 1st ed. Cementing in Touch. Schlumberger, Sugarland, Texas, 2017, 213 P.

[25] Gaurina-Međimurec, N., Pašić, B., Mijić, P., and Medved, I., Drilling fluid and cement slurry design for naturally fractured reservoirs. Applied Sciences 11, art. 767, 2021. DOI: https://doi.org/10.3390/app11020767.

[26] Foroushan, H.K., Ozbayoglu, E.M., and Gomes, P.J., How realistic is the calculated cementing displacement efficiency? Galveston, Texas, USA, 2020, pp. D082S000R004. DOI: https://doi.org/10.2118/199553-MS.

[27] Zulqarnain, M., and Tyagi, M., Development of simulations-based correlations to predict the cement volume fraction in annular geometries after fluid displacements during primary cementing. Journal of Petroleum Science and Engineering 145, pp. 1–10, 2016. DOI: https://doi.org/10.1016/j.petrol.2016.03.012.

[28] Calvert, D.J., and Smith, D.K., API oilwell cementing practices. All Days, OTC, Houston, Texas, 1990, pp. OTC-6210-MS. DOI: https://doi.org/10.4043/6210-MS.

[29] Khalilova, P., Koons, B., Lawrence, D.W., and Elhancha, A., Newtonian fluid in cementing operations in deepwater wells: friend or foe? Paper presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, 2013. DOI: https://doi.org/10.2118/166456-MS.

[30] Lavrov, A., and Torsæter, M., Physics and mechanics of primary well cementing. Springer International Publishing, 2016, 108 P. DOI: https://doi.org/10.1007/978-3-319-43165-9.

[31] Enayatpour, S., Van-Oort, E., Advanced modeling of cement displacement complexities. Paper presented at the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 2017. DOI: https://doi.org/10.2118/184702-MS

[32] Maleki, A., and Frigaard, I., Primary cementing of oil and gas wells in turbulent and mixed regimes. J Eng Math., 107, pp. 201–230, 2017. DOI: https://doi.org/10.1007/s10665-017-9914-x.

[33] Lavrov, A., Lost circulation in primary well cementing. Energy Procedia. 114, pp. 5182–5192, 2017. DOI: https://doi.org/10.1016/j.egypro.2017.03.1672

[34] Vite-Rodríguez, H.M., Cementación primaria con lechadas de cemento de baja densidad en formaciones de baja presión Perú. Thesis. Universidad Nacional de Piura, Peru. [online]. 2019. Available at: https://repositorio.unp.edu.pe/handle/UNP/1976

[35] Chaudhry, A.M., Development of Software application for optimization of primary cementing operations using Visual Basic. Paper presented at the SPE Annual Technical Conference and Exhibition, Dubai, UAE, September 2016. DOI: https://doi.org/10.2118/184485-STU

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.