Rheological characterization of asphalt binders used in strain relief asphalt mixtures (SRAM)1

Caracterización reológica de ligantes asfalticos empleados en capas asfálticas de alivio de deformaciones

DOI:

https://doi.org/10.15446/dyna.v84n200.56966Palabras clave:

asphalt mixture interlayer, polymer-modified asphalt, rheology, MSCR (en)capa asfáltica intermedia, asfalto modificado con polímeros, reología, MSCR (es)

Descargas

interesting solution to prevent reflective cracking. Recent advances in polymer technology have led to binders that can be used to produce

interlayer mixtures with good mechanical properties. In this study, two polymer-modified asphalt binders were evaluated, both from the

production of strain relief asphalt mixtures used as interlayers in the field. The binder characterization was presented in two groups: (i) the

empirical tests required in the Brazilian specification, and (ii) the rheological properties (frequency/temperature sweep and MSCR tests).

Results showed that the difference in rheological properties of the asphalt binder used for strain relief asphalt mixtures did not follow the

same difference obtained according to the empirical tests of the Brazilian specification. The G*/sinδ and MSCR parameters (Jnr and

percentage of recovery) were able to differentiate the asphalt binders, but the MSCR parameters were more sensitive.

Recibido: 12 de abril de 2016; Revisión recibida: 18 de octubre de 2016; Aceptado: 15 de diciembre de 2016

Abstract

The use of ´interlayers´ that tolerate high tensile and shear strain that exists above cracks in deteriorated pavements is becoming an interesting solution to prevent reflective cracking. Recent advances in polymer technology have led to binders that can be used to produce interlayer mixtures with good mechanical properties. In this study, two polymer-modified asphalt binders were evaluated, both from the production of strain relief asphalt mixtures used as interlayers in the field. The binder characterization was presented in two groups: (i) the empirical tests required in the Brazilian specification, and (ii) the rheological properties (frequency/temperature sweep and MSCR tests). Results showed that the difference in rheological properties of the asphalt binder used for strain relief asphalt mixtures did not follow the same difference obtained according to the empirical tests of the Brazilian specification. The G*/sinδ and MSCR parameters (Jnr and percentage of recovery) were able to differentiate the asphalt binders, but the MSCR parameters were more sensitive.

Keywords :

asphalt mixture interlayer, polymer-modified asphalt, rheology, MSCR.Resumen

El uso de capas intermedias que toleren los altos esfuerzos de tensión y cortantes que existen alrededor de las grietas de pavimentos deteriorados se ha constituido en una solución interesante para prevenir la reflexión de grietas. Avances recientes en la tecnología de polímeros han generado ligantes que pueden ser usados para producir mezclas para capas intermedias con buenas propiedades mecánicas. En este estudio, dos asfaltos modificados con polímeros fueron evaluados, ambos empleados en la producción de mezclas asfálticas de alivio de deformaciones usadas como capas intermedias en campo. La caracterización de los ligantes se presentó en dos grupos: (i) los ensayos empíricos requeridos por la especificación brasilera, y (ii) las propiedades reológicas (barrido de frecuencia/temperatura y ensayos MSCR). Los resultados mostraron que el ligante asfáltico usado para las mezclas asfálticas de alivio de deformaciones presentó propiedades reológicas considerablemente diferentes, a pesar de que su caracterización a través de ensayos empíricos es similar. Los parámetros G*/sinδ y MSCR (Jnr y porcentaje de recuperación) lograron diferenciar los ligantes asfálticos, aunque los parámetros del MSCR mostraron mayor sensibilidad.

Palabras clave :

capa asfáltica intermedia, asfalto modificado con polímeros, reología, MSCR.1. Introduction

Reflective cracks are a major concern to highway management personnel, because they can significantly reduce the service life of hot mix asphalt (HMA) overlays of flexible and rigid pavements. The basic mechanism for reflective cracking is stress/strain concentration in the overlay caused by the movement in the existing pavement at the vicinity of joints or cracks, which can happen through bending, shearing, or thermal stress. As mentioned by Hu et al. [1], five key performance factors must be considered when designing an asphalt overlay: (a) traffic loading level, (b) climate, (c) asphalt overlay thickness, (d) overlay mix type, and (e) load transfer efficiency at joints or cracks. The crack propagation mechanism depends on the nature of the induced displacement, and it may consist of the following modes, as stated by Goulias and Ishai[2]:

-

Normal horizontal tension, generally caused by displacement due to thermal effect;

-

Normal vertical shear due, mainly, to traffic loads or base and sub-grade displacements; and

-

Parallel horizontal shear induced by lateral displacement due to transverse instability.

In Brazil, the thermal stresses are not the main concern related to reflective cracking, but the load stresses. The moving wheel load creates bending stresses at the bottom of the asphalt layer and, at almost the same time, it induces shear stresses perpendicular to the bottom face of the asphalt layer when the load is simultaneously moving across the crack.

As mentioned by Von Quintus et al. [3], there is no material or treatment method that will prevent reflective cracks from occurring under all conditions, with the exception of the Full Depth Recycling (FDR) technique for flexible pavements and rubblization for rigid pavements. However, these alternatives will not always be a cost-effective rehabilitation strategy. Numerous materials and methods have been applied to solve the reflective cracking mechanism with varying degrees of success. Some of the techniques available to mitigate, or even retard, this problem are: increased overlay thickness; modification of asphalt and mixture properties; cold in-place recycling; mill and overlay; reinforcing interlayer; stress absorbing membrane interlayer; treatment at cracks/joints in the existing pavements; and stress relief asphalt mixtures (SRAM). The last one is the focus of the present study.

In this paper, two asphalt binders, previously applied in the field as part of the strain relief asphalt mixtures used as the rehabilitation strategy, were selected for rheological evaluation. The Brazilian standard specification for polymer-modified asphalt binders does not include its rheological properties, which makes it more challenging to select the appropriate material, depending on its application location (climate and traffic), and structural conditions. The main objective of this paper is to compare the characteristics of these two polymer-modified asphalt binders according to the Brazilian standard specification and to some of the Superpave tests and differentiate them in terms of their ability to recover from applied loads at elevated temperatures.

2. Asphalt mixtures used as interlayers to combat reflective cracking

Sand mix, sand anti-fracture (SAF), reflective crack relief interlayer (RCRI), stress absorbing membrane interlayer (SAMI), and Strata are typical examples of strain tolerant interlayer systems. These interlayers are usually used as either a substitute layer for a leveling binder course, or a supplementary layer that is not considered in the HMA overlay design [4]. The strain relief asphalt mixture interlayers are thin layers (normally 2.5cm) composed of fine aggregates and rich polymer-modified asphalt binders, although the use of asphalt rubber was also investigated with the same purpose [5.6]. Bennert and Maher [7] mentioned some interesting points to be observed when dealing with asphalt interlayer systems:

-

How effective are asphalt interlayer systems over commonly used HMA mixtures in overlaying flexible, concrete or composite pavements?

-

Can these mixtures be evaluated in the laboratory in a way that such evaluation represents realistic field conditions? And

-

To what magnitude do construction variables affect the performance of the asphalt interlayer pavement system?

The previous field application of strain relief asphalt mixtures as interlayers to control reflective cracking vary from somewhat successful to inefficient, depending on different factors involved in field applications. The role of this type of interlayer in a road structure is to provide a flexible layer able to deform without breaking in order to allow the large movements taking place in the vicinity of the crack. The application performance depends on material characteristics, construction efficiency, supporting conditions of the existing pavement, and the overlay design [4].

The best performance of asphalt mixtures used as an interlayer (prepared with rich polymer-modified binders), when compared to conventional HMA, was already confirmed by field experience [7]. And the asphalt binder played a major role in this matter. Recent advances in polymer technology have led to binders that can be used to produce mixture interlayers with good fracture properties, and even waste recycled plastic was already investigated as part of the asphalt mix composition [8]. Shimazaki et al. [9] developed high-performance asphalt to be used in the asphalt mixtures overlay. The authors verified the effectiveness of the Stone Matrix Asphalt (SMA) with the developed high-performance asphalt for prevention of reflective cracking by means of laboratory and field testing.

Asphalt binder is a viscoelastic material and those with a high temperature susceptibility are likely to deform when facing summer temperatures and become brittle at winter temperatures. In developing high performance asphalt binders, its aim is to create a material which maintains flexibility and stress relaxation characteristics even in low-temperature regions, where cracks are likely to occur, and also maintain its hardness and resistance to deformation in high-temperature regions. To decrease the temperature susceptibility of high performance asphalts, the polymer amount is generally increased as much as possible. However, there is a concern that polymer concentrations may considerably decrease its flexibility and workability, because of its high viscosity. In addition, the increase in the amount of many types of polymer causes a phase change from the asphalt to the polymer phases, so the compatibility between polymer and asphalt becomes an issue.

Polymer-modified binders (PMB) started being used extensively about 30 years ago with the quest for improving the mechanical performance of flexible pavements, particularly on the wearing course, and for enhancing the resistance to the main distresses [10]. This development came in response to traffic increases and to reduce maintenance periods and costs. Polymer-modified asphalt binders have been used in strain relief asphalt mixtures in order to improve its resistance to reflective crack propagation, where vertical stresses and shear strain levels are severe. Instead of the conventional use of 2-3% SBS in polymer-modified binders, resourcing to higher SBS contents in the range of 6-7% allows for a phase inversion in the PMB microstructure: the swollen polymer becomes the continuous phase in which asphaltenes are dispersed [10].

Not much attention has been given to asphalt binder properties, especially designed for strain relief asphalt mixtures used as interlayers to mitigate reflective cracking. There is still a lack of information about the physical, chemical and rheological characteristics of the asphalt binder that should provide elasticity to withstand and partially absorb the tension, shear, and bending stresses exerted on the pavement. Conventional specifications in Brazil for asphalt mixtures, even the ones used as interlayers, normally include empirical asphalt binder requirements and a volumetric mix design. These would not consistently lead to mixtures capable of withstanding the crack/joint movement [11]. Also, there is still much work to be done to evaluate whether these asphalt mixtures will significantly retard or eliminate reflective cracking in a cost-effective manner [12].

Regarding the asphalt binder content, a minimum of 7.0% is generally requested for the reflective crack resistant asphalt mixture [7,11,13]. However, the recommendation of at least a 7.0% asphalt binder and air voids between 0.5 and 2.5% observed in the literature seems to be highly influenced by the laboratory compaction method [14].

3. Case studies - Evaluation of asphalt binders

The key in selecting a rehabilitation strategy is to make a comprehensive evaluation of the existing pavements. This includes understanding the materials used, the traffic history, and the construction techniques applied. The polymer-modified asphalt binders investigated in this paper were collected from two job sites in the State of São Paulo, where the rehabilitation strategy used, on both sites, was: 50mm milling, then reconstruction with 20mm strain relief asphalt mixture + 50mm HMA, as presented in Fig. 1. The remaining infrastructure consisted of 7mm HMA, a granular base and a sub-base. Previous investigation of the test site conditions indicated the presence of fatigue cracking (bottom-up) on the asphalt surface layer without compromising the underlying layers (base and sub-base). The rehabilitation strategy indicated was selected based on various factors, such as: (i) correcting the main functional defects detected (mainly surface cracking); (ii) efficient construction process, minimizing lane closure time; (iii) mitigation of the reflective cracking phenomenon (after milling, there were still cracks in the remaining HMA); and (iv) the need for a fast and approximately 2-year lasting solution, before the reconstruction plan of the highway pavements. The polymer-modified asphalt binders, selected from the field applications of strain relief asphalt mixtures mentioned above (as presented in Fig. 1), were further investigated.

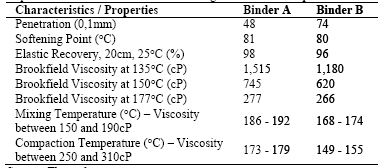

In preparing the SRAMs, different asphalt binders and aggregate sources were used, mainly because of the different geographic location of the job sites in the State of São Paulo. Table 1 presents both asphalt binder characteristics, according to the requirements of the Brazilian standard specification for polymer-modified asphalt binders. The commercial names of the polymer asphalt binders were suppressed and on the paper they were named only Binder A, and Binder B. The elastic recovery measurement has been used as one of the main tests to characterize, and also classify, the polymer-modified binders in Brazil.

Figure 1: Rehabilitationstrategy used in two highways in Brazil.

Source: The authors.Table 1: Asphalt binders characterization according to the Brazilian specification.

Clopotel and Bahia[15] did an interesting study on the elastic recovery test for modified asphalt binders. The authors mentioned that, although the elastic recovery test is widely used, there is significant debate about the real value of this test and why it is being used. Some experts claim that the best benefit of this test is to assure that polymers are used; others claim that elasticity is an indication of durability and general quality. As mentioned by the authors, there is no doubt that this test is a good indicator of the use of elastomeric polymers, but it is not a good indicator of other types of polymers, and it is difficult to find direct evidence that the elastic behavior is related to asphalt binder durability or general quality.

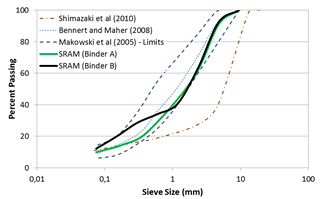

Often, the finely-graded mixtures with modified asphalt binders are not specifically designed or checked for their resistance to reflective cracking [16-18]. Regarding the gradation of the strain relief asphalt mixture, Fig. 2 illustrates the ones used with Binder A and Binder B, and one can see that both are in accordance with the limits proposed by Makowski et al. [19]. Fig. 2 also presents the aggregate gradations used in other studies related to this type of asphalt mixture. The designed asphalt binder content of both SRAMs was 7.0%, despite the difference in gradation and asphalt binder characteristics. More information on the mixture design can be found elsewhere [20,21].

Figure 2: Strain Relief Asphalt Mixture - Aggregate gradations

4. Testing methods

4.1. Rheological characterization

Dynamic shear modulus (|G*|) and phase angle (δ) are two key rheological parameters which characterize Performance Grade (PG) asphalt binders introduced in the Superpave binder specifications. The rheological tests in the present study were carried out using the Dynamic Shear Rheometer (DSR) with parallel plate geometry of 25mm diameter and 1mm gap. Frequency sweeps at 0.1 up to 100Hz were performed at strain controlled mode and at temperatures between 52°C and 88°C (6°C steps), to measure the asphalt binders |G*| and δ in accordance with ASTM D7175-15 specification. Both parameters define the resistance to shear deformation of the asphalt binder in the linear viscoelastic region. The parameters |G*|/sinδ and |G*|.sinδ were determined for 10rad/s and the above mentioned temperatures before and after the RTFOT aging.

4.2. Multiple Stress Creep and Recovery (MSCR)

The MSCR test has been used by some state and federal agencies and researchers to evaluate the binders potential for permanent deformation resistance and to characterize high temperature properties of polymer-modified binders. According to this standard (ASTM D7405-15), the binder sample is loaded at a constant creep stress for 1 second followed by a zero stress recovery period of 9 seconds. Twenty cycles of creep and recovery are run at 100Pa creep stress followed by ten cycles at 3,200Pa creep stress. The non-recoverable compliance (Jnr) and percent recovery after ten cycles at 100Pa and 3,200Pa were reported. A 1mm gap was used in 25.0mm parallel plate geometry to perform this test. Although the testing temperature is normally selected according to the binder high PG grade, three temperatures were investigated in this study (after RTFOT aging): 70°C, 76°C, and 82°C.

5. Results and discussions

The following subsections present the rheological characterization of two commercially available polymer- modified asphalt binders applied in the field, as part of strain relief asphalt mixtures used as interlayers. The asphalt binder samples were tested before and after the rolling thin-film oven test (RTFOT), which should give an insight into the effectiveness of the modification in reducing the oxidative aging of the binders. It was previously studied that cross-linked PMB has a significantly lower oxidation degree process [22].

5.1. Rheological characterization

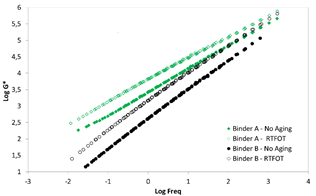

The rheological characteristics were investigated for the two polymer-modified asphalt binders applied in the field as part of the strain relief asphalt mixtures, named Binder A and Binder B (Fig. 3). From the mentioned Figure, one can observe that Binder A presented a higher dynamic shear modulus than Binder B. The increase in dynamic shear modulus after RTFOT was measured for both binders, and based on the average ratio (|G*|RTFOT/|G*|no aging) for the different temperatures and frequencies, Binder A was less susceptible to short-term aging (average ratio of 1.08) than Binder B (average ratio of 1.25).

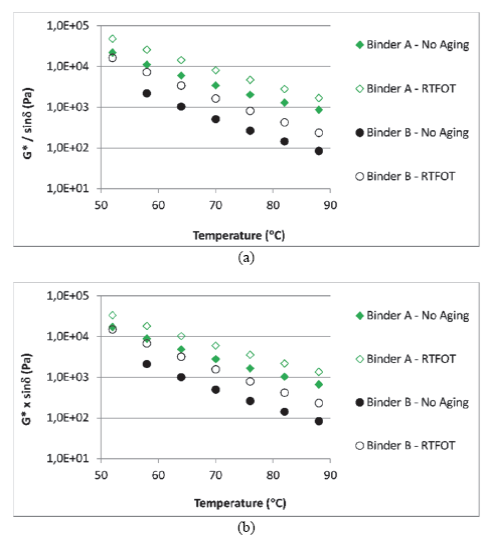

In SHRP studies, mainly carried out on unmodified binders, |G*|/sinδ was initially suggested to indicate the resistance of binders to rutting at different temperatures, and |G*|×sinδ was suggested for fatigue cracking [23]. These parameters were derived by addressing each type of failure, understanding the failure mechanisms, the contribution of the binder to failure resistance, and selecting the required measurement that would best reflect those contributions of the binder [24]. Both Superpave parameters were also determined, and results are presented in Fig. 4.

The Superpave specification first attempt to address fatigue cracking of asphalt binders was based on an experimental test site built in the 1950s in the State of California (USA). The Zaca-Wigmore road test assisted the development of asphalt binder parameters to be considered in highway design projects and its durability. The parameter |G*|×sinδ of different asphalt binders from the constructed sections was compared to the percentage of fatigue cracking, and it was decided to limit the value of G*×sinδ to 3,000kPa at an intermediate temperature of 25.5°C and frequency of 10rad/s [25](Gibson et al., 2012).

Figure 3: Mastercurves (T=58°C) of Binder A and Binder B under no aging and RTFOT conditions.

Figure 4: Traditional SHRP parameters: (a) G*/sinδ, and (b) G* x sinδ

After some years, another study [26] (Bahia et al., 2001) concluded that the Superpave parameter did not address the modified binders characteristics correctly, so laboratory fatigue tests in asphalt mixes were performed. Poor correlation was found between these results and the values of |G*|×sinδ. The ASSHTO specification of the Performance Grade of asphalt binders still maintain this parameter, although other fatigue parameters are under investigation, such as the Linear Amplitude Sweep (LAS).

Regarding the permanent deformation, later studies showed that the |G*|/sinδ parameter performed poorly in predicting the performance of modified binders [27], and thus attempts were made to develop new test methods to predict performance independent of the type of modification [26], as the Multiple Stress Creep and Recovery (MSCR) test presented below.

5.2. Multiple Stress Creep and Recovery (MSCR)

The determination of the non-recoverable creep compliance, Jnr, and the percentage of recovery (εr) are described in detail at ASTM D7405-15, and the tests results are illustrated in Fig. 5 and presented in Table 2.

Although both binders presented similar elastic recovery according to the Brazilian specification, the Jnr value at 100Pa and 3,200Pa indicate that Binder B has considerably higher compliance value for the three temperatures evaluated. A previous study has also shown that Jnr correlated well with the compliance from the mixture test results [28]. As mentioned by D´Angelo and Dongré [29], the ability of Jnr to characterize the stress dependence of polymer-modified and neat asphalt binders makes it a more discriminating specification parameter that is blind to the type of modification. According to these authors, MSCR parameters (Jnr and percentage recovery) were able to characterize the extent of dispersion of SBS in PMB, what makes the test able to discriminate between the dump-and-stir types of PMAs and those that have been optimally dispersed [29]. A previous study showed that the comparison of test results between the MSCR and elastic recovery (ER) had shown a good correlation for some binders, but not for all [30]. The larger the recoverable part of modified asphalt deformation is, the stronger its ability for resisting permanent deformation [31].

Figure 5: Multiple Stress Creep and Recovery data: (a) Binder A (under low stress), (b) Binder A (under high stress), (c) Binder B (under low stress), and (d) Binder B (under high stress).

Source: The authorsTable 2: Multiple Stress Creep and Recovery test results.

6. Summary and Conclusions

This paper presented the rheological characterization of two polymer-modified asphalt binders previously applied in the field as part of strain relief asphalt mixtures in Brazil. The authors believe that the binder ability to recover from applied loads under elevated temperatures, common in Brazil, is relevant to its performance. The major conclusions of this study are:

-

The elastic recovery test, conventionally used in Brazil to characterize polymer-modified binders, was not able to differentiate the asphalt binders investigated in this study;

-

The G*/sinδ and MSCR parameters (Jnr and percentage of recovery) discriminated both different asphalt binders, but the MSCR parameters were more sensitive;

-

The binder with lowest non-recoverable compliance and highest percent recovery (Binder A), was also less susceptible to short-term aging (RTFOT);

-

More emphasis is needed on the materials that are used as strain relief asphalt mixture interlayers, especially asphalt binders. The rheological properties of modified asphalt binders depend on formulation variables, and not necessarily, on modified binders that are suitable for being used as part of a strain relief asphalt mixture.

References

Referencias

Hu, S., Zhou, F. and Scullion, T., Reflection cracking-based asphalt overlay thickness design and analysis tool. Transportation Research Record. 2155, pp. 12-23, 2010. DOI: 10.3141/2155-02.

Goulias, D.G. and Ishai, I., Experimental system for simulating crack propagation in asphalt pavements and effectiveness of geosynthetics in crack retardation. Journal of Testing and Evaluation. ASTM. 27(2), pp. 106-113, 2010

Von Quintus, H.L., Mallela, J. and Lytton, R.L., Techniques for mitigation of reflective cracking. In: FAA Worldwide Airport Technology Transfer Conference, Atlantic City, New Jersey,2000.

Baek, J. and Al-Qadi, I.L., Sand mix interlayer to control reflective cracking in hot-mix asphalt overlay. Transportation Research Record. 2227, pp. 53-60, 2011. DOI: 10.3141/2227-06.

Greene, J., Kim, S., Datre, N. and Choubane, B., Effect of a stress absorbing membrane interlayer on instability rutting. CD-ROM. In: Transportation Research Board Meeting, Washington, D.C., 2012.

Chen, Y., Lopp, G. and Roque, R., Effects of an asphalt rubber membrane interlayer on pavement reflective cracking performance. Journal of Materials in Civil Engineering, 25(12), pp 1936-1940, 2013.

Bennert, T. and Maher, A., Field and laboratory evaluation of a reflective crack interlayer in New Jersey. Transportation Research Record, 2084, pp. 114-123, 2008. DOI: 10.3141/2084-13.

Suparma, L.B., Laboratory design and performance of stress absorbing membrane interlayer (SAMI) incorporating waste recycled plastics. Media Teknik, 2, pp. 31-38, 2005.

Shimazaki, M., Konno, M., Takahashi, M. and Kasahara, A., Development of high performance asphalt for prevention of reflective cracking. In: First International Conference on Pavement Preservation; 2010, pp. 227-245.

Simard, D. and Olard, F., Long-Life overlaysby use of highly modified bituminous mixtures. In: 7th RILEM International Conference on Cracking in Pavements, 2012.

Blankenship, P., Iker, N. and Drbohlav, J., Interlayer and design considerations to retard reflective cracking. Transportation Research Record. 1896, pp. 177-186, 2004. DOI: 10.3141/1896-18.

Kim, M., Buttlar, W.G., Baek, J. and Al-Qadi, I.L., Field and laboratory evaluation of fracture resistance of illinois hot-mix asphalt overlay mixtures. Transportation Research Record. 2127, pp. 146- 154. 2009. DOI: 10.3141/2127-17.

TxDOT. Texas Department of Transportation - SS 3165. Crack Attenuating Mixture in Special Specification, 2004.

Vasconcelos, K.L., Mantovanin, P., Bernucci, L.B., Chaves, J.M. and Marcandali, A.H., Asphalt mixture as interlayer to prevent reflective cracking - effect of compaction in mix design. In: International Symposium on Asphalt Pavement (ISAP), Fortaleza, Brazil, 2012.

Clopotel, C.S. and Bahia, H.U., Importance of elastic recovery in the DSR for binders and mastics. Engineering Journal. 16(4), pp. 99-106, 2012. DOI: 10.4186/ej.2012.16.4.

Blankenship, P., Iker, N. and Drbohlav, J., Interlayer and design considerations to retard reflective cracking. Transportation Research Record. Journal of the Transportation Research Board, 1896(1), pp. 177-186, 2004.

Cooley, L.A., James, R. S. and Buchanan, M.S., Development of Mix design criteria for 4.75mm superpave mixes. Transportation Research Record, (02–04), pp. 125-133, 2002.

Cantrell, L., Design and evaluation of 4.75 mm mixture for thin asphalt overlay in Washington state. MSc Thesis, Washington State University. Washington, USA, 2013.

Makowski, L., Bischoff, D.L., Blankenship, P., Sobczak, D. and Haulter, F., Wisconsin experiences with reflective crack relief projects. Transportation Research Record. 1905, pp. 44-55, 2005. DOI: 10.3141/1905-06.

Avelar, P.G., Estudo da aderência entre camadas asfálticas de pavimentos. MSc Thesis, Department of Transportation Engineering, University of São Paulo, São Paulo, Brasil, 2012.

Gaspar, M.S, Vasconcelos, K.L., Silva, A.H.M. and Bernucci, L.L.B., Highly modified asphalt binder for asphalt pavement rehabilitation. Accepted for presentation on the 96th Annual Meeting of the Transportation Research Board, 2017.

Dressen, S., Ponsardin, M., Planche, J-P., Pittet, M. and Dumont, AG., Durability study: Field aging of conventional and polymer modified binders. In: 89th Transportation Research Board Meeting; 2010; Washington, D.C.

Anderson, D.A. and Kennedy, T.W., Development of SHRP binder specification. Journal of the Association of Asphalt Paving Technologists, 62, pp. 481-507, 1993.

Anderson, D.A., Christensen, D.W. and Bahia, H., Physical properties of asphalt cement and the development of performance-related specifications. Journal of the Association of Asphalt Paving Technologists, 60, pp. 437-475, 1991.

Gibson, N., Qi, X., Shenoy, A., Al-Khateeb, G., Kutay, M.E., Andriescu, A., Stuart, K., Youtcheff, J. and Harman, T., Performance testing for superpave and structural validation. Federal Highway Administration, Report FHWA-HRT-11-045, November 2012.

Bahia, H.U., Hanson, D.I., Zeng, M., Zhai, H., Khatri, M.A. and Anderson, R.M., Characterization of modified asphalt binders in superpave mix design. NCHRP Report 4592001; 2001; TRB.

Bahia, H., Modified asphalt binders for paving applications. Asphalt Mix Design and Construction, pp. 84-154, 2006. DOI: 10.1061/9780784408421.

Tabatabaee, N. and Tabatabaee HA., Multiple stress creep and recovery and time sweep fatigue tests: Crumb rubber modified binder and mixture performance. Transportation Research Record, 2180, pp. 67-74, 2010. DOI: 10.3141/2180-08.

D’Angelo, J. and Dongré, R., Pratical use of multiple stress creep and recovery test. Transportation Research Record, 2126, pp. 73-82, 2009. DOI: 0.3141/2126-09.

D’Angelo, J., Dongré, R. and Reinke, G., Evaluation of repeated creep and recovery test method as an alternative to SHRP requirements for polymer modified asphalt binders. In: Canadian Technical Asphalt Conference; 2006; Prince Edward Island, Canada.

Meng, G. and Yiqiu, T., Effects of various modifiers on rheological property of asphalt. In: Multi-Scale Model & Charact. of Infrastruct. Mater. RILEM 8. 2013. DOI: 10.1007/978-94-007-6878-9_25.

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Kai Yang, Rui Li. (2021). Characterization of bonding property in asphalt pavement interlayer: A review. Journal of Traffic and Transportation Engineering (English Edition), 8(3), p.374. https://doi.org/10.1016/j.jtte.2020.10.005.

2. Matheus S. Gaspar, Bianca Nogueira, Kamilla L. Vasconcelos, Leni F. M. Leite, Liedi L. B. Bernucci. (2021). Effect of Different Creep and Recovery Times on the MSCR Test for Highly Modified Asphalt Binder. Journal of Testing and Evaluation, 49(1), p.313. https://doi.org/10.1520/JTE20180584.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2017 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.