Publicado

Comportamiento de una mezcla asfáltica con incorporación de plástico para pavimentos aeroportuarios

Behavior of an asphalt mixture with the incorporation of plastic for airport pavements

DOI:

https://doi.org/10.15446/dyna.v92n235.117161Palabras clave:

mezcla asfáltica densa en caliente, pavimentos, aeropuertos, asfalto modificado, PET (es)hot-mixture asphalt, pavements, airports, modified asphalt, PET (en)

Descargas

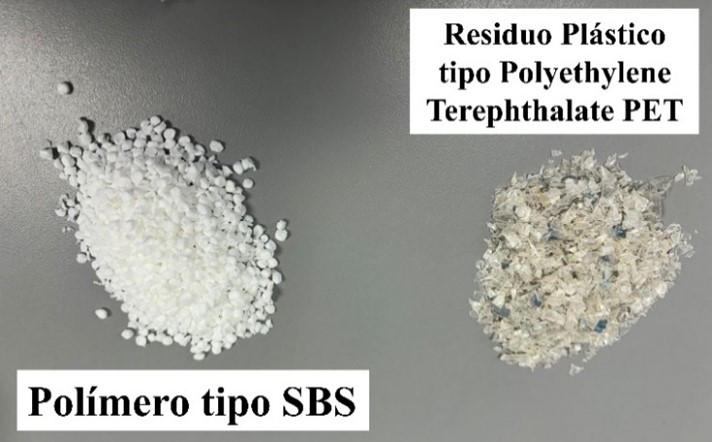

Este trabajo analizó el comportamiento físico mecánico y la durabilidad de dos mezclas asfálticas tipo P-401 fabricadas con asfalto modificado con residuos de plástico y con polímero. Para tal fin se realizó el diseño de mezclas mediante el ensayo Marshall a fin de determinar el contenido óptimo de asfalto. Fueron realizados ensayos para evaluar el comportamiento mecánico mediante ensayos de carga monotónica (resistencia a la tracción indirecta), repetida (módulo resiliente, resistencia a la fatiga) y estática (fluencia estática). Análisis estadístico ANOVA se emplearon para determinar variaciones significativas entre los resultados de las dos mezclas. Los resultados indican que la incorporación de residuos plásticos es viable técnicamente y proporciona similar desempeño mecánico y durabilidad en la mezcla asfáltica P-401 en comparación al asfalto modificado con polímero. Adicionalmente, proporciona una forma final de disposición ambientalmente segura de residuos sólidos.

This paper analyzed the physical-mechanical behavior and durability of two P-401 asphalt mixtures manufactured with asphalt modified with plastic waste and polymer. For this purpose, the mixture design was carried out using the Marshall test to determine the optimal asphalt content. Tests were carried out to evaluate the mechanical behavior using monotonic load tests (indirect tensile strength), repeated (resilient modulus, fatigue resistance) and static (static creep). ANOVA statistical analysis was used to determine significant variations between the results of the two mixtures. The results indicate that the incorporation of plastic waste is technically feasible and provides similar mechanical performance and durability in the P-401 asphalt mixture compared to polymer-modified asphalt. Additionally, it provides a final form of environmentally safe disposal of solid waste.

Referencias

[1] Ministerio de Transporte de Colombia. Anuario Nacional de Transporte. Bogotá, 2021.

[2] Ministerio de Transporte de Colombia. Anuario Nacional de Transporte. Bogotá, 2022.

[3] Correia, D., and Ferreira, A., Energy harvesting on airport pavements: state-of-the-art, Sustainability, 13(5893), pp. 1-20, 2021. DOI: https://doi.org/10.3390/su13115893

[4] White, G., State of the art: asphalt for airport pavement surfacing, International Journal of Pavement Research and Technology, 11(1), pp. 77-99, 2018. DOI: https://doi.org/10.1016/j.ijprt.2017.07.008

[5] White, G., State of the art: interface shear resistance of asphalt surface layers, International Journal of Pavement Engineering, 18(10), pp. 887–901, 2017. DOI: https://doi.org/10.1080/10298436.2015.1126270

[6] Loizos A., and Charonitis, G., Bearing capacity and structural classification of flexible airport pavements, Journal of Transportation Engineering, 130(1), pp. 34–42, 2004. DOI: https://doi.org/10.1061/ASCE0733-947X2004130:134

[7] Loprencipe, G., and Zoccali, P., Comparison of methods for evaluating airport pavement roughness, International Journal of Pavement Engineering, 20(7), pp. 782–791, 2019. DOI: https://doi.org/10.1080/10298436.2017.1345554

[8] Miah, M.T., Oh, E., Chai, G., and Bell, P., An overview of the airport pavement management systems (APMS), International Journal of Pavement Research and Technology, 13(6) pp. 581–590, 2020. DOI: https://doi.org/10.1007/s42947-020-6011-8

[9] Federal Aviation Administration FAA, AC 150/5370-10H, Standard Specifications for Construction of Airports. Washington, DC, 2018.

[10] Bastidas-Martínez J.G., and Rondón-Quintana H.A., Caracterización de mezclas de concreto asfáltico. Editorial Universidad Piloto de Colombia, Bogotá, Colombia, 2020. DOI: https://doi.org/10.2307/j.ctv2cw0t4h

[11] Sulyman, M., Haponiuk, J., and Formela, K., Utilization of Recycled Polyethylene Terephthalate (PET) in engineering materials: a review, International Journal of Environmental Science and Development, 7(2), pp. 100–108, 2016. DOI: https://doi.org/10.7763/IJESD.2016.V7.749

[12] Almahdi, B.A., Ahmeda, A.G., Adwan, I., and Ladin, M.A. Feasibility of utilizing waste polyethylene terephthalate as replacement in asphalt binder mixture, KBES, 2(1), pp. 1–11, 2021. DOI: https://doi.org/10.1016/j.conbuildmat.2021.123377

[13] You, L., Long, Z., You, Z., Ge, D., Yang, X., Xu, F., Hashemi, M., and Diad, A., Review of recycling waste plastics in asphalt paving materials, Journal of traffic and Transportation Engineering (English Edition), 9(5), pp. 742-764, 2022. DOI: https://doi.org/10.1016/j.jtte.2022.07.002

[14] Rincón-Estepa, J.A., González-Salcedo, E.V., Rondón-Quintana, H.A., Reyes-Lizcano, F.A., and Bastidas-Martínez, J.G., Mechanical behavior of low-density polyethylene waste modified hot mix asphalt, Sustainability, 14(7), pp. 1-19, 2022. DOI: https://doi.org/10.3390/su14074229

[15] Moghaddam, T., Karim, M., and Syammaun, T., Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles, Construction and Building Materials, 34(1), pp. 236–242, 2012. DOI: https://doi.org/10.1016/j.conbuildmat.2012.02.054

[16] Moghaddam, T., Soltani, M., and Karim, M., Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test, Materials & Design, 53(1), pp. 317–324, 2014. DOI: https://doi.org/10.1016/j.matdes.2013.07.015

[17] Esfandabad, A.S., Motevalizadeh, S.M., Sedghi, R., Ayar, P., and Asgharzadeh, S.M., Fracture and mechanical properties of asphalt mixtures containing granular polyethylene terephthalate (PET), Construction and Building Materials, 259(120410), pp. 1–10, 2020. DOI: https://doi.org/10.1016/j.conbuildmat.2020.120410

[18] Ziari, H., Kaliji, A.G., and Babagoli, R., Laboratory evaluation of the effect of waste plastic bottle (PET) on rutting performance of hot mix asphalt mixtures, Petroleum Science and Technology, 34(9), pp. 819–823, 2016. DOI: https://doi.org/10.1080/10916466.2016.1169290

[19] Dehghan, Z., and Modarres, A., Evaluating the fatigue properties of hot mix asphalt reinforced by recycled PET fibers using 4-point bending test, Construction and Building Materials, 139, pp. 384–393, 2017. DOI: https://doi.org/10.1016/j.conbuildmat.2017.02.082

[20] Jegatheesan, N., Rengarasu, T.M., and Bandara, W., Mechanical properties of modified hot mix asphalt containing polyethylene terephthalate fibers as binder additive and carbonized wood particles as fine aggregate replacement, Asian Transport Studies, 6(100029), pp. 1-11, 2020. DOI: https://doi.org/10.1016/j.eastsj.2020.100029

[21] Azarhoosh, A., Koohmishi, M., and Hamedi, G.H., Rutting resistance of hot mix asphalt containing coarse recycled concrete aggregates coated with waste plastic bottles, Advances in Civil Engineering, 2021(1), pp. 1-11, 2021. DOI: https://doi.org/10.1155/2021/9558241

[22] Ghabchi, R., Dharmarathna, C.P., and Mihandoust, M., Feasibility of using micronized recycled Polyethylene Terephthalate (PET) as an asphalt binder additive: a laboratory study, Construction and Building Materials, 292(123377), 2021. DOI: https://doi.org/10.1016/j.conbuildmat.2021.123377

[23] Ahmadinia, E., Zargar, M., Karim, M., Abdelaziz, M., and Ahmadinia, E., Performance evaluation of utilization of waste Polyethylene Terephthalate (PET) in stone mastic asphalt, Construction and Building Materials, 36, pp. 984–989, 2012. DOI: https://doi.org/10.1016/j.conbuildmat.2012.06.015

[24] Gürü, M., Çubuk, M., Arslan, D., Farzanian, S.A., and Bilici, I., An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material, Journal of Hazardous Materials, 279, pp. 302–310, 2014. DOI: https://doi.org/10.1016/j.jhazmat.2014.07.018

[25] Ameri M., and Nasr, D., Performance properties of devulcanized waste PET modified asphalt mixtures, Petroleum Science and Technology, 35(1), pp. 99–104, 2017. DOI: https://doi.org/10.1080/10916466.2016.1251457

[26] INVIAS, Instituto Nacional de Vías - INVIAS. Especificaciones Generales para Construcción de Carreteras. Bogotá D.C., Colombia, 2022.

[27] NCHRP National Cooperative Highway Research Program, Simple Performance Test for Superpave Mix Design, National Academy Press, 2002.

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2025 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.