Convective drying of squash (Cucurbita moschata): Influence of temperature and air velocity on effective moisture diffusivity, carotenoid content and total phenols

Secado convectivo de zapallo (Cucúrbita moschata): Influencia de la temperatura y velocidad de aire sobre la difusividad efectiva de humedad, contenido de carotenoides y fenoles totales

DOI:

https://doi.org/10.15446/dyna.v84n202.63904Palabras clave:

Convective drying, cucurbita moschata-UNAPAL Abanico 75, total phenols, carotenoids, response surface methodology, air temperature (en)Secado convectivo, cucúrbita moschata-UNAPAL Abanico 75, fenoles totales, carotenoides, metodología superficie de respuesta, temperatura del aire (es)

Descargas

Recibido: 5 de abril de 2017; Revisión recibida: 8 de junio de 2017; Aceptado: 18 de julio de 2017

Abstract

The influence of air temperature and air velocity on convection drying of pumpkin (Cucurbita moschata - UNAPAL Abanico 75) is studied using drying kinetics and changes in the content of total phenolic and carotene compounds. The response surface methodology was used to optimize the operating conditions for pumpkin pulp drying. The studied factors included drying temperature (45-65 °C) and air velocity (4 and 7 m.s-1). The optimum pumpkin pulp drying conditions were 55 °C and 7m.s-1 for the air temperature and velocity, respectively. The drying time was approximately 390 min. The flour had 6.34 ± 0.10% (db) for moisture, 141.5 ± 1.32 mg carotene/100g sample for total carotenoids and 72.9 ± 2.2 mg GAE/100g sample for total phenols.

Keywords:

Convective drying, cucurbita moschata-UNAPAL Abanico 75, total phenols, carotenoids, response surface methodology, air temperature..Resumen

Se estudia la influencia de la temperatura y la velocidad del aire en el secado convectivo de zapallo (Cucúrbita moschata- UNAPAL Abanico 75), por medio de la cinética de secado y los cambios en el contenido de compuestos fenólicos y carotenos totales. Se empleó la metodología de superficie de respuesta para optimizar las condiciones de operación en el secado de pulpa de zapallo. Los factores estudiados fueron, temperatura de secado (45 - 65 °C) y velocidad de aire (4 y 7 m.s-1). Las condiciones óptimas de secado de pulpa de zapallo fueron; 55 °C y 7m. s-1, para la temperatura y velocidad de aire respectivamente. El tiempo de secado fue 390 min aproximadamente. La harina obtenida presento humedad 6.34 ± 0.10 % (bh), carotenoides totales; 141.5 ± 1.32 mg/100 g de muestra, fenoles totales; 72.9 ± 2.2 mg /100 g de muestra.

Palabras clave:

Secado convectivo, cucúrbita moschata-UNAPAL Abanico 75, fenoles totales, carotenoides, metodología superficie de respuesta, temperatura del aire..1. Introduction

The pumpkin variety Unapal Abanico 75 is the result of different genetic crosses between populations of Cucurbita moschata made by the Universidad Nacional de Colombia, Palmira. Its fruit is characterized by a high content of dry matter (between 16 and 25 %). This horticultural crop has a high potential for agriculture because of its nutritional value and is used for fresh consumption and processed foods, such as flour, pulp and dehydrated products [1]. Significant contents of the following have been identified in pumpkin: ascorbic acid (vitamin C), minerals (calcium, iron, phosphorus), amino acids (thiamine and niacin), phenolic compounds (236 ± 1.8 - 1113 ± 4 mg GAE/100g of dry sample) and pro-vitamin A in the form of total carotenoids (490.1 - 1365.8 μg/g) [2,3,4].

This crop is perishable because of its high moisture content (90%), causing it to deteriorate within a few weeks of harvest [5]. Preserving pumpkin with its nutritional, functional, flavor and color characteristics is a difficult task [6,7]; drying with hot air is one of the more frequent techniques used to achieve this. Currently, this technique is used in post-harvest processes of agricultural products and grains, eliminating part of the water through processes of transfer of mass and heat, simultaneously. This decrease in moisture minimizes the phenomenon of deterioration by microorganisms or enzymes in foods [8,9]. However, drying with hot air leads to a loss of product quality in terms of taste, color, and nutritional and functional contents in terms of bioactive compounds such as phenols and total carotenoids [10].

Different studies have been presented on kinetics of hot air pumpkin drying, either with the objective of determining mass transfer, energy required to dehydrate or sample layer thickness [7,11,12]. However, other drying techniques have also been studied; Osmotic dehydration (OD), microwave, hot air and combined microwave, vacuum drying, among others [6,13,14]. Similarly, more complete studies are made on slices of pumpkin, which have the influence of drying in terms of color, sensory evaluation, total carotenoid content, phenolic acids more abundant and beta-carotene degradation [4,2,10]. However, the effect of drying with hot air on carotenoids and phenols was not addressed with the UNAPAL Abanico 75 pumpkin variety, which is characterized by a promising vegetable for agroindustrial purposes, due to its high content of dry matter [1].

Therefore, this work aims to investigate the influence of the variables (temperature and air velocity) in the drying process on the characteristics of the final product, aiming to investigate the effect of air temperature and drying rate on the fresh squash pulp in terms of final moisture content (FMC), carotenoids (TC) and total phenolic content (TPC).

2. Materials and method

Pumpkin fruits (UNAPAL- Abanico 75 variety) were collected from the municipalities of Dagua and Yumbo (Valle de Cauca - Colombia), 4.5 months old. The fruits were washed, cut, and blanched at a boiling temperature for 9 minutes. The pulp was separated and cut (0.3x7x0.5 cm) in a food processor (Javar, Colombia).

2.1. Determination of moisture and quantification of total phenols and carotenoids

2.1.1. Determination of moisture content (FMC)

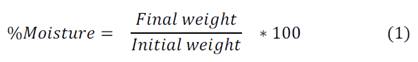

The moisture percentage (%M) was determined with the final and initial weights using a moisture balance (XM60 e=0.01 Precision, Swiss); see (Eq. 1).

2.1.2. Quantification of total carotenoids (TC)

The carotenoids were quantified in triplicate [15,16]. 0.01 ± 0.001 g of the sample (bh) was taken and weighed in a test tube; seven (7) mL of a 4:3 ethanol-hexane solution were added, protected from light in a cold bath (2 °C) and stirred for 60 min on an orbital shaker (MRC TOS-4030F, USA) at 250 rpm. Subsequently, 1 mL of distilled water was added and stirred for 15 min. The absorbance of the samples at 450 nm was read against a hexane blank (97.0% Sigma-Adrich, Spain). A Spectrophotometer UV-Vis, Jenway 6320D, was used. The total carotenoid content of the hexane extracts was calculated with (Eq. 2).

Where 536.85 g/mol is the molecular weight of β-carotene, 3 is the volume (mL) of hexane, 0.01 g is the weight of the added sample, and 137.4 m.M -1 is the extinction coefficient for β-carotene in hexane.

2.1.3. Determination of the total phenolic content (TPC)

Pumpkin flour was extracted with 10 mL of 80% methanol (GC) Sigma-Aldrich (Germany). The samples were centrifuged at 3000 rpm for 10 min at 5 °C. The supernatant was removed and passed through a Walman filter No. 42. The TPC was determined according to [17]. One milliliter of extract was placed in a 25 ml container; nine milliliters of distilled water and one milliliter of Folin-Ciocalteu reagent were added, stirred and left to stand for 5 min; then, 10 mL of 7.5% Na2CO3 was added and brought to 25 ml with distilled water; the reaction was stirred and allowed to stand for 60 min at 40 °C in darkness. The absorbance at 760 nm was recorded using a spectrophotometer (UV-VIS, Shimadzu, model UV-1700 Pharmaspec). A calibration curve of gallic acid (3,4,5-trihydroxybenzoic acid, Sigma Chemical Co., St. Louis, MO, USA) was obtained in an 80% methanol solution (HPLC grade methanol), relating the absorbance (ABS) and concentration (ABS = 4.7787 x concentration - 0.0003, (R2 = 0.999)). The results are expressed as gallic acid equivalents (GAE) in mg/100 g of raw material (db).

2.2 Drying process and data collection

The pumpkin pulp samples were dehydrated in a tray dryer (FIQ, Colombia). The drying air velocity (VAS) was regulated with a velocity controller on the axial flow ventilation unit. The air was heated with an electric device with five 1000-W resistors arranged in a unit separate from the drying chamber. The air temperature (TAS) was controlled with a heater power control unit. The pumpkin sample, with rectangular geometry, was extended in the tray with a load density of 1.33 kg.m-3. Preliminary experiments with analysis of variance selected the factors that affected the response variables and their ranges. Experiments were carried out at the following intervals: TAS (45 °C to 65 °C), VAS (6 to 8 m.s-1) in the transverse direction and process time (330 to 630 min). Measurements of temperature, air velocity, and relative humidity of the drying air were recorded in the air inlet and outlet holes every 10 min. The dry and wet bulb temperatures were recorded with thermocouples integrated into the drying cabinet. A digital balance was used to record the weight change of the sample over time. The relative humidity and temperature were also measured with a digital thermo hygrometer (Extech, VWR 35519, USA).

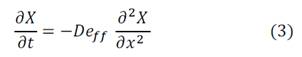

2.3 Diffusivity coefficient

The effective diffusivity was determined with the second law of Fick (Eq. 3) [7,18]. The geometry of the pumpkin samples was rectangular and negligible external contraction and resistance and uniform initial moisture distribution were assumed. (Eq. 4) represents the solution of Fick's law and was used to determine the diffusivity constant of each experiment.

Where X represents the global moisture content (%), 𝑥 is the length (m) and 𝑡 is time (s)

MR represents the moisture ratio, 𝐷𝑒 𝑓𝑓 , is the effective diffusivity of the moisture (m2 s-1), t is the drying time (s) and L is half the thickness of the pumpkin cut into rectangles (m). The coefficient of diffusivity was calculated from the linearized slope in (Eq. 4). The MR value was calculated using (Eq. 5).

where 𝑋 𝑖 is the initial moisture content (dry basis, 𝑋 𝑡 is the moisture content (dry basis) at time t based on the recorded weight, and 𝑋 𝑒 is the equilibrium moisture content.

2.4 Activation energy (Ea)

The activation energy was determined from the effective diffusivity coefficient at a constant air velocity (6, 7 and 8 m.s-1) at the different temperatures associated with the experiments. (Eq. 6) of Arrhenius was used for the determination:

Where 𝐸𝑎 is the activation energy (KJ/mol), 𝑅 is the universal constant of the gasses (8.3143 x 10-3 kJ/mol K), T is the air temperature (K), and 𝐷𝑒𝑓𝑓 0 is the diffusivity in (m2.s-1). The linearized slope based on (Eq. 6) is associated with the activation energy.

2.5 Experiment design

The response surface methodology was used to investigate the effects of TAS (°C) and VAS (m.s-1) on the final moisture content (FMC), TC and TPC during the drying of the pumpkin pulp. The ranges of the process variables were determined with a preliminary experiment.

A central composite rotary design (CCRD) was used, including 12 experiments consisting of 4 replicates at the central points and 4 axial points (α = ± 1.68179) and 22 factorial points (Table 1). The experiment data were adjusted to a second order polynomial model (Eq. 7) to predict the behavior of FMC (db), TC concentration (mg/100 g of sample) and TPC (mg GAE/100 g of sample).

Where φ is the response variable, β0 is a constant number, βi, βii and βij are the linear, quadratic and cross coefficients, respectively. Λi and λj are the levels of the independent variables and the error is represented by ε. The adjustment to the model is interpreted by the correlation between the factors and the responses through the coefficient of determination (R2). The more significant combinations of factors in the model were identified using an ANOVA variance analysis (p≤0.005), using Minitab 17.0 statistical software (Minitab® 17.0, Minitab Inc., PA, USA).

Source: The AuthorsTable 1: Experiment values and response variables for central composite rotable design (CCRD)

3. Results and discussion

3.1 Drying kinetics

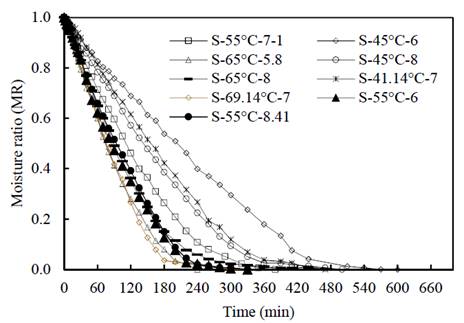

In drying, wet material is subjected to the action of a hot and dry air stream, which evaporates the moisture and increases the humidity of the air [17,19]. The process ends by reaching moisture equilibrium, when the vapor pressure of the solid's moisture equals the partial pressure of the gas stream [20]. The drying time differed in each experiment since the process was stopped when there was no change in the weight of the sample, for example, a pumpkin sample with initial moisture of 86.68 ± 0.67% was subjected to drying at 55 °C and an air velocity of 7 m.s-1, with a time to reach moisture equilibrium of about 390 min; while, at a temperature of 69 °C and air velocity of 7 m.s-1, the time was 330 min, achieving a FMC of 6.10 ± 0.04 and 7.82 ± 0.06%, respectively, evidencing that an increase of 14 °C in the drying air temperature represented a change of about two percentage points in the moisture and 60 min less in the drying time. These results are comparable with those reported by [11] who dried pumpkin at 50, 55 and 60 °C with initial moisture of 92.02 °C (db) to a final moisture of 10.03% (db) in a time of 750, 390 and 270 min, respectively.

Fig. 1 shows the moisture ratio (MR) changes with respect to the drying time at different temperatures, curves that are comparable with studies carried out on commercial pumpkin [11, 5], typical behaviors of the drying curves. As for the decrease of the moisture ratio (MR), this is proportional to the change in the weight of the sample. Therefore, low MR values indicate small changes in the recorded weight of the sample in relation to time. The moisture ratio decreases as the drying time passes, however, for a same point in time, the MR can be different because of a change in temperature or change in air velocity, evidencing more relevant changes from the effect of temperature.

Figure 1: Moisture as a function of drying time

3.2 Effective diffusivity and activation energy

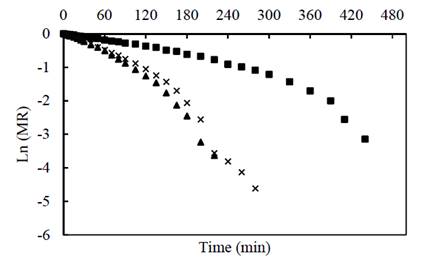

In Fig. 2, Ln values (MR) versus drying time are presented for three TAS conditions, grouped by VAS factor (7m.s-1). A linear trend was observed at the beginning of the drying as a result of the pumpkin drying during the period of constant drying, indicating that the phenomenon is controlled by diffusion [7].

It is also possible to establish the dependence of Ln (MR) on TAS by observing the slope of the curves since it increased with the increase in the TAS (Fig. 2-4), where slopes of the curves decreased with the decrease in temperature, independent of VAS; this difference is reflected in the increase of moisture diffusivity in the pumpkin samples.

Figure 2: Ln (MR) as a function of drying time (min) of the pumpkin at an air velocity of 7 m.s-1, (△) 41 °C, (□) 55 °C, (x) 69 °C

Figure 3: Ln (MR) as a function of drying time (min) of the pumpkin at an air velocity of 6 m.s-1, (△) 65° C, (□) 45°C, (x) - 55°C

Figure 4: Ln (MR) as a function of drying time (min) at an air velocity of 8 m.s-1 (△) 55°C, (□) 65°C, (x) 45°C

The behavior was similar when the experiments were grouped by air velocity (Table 2). This behavior coincides with studies performed by [21,22], for drying pumpkin with different geometries. As for the result of the curves obtained when plotting Ln (MR), these results did not present a typical behavior of straight lines during the period, possibly affected by the pretreatment (blanching) since this behavior is comparable to the one presented by [7], who studied different pretreatments before drying pumpkin at temperatures of 40, 60 and 80 °C.

Source: The AuthorsTable 2: Calculated effective diffusivity values

The calculated effective diffusivity values (Deff) are in Table 2. Results that are similar in magnitude to those reported by [11], for drying var. Cucurbita pepo L. in slices, with diffusivity values of 3.88 × 10 -10. m 2 .s-1 at 50 °C, and lower than those given by [12] for Cucurbita moschata and [14] for Cucurbita maxima, with the following values: (Deff) 1.07 × 10-8 m 2 .s-1 at 30 °C, 4.75 × 10 -8 m 2.s-1 at 70 °C and 1.13 × 10 -9 at 50 °C, 5.70 × 10 -9 m2 . s-1 70 °C, respectively.

The activation energy (Ea) was calculated with equation 5, taking the slope of the curve, ln (Deff), at 1 / (T + 273.15), for each drying air velocity: 21.61 kJ/mol, 5.83 kJ/mol and 33.55 kJ/mol, for 6, 7 and 8 m.s-1, respectively (Table 3). The Ea values obtained in the same plant matrix are lower than those reported by [12] and [11] with results of 32.262 kJ/mol, 86.254 kJ/mol and 78.93 kJ/mol, possibly because of the inclusion of the blanching operation in the process. An operation that favors the movement of water to the surface of the material for its evaporation and, consequently, increases the effective diffusivity coefficient and decreases the activation energy value, as stated by [7], for different pulp pretreatments (blanching, steam and oil / water), with results of 24.878 kJ/mol, 28.672 kJ/mol, 21.44 kJ/mol and [23], in blanching and non blanching nopals, obtaining an activation energy of 35.85 kJ/mol and 28.21 kJ/mol, respectively.

Source: The AuthorsTable 3: Activation energy values

3.3 Response surface

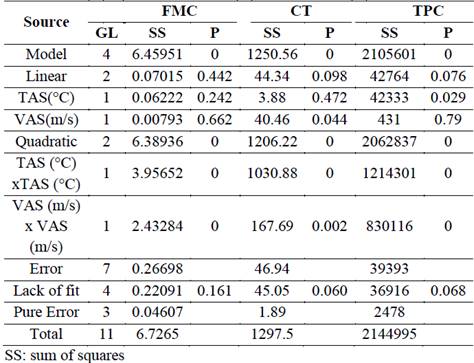

The results of the series of drying experiments are shown in Table 1. The multiple linear regression analysis of the experiment data produced second-order polynomial models for the prediction of moisture, TPC and TC. An analysis of variance (ANOVA) was carried out to determine the significant effects of process variables for each response and the adaptation of second order polynomial models to the experiment data.

Regression coefficients were obtained for the equations of the proposed models and the level of statistical significance of all the main effects calculated for each response (Table 4). In addition, the ANOVA showed that the lack of fit was not significant at the 95% confidence level for the predictive models of moisture, TC and TPC established for the response surface.

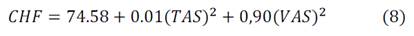

Source: The AuthorsTable 4: Analysis of variance for the final moisture prediction model

The data obtained from the central composite rotational design (CCDR) were fit to second order polynomial equations. The second order models responded to (Eq. 8-10), estimating the final moisture content and the concentration of total carotenoids and phenols as a function of temperature and air velocity interaction in the convective drying. The second-order models for moisture and total carotenoids and phenols had an adjusted correlation coefficient R2 adjusted of 0.9376, 0.9431 and 0.9711, respectively. Thus, it is possible to state that 93.7, 94.3 and 97.1% of the variation can be explained by the models.

To visualize the combined effects of two factors on the response variables, the response surfaces and the contours were generated for each of the adjusted models that predicted the behavior of each response variable as a function of two independent variables. The effects of drying air temperature and air velocity on FMC, TC and TPC were seen for the evaluation of these diagrams.

The effect of TAS and VAS on FMC in the dehydrated pumpkin was significant and ranged from 6.06 to 7.99%, evidencing a synergy between temperature and air velocitye. On the other hand, the analysis of variance of the proposed model for final moisture prediction had a probability value of 0.00, less than α = 0.05 (Table 4), indicating that the model is highly significant and could be used for the determination of final moisture in dehydrated pumpkin and the lack of fit was not significant (p> 0.05). For the above, the model is represented in the known design, which is appreciable in Fig. 5-b, where, at temperatures near to 45 °C and 65 °C and air velocity of 6 and 8 m.s-1, the moisture was higher compared to the area of the surface around 55 °C and 7 ms-1. This is because the high temperatures during the drying did not achieve a greater reduction of moisture, which is explained as a function of the model coefficients.

Figure 3: Response surface and contour for the final moisture (FMC) (a, b), total carotenoids (TC) (c, d) and total phenols (TPC) (e, f), as a function of air drying temperature and velocity.

3.4 Total Carotenoid Content (TC)

For the carotenoid model, the probability value was highly significant (p <0.05) (Table 4), ranging from 115.6 ± 0.85 to 141.8 ± 0.81 mg/100 g of sample. The model is represented in the response surfaces Figs. 5-c and 5-d for the total carotenoid content; in addition, the drying rate favored the retention of carotenoids. These results are comparable with studies by [10] on the reduction of the beta-carotene content in samples subjected to heat treatment at low (60 °C) and high (70, 80, 90 and 100 °C) temperatures for 2 h, with results of 14.0531 mg/g and 8.15, 7.25, 4.86 and 4.19 mg/g, respectively.

However, temperatures above 50 °C led to an increase in the total carotenoid content, as compared to the temperature 45 °C, perhaps because of a higher availability of these compounds since the heat treatment inactivates the oxidative enzymatic activity, also causing breakage of some structure types and leading to a higher concentration of beta-carotene [11, 10]. Additionally, the loss of moisture means that soluble solids are more concentrated in the sample.

3.5 Total Phenolic Content (TPC)

Table 1 shows the content of total phenols present in the dehydrated pumpkin, which varied from 27.7 ± 1 to 79.9 ± 22 mg GAE/100 g of sample. [2] found that a higher concentration of phenolic compounds was observed at 55 °C and 7 m.s -1, but the results obtained were 74.6 ± 2.9 mg GAE/100 g of db, with 236 ± 1.8 and 283 ± 8 mg GAE/100 g of dry sample in samples of pumpkin pulp (Cucurbita moschata Duch.). Possibly this difference was due to the influence of post-harvest processing and storage since phenolic compounds can be formed during processing from the availability of precursors of phenolic molecules or by non-enzymatic interconversions between them [2,8]. Also, immersion in water at temperatures above 90 °C, as done during blanching, can be attributed to losses of some phenolic compounds by leaching [24].

In this experiment, at temperatures higher than 55 °C, the total phenolic content decreased, with concentrations of 37.1 ± 2.6 and 41.0 ± 1.2 mg GAE/100 g of sample obtained at 65 and 69 °C, respectively, changes that indicate the influence of temperature on the phenolic content. Similar results were obtained by [5] (27.7 ± 1.0 mg GAE/100 g of sample) in Cucurbita pepo with 33.5 mg GAE/100g of dry sample, as quantified in flour obtained at 70 °C, in contrast to temperatures close to 40 °C, probably because of the low release of phenolic compounds bound to cellular structures with that level of thermal energy, provided by the drying treatments [24].

4. Optimal drying conditions

In the search of optimum conditions, the minimum and maximum response method for total carotenoids and phenols was used, based on predictive models obtained in a composite central design. The following conditions were obtained: 6.2% for moisture at 55 °C and 7 m.s-1; carotenoid concentration (141.89 mg/100g sample) at 55 °C and 7 m. s-1; total phenol concentration (74.6 mg GAE/100 g sample) at 55.7 °C and 6.9 m.s-1. Thus, the optimum drying points for the pumpkin pulp were 55 °C and 7m.s-1, conditions in which the drying time would be approximately 5.5 to 6 hours, with minimum moisture between 6 and 7%, suitable for obtaining a commercial flour and subsequent products based on pumpkin pulp such as pasta, biscuits, baked goods, and fiber supplements, among others, with moisture at 10.54 ± 1.2%, 12.64 ± 0.001, and 10.3 ± 0.16% [2, 25-27].

4.1 Drying efficiency (ƞ)

The drying efficiency (ƞ) was calculated using (Eq. 11); the energy efficiency was calculated in the range of 90.09 to 92.93% for the drying of the pumpkin pulp in the dryer tray.

The maximum efficiency percentage was 92.93%, which corresponded to the optimum drying conditions (55 °C and 7 m.s-1), while the efficiency was lower compared to the other experiments under drying conditions at 65 °C and 6m/s with an efficiency of 90.09%. In general, the efficiency did not pkresent significant differences since, in all of the experiments, the value exceeded 90% water removal. Moderate temperatures, slightly high air velocities, and average processing times are needed to increase ƞ. In this study, a higher temperature significantly affected the heat losses because of the insufficient insulation and hermetics of the dryer tray. The effect of the air velocity on the heat losses was less than the effect of the temperature; in addition, the increase in the air velocity caused an increase in the ƞ.

Conclusions

The optimum conditions for air drying pumpkin based on the variables TAS (°C) and VAS (m.s-1) to reach were 55.7 °C and 7.0 m.s-1 respectively. These conditions also led to a higher concentration of total carotenoids, phenols and moisture lower than 6% in squash flour, which can be used to make various products such as pasta, biscuits, candies, and baked goods.

The calculated effective diffusivity values varied between 5.01 × 10 -10 and 1.75 × 10 -10 m 2. s.-1 in the ranges of the TAS and VAS. Increases in the effective diffusivity and decreases in the activation energy resulted from the temperature increases, and the dependence of temperature on the diffusivity coefficients was described by an Arrhenius type relationship. These types of properties, including diffusion of moisture and activation energy, should be studied for each crop because there is not much information available for their determination.

References

Referencias

Baena, D., Ortiz, S., Valdés, M. and Estrada, E., UNAPAL - Abanico 75: new butternut pumpkin cultivar, with high dry matter content in fruit for agribusiness purposes. Acta Agronómica, 59, pp 285-292, 2010. DOI: 10.15446/acag.

Aydin, E. and Gocmen, D., The influences of drying method and metabisulfite pre-treatment on the color, functional properties and phenolic acids contents and bioaccessibility of pumpkin flour. LWT - Food Science and Technology, 60, pp 385-392, 2015. DOI: 10.1016/j.lwt.2014.08.025.

Vallejo, F., Baena, D., Ortiz, S., Estrada, I. and Tobar, E., Unapal- Dorado, pumpkin new cultivar with high dry matter for fresh consumption. Acta Agronómica, 59, pp. 127-134, 2010. DOI: 10.15446/acag

Wang, S., Dong, J. and Kyung, B., Physicochemical property of pumpkin slices dehydrated with red algae extract. Journal of the Korean Society for Applied Biological Chemistry, 54, pp. 921-925, 2011. DOI: 10.1007/BF03253181

Oloyeda, F.M., Agbaje, G., Obuotor, E.M. and Obisesan, I.O., Nutritional and antioxidant profiles of pumpkin (Cucurbita pepo Linn.) immature and mature fruits as influenced by NPK fertilizer. Food Chemistry, 135, pp. 460-463, 2012. DOI: 10.1016/j.foodchem.2012.04.124.

Garcia, C., Mauro, M.A. and Kimura, M., Kinetics of osmotic dehydration and air-drying of pumpkins (Cucurbita moschata). Journal of Food Engineering, 82, pp. 284-291, 2007. DOI: 10.1016/j.jfoodeng.2007.02.004.

Tunde, A. and Ogunlakin, G.O., Influence of drying conditions on the effective moisture diffusivity and energy requirements during the drying of pretreated and untreated pumpkin. Energy Conversion and Management, 52, pp. 1107-1113, 2011. DOI: 10.1016/j.enconman.2010.09.005.

Gliemmo, M.F., Latorre, M.E., Gerschenson, L.N. and Campos, C.A., Color stability of pumpkin (Cucurbita moschata, Duchesne ex Poiret) puree during storage at room temperature: Effect of pH, potassium sorbate, ascorbic acid and packaging material. LWT- Food Science and Technology, 42, pp. 196-201, 2009. DOI: 10.1016/j.lwt.2008.05.011.

Workneh, T., Zinash, A. and Woldetsadik, K., Blanching, salting and sun drying of different pumpkin fruit slices. Journal of Food Science and Technology, 51, pp. 3114-3123, 2014. DOI: 10.1007/s13197-012-0835-4.

Dutta, D., Dutta, A., Raychaudhuri, U. and Chakraborty, R., Rheological characteristics and thermal degradation kinetics of beta-carotene in pumpkin puree. Journal of Food Engineering, 76, pp. 538-546, 2006. DOI: 10.1016/j.jfoodeng.2005.05.056.

Doymaz, İ., The kinetics of forced convective air-drying of pumpkin slices. Journal of Food Engineering, 79, pp. 243-248, 2007. DOI: 10.1016/j.jfoodeng.2006.01.049.

Guiné, R.P.F., Henrriques, F. and João Barroca, M., Mass transfer coefficients for the drying of pumpkin (Cucurbita moschata) and dried product quality. Food and Bioprocess Technology, 5, pp. 176-183, 2012. DOI: 10.1007/s11947-009-0275-y.

Alibas, I., Microwave, air and combined microwave–air- drying parameters of pumpkin slices. LWT - Food Science and Technology, 40, pp. 1445-1451, 2007. DOI: 10.1016/j.lwt.2006.09.002

Arévalo-Pinedo, A. and Xidieh-Murr, F.E.,. Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. Journal of Food Engineering, 80, pp 152-156, 2007. DOI: 10.1016/j.jfoodeng.2006.05.005.

Barrett, D. and Anthon, E., Lycopene content of California-Grown tomato varieties. Acta Horticulturae, 542, pp. 165-174, 2001. DOI: 10.17660/ ActaHortic.2001.542.20.

Ordoñez, L. and Ledezma, D., Lycopene concentration and physico-chemical properties of tropical fruits. Food and Nutrition Sciences, 4, pp. 758-762, 2013. DOI: 10.4236/fns.2013.47097.

Singleton, V.R., Orthifer, R. and Lamuela-Raventos, R.M., Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods in Enzymology 299, pp. 152-178, 1999. DOI: 10.1016/S0076-6879(99)99017-1.

Crank, J., The mathematics of diffusion. Oxford University Press, USA, 1979.

Fernando, W.J.N., Low, H. and Ahmad, A., Dependence of the effective diffusion coefficient of moisture with thickness and temperature in convective drying of sliced materials. A study on slices of banana, cassava and pumpkin. Journal of Food Engineering, 102, pp. 310-316, 2011. DOI: 10. 1016/j.jfoodeng. 2010.09.004.

Álava-Pincay C.L., Desarrollo del proceso y caracterización de harina de zapallo y formulación de subproductos. Tesis, Departamento de Ingeniería de Alimentos, Escuela Superior Politécnica del Litoral, Ecuador, [en línea]. 2007. Disponible en: http://www.dspace.espol.edu.ec/xmlui/handle/123456789/11932.

Ciurzyńska, A., Lenart A. and Gręda, K., Effect of pre-treatment conditions on content and activity of water and colour of freeze-dried pumpkin. LWT - Food Science and Technology, 59, pp. 1075-1081, 2014. DOI: 10.1016/j.lwt.2014.06.035.

Tripathy, P., Kumar, S., A methodology for determination of temperature dependent mass transfer coefficients from drying kinetics: Application to solar drying. Journal of Food Engineering, 90, pp. 212-218, 2009. DOI: 10.1016/j.jfoodeng.2008.06.025

Martínez, S., Flores, O., Mercado, F. y López, O., Características de secado de nopal (Opuntia ficus-indica) por lecho fluidizado. Acta Universitaria-Facultad de Alimentos – Guanajuato, [en línea]. 20, pp. 70-76, 2010. Disponible en: http://www.redalyc.org/ articulo.oa?id=41618860010.

Acosta-Estrada, J., Gutiérrez-Uribe, J.A. and Serna-Saldivar, S., Bound phenolics in foods, a review. Food Chemistry, 152, pp. 46-55, 2014. DOI: 10.1016/j.foodchem.2013.11.093.

Äœerniauskienä, J., Kuläitiene, J., Daniläœenko, H., Jarienä, E. and Jukneviäœienä, E., Pumpkin fruit flour as a source for food enrichment in dietary fiber. Not Bot Horti Agrobo, 42, pp. 19-23, 2014. DOI: 10.15835/nbha4219352.

Mirhosseini, H., Rashid, NF., Amid, W., Cheong, M., Kazemi, M. and Zulkurnain, M., Effect of partial replacement of corn flour with durian seed flour and pumpkin flour on cooking yield, texture properties, and sensory attributes of gluten free pasta. LWT - Food Science and Technology, 63, pp. 184-190, 2015. DOI: 10.1016/j.lwt.2015.03.078.

Noor, A. and Komathi, C.A., Acceptability attributes of crackers made from different types of composite flour. International Food Research Journal, [online]. 16, pp. 479-482, 2009. Available at: http://www.ifrj.upm.edu.my/16%20(4)%202009/03%20IFRJ-2008.

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Imdadul Hoque Mondal, Latha Rangan, Ramagopal V. S. Uppaluri. (2022). Tray drying characteristics of Musa splendida and Musa balbisiana Colla psuedo-stem. Journal of Thermal Analysis and Calorimetry, 147(16), p.8743. https://doi.org/10.1007/s10973-021-11183-6.

2. Sladjana Stajcic, Lato Pezo, Gordana Cetkovic, Jasna Canadanovic-Brunet, Anamarija Mandic, Vesna Tumbas-Saponjac, Jelena Vulic, Vanja Travicic, Miona Belovic. (2024). Antioxidant activity according to bioactive compounds content in dried pumpkin waste. Journal of the Serbian Chemical Society, 89(1), p.13. https://doi.org/10.2298/JSC230517043S.

3. Salima Baississe, Nadia Boulelouah, Hanane Bedjaoui, Mohamed Seghir Mehaoua, Lies Reguieg. (2022). Convection Drying Influence on Thermo-Physical Properties, Bioactive Substances, Color and Texture Profile of Red Pepper (Capsicum Spp) . Acta Universitatis Cibiniensis. Series E: Food Technology, 26(1), p.83. https://doi.org/10.2478/aucft-2022-0007.

4. Monica J. Ortiz-Jerez, Yendy X. Serna, y Jose E. Zapata. (2024). Kinetics of conductive hydro-drying of pumpkin (Cucurbita moschata) pulp. Heliyon, 10(17), p.e36982. https://doi.org/10.1016/j.heliyon.2024.e36982.

5. Karoline Costa Santos, Jaqueline Souza Guedes, Meliza Lindsay Rojas, Gisandro Reis Carvalho, Pedro Esteves Duarte Augusto. (2021). Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrasonics Sonochemistry, 70, p.105304. https://doi.org/10.1016/j.ultsonch.2020.105304.

6. Imdadul Hoque Mondal, Latha Rangan, Ramagopal V. S. Uppaluri. (2020). Parametric optimality of tray dried Musa balbisiana Colla blossom. Journal of Food Science and Technology, 57(12), p.4599. https://doi.org/10.1007/s13197-020-04498-z.

7. Chaima Rekik, Collette Besombes, Wafa Hajji, Hela Gliguem, Sihem Bellagha, Arun S. Mujumdar, Karim Allaf. (2021). Study of interval infrared Airflow Drying: A case study of butternut (Cucurbita moschata). LWT, 147, p.111486. https://doi.org/10.1016/j.lwt.2021.111486.

8. Carlos J. Márquez-Cardozo, Birina L. Caballero-Gutiérrez, Héctor J. Ciro-Velázquez, Diego A. Restrepo-Molina. (2021). Effect of pretreatment and temperature on the drying kinetics and physicochemical and techno-functional characteristics of pumpkin (Cucurbita maxima). Heliyon, 7(4), p.e06802. https://doi.org/10.1016/j.heliyon.2021.e06802.

9. Jing Luo, Huan Wang, Sijia Chen, Shengjing Ren, Hansen Fu, Ruirui Li, Caiyun Wang. (2021). CmNAC73 Mediates the Formation of Green Color in Chrysanthemum Flowers by Directly Activating the Expression of Chlorophyll Biosynthesis Genes HEMA1 and CRD1. Genes, 12(5), p.704. https://doi.org/10.3390/genes12050704.

10. Bảo Lộc Nguyễn, Thị Ngọc Dễ Nguyễn, Chí Nhân Trần, Nhật Minh Phương Nguyễn. (2025). Đánh giá tác động của quá trình chần đến chất lượng puree xoài cát chu (Mangifera indica L.) bảo quản lạnh đông . CTU Journal of Science, 61(2), p.172. https://doi.org/10.22144/ctujos.2025.039.

11. Meliza Lindsay Rojas, Izabela Dutra Alvim, Pedro Esteves Duarte Augusto. (2019). Incorporation of microencapsulated hydrophilic and lipophilic nutrients into foods by using ultrasound as a pre-treatment for drying: A prospective study. Ultrasonics Sonochemistry, 54, p.153. https://doi.org/10.1016/j.ultsonch.2019.02.004.

12. Natali López-Mejía, Hugo Alexander Martínez-Correa, Margarita María Andrade-Mahecha. (2019). Pancake ready mix enriched with dehydrated squash pulp (Cucurbita moschata): formulation and shelf life. Journal of Food Science and Technology, 56(11), p.5046. https://doi.org/10.1007/s13197-019-03977-2.

13. Jingjie Fang, Sitong Liu, Sijia Chen, Huijie Deng, Linxia Zhao, Xinwei Liang, Ziqiang Chen, Xiaoqin Zhang, Songwen Xu, Caiyun Wang, Jing Luo. (2025). A R1-type MYB CmREVEILLE2 regulates light-mediated chlorophyll biosynthesis and green color formation in chrysanthemum flowers. Horticulture Advances, 3(1) https://doi.org/10.1007/s44281-025-00069-4.

14. Adriano Araújo, Rosinelson Pena. (2023). Combined Pulsed Vacuum Osmotic Dehydration and Convective Air-Drying Process of Jambolan Fruits. Foods, 12(9), p.1785. https://doi.org/10.3390/foods12091785.

15. Md. Abdul Halim, Md. Abdul Wazed, Sami Al Obaid, Mohammad Javed Ansari, Anika Tahosin, Md. Tajminur Rahman, Fatehatun Noor, N.H.M. Rubel Mozumder, Anwara Akter Khatun. (2024). Effect of storage on physicochemical properties, bioactive compounds and sensory attributes of drinks powder enriched with pumpkin (cucurbita moschata L.). Journal of Agriculture and Food Research, 18, p.101337. https://doi.org/10.1016/j.jafr.2024.101337.

16. Oscar J. Medina, William Patarroyo, Lucia M. Moreno. (2022). Current trends in cacti drying processes and their effects on cellulose and mucilage from two Colombian cactus species. Heliyon, 8(12), p.e12618. https://doi.org/10.1016/j.heliyon.2022.e12618.

17. Paini Sri Widyawati, Indah Epriliati, Susana Ristiarini, Antoni Ungirwalu, Melvin Emil Simanjuntak. (2025). Drying kinetics of Papua black fruit leaves (Haplolobus Monticola Blumea) using parallel countered-rotary-wind drying. Heat and Mass Transfer, 61(11) https://doi.org/10.1007/s00231-025-03622-z.

18. Chaima Rekik, Wafa Hajji, Hela Gliguem, Karim Allaf, Sihem Bellagha. (2024). Energy saving and quality preservation through modulating time related conditions during interval drying of pumpkin (Cucurbita maxima). Food and Bioproducts Processing, 144, p.220. https://doi.org/10.1016/j.fbp.2024.01.006.

19. Meliza Lindsay Rojas, Isabela Silveira, Pedro Esteves Duarte Augusto. (2020). Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food and Bioproducts Processing, 119, p.20. https://doi.org/10.1016/j.fbp.2019.10.008.

20. Nhật Minh Phương Nguyễn, Kim Bảo Trần, Minh Đô Lê, Như Ảnh Trần, Chí Nhân Trần, Thị Ánh Ngọc Tống. (2024). Xây dựng quy trình công nghệ chế biến puree bí đỏ (Cucurbita moschata D.) đóng hộp. CTU Journal of Science, 60(SDMD), p.229. https://doi.org/10.22144/ctujos.2024.454.

21. Luis E. Ordoñez-Santos, Jessica Esparza-Estrada, Pedro Vanegas-Mahecha. (2020). Potencial agroindustrial del epicarpio de mandarina como alternativa de colorante natural en pan. TecnoLógicas, 23(48), p.17. https://doi.org/10.22430/22565337.1465.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2017 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.