Publicado

Optimization of enzymatic hydrolysis of corn starch to obtain glucose syrups by genetic algorithm

Optimización de la hidrólisis enzimática del almidón de maíz para obtener siropes de glucosa mediante algoritmos genéticos

DOI:

https://doi.org/10.15446/dyna.v92n235.116302Palabras clave:

hidrólisis enzimática, jarabes de glucosa, amilasas, algoritmo genético, equivalente de dextrosa (es)enzymatic hydrolysis, glucose syrups, amylases, genetic algorithm, dextrose equivalent (en)

Descargas

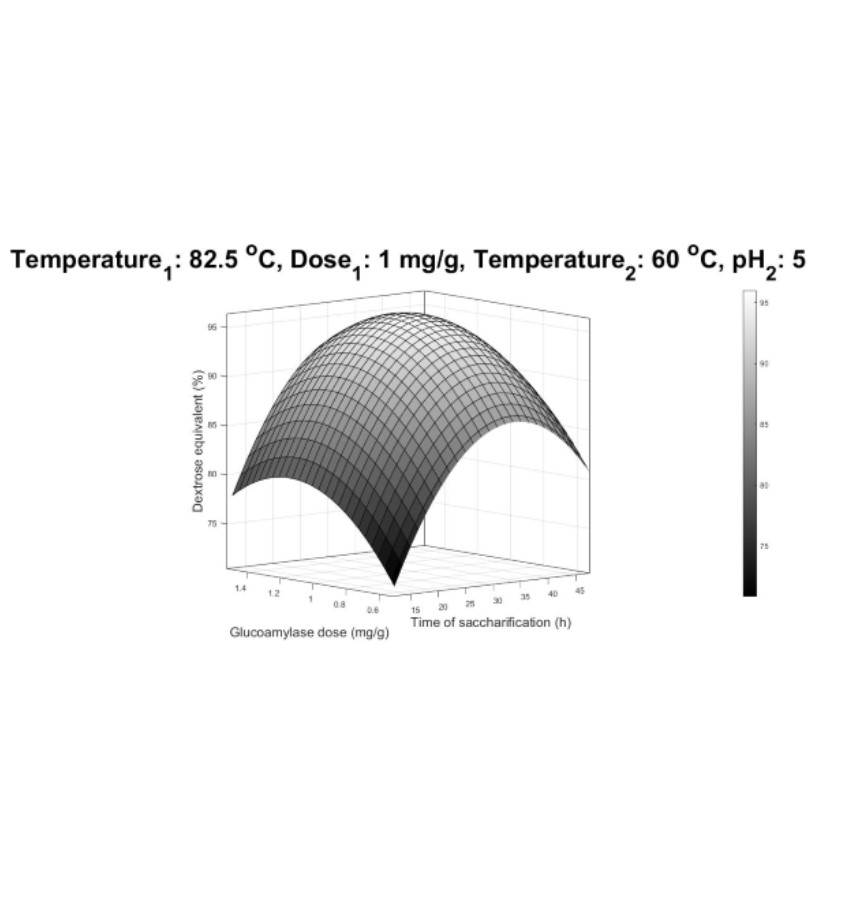

Este trabajo corresponde a la optimización de las variables de operación de la hidrólisis enzimática de almidón de maíz para la obtención de jarabes de glucosa utilizando el algoritmo genético de Matlab (2020a). Para ello, el proceso de hidrólisis se modeló matemáticamente mediante la metodología de superficie de respuesta. El diagrama de Pareto indicó que las variables de sacarificación ejercen la mayor influencia en la conversión del almidón. Este modelo matemático es de gran utilidad para una mejor comprensión y control operacional de la hidrólisis a nivel industrial. La solución del problema de optimización muestra que puede alcanzarse un equivalente máximo de dextrosa del 98,13% si la hidrólisis se realiza en las condiciones operacionales óptimas, las cuales se comprobaron experimentalmente. Los resultados muestran que, para alcanzar el mayor rendimiento, la licuefacción debe llevarse a cabo a una temperatura de 92oC, pH de 6,3, dosis de α-amilasa de 1,5 mg de enzima/g de almidón y tiempo de hidrólisis de 1 hora; mientras que la sacarificación debe realizarse a una temperatura de 57oC, pH de 4,9, dosis de glucoamilasa de 1,15 mg de enzima/g de almidón y tiempo de hidrólisis de 34 horas. El fenómeno de reversión se detectó cuando el tiempo de hidrólisis superó las 35 horas, con una incidencia negativa sobre el equivalente en dextrosa.

This work corresponds to the optimization of the operating variables of the enzymatic hydrolysis of corn starch to obtain glucose syrups using the genetic algorithm of Matlab (2020a). For this reason, the hydrolytic process is mathematically modeled by response surface methodology. Pareto chart indicated that saccharification variables exert the highest influence on starch conversion. This mathematical model is beneficial for a better understanding and operational control of hydrolysis at the industrial level. The optimization problem solution shows that a maximum dextrose equivalent of 98.13% can be reached if the hydrolysis is performed under optimal operating conditions, which were also confirmed experimentally. The results show that to achieve the highest yield, liquefaction should be carried out at a temperature of 92oC, pH of 6.3, α-amylase dose of 1.5 mg enzyme/g starch and hydrolysis time of 1 hour; while saccharification should be conducted at a temperature of 57oC, pH of 4.9, glucoamylase dose of 1.15 mg enzyme/g starch and hydrolysis time of 34 hours. The reversion phenomenon is detected when the hydrolysis time exceeds 35 hours, with a negative incidence on the dextrose equivalent.

Referencias

[1] Hobbs, L., Sweeteners from starch: production, properties and uses, in: BeMiller, J., and Whistler, R., Starch: chemistry and technology, 3rd ed., 2009, pp. 797-832. DOI: https://doi.org/10.1016/B978-0-12-746275-2.00021-5

[2] BeMiller, J.N., Starches: Conversions, modifications, and uses, in: BeMiller, J.N. Carbohydrate chemistry for food scientists, 3rd ed., AACC International Press, [online]. 2019, pp. 191-221. Available at: http://www.sciencedirect.com/science/article/pii/B9780128120699000078. DOI: https://doi.org/10.1016/B978-0-12-812069-9.00007-8

[3] Helstad, S., Corn Sweeteners, in: Serna, S., Corn, 3rd ed., Oxford, AACC International Press, [online]. 2019, pp. 551-591. Available at: https://www.sciencedirect.com/science/article/pii/B9780128119716000206. DOI: https://doi.org/10.1016/B978-0-12-811971-6.00020-6

[4] Fernandes, P., and Carvalho, F., Enzymes in food processing, Cap 8, in: Dhillon, G., and Kaur, S., Agro-industrial wastes as feedstock for enzyme production, 1st ed., San Diego, Academic Press, [online]. 2016, pp. 173-199. Available at: http://www.sciencedirect.com/science/article/pii/B9780128023921000083. DOI: https://doi.org/10.1016/B978-0-12-802392-1.00008-3

[5] Serj, H.O., Enzymes in starch modification, in: Whitehurt, R. and Law, B., Enzymes in Food Technology, UK, Sheffield Academic Press, 2002, pp. 200-228.

[6] Acosta, J.C., et al. Enzymatic hydrolysis of wheat starch for glucose syrup production, DYNA, 87(214), pp. 173-182, 2020. DOI: https://doi.org/10.15446/dyna.v87n214.82669

[7] Läufer, A., Starch biorefinery enzymes, in: Wagemann, K., and Tippkötter, N., Biorefineries, Cham, Springer International Publishing, 2017, pp. 137-152. DOI: https://doi.org/10.1007/10_2016_60.

[8] Salcedo, J., et al. Enzymatic modification of cassava starch (Corpoica M-Tai) around the pasting temperature DYNA, 85(204), pp. 223-230, 2018. DOI: https://doi.org/10.15446/dyna.v85n204.66620

[9] Friedl, A., Bioethanol from sugar and starch, in: Kaltschmitt, M., Energy from Organic Materials (Biomass): a volume in the encyclopedia of sustainability science and technology, 2nd Ed., Springer, New York, USA, 2019, pp. 905-924. Doi: https://doi.org/10.1007/978-1-4939-7813-7_432

[10] Fatourehchi, F., et al. Production of glucose syrup through enzymatic hydrolysis of flint and floury corn flour mixtures and evaluating its properties as cost-effective syrup, Journal of Food Science Technology, 19(129), pp. 23-39, 2022. DOI: https://doi.org/10.22034/FSCT.19.129.23

[11] Acosta, J.C., et al. Enzymatic hydrolysis of wheat starch for glucose syrup production DYNA, 87(214), pp. 173-182, 2020. DOI: http://doi.org/10.15446/dyna.v87n214.82669.

[12] Morales, A., et al. Optimization of the enzymatic clarification process of glucose syrups derived from agro-industrial residues, DYNA, 91(233), pp. 9-16, 2024. DOI: https://doi.org/10.15446/dyna.v91n233.112080.

[13] Lambora, A., et al., Genetic Algorithm. A literature review, in: Proceedings of 2019 International Conference on Machine Learning, Big Data, Cloud and Parallel Computing (COMITCon), 2019, pp. 380-384. DOI: https://doi.org/10.1109/COMITCon.2019.8862255

[14] Miller, G.L., Use of dinitrosalicylic acid reagent for determination of reducing sugar, Analytical Chemistry, 31, pp. 426-428, 1959. DOI: https://doi.org/10.1021/ac60147a030

[15] Lowry, O.H., et al. Protein measurement with the Folin-phenol reagent, Journal of Biological Chemistry, 193, pp. 265-275, 1951. DOI: https://doi.org/10.1016/S0021-9258(19)52451-6

[16] Akhtar, A., et al. Biochemical and morphological risk assessment of transgenic wheat with enhanced iron and zinc bioaccessibility, Journal of Cereal Science, 91, pp. 102881, 2020. DOI: https://doi.org/10.1016/j.jcs.2019.102881.

[17] Nakov, G., et al. The effect of einkorn (Triticum monococcum L.) whole meal flour addition on physico-chemical characteristics, biological active compounds and in vitro starch digestion of cookies, Journal of Cereal Science, 83, pp. 116-122, 2018. DOI: https://doi.org/10.1016/j.jcs.2018.08.004.

[18] Montgomery, D.C. Design and analysis of experiments. Wiley, New York, USA, 2017.

[19] CRA. Analytical Methods of the Member Companies of the Corn Refiners Association, [online]. 2024. Available at: https://corn.org/analytical-methods.

[20] Miafo, A.-P.T., et al. Free sugars and non-starch polysaccharides–phenolic acid complexes from bran, spent grain and sorghum seeds, Journal of Cereal Science, 87, pp. 124-131, 2019. DOI: https://doi.org/10.1016/j.jcs.2019.02.002.

[21] Oliveira, N.A.d., et al. Green coffee extracts rich in diterpenes – Process optimization of pressurized liquid extraction using ethanol as solvent, Journal of Food Engineering, 224, pp. 148-155, 2018. DOI: https://doi.org/10.1016/j.jfoodeng.2017.12.021.

[22] Montgomery, D., et al. Introduction to linear regression analysis. Wiley, New York, USA, 2021.

[23] Serrano, J., et al. Influence of imbibition temperature on the extraction stage of the cane sugar production, Journal of Food Engineering, 345, pp. 111414, 2023. DOI: https://doi.org/10.1016/j.jfoodeng.2023.111414.

[24] Peláez, H., et al. Simultaneous saccharification and fermentation of cassava stems, DYNA, 80(180), pp. 97-104, 2013.

[25] Olsen, H., Enzymes in starch modification, in: Whitehurt, R. and Law, B., Enzymes in Food Technology, Sheffield Academic Press, UK, 2002, pp. 200-228.

[26] Balakrishnan, D., Kumar, S.S., and Sugathan, S., Amylases for food applications—Updated information. in: Parameswaran, B., Varjani, S., and Raveendran, S. Eds., Green Bio-processes. Energy, Environment, and Sustainability. Springer, Singapore, 2019. DOI: https://www.doi.org/10.1007/978-981-13-3263-0_11.

[27] Wong, D., Enzymes, mechanism and theory in food chemistry, 2nd Ed., Springer International Publishing, Singapore, 2018. DOI: https://www.doi.org/10.1007/978-3-319-50766-8_5

[28] Fallahi, P., et al., Depolymerizating enzymes in human food: bakery, dairy products, and drinks, in: Nunes, C.S., and Kumar, V., Enzymes in human and animal nutrition, Academic Press, [online]. 2018, pp 211-237. Available at: http://www.sciencedirect.com/science/article/pii/B9780128054192000101. DOI: https://doi.org/10.1016/B978-0-12-805419-2.00010-1

[29] Zhu, D., et al., 3.01 - Industrial Enzymes, in: Moo, M., Comprehensive Biotechnology, 3rd edition, Oxford, Pergamon, 2019, pp 1-13. DOI: https://doi.org/10.1016/B978-0-444-64046-8.00148-8

[30] Purich, D., and Allison, D., The enzyme reference: a comprehensive guidebook to enzyme nomenclature, reactions, and methods. Academic Press, 2002. DOI: https://doi.org/10.1016/B978-012568041-7/50002-2

[31] Chen, P.-Y., et al. Developing an integrated model relating substrate water content to indoor temperature reduction for irrigation-decision support of a green roof, Heliyon, 10(15), art. 33983, 2024. DOI: https://doi.org/10.1016/j.heliyon.2024.e33983.

[32] Alventosa, A., et al. How does firms’ cost structure affect their quality–price mix? An experimental analysis, Journal of Behavioral and Experimental Economics, 107, art. 102109, 2023. DOI: https://doi.org/10.1016/j.socec.2023.102109.

[33] Pulido Teuta, J., et al. A high-performance liquid chromatography method validation and a Box–Behnken experimental design for the extraction optimization of quercitrin from Nectandra reticulata, RSC Advances, 14(30), pp. 21874-21886, 2024. DOI: https://doi.org/10.1039/d4ra01723d.

[34] Hua, X., and Yang, R., Enzymes in starch processing, in: Chandrasekaran, M., Enzymes in food and beverage processing, CRC Press, New York, USA, 2016, pp 138-169.

[35] Lee, C.Y. and deMan, J.M., Enzymes, in: deMan, J.M., Finley, J.W., et al, Principles of food chemistry, Cham, Springer International Publishing, 2018, pp 397-433. DOI: https://doi.org/10.1007/978-3-319-63607-8_10

[36] Van der Maarel, M., Starch-processing enzymes in: Whitehurst, R. and van Oort, R., Enzymes in food technology 2, John Wiley & Sons, New York, USA, 2010, pp 320-331. DOI: https://doi.org/10.1002/9781444309935.ch14

[37] Carvalho, F., and Fernandes, P., Enzymes in sweeteners production, in: Parameswaran, B., Varjani, S., et al, Green Bio-processes: enzymes in industrial food processing, Springer, Singapore, 2019, pp 151-179. DOI: https://doi.org/10.1007/978-981-13-3263-0_9.

[38] Raghul, S., and Bhat, S., Enzymes: basics and development of novel biocatalysts, in: Chandrasekaran, M., Enzymes in food and beverage processing, 1, CRC Press, New York, USA, 2016, pp 3-38. DOI: https://doi.org/10.1201/b19408-2

[39] Rathna, R. et al, Intriguing disposition of marine algae-derived enzymes, in: Parameswaran, B. et al., Green Bio-processes: energy, environment, and sustainability, Springer, Singapore, 2019. DOI: https://doi.org/10.1007/978-981-13-3263-0_16.

[40] Elmarzugi, N. et al., Amylase economic and application value. World Journal of Pharmacutical Research, 3(3), pp. 4890-4906, 2014.

[41] Sunarti, T.C., Derosya, V., and Yuliasih, I., Acid modification of sago hampas for industrial purposes, in: Ehara, Y. Toyoda, and Johnson, V., Multiple contributions to food security and sustainable livelihoods, Springer, Singapore, 2018, pp. 271-281. DOI: https://doi.org/10.1007/978-981-10-5269-9_20

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. So-Won Jang, Hwan Hee Yu, Jong-Chan Kim, Mi Jang. (2026). Optimizing brown rice liquefaction and saccharification using response surface methodology for grain ethanol production. Scientific Reports, https://doi.org/10.1038/s41598-026-40430-9.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2025 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.