Publicado

Optimization of the refined used lubricating oil/diesel mixture to incorporate it into drilling fluids

Optimización de la mezcla aceite lubricante usado refinado/diésel para incorporarlo en fluidos de perforación

DOI:

https://doi.org/10.15446/dyna.v91n233.113840Palabras clave:

drilling fluids, refining, rheology, reuse, used oil (en)fluidos de perforación, refinación, reología, reutilización, aceite usado (es)

Descargas

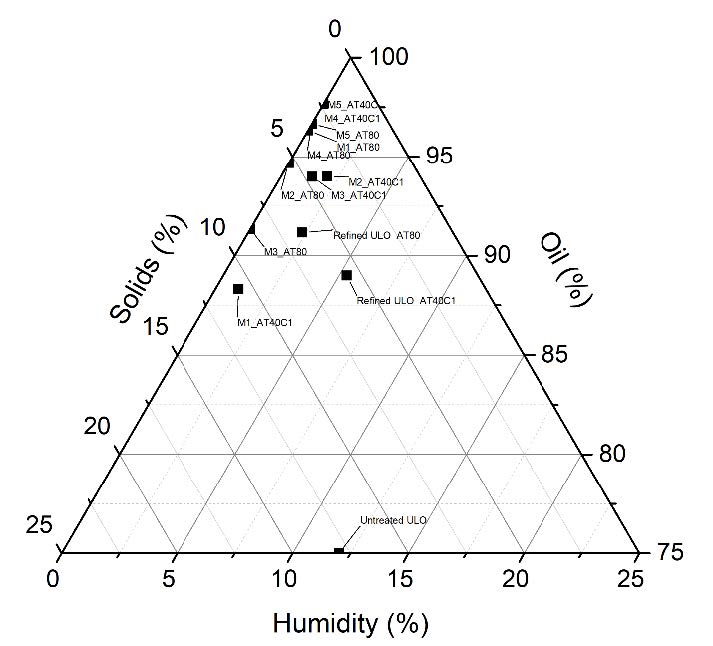

The use of refined used lubricating oils (RULO) is an opportunity for use for the industrial sector, improving the environment. The objective of the research was to evaluate different RULO/diesel mixtures from the AT80 and AT40C1 treatments. The experiment consisted of applying different proportions of RULO, forming five different mixtures between ALUR/diesel. The mixes were 85/15, 70/30, 55/45, 40/60 and 30/70. The results showed that the best mixtures were M4 and M5 of the AT80 treatment, with average density of 0.80 g/cm3, viscosity of 5.83 cP, electrical stability of 1694.33 V, flash point of 95°C and 96.67% oil. With these results, a new alternative and use is created, reducing diesel and economic costs for the oil industry that prepares oil-based drilling fluids.

El aprovechamiento de los aceites lubricantes usados refinados (ALUR), son una oportunidad de uso para el sector industrial, mejorando el medio ambiente. El objetivo de la investigación fue evaluar diferentes mezclas de ALUR/diesel a partir de los tratamientos AT80 y AT40C1. El experimento consistió en aplicar diferentes proporciones de ALUR, formando cinco mezclas diferentes entre el ALUR/diésel. Las mezclas fueron 85/15, 70/30, 55/45, 40/60 y 30/70. Los resultados mostraron que las mejores mezclas fueron M4 y M5 del tratamiento AT80, con promedios de densidad de 0.80 g/cm3, viscosidad de 5.83 cP, estabilidad eléctrica de 1694.33 V, punto de inflamación de 95°C y 96.67% de aceite. Con estos resultados se crea una nueva alternativa y aprovechamiento, disminuyendo el diésel y los costos económicos a la industria petrolera que prepara fluidos de perforación base aceite.

Referencias

[1] Nabi, M.N., Rasul, M.G., Rahman, S.M.A., Ristovski, Z.D., Brown, R.J., and Dowell, A., Study of performance, combustion and emission characteristics of a common rail diesel engine with tea tree oil-diglyme blends. Energy. 180, pp. 216-228, 2019. DOI: https://doi.org/10.1016/j.energy.2019.05.070

[2] Dudak, L., Milisavljevic S., Jocanovic M., Kiss F., Ševic D., Karanovic V., and Orošnjak M., Life cycle assessment of different waste lubrication oil management options in Serbia. applied sciences. 11, art. 6652, 2021. DOI: https://doi.org/10.3390/app11146652

[3] Sánchez-Alvarracín, C., Criollo-Bravo, J., Albuja-Arias, D., García-Ávila, F., and Pelaez-Samaniego, M.R., Characterization of used lubricant oil in a Latin-American medium-size city and analysis of options for its regeneration. Recycling. 6(10), pp 2-22, 2021.

[4] Tsambe, M.Z.A., de Almeida, C.F.; Ugaya, C.M.L., de Abreu-Cybis, L.F., Application of life cycle sustainability assessment to used lubricant oil management in South Brazilian region. Sustainability. 13. (13583), pp 2-16, 2021. DOI: https://doi.org/10.3390/su132413583

[5] Naife, T.M., Rashid, S.A., and Abdul, J.M.F., Treatment of used lubricant oil by solvent extraction. Iraqi Journal of Chemical and Petroleum Engineering. 23(1), pp 43-50, 2022. DOI: https://doi.org/10.31699/IJCPE.2022.1.6

[6] Tan, H.L., Azmi, N.N. Veny, H., Lim, Y.P., and Passarella, R., A comparative study on treatment for recycling of waste lubricating oil. Malaysian Journal of Chemical Engineering & Technology. 5(1), pp 43–53, 2022. DOI: https://doi.org/10.24191/mjcet.v5i1.15726

[7] Emima, Y., Rajesh, M., and Kuchipudi, S.R., Experimental investigation on performance and exhaust emission characteristics of diesel engine using eesame blends with diesel and additive. International Journal of Recent Technology and Engineering. 8(1S3), Pp 6-11, 2019.

[8] Igbafe, S., Azuokwu, A.A., and A.I. Igbafe, A.I., Production and characterization of chrysophyllum albidum seed oil derived bio-lubricant for the formulation of oil-based drilling mud. Journal of Biotechnology and Biochemistry. 6(2), pp 27-32, 2020. DOI: https://doi.org/10.9790/264X-0602012732

[9] Murtaza, M., Alarifi, S.A., Kamal, M.S., Onaizi, S.A., Al-Ajmi, M., and Mahmoud, M., Experimental investigation of the rheological behavior of an oil-based drilling fluid with rheology modifier and oil wetter additives. Molecules. 26(4877), pp 2-16, 2021. DOI: https://doi.org/10.3390/molecules26164877

[10] Oghenejoboh, K.M., Ohimor E.O., and Olayebi, O., Application of re-refined used lubricating oil as base oil for the formulation of oil based drilling mud - A comparative study. Journal of Petroleum Technology and Alternative Fuels. 4(4), pp. 78-84, 2013.

[11] Wu-Juan, S., Guo-Qing, T., Hang-Juan H., Guo-Min, L., Cong-Yu, K., Jun-Feng, H., and Xun-Li, Z., Synthesis and caracterization of a multifunctional oil-based drilling fluid additive. Environmental Earth Sciences. 77(793), pp 2-8, 2018. DOI: https://doi.org/10.1007/s12665-018-7982-5.

[12] Ahmed, W.A., and Kalkan, E., Drilling fluids. Types, formation choice and environmental impact. International Journal of Latest Technology in Engineering, Management & Applied Science. VIII(XII), pp 66-71, 2019.

[13] Kania, D., Yunus, R., Omar, R., Rashid, S.A., and Jan, B.M., A review of biolubricants in drilling fluids: recent research, performance, and applications. Journal of Petroleum Science and Engineering 135(2015), 177–184, 2015. DOI: https://doi.org/10.1016/j.petrol.2015.09.021

[14] Arbad, N., and Teodoriu, C., A review of recent research on contamination of oil well cement with oil-based drilling fluid and the need of new and accurate correlations. Chemestry Engineering. 4(28), pp 2-20, 2020. DOI: https://doi.org/10.3390/chemengineering4020028

[15] Destiny, A.J., and Amanze, F.C., Performance of rubber seed oil as an alternative to diesel in oil- based drilling mud formulation. International Journal of Advances in Applied Sciences. 10(1), pp. 47-592021. DOI: https://doi.org/10.11591/ijaas.v10.i1

[16] Alvarez-Rivera, J.A., Castañón-Nájera, G., Urrieta-Saltijeral, J.M., Laínes-Canepa, J.R., Hernández-Barajas, J.R., Pampillón-González, L., and Morales-Bautista, C.M., Handling of used lubricating oil in Tabasco, Mexico. DYNA, 89(223), pp. 121-126, 2022. DOI: https://doi.org/10.15446/dyna.v89n221.101484

[17] Alvarez-Rivera, J.A., Castañón-Nájera, G., Urrieta-Saltijeral, J.M., Laínes-Canepa, J.R., Hernández-Barajas, J.R., Pampillón-González, L., and Morales-Bautista, C.M., Refining used lubricant oils with different concentration levels of sulfuric acid and nonylphenol. Tribology in Industry 45(1), pp 168-177. 2023. DOI: https://doi.org/10.24874/ti.1411.11.22.03

[18] Tuccar, G., Tosun, E., and Uludamar, E., Investigations of effects of density and viscosity of diesel and biodiesel fuels on NOx and other Emission Formations. Academic Platform Journal of Engineering and Science. 6(2), pp 81-85, 2018.

[19] Pardo-García, C., Orjuela-Abril, S., and Pabón-León, J., Investigation of emission characteristics and lubrication oil properties in a dual diesel–hydrogen internal combustion engine. Lubricants. 10(59), pp. 2-15, 2022. DOI: https://doi.org/10.3390/lubricants10040059

[20] Kurre, S.K., Pandey, S., Khatri, N., Bhurat, S.S., Kumawat, S.K., Saxena, S., and Kumar, S., Study of lubricating oil degradation of CI engine fueled with diesel-ethanol blend. Tribology in Industry. 43(2), pp 222-223, 2021. DOI: https://doi.org/10.24874/ti.913.06.20.11

[21] Naima, K., and Liazid, A., Waste oils as alternative fuel for diesel engine: a review. Journal of Petroleum Technology and Alternative Fuels. 4(3), pp. 30-43, 2013. DOI: https://doi.org/10.5897/JPTAF12.026

[22] Soomro, S.A., and Brohi, K.M., Effect of Synthesized biodiesel on the rheological properties of oil based drilling mud. Engineering Science and Technology International Research Journal, 4(1), pp. 28-33, 2020.

[23] Błaz, S., Zima, G., Jasin ́ski, B., and Kremieniewski, M., Invert drilling fluids with high internal phase content. Energies. 14(4532), pp 2-14, 2021. DOI: https://doi.org/10.3390/en14154532.

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.