Comparisson of three IRP-based models to reduce logistics costs and greenhouse gas emissions

Comparación de tres modelos basados en el IRP para reducir costos logísticos y emisiones de gases efecto invernadero

DOI:

https://doi.org/10.15446/dyna.v85n205.68282Palabras clave:

goods distribution, multiobjective model, collaborative inventory, Greenhouse Gases (en)distribución de mercancías, modelo multiobjetivo, inventario colaborativo, Gases de efecto invernadero (es)

Descargas

Goods distribution processes must reconcile the economic interests of the companies, which seek higher levels of profitability through costs reduction and service level improvements, with the negative impacts to society and environment, such as chemical pollution and the generation of vehicular congestion and accidents. This article presents the comparison of three models that analyze the logistics costs associated with the distribution of goods and the greenhouse gas emissions generated by such processes. These models use the Vehicle Routing Problem (IRP) as the basis for optimizing the logistics activities, from which, through multi-objective approaches the CO2 emissions are analyzed. As the main result of the article, it can be observed that the multiobjective models allow finding an adequate combination between logistics costs and emissions, which is attractive to companies and society.

Los procesos de distribución de mercancías deben conciliar los intereses económicos de las empresas, que buscan mayores niveles de rentabilidad a través de disminución de los costos y mejoras del nivel de servicio, con los impactos negativos que se producen a la sociedad y al medio ambiente, como es el caso de la contaminación química y problemas de calidad de vida, como la generación de congestión vehicular y accidentes. En este articulo se presenta la comparación de tres modelos que analizan los costos logísticos asociados a la distribución de mercancías y las emisiones de gases efecto invernado que generan dicho procesos. Estos modelos utilizan el Problema de Ruteo de Vehículos (IRP) como base para optimizar las actividades logísticas, a partir del cual, mediante enfoques multobjetivo se analizan las emisiones de CO2. Como principal resultado del articulo se observa que los modelos multiobjetivo permiten encontrar una combinación adecuada entre los costos logísticos y las emisiones, que sea atractivo para empresas y la sociedad.

Recibido: 13 de octubre de 2017; Revisión recibida: 11 de marzo de 2018; Aceptado: 11 de mayo de 2018

Abstract

Goods distribution processes must reconcile the economic interests of the companies, which seek higher levels of profitability through costs reduction and service level improvements, with the negative impacts to society and environment, such as chemical pollution and the generation of vehicular congestion and accidents. This paper presents the comparison of three models that analyze the logistics costs associated with the distribution of goods and the greenhouse gas emissions generated by such processes. These models use the Vehicle Routing Problem (IRP) as the basis for optimizing the logistics activities, from which, through multi-objective approaches the CO2 emissions are analyzed. As the main result of the article, it can be observed that the multiobjective models allow finding an adequate combination between logistics costs and emissions, which is attractive to companies and society.

Keywords:

goods distribution, multiobjective model, collaborative inventory, greenhouse gases.Resumen

Los procesos de distribución de mercancías deben conciliar los intereses económicos de las empresas, que buscan mayores niveles de rentabilidad a través de disminución de los costos y mejoras del nivel de servicio, con los impactos negativos que se producen a la sociedad y al medio ambiente, como es el caso de la contaminación química y problemas de calidad de vida, como la generación de congestión vehicular y accidentes. En este artículo se presenta la comparación de tres modelos que analizan los costos logísticos asociados a la distribución de mercancías y las emisiones de gases efecto invernado que generan dichos procesos. Estos modelos utilizan el Problema de Ruteo de Vehículos (IRP) como base para optimizar las actividades logísticas, a partir del cual, mediante enfoques multiobjetivo, es posible analizar también las emisiones de gases contaminantes como el CO2. Como principal resultado de la investigación que deriva este artículo, se observa que los modelos multiobjetivo permiten encontrar una combinación adecuada entre los costos logísticos y las emisiones de CO2, que sea atractivo para empresas y la sociedad.

Palabras clave:

distribución de mercancías, modelo multiobjetivo, inventario colaborativo, gases de efecto invernadero.1. Introduction

Transport processes in cities, regions and countries have increased due to new marketing processes generated by globalization and changes in consumers habits. These highly dynamic transportation processes generate high costs in organizations, which have been studied for many years and have usually sought for their optimization through models such as the Travelling Salesman Problem (TSP) or the vehicle routing problem (VRP). However, these transport processes not only generate economic impacts for companies, but also for society and cities, as it generates congestion and physical and chemical pollution. For that reason, practitioners in charge of these professional areas within companies and also academics must to continue with search processes looking for models that will improve both the economic and social/environmental conditions for companies and society.

Many authors have argued that collaboration among supply chain is one of the main strategies to reduce the cost of goods distribution, highlighting the Vendor Managed Inventory model -VMI as one of the more important ways companies can collaborate. Through VMI the inventory quantity can be optimized for multiple companies and from there to configure more efficient distribution systems, which effectively reduces the costs and the intensity of transport activities, as a result of a better allocation of inventory. This is the concept behind the Inventory Routing Problem -IRP optimization model, which, based on the collaborative inventory, allows transportation and inventory costs to be reduced simultaneously.

This paper analyzes the effect of the IRP model on the inventory and transportation costs of goods distribution, but also considering the effect of CO2 emissions, seeking to reduce the greenhouse gas emissions produced by the logistics activities. The impact on these variables was studied using three optimization processes: the IRP Model, a multiobjective model of IRP vs. CO2 emissions and finally a multiobjective model that contemplates the IRP background, but optimizing separately the inventory and transportation costs and also including CO2 emissions as a third objective function.

2. Inventory collaboration and optimization processes

Collaboration in logistics and supply chain is understood as the joint effort of several organizations seeking to obtain superior benefits to those that can be found separately. For this the companies cooperate in processes such as transportation, inventory management, storage, facility design, information exchange and other logistics activities [1-3]. Since many years supply chain collaboration has been developed through approaches such as Quick Response (QR), Efficient Customer Response (ECR), Continuous product Replenishment (CPR), Vendor Managed Inventory (VMI), Planning, Collaborative Forecasting and Replenishment (CPRF) and Centralized Inventory Management, among others [3-5].

According to Díaz-Batista and Pérez-Armayor [6], inventory collaboration in supply chains produces a lower total annual cost than when companies work individually, generating performance improvements in the entire supply chain [7-9]. The main problem lies in the allocation of inventory and transportation, which has been studied by multiple authors [10-12], for what the most used techniques are the VMI [13] and the IRP [14]. Through the IRP it is possible to simultaneously assign the inventory quantity and the routes to supply a set of customers that collaborate with one or several suppliers [14-17].

In the IRP model, the inventory is assigned to the customers in the planning periods and from there the routes are assigned to its supply [18-20]. For this, it is required that the supplier, who makes the supply decisions, know the information about customer demands, inventory levels and other parameters for the stock management and also the transportation process information, from which generates the routes are generated [21]. Campbell and Savelsbergh [22] studied the IRP model for long-term decision-making approaches, using a decomposition scheme of two-step decisions: in the first one the inventory is assigned and in the second the routes are generated. Other authors have performed schemes for the simultaneously allocation of inventory and routes generation [1,15,21].

The joint assignment of inventory and transportation can be performed using multiobjective optimization approaches, as it is made in the works of Pechlivanos [23], Chen and Lee [24], Liang [25], Liao et al. [26], Afshari et al., [27], Shankar et al. [28], Nekooghadirli et al [29], Andriolo et al., [30], Pasandideh et al., [31] and Pasandideh et al ., [32].

Both for the IRP or multiobjective solutions there are require heuristic and metaheuristic techniques. The most used heuristic and metaheuristic for solving these optimization problems are Simulated annealing, Genetic algorithms, Evolution algorithms, Evolutionary programming, Artificial immune system algorithm, Particle swarm optimization and tabu search [33,34].

Particularly, to solve multiobjective optimization models, the main methods are: MOGA (Multi- Objective Genetic Algorithm), NSGA y NSGA-II (Nondominated Sorting Genetic Algorithm), SPEA y SPEA2 (Strength Pareto Evolutionary Algorithm), PAES (Pareto Archived Evolution Strategy) y PESA (Pareto Envelope-based Selection Algorithm), MO-VNS (Multiobjective Variable Neighborhood Search), DEPT (Differential Evolution with Pareto Tournaments), MO-TLBO (Multiobjective Teaching-Learning-Based Optimization), MOABC (Multiobjective Artificial Bee Colony), among others [33,34-37].

3 Methodology

In order to analyze the impact of the distribution processes on greenhouse gas emissions, different distribution processes were designed from three mathematical optimization processes:

-

IRP Model.

-

Multiobjective analysis using as objective functions the IRP and the CO2 emissions.

-

Multiobjective model using the IRP background, but optimizing as separate objective function the inventory and transportation costs and also including CO2 emissions as a third objective function.

For the three optimization processes, the same parameters were used and two genetic algorithms were used for its development. The first is a genetic algorithm specially configured for the solution of the IRP model, which evaluates the jointly allocation of inventory and transport routes, as is presented in Arango et al. [21]. For the multiobjective analysis an algorithm based on the NSGA2 is used, similar to what is presented in [14,37,38].

The emission factor of a typical vehicle used for the urban goods distribution was used to analyze the effect of the CO2 emission. The vehicle corresponds to a VAN with an average city emission of e = 190 g of CO2 / km [39]. This parameter is multiplied by the number of kilometers traveled, in order to calculate the amount of CO2 gases emitted.

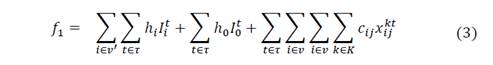

The objective function for the IRP model is presented in equation 1, subject to a set of constraints as formulated in [14,15,21,38].

The first term is the sum of the inventory costs, which is obtained by multiplying the holding cost h 𝑖 by the amount of product 𝐼 𝑖 𝑡 hold in every time t for every customer i. The second term is the inventory costs at the supplier facility represented with the sub index 0. Transport costs are calculated by multiplying the transport costs 𝑐 𝑖𝑗 of traveling from node i to j by the binary variable 𝑥 𝑖𝑗 𝑘𝑡 which is equal to 1 if the vehicle k travel from I to j in the period t and zero otherwise. The set v includes all the nodes of the problem and 𝑣 ′ only includes the customers’ nodes.

In the case of the multiobjective models, the formulation of the first model, in which the IRP costs and the CO2 are evaluated is presented in equation 2. In equation 5, the formulation for the multiobjective model separating transport costs, inventory and the CO2 emission is presented.

The Multiobjective model formulation separating transport costs, inventory and CO2 emission is:

Those objective functions are restricted to the following equations that assure the correct distribution process and correspond to the IRP Model constraints, according to Arango et al. [15] and Archetti et al., [16].

For an explanation of the restrictions, readers may refer to [15-16] and [18].

The input parameters are obtained from the instance of 15 customers and one supplier proposed by Archetti [16], increasing the amount of inventory that can be stored in each of the customers, as a strategy to produce better distribution costs and decrease the CO2 Emission. These parameters are presented in Table 1.

Source: The authors.Table 1: Input parameters

4. Results

The IRP model, in which transport and inventory costs are added, generates a distribution process in which is not necessary to supply all the customers in all the periods. This produces a decrease in transport costs generated by an increase in inventory costs. The distribution plan that is generated from the best individual of the genetic algorithm used to solve the model is presented in figure 1. In the gray part is shown the inventory quantity that must be delivery to each of the customers, while in the unlabeled part the distribution sequence is presented.

Figure 1: IRP Result -individual solution.

This way, for period 1 only customers 1, 14, 10, 12, 13, 15, 6 and 9 should be served in that sequence. The quantities to be delivery are 128, 260, 108, 184, 220, 219, 30 and 88, respectively.

This distribution process generates a total cost of $ 2839.7, of which $ 468.2 correspond to inventory costs and produces a CO2 amount of 454.39 g.

In the multiobjective model in which both the IRP costs and the CO2 emission are simultaneously optimized. A single optimal individual is produced, which is presented in figure 2. This result generates a cost of $ 2851.5, of which $ 463.9 are inventory cost and a CO2 emission of 453.6 g that is virtually identical to the solution generated by the IRP model. However, this solutions corresponds to a distribution system that assigns inventory and routes to customers in a different way than the IRP model does. For this reason, a slight decrease in CO2 emissions is generated, as a consequence of an increase in the distribution costs.

Figure 2: Multiobjective Model Solution (IRP vs. CO2 emission).

The multiobjective model, in which the transport, inventory and CO2 emission costs are analyzed separately, generates a set of individuals similar to those presented in figures 1 and 2. The set of individuals are produced by the non-dominance of the solutions, so it is not possible to argue that one solution is better than another and for that reason the decision maker, depending on his preference, can take any of the individuals solutions produced by the model. Table 2 presents the results for the 3 optimized objective functions, and includes a column adding the inventory and transport cost.

Source: The authors.Table 2: Results of the three objective functions multi-objective model.

Table 2 shows that the values of total cost and CO2 emissions for each individual are higher than those reported in the solutions for the single IRP model and for the multiobjective IRP vs. CO2 emissions. However, inventory values in each solution are lower, with a behavior that the lower the inventory level the higher the transport cost and the CO2 emission, as a consequence of an increase in the transportation intensity in order to minimize inventory.

The behavior of the three-functions multiobjective model differs in its results to the previous models, since in the first the transport and inventory costs are added up, so in the optimization process the costs are compensated, while in the three-functions multiobjective model the algorithm must also look for which is the best solution that generates the minimum inventory costs without an excessively increase in transport costs. In order to compare these solutions, the problem was solved supplying all customers in each of the periods, what minimizes the inventory costs. For that, the Vehicle Routing Problem - VRP was used and solved with a genetic algorithm, for that the transport cost is $ 1722.5 for each period, which corresponds a total cost of $ 8612.5 for the 5 periods. This single VRP cost is higher than the transport cost for all individuals produced by the three-functions multiobjective model and becomes a non-optimal solution for the distribution process

Table 3 presents the results of the three models. The individual solution one is selected for the three-function multiobjective model (presented in figure 3), which is the individual that generates the lowest CO2 emissions for that model.

Source: The authors.Table 3: Comparison of the three models.

Figure 3: Individual 1 of the three-function multiobjective model.

From the results presented in Table 3, it is possible to observe that the total cost, inventory and CO2 emissions for the IRP and multiobjective IRP vs. CO2 are very similar, but differ with the solution that produced the fewer emissions in the three-function multiobjective model. This is caused by the reduction of the inventory costs, due to the three-function multiobjective algorithm generates solutions that somehow represent the best conditions for each of the objective functions, this way producing solutions with smaller inventory quantities but generating higher transport costs and CO2 emissions.

From this result, it is possible to infer that companies must make efforts in collaborative processes that allow to simultaneously reduce inventory, transportation and CO2 emissions, since a local optimum, as is the case of individual 1 of the three-functions multiobjective model, which generates the smallest inventory with a cost of 403.7, what is equivalent to a 13% reduction compared to the inventory for the IRP vs. CO2 emissions model, is also generating a 138% increase in CO2 emissions and a 114% higher distribution costs, which is not beneficial for both, companies or the environment.

5. Conclusions

Through inventory collaboration it is possible to reduce goods distribution cost for companies, but also to minimize the CO2 emission for these logistics activity, which contributes to the reduction of pollution problems in cities. Based on the results found in this paper, the search for the reduction of inventory costs in companies generates large increases in logistical costs as well as greenhouse gas emissions, which is not beneficial for Company nor the environment.

In this paper, the collaborative process through inventory and its effect on the pollutant gases emission are analyzed from different models, finding that it is better to use the IRP, which combines inventory and transport costs, than the three-function multiobjective model. This is because the multiobjective model, which seeks to simultaneously minimize transport, inventory and CO2 emissions, within its optimization process, must look for solutions that generate adequate relations between these three variables. This leads to the production of distribution plans that increase CO2 emissions and total costs, as a consequence of finding lower inventory cost, what is a local optimum that is not good for integral logistics.

As future research lines, it is recommended to use more objectives that are important for companies and customers, as it can be the service level. Other routing conditions are also important to be included in the presented models, as several suppliers, backhauls, dynamic conditions and multiple distribution levels. Finally it is interesting to include other logistics activities in the optimization process, as it can be warehousing and purchasing processes. These research lines allow to model more realistic situations and improve decision making in logistics activities.

References

Referencias

Chan, F.T.S. and Prakash, A., Inventory management in a lateral collaborative manufacturing supply chain: a simulation study. International Journal of production Research, 50(16), pp. 4670-4685, 2012.

Simatupang, T. and Sridharan, R., An integrative framework for supply chain collaboration. International Journal of Logistics Management, 16, pp. 257-274, 2005.

Arango-Serna, M.D., Adarme-Jaimes, W. y Zapata-Cortes, J.A., Inventarios colaborativos en la optimización de la cadena de suministros. DYNA, 80(181), pp. 71-80, 2013.

Holweg, M., Disney, S., Holmström, J. and Smaros, J., Supply chain collaboration: making sense of the strategy continuum. European Management Journal, 23(2), pp. 170-181, 2005.

Derroiche, R., Neubert, G. and Bouras, A., Supply chain management: a framework to characterize the collaborative strategies. International Journal of Computer Integrated Manufacturing, 21(4), pp. 426-439, 2008.

Díaz-Batista, J. and Pérez-Armayor, D., Optimización de los niveles de inventario en una cadena de suministro. Ingeniería Industrial, 33(2), pp. 126-132, 2012.

Won-Cho, D., Hae-Lee, Y., Youn-Lee, T. and Gen, M., An adaptive genetic algorithm for the time dependent inventory routing problem. Journal of Intelligent Manufacturing, 25(5), pp 1025-1042, 2014.

Bertazzi, L. and Esperanza, M.G., Inventory routing problems with multiple customers. EURO J Transp Logist 2. pp 255-275, 2013.

Moin, N.H., Salhi, S. and Aziz, N.A.B., An efficient hybrid genetic algorithm for the multi-product multi-period inventory routing problem. Int. J. Production Economics, 133 pp. 334-343, 2011.

Rushton, P. Croucher, P. and Baker, P., The handbook of logistics and distribution management, 3rd edition. London, Ed. Kogan Page Limited, 2010.

Estrada, M.A., Análisis de estrategias eficientes en la logística de distribución de paquetería. PhD. Thesis, Programa de Doctorado de Ingeniería Civil, E.T.S. de Ingenieros de Caminos, Canales y Puertos de Barcelona, Universitat Politècnica de Catalunya, España, 2007.

Arango, M.D., Zapata, J.A. y Adarme, W., Aplicación del modelo de inventario manejado por el vendedor en una empresa del sector alimentario colombiano, Revista EIA, 15, pp. 21-32, 2011.

Gonzalez-Feliu, J., Peris-Pla, C. and Rakotonarivo, D., Simulation and optimization methods for logistics pooling in the outbound supply chain. Third International Conference on Value Chain Sustainability, Towards a Sustainable Development and Corporate Social Re- sponsibility Strategies in the 21st Century Global Market, Nov 2010, Spain, pp. 394-401, 2010.

Arango, M.D. and Zapata, J.A., Multiobjective model for the simultaneous optimization of transportation costs, inventory costs and service level in goods distribution, IEEE Latin America Transactions,. 15(1), Jan. 2017 pp. 129-136, 2017.

Arango, M.D., Zapata, J.A. and Gutierrez, D., Modeling the inventory routing problem (IRP) with multiple depots with genetic algorithms, IEEE Latin American Transactions., 13(12), pp.3959-3965, 2015.

Archetti, C., Bertazzi, L., Laporte, G. and Speranza, M.G., A branch-and- cut algorithm for a vendor-managed inventory-routing problem, Transportation Science, 41(3), pp. 382-391, 2007.

Coelho, L.C., Cordeau, J-F. and Laporte, G., Thirty years of inventory-routing, Transportation Science, 48, pp. 1-19, 2013.

Coelho, L.C. and Laporte, G., The exact solution of several classes of inventory-routing problems, Computers & Operations Research, 40(2013), pp. 558-565, 2013.

Archetti, C., Bianchessi, N., Irnich, S. and Speranza, M.G., Formulations for an inventory routing problem, Intl. Trans. in Op. Res. 21, pp. 353-374, 2014.

Zeng, Z. and Zhao, J., Study of stochastic demand inventory routing problem with soft time windows based on MDP. In: Zeng, Z., Wang, J., (eds), Advances in neural network research and applications. Lecture Notes in Electrical Engineering, 67. Springer, Berlin, Heidelberg, pp. 193-200, 2010.

Arango-Serna, M.D, Andrés-Romano, C. and Zapata-Cortés, J.A., Collaborative goods distribution using the IRP model, DYNA, 83(196), pp. 204-2012, 2016.

Campbell, A. and Savelsbergh, M.A., Decomposition approach for the inventory-routing problem. Transportation Science 38(4), pp. 488-502, 2004.

Seferlis, P. and Pechlivanos, L., Optimal inventory and pricing policies for supply chain networks. European Symposiumon Computer-Aided Process Engineering- 14, 2004.

Chen, C.L. and Lee, W.C., Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices, Computers and Chemical Engineering 28, pp. 1131-1144, 2004.

Liang, T.F., Fuzzy multi-objective production/distribution planning decisions with multi-product and multi-time period in a supply chain, Computers & Industrial Engineering, 55, pp. 676-694, 2008.

Liao, H-S., Hsieh, C-H. and Lai, P-G., An evolutionary approach for multi-objective optimization of the integrated location-inventory distribution network problem in vendor-managed inventory, Expert Systems with Applications 38, pp. 6768-6776, 2011.

Afshari, M., Sharafi, T., ElMekkawy, T. and Peng, Q., Optimizing multi- objective dynamic facility location decisions within green distribution network design. Procedia CIRP 17, pp. 675-679, 2014.

Shankar, B.L., Basavarajappa, S., Kadadevaramath, R.S. and Chen, J.C.H., A bi-objective optimization of supply chain design and distribution operations using non-dominated sorting algorithm: A case study, Expert Systems with Applications, 40, pp. 5730-5739, 2013.

Nekooghadirli, N., Tavakkoli-Moghaddam, R., Ghezavati, V.R. and Javanmard, S., Solving a new bi-objective location-routing-inventory problem in a distribution network by meta-heuristics, Computers & Industrial Engineering, 76, pp. 204-221, 2014.

Andriolo, A., Battini, D., Persona, A. and Sgarbossa, F., Haulage sharing approach to achieve sustainability in material purchasing: new method and numerical applications, Int. J. Production Economics, 164, pp. 308-318, 2015.

Pasandideh, S.H.R., Niaki, S.T.A. and Asadi, K., Optimizing a bi- objective multi-product multi-period three echelon supply chain network with warehouse reliability, Expert Systems with Applications, 42, pp. 2615-2623, 2015.

Pasandideh, S.H.R., Niaki, S.T.A. and Asadi, K., Bi-objective optimization of a multi-product multi-period three-echelon supply chain problem under uncertain environments: NSGA-II and NRGA, Information Sciences, 292, pp. 57-74, 2015.

Arango, M.D., Zapata, J.A. and Andres, C., Metaheuristics for goods distribution. Proceedings of 2015 International Conference on Industrial Engineering and Systems Management (IESM), IEEE Publications, pp. 99-107, 2015. DOI. 10.1109/IESM.2015.7380143, 2015.

Villalobos, M.A., Análisis de heurísticas de optimización para problemas multiobjetivo. PhD. Thesis, Departamento de Matemáticas. Centro de investigación y de estudios avanzados del Instituto Politécnico Nacional, Mexico, 2005.

López, J., Zapotecas, S. and Coello, C.A., An introduction to multiobjective optimization techniques. In: Ajith, A., Lakhmi, J. and Goldberg, R. (eds)., Evolutionary multiobjective optimization: theoretical advances and applications, London, Springer-Verlag, pp. 7-32, 2009.

González-Álvarez, D., Optimización multiobjetivo y paralelismo para descubrir Motifs en secuencias de ADN, PhD. Thesis, Universidad de Extremadura, Extremadura, España, 2013.

Zapata-Cortes, J.A., Optimización de la distribución de mercancías utilizando un modelo genético multiobjetivo de inventario colaborativo de m proveedores con n clientes, PhD. Thesis, Universidad Nacional de Colombia, Medellín, [en línea]. 2016. Disponible en: www.bdigital.unal.edu.co/53703/1/71366786. 2016.pdf, 2016

Arango-Serna, M.D., Zapata-Cortes, J.A. and Serna-Uran, C.A., Collaborative multiobjective model for urban goods distribution optimization, in: García-Alcaraz, J., Alor-Hernández, G., Maldonado-Macías, A., Sánchez-Ramírez, C. (eds), New perspectives on applied industrial tools and techniques. Management and Industrial Engineering. Springer, Cham, 2018.

Ford Motor Company. Ford Transit, [online]. [Date of reference: April of 2016]. 2016. Available at: http://es.ford.com/trucks/ transitvanwagon/specifications/

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Júlio César Ferreira, Maria Teresinha Arns Steiner, Osíris Canciglieri Junior, Yibing Li. (2020). Multi-objective optimization for the green vehicle routing problem: A systematic literature review and future directions. Cogent Engineering, 7(1) https://doi.org/10.1080/23311916.2020.1807082.

2. Julian Andres Zapata-Cortes, Martin Darío Arango-Serna, Conrado Augusto Serna-Úran, Hermenegildo Gil-Gómez. (2021). New Perspectives on Enterprise Decision-Making Applying Artificial Intelligence Techniques. Studies in Computational Intelligence. 966, p.463. https://doi.org/10.1007/978-3-030-71115-3_20.

3. Annisa Kesy Garside, Robiah Ahmad, Mohd Nabil Bin Muhtazaruddin. (2024). A recent review of solution approaches for green vehicle routing problem and its variants. Operations Research Perspectives, 12, p.100303. https://doi.org/10.1016/j.orp.2024.100303.

4. Mengru Shen, Nan Xu, Yi Zhou, Tianyang Li, Hongchun Zhang. (2023). Research on the design and network optimisation of the unified warehouse and distribution mode of express delivery in rural areas. International Conference on Mathematics and Machine Learning. , p.314. https://doi.org/10.1145/3653724.3653779.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2018 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.