Publicado

Use of end-of-life tires for the production of a waterproofing agent as a strategy to promote the circular economy

Aprovechamiento de neumáticos al final de su vida útil para la producción de impermeabilizante como estrategia de promoción de la economía circular

DOI:

https://doi.org/10.15446/dyna.v91n234.116103Palabras clave:

waste tire, circular economy, waterproofing, waterborne coating (en)neumáticos usados, economía circular, impermeabilización, recubrimientos base agua (es)

Descargas

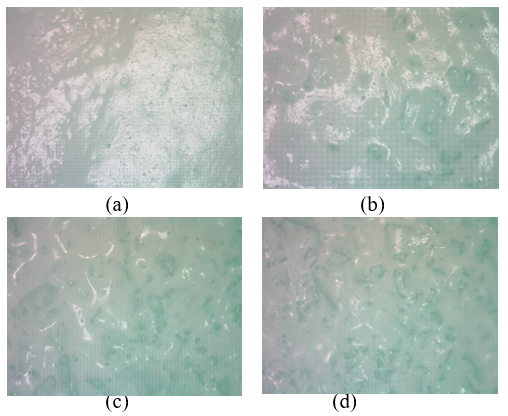

This paper develops a formulation to produce a laboratory-scale waterproofing for exterior walls and roofs using recycled tires. It begins by identifying its chemical composition using Fourier transform infrared spectroscopy and selects a technology using the ELECTRE method. It uses a reticular simplex mixing design of experiments to adjust the resin proportions according to their mechanical properties. In addition, it evaluates the critical pigment volume content and parameters such as water absorption, permeability, total solids content and mechanical properties for quality assurance. Acrylic emulsions were found to be favorable in cost, application, safety, and efficiency; the flexible resin offers better elongation and the rigid one better tensile strength, with less than 10% tire reducing porosity. The results support the competitiveness of the product and confirm the effective use of recycled tires in waterproofing, offering a favorable and functional approach to construction.

Este trabajo desarrolla una formulación para producir un impermeabilizante a escala de laboratorio para paredes exteriores y cubiertas utilizando neumáticos reciclados. Inicia identificando la composición química mediante espectroscopia infrarroja por transformada de Fourier y selecciona una tecnología mediante el método ELECTRE. Utiliza un diseño de experimentos de mezcla simple reticular para ajustar las proporciones de resina en función de sus propiedades mecánicas. Además, evalúa el contenido crítico de volumen de pigmento y parámetros como la absorción de agua, permeabilidad, contenido total de sólidos y las propiedades mecánicas para el aseguramiento de la calidad. Las emulsiones acrílicas resultaron favorables en coste aplicación, seguridad y eficacia; la resina flexible ofrece mejor alargamiento y la rígida mejor resistencia a la tracción, con menos de un 10% de porosidad reductora del neumático. Los resultados apoyan la competitividad del producto y confirman el uso eficaz de neumáticos reciclados en la impermeabilización, ofreciendo un enfoque favorable y funcional para la construcción.

Referencias

[1] Casini, M., Advanced technology, tools and materials for the digital transformation of the construction industry, cap. 1.3, Low-Carbon and sustainable cities. [online]. 2022. Available at: https://app.knovel.com/hotlink/khtml/id:kt012RPNH3/construction-4-0-advanced/low-carbon-sustainable

[2] Gijsbertus, E., Catarina, C., and Leendert, G., Polymer coatings - A guide to chemistry, characterization, and selected applications, Cap 4. Coating compositions in general. [online], John Wiley & Sons. 2018, Available at: https://app.knovel.com/hotlink/khtml/id:kt011QZ3L2/polymer-coatings-guide/coating-compositions

[3] Casini, M., Advanced technology, tools and materials for the digital transformation of the construction industry, cap 7. Nanocomposite concrete. [Online]. 2022. Available at: https://app.knovel.com/hotlink/khtml/id:kt012RPSK1/construction-4-0-advanced/nanocomposite-concrete

[4] Höfer-Rainer, M., Green chemistry principles and global drivers for sustainability - An introduction. Royal Society of Chemistry (RSC). [Online]. 2019. Available: https://app.knovel.com/hotlink/khtml/id:kt012VYN26/green-chemistry-surface/green-chemistry-principles.

[5] Gündüz, G., Chemistry, materials, and properties of surface coatings - Traditional and evolving technologies, cap 1. Future forecast. [Online]. 2015. Available at: https://app.knovel.com/hotlink/khtml/id:kt0132BATP/chemistry-materials-properties/future-forecast.

[6] Koleske, J.V., Paint and coating testing manual - Fifteenth edition of the Gardner-sward Handbook, cap 78. Ultraviolet radiation systems. [Online]. 2012. Available at: https://app.knovel.com/hotlink/pdf/id:kt00B7Y83A/paint-coating-testing/curing-equ-ultraviolet DOI: https://doi.org/10.1520/MNL17-2ND-EB

[7] Pacheco-Torgal, F., Introduction to the environmental impact of construction and building materials, in: Eco-efficient construction and building materials, Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., and Magalhães, A., Eds. Woodhead Publishing, 2014, pp. 1–10. DOI: https://doi.org/10.1533/9780857097729.1

[8] Leon, A., Chen, Q., Palaganas, N., Palaganas J., Manapat J., and Advincula, R., High performance polymer nanocomposites for additive manufacturing applications, React Funct Polym, 103, pp. 141–155, 2016. DOI: https://doi.org/10.1016/j.reactfunctpolym.2016.04.010

[9] Dixit, S., Goel, R., Dubey, A., Shivhare, P., and Bhalavi, T., Natural fibre reinforced polymer composite materials - A review. Polymers from Renewable Resources, 8(2), pp. 71–78, 2017, DOI: https://doi.org/10.1177/204124791700800203

[10] Hejna, A., Korol, J., Przybysz-Romatowska, M.Ł., Zedler, B., and Chmielnicki, F.K., Waste tire rubber as low-cost and environmentally-friendly modifier in thermoset polymers – A review. Waste Management, 108, pp. 106–118, 2020, DOI: https://doi.org/10.1016/j.wasman.2020.04.032

[11] Zabalza-Bribián, I., Valero-Capilla, A., and Aranda-Usón, A., Life cycle assessment of building materials: comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential, Build Environ, 46(5), pp. 1133–1140, 2011. DOI: https://doi.org/10.1016/j.buildenv.2010.12.002

[12] Na, O., and Xi, Y., Mechanical and durability properties of insulation mortar with rubber powder from waste tires, J Mater Cycles Waste Manag, 19(2), pp. 763–773, 2017, DOI: https://doi.org/10.1007/S10163-016-0475-2/METRICS

[13] Wang, Q., Cui, Y., and Xue, J., Study on the improvement of the waterproof and mechanical properties of hemihydrate phosphogypsum-based foam insulation materials, Constr Build Mater, 230, art. 117014, 2020. DOI: https://doi.org/10.1016/J.CONBUILDMAT.2019.117014

[14] Al-Jabari, M., Al-Rashed, R., Ayers M.E., and Clement, D., Materials selection and proportioning for watertight and durable concrete, in: Integral waterproofing of concrete structures, Al-Jabari, M., Ed., Woodhead Publishing Series in Civil and Structural Engineering, Woodhead Publishing, 2022, pp. 109–134. DOI: https://doi.org/10.1016/B978-0-12-824354-1.00004-0

[15] Al-Jabari, M., Waterproofing coatings and membranes, in: Integral waterproofing of concrete structures, Al-Jabari, M., Ed., in Woodhead Publishing Series in Civil and Structural Engineering. Woodhead Publishing, 2022, pp. 393–435. DOI: https://doi.org/10.1016/B978-0-12-824354-1.00012-X

[16] Edun, A., and Hachem-Vermette, C., Energy and environmental impact of recycled end of life tires applied in building envelopes, Journal of Building Engineering, 39, art. 102242, 2021. DOI: https://doi.org/10.1016/j.jobe.2021.102242

[17] Kim-Jin K.S. Introduction, 2019, Royal Society of Chemistry (RSC). [Online]. Available at: https://app.knovel.com/hotlink/khtml/id:kt011IVUD2/rubber-recycling-challenges/thermoplas-introduction

[18] Martínez, J.D., An overview of the end-of-life tires status in some Latin American countries: proposing pyrolysis for a circular economy, Renewable and Sustainable Energy Reviews, 144, art. 111032, 2021. DOI: https://doi.org/10.1016/J.RSER.2021.111032.

[19] Park, J., Díaz-Posada, N., and Mejía-Dugand, S., Challenges in implementing the extended producer responsibility in an emerging economy: the end-of-life tire management in Colombia, J. Clean Prod, 189, pp. 754–762, 2018. DOI: https://doi.org/10.1016/j.jclepro.2018.04.058.

[20] Denguir, Y., Estudio del uso de neumáticos fuera de uso (NFU) como material para la construcción de terraplenes. Aplicación a la ampliación del vertedero de residuos controlado de les Borges Blanques (Lleida). [Online]. 2021. [Accessed: Jun. 03, 2024] Available at: https://riunet.upv.es:443/handle/10251/173175

[21] Sienkiewicz, M., Janik, H., Borzędowska-Labuda, K., and Kucińska-Lipka, J., Environmentally friendly polymer-rubber composites obtained from waste tyres: aq review, J Clean Prod, 147, pp. 560–571, 2017. DOI: https://doi.org/10.1016/j.jclepro.2017.01.121.

[22] Mohajerani, A., Recycling waste rubber tyres in construction materials and associated environmental considerations: a review, Resour Conserv Recycl, 155, art. 104679, 2020. DOI: https://doi.org/10.1016/j.resconrec.2020.104679.

[23] Das Gupta, S., Mukhopadhyay, R., Baranwal, K.C., and Bhowmick, A., Reverse engineering concepts, in: Engineering of rubber products, Taylor & Francis Group, Boca Ratón, USA, 2013, pp. 194–199. DOI: https://doi.org/10.1201/b15435

[24] Araujo-Morera, J., Verdejo, R., López-Manchado, M., and Hernández Santana, M., Sustainable mobility: the route of tires through the circular economy model, Waste Management, 126, pp. 309–322, 2021. DOI: https://doi.org/10.1016/J.WASMAN.2021.03.025

[25] Valentini, F., and Pegoretti, A., End-of-life options of tyres. a review. Advanced Industrial and Engineering Polymer Research, 5(4), pp. 203–213, 2022, DOI: https://doi.org/10.1016/j.aiepr.2022.08.006

[26] Ramarad, S., Khalid, M., Ratnam, C.T., Chuah, A.L, and Rashmi, W., Waste tire rubber in polymer blends: a review on the evolution, properties and future, Prog Mater Sci, 72, pp. 100–140, 2015, DOI: https://doi.org/10.1016/j.pmatsci.2015.02.004.

[27] Fazli, A., and Rodriguez, D., Waste rubber recycling: a review on the evolution and properties of thermoplastic elastomers. Materials, 13(3), art. 782, 2020. DOI: https://doi.org/10.3390/ma13030782.

[28] Mengistu, D., Nilsen, V., Heistad, A., and Kvaal, K., Detection and quantification of tire particles in sediments using a combination of simultaneous thermal analysis, Fourier Transform Infra-Red, and parallel factor analysis. Int J Environ Res Public Health, 16(18), 2019. DOI: https://doi.org/10.3390/ijerph16183444.

[29] Gunasekaran, S., Natarajan, R.K., and Kala, A., FTIR spectra and mechanical strength analysis of some selected rubber derivatives. Spectrochim Acta A Mol Biomol Spectrosc, 68, pp. 323–330, 2007. DOI: https://doi.org/10.1016/j.saa.2006.11.039.

[30] Lee, Y.S., Lee, W.-K., Cho, S.-G., Kim, I., and Ha, C.-S., Quantitative analysis of unknown compositions in ternary polymer blends: a model study on NR/SBR/BR system. J Anal Appl Pyrolysis, 78(1), pp. 85–94, 2007, DOI: https://doi.org/https://doi.org/10.1016/j.jaap.2006.05.001.

[31] Al-Jabari, M., Fundamentals and categorizations of waterproofing technologies, in: Integral waterproofing of concrete structures, Al-Jabari, M., Ed., in Woodhead Publishing Series in Civil and Structural Engineering, Woodhead Publishing, 2022, pp. 165–198. DOI: https://doi.org/10.1016/B978-0-12-824354-1.00006-4.

[32] Gündüz, G., Chemistry, materials, and properties of surface coatings - Traditional and evolving technologies, cap 9. Silicon resins. [Online]. 2015. Available at: https://app.knovel.com/hotlink/khtml/id:kt0132BATP/chemistry-materials-properties/future-forecast.

[33] Jones, F.N., Polyurethanes and Polyisocyanates, John Wiley & Sons. [Online]. 2017. Available at: https://app.knovel.com/hotlink/khtml/id:kt011JHDH1/organic-coatings-science/polyurethanes-polyisocyanates

[34] Gündüz, G., Chemistry, materials, and properties of surface coatings - Traditional and evolving technologies. cap 11. Acrylic and vinyl resins [Online]. 2015. Available at: https://app.knovel.com/hotlink/khtml/id:kt0132BATP/chemistry-materials-properties/future-forecast.

[35] Ronald, M., and Luis, F.P., Asphalt emulsions formulation: state-of-the-art and dependency of formulation on emulsions properties. Constr Build Mater, 123, pp. 162–173, 2016. DOI: https://doi.org/10.1016/j.conbuildmat.2016.06.129

[36] Kleinsteinberg, F., Wetting- and dispersing additives, in: Additives for waterborne coatings, Vincentz Network, Hannover, Germany, 2014. pp. 20–38. DOI: https://doi.org/10.1515/9783748602187-003.

[37] Gijsbertus, E., and Catarina, C., Leendert, G., Polymer coatings - A guide to chemistry, characterization, and selected applications. Cap 5. Additives and particulates. John Wiley & Sons. [online], 2018, Available at: https://app.knovel.com/hotlink/khtml/id:kt011QZ3Z4/polymer-coatings-guide/additives-particulates

[38] Müller, B., and Poth, U., Coatings formulation, 2nd Revised Edition. Vincentz Network, Hanover, 2011.

[39] Kirchner, J., Defoaming of coating systems, in Additives for waterborne coatings, Vincentz Network, Hannover, Germany, 2014. pp. 39–55. DOI: https://doi.org/10.1515/9783748602187-004.

[40] Koleske J.V., Paint and coating testing manual – cap 32. Coalescing aids 15th Ed., Gardner-Sward Handbook, [Online] 2012. Available at: https://app.knovel.com/hotlink/khtml/id:kt00B7X494/paint-coating-testing/coalescing-aids

[41] Fazli, A., and Rodriguez, D., Effect of Ground Tire Rubber (GTR) particle size and content on the morphological and mechanical properties of recycled High-Density Polyethylene (rHDPE)/GTR Blends, Recycling, 6(3), 2021. DOI: https://doi.org/10.3390/recycling6030044

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.