Zootechnical and physiological performance of broilers in the final stage of growth subjected to different levels of heat stress

Desempeño zootécnico y fisiológico de pollos de engorde en la fase final de crecimiento sometidos a diferentes niveles de estrés térmico

DOI:

https://doi.org/10.15446/rfna.v71n2.71927Keywords:

Broilers, Heat stress, Animal comfort (en)Pollos de engorde, Estrés térmico, Confort animal (es)

Recibido: 20 de marzo de 2017; Aceptado: 17 de enero de 2018

ABSTRACT

The objective of this work was to study the influence of different levels of thermal stress from the environment, including comfort levels (25 °C), heat stress (28 °C), moderate heat (31 °C), high heat (34 °C) and severe heat (37 °C), on the performance of broilers in the late growth (22-42 days), housed in environmental chambers. It has been determined the physiological and behavioral parameters of chickens (weight gain (WG), day weight gain (DWG), feed intake (FI), feed conversion ratio (FC), mortality (MORT), percentage of carcass of age as body weight (BW), carcass (CAR), breast (Bre), drumstick (Drum), wings (Win)), according the specific ranges of temperature; and was calculated the Temperature Index Black Globe Humidity (BGHI), for control and evaluation of the thermal environment of the treatments. In general, birds kept in temperature between 25-28 °C, during the three last week of life, performed better than those exposed to other situations, and indicating this would be the ambient temperature to the desired setting for birds in its final phase, compared with the other treatments, including those who remained at recommended temperature as thermal comfort throughout the experimental period.

Keywords:

Broilers, Heat stress, Animal comfort.RESUMEN

El objetivo de este trabajo fue estudiar la influencia de diferentes niveles de estrés térmico del ambiente, incluyendo niveles de confort (25 °C), estrés por calor (28 °C), calor moderado (31°C), calor alto (34 °C) y calor severo (37 °C), en el desempeño de pollos de engorde en el la última fase de crecimiento (22-42 días), alojados en cámaras climáticas. Se determinaron los parámetros fisiológicos y de comportamiento de los pollos (ganancia de peso (WG), ganancia de peso diaria (DWG), consumo de alimento (FI), índice de conversión alimenticia (FC), mortalidad (MORT), porcentaje de carcasa con relación a la edad y peso corporal (BW), carcasa (CAR), pecho (Bre), muslos (Drum), alas (Win)), de acuerdo a los rangos específicos de temperatura; y se calculó el Índice de Temperatura de Globo Negro y Humedad (ITGH), para el control y evaluación térmica de los tratamientos. En general, las aves mantenidas en temperatura entre 25-28 °C, durante las tres últimas semanas de vida, se comportaron mejor que las expuestas a otras situaciones, e indicando que esta podría ser la temperatura ambiente deseada para las aves en su fase final, en comparación con los otros tratamientos, incluidos los que se mantuvieron a la temperatura recomendada como confort térmico durante todo el período experimental.

Palabras clave:

Pollos de engorde, Estrés térmico, Confort animal.Ambience in contemporary poultry is strictly related to thermal comfort of birds, which, for being homeothermic animals, have their body temperature influenced by the environment to which are exposed (Cândido et al., 2016). It is understood that the ambient temperature can influence the zootechnical performance of the poultry, such as, feed consumption, animal welfare, productivity and maintenance requirement. Thus, in countries of tropical and subtropical climates, such as Brazil, the intense solar radiation and high values of temperature and relative humidity, especially in summer, generate almost permanent thermal discomfort conditions, generating considerable economic losses, reduced performance and increased mortality (Souza et al., 2016).

Outside the comfort zone occurs decrease in productive performance, reproductive and resistance of the organism, and the extreme outside this area can be lethal. Therefore, if thermal comfort is not reached and the bird is exposed to heat stress, a situation that is quite frequent in a major part of the year, especially in the summer, there will be a drop in feed intake, weight gain, leading to worse feed conversion and higher mortality (Nazareno et al., 2011). Hence, it is very important to know the temperature limits supported by the animals, as well as those considered ideal (understood by zones of thermal comfort) for each age and physiological state.

The temperature ranges that have been used as comfort for the birds in conditions of tropical and subtropical countries like Brazil, are mainly based on data obtained from temperate regions. Thus, it is understood that the thermal comfort zones may be outdated due to changes in the genetic patterns, nutrition, environmental management and other factors, highlighting mainly mentioned acclimatization to the country conditions (Cassuce et al., 2013; Menegali et al., 2013).

By assessing broiler performance under diverse climatic conditions, Cassuce et al. (2013) noted that birds remained within a temperature range below the previously recommended as ideal in literature showed better performances. These authors also highlighted the need for refining the data on temperature ranges for comfort conditions, suggesting further investigations towards other thermal bands of the environment. Besides that, Cândido et al. (2016) found that for early stage broilers the best poultry performance and ideal comfort indices (based on Black Globe Humidity and Temperature Index) were achieved within a temperature range between mild cold and Cassuce comfort temperature, rather than those previously reported in the literature.

Therefore, in view of the above, and especially the lack of conclusive information from recent research, it is necessary to carry out a larger number of researches that investigate and determine the ideal temperature range for broiler breeding in the period from 21 to 42 days of life, growth phase or final cycle of creation. Since the maintenance of the birds in the ideal temperature range improve the production performance as well as energy savings (both in heating systems, as cooling), in poultry facilities.

The aim of this work was study the influence of different levels of environmental thermal stress in the broilers, such as comfort and heat stress light, moderate, acute and severe, on the broiler performance in the final stage of growth (21 to 42 days), housed in climatic chambers. All procedures used in this experiment were approved by the Committee on Ethics in Animal Use (CEUA) of the Federal University of Viçosa - UFV, Minas Gerais, Brazil, Protocol No. 092/2013.

MATERIALS AND METHODS

Place of experiment and climatic chambers

The experiment was conducted in Viçosa is located at latitude 20°45'S and longitude 42°52'W, with an average altitude of 712 m. The experimental phase was conducted in five climatic chambers, with the dimensions of 2.4 x 3.3 x 2.5 m (height, length and width) each, located in the experimental area of the Center for Research in Ambience and Systems Engineering Agroindustrial (AMBIAGRO) belonging the area of Rural Constructions and Ambience of the Department of Agricultural Engineering of the Federal University of Viçosa, Viçosa, Minas Gerais, Brazil.

Each climate chamber was equipped with an electric resistance air heater (with 2000 watts of power), a hot / cold split air conditioner of 12,000 BTU h-1 and an air humidifier with a capacity of 4.5 L and fog flow (mean value) of 300 mL h-1. The heater and humidifier were operated by electronic controller MT-531 R i plus of temperature and humidity (control temperature -10 to 70 °C, with resolution of 0.1 °C; control humidity 20 to 85% RH, with resolution of 0.1% RH). The ventilation applied was done by means of AMB axial fans, model FD 08025S1M DC 12V 0.15A, with automatic activation, in order to gradually allow from 01 to 06 air changes per hour during the first three weeks of Birds life and 6 to 10 air renovation per hour until the end of experiment.

Broiler management

One-day male chicks of the Cobb-vantress lineage, with average weights of 45.36 g and originating from the company Pif-Paf Alimentos.

The feed was provided freely, so that the feeders were always supplied, this management were done twice a day, at the hours of 8:00 am and 4:00 p.m. Commercial feed was given during the first week of life of the birds in a tray-type feeder and, from the second week until the end of the experiment, in gutter feeders. The drinking troughs were of the fountain type of pressure for the firsts 8 days, and later replaced for nipple drinkers. The drinkers were manually supplied at the same time of the feed supply.

The light program adopted was one hour of darkness per day in the period of one to four days of age, 9 hours of darkness per day until 21 days and 8 hours of darkness per day until 36 days. When the broilers completed 36 days old was decrease of 1 hour per day until reaching slaughter, following the recommendations by Cobb Manual (2012). For chicks used in the experimental phase, chicks from 1 day old until the end of the 3rd week of life, i.e. from 1 to 21 days, were managed according to a Cobb Manual (2012).

Experimental Phase

The experimental phase was comprised between the beginning of the 4th week until the end of the 6th week of life of the birds, that is, from 21 to 42 days of age, period classified as termination phase for broilers. The broilers were submitted to five different treatments, one representative of the thermal comfort situation as indicated by Cassuce et al. (2013), and four levels of heat stress, from mild to severe, namely:

CT: Comfort Temperature determined by Cassuse et al. (2013) (25 °C from 7:00 a.m. to 7:00 p.m. and 2 °C from 7:00 p.m. to 7:00 a.m.)

LHS: Light Heat Stress (28 °C from 7:00 a.m. to 7:00 p.m. and 2 °C from 7:00 p.m. to 7:00 a.m.)

MHS: Moderate Heat Stress (31 °C from 7:00 a.m. to 7:00 p.m. and 2 °C from 7:00 p.m. to 7:00 a.m.)

AHS: Acute Heat Stress (34 °C from 7:00 a.m. to 7:00 p.m. and 2 °C from 7:00 p.m. to 7:00 a.m.)

SHS: Severe Heat Stress (37 °C from 7:00 a.m. to 7:00 p.m. and 2 °C from 7:00 p.m. to 7:00 a.m.)

Control and evaluation of the thermal environment in the climatic chambers

The relative humidity values inside the climatic chambers for all treatments were maintained in the range of 60% ± 5%. These ranges of relative air humidity values are considered adequate for poultry production, regardless of bird age, and the ambient temperature, according to results of some studies considered by Oliveira et al. (2006) and Menegali et al. (2013).

Throughout the experimental period, the thermal data of temperature and relative humidity of the air inside the climatic chambers were recorded daily and every five minutes. For this monitoring, HOBO dataloggers model H1 were used, with the resolution of ± 0.1 °C (temperature) and 1% (humidity), and accuracy of ± 0.5 °C (temperature) and ± 1% (humidity).

Black globe temperature values were collected by TESTO dataloggers model H1, with resolution of ± 0.1 °C (temperature). The black globes were installed inside each climatic chamber, in the median height of the animals. With these values, the Black Globe Humidity Index (BGHI) were calculated for each the thermal environment inside the climatic chambers.

The BGHI were calculated according to Equation 1 (Cassuce et al., 2013):

Tbg: black globe temperature (k) Tdp: dew point temperature (k)

Parameters of zootechnical performance

The data referring to zootechnical performance were collected and recorded at 21, 28, 35 and 42 days of the broilers life (beginning and end of each experimental week), according to Cassuce et al. (2013): initial weight (g); food conversion; day weight gain (g); feed intake (g); mortality (%); and productive efficiency index or production factor - IPE (%).

The feed conversion (FC) values of the considered period (weekly) or final conversion (Equation 2), were obtained each week of research and accumulated at the end of the research, respectively.

The daily weight gain (DWG), at the end of each weekly period, was determined by means of the broiler weight difference at the beginning and at the end of the period considered (Equation 3).

The record of daily mortality (MORT) was done on the day of the event, removing the dead broilers found. Mortality, in the study period, was obtained through the usual equation of poultry management, expressed as a percentage (Equation 4).

Parameters of Yield of Carcass

Carcass, breast, drumstick and wing yield were obtained at the time of slaughter of the animals at 42 days of age and also the weights of edible viscera (gizzard, liver and heart). For this, on the day of slaughter, four birds from each experimental unit were collected at random, which were identified and weighed to obtain slaughter weight, which served as a reference for the calculation of carcass yields.

After slaughter, birds were bled-out, plucked and eviscerated, carcass yield (CY) analyzes were determined and calculated as follows (Equation 5):

Then, the breast was removed without skin and the drumstick. These cuts were weighed and the it was yield calculated in relation to the weight of the carcass, as follows (Equation 6), (Buzati, 2011).

Experimental design

The broilers were housed in four cages per climatic chamber, with the following dimensions: 1.0 m width x 0.5 m depth x 0.5 m height, with 7 birds in each cage (density of 14 broilers m-2), a zootechnical parameter frequently practiced in Brazil. Each climatic chamber was considered a treatment with 28 birds, for a total of 140 birds in the experimental phase, with average of broilers weight of 1163.9 g at 21 days old (Figure 1).

Figure 1: Experimental design of broilers distribution in the five climatic chambers

The treatments were applied under a completely randomized design with four replicates, in each climatic chamber, according to a split plot scheme. The data were analyzed using regression analysis and the models chosen based on the significance of the regression coefficient, the coefficient of determination and the biological significance of the broilers. The data were submitted to analysis of variance and the means were compared by the Tukey Test at 5%, using the statistical program SAEG.

RESULTS AND DISCUSSION

Evaluation of the thermal environment based on the BGHI

As can see from the data presented in Table 1, the values of air temperature and relative humidity of the air, obtained inside each climatic chamber, remained close to the values proposed for each thermal-environmental condition described in the methodology, indicating that the environmental thermal control of the chambers was adequate.

Table 1: Temperature values and relative humidity of the ambient air and respective BGHI values, corresponding to the final broiler period of rearing (21 to 42 days of age).

Medeiros et al. (2005) reported that BGHI values above 77 began to have a negative effect on zootechnical performance. For Oliveira et al. (2000), the maximum tolerated limit of BGHI for broilers with more than three weeks old is 76. According to Oliveira et al. (2006), the BGHI indices that typify a pleasant thermal environment for birds vary from 77 to 80 within the first week; however, such range is between 73 and 76 during the second and third weeks.

In this way, it can be inferred, based on the mentioned authors, that the conditions of MHS, AHS and SHS applied in this experiment are above the comfort limit, and CT and LHS conditions are within the limits of thermal comfort for broilers from 21 to 42 days of age.

Evaluation of the zootechnical performance of broiler chickens during the final stage of growth

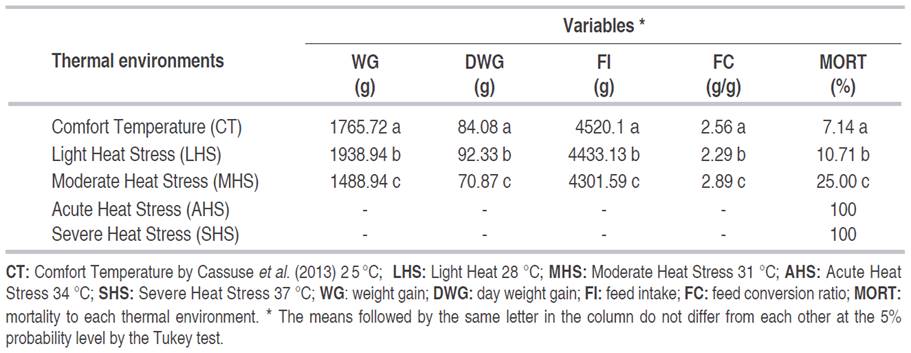

As can be observed in Table 2, there was a difference between the different treatments (thermal environments), the mean results of weight gain (WG), day weight gain (DWG), feed intake (FI), food conversion (FC) and mortality (MORT) during the final three weeks of life of the broilers.

Table 2: Comparison between the animal performance parameters related to thermal environments.

The highest body weights of the broilers represented in WG and DWG were observed at the temperature 28 °C (LHS) during the whole experimental period, indicating that the increase of 3 °C in the environmental temperature of the birds compared to that currently used in the literature (25 °C) would be feasible, as there is an improvement in the productive indexes of broilers. Thus, less energy expenditure would occur in the process of cooling the environment, this result is in agreement with the results observed by Cassuse et al. (2013), making necessary to adjust the parameters currently used for Brazilian poultry farming.

A significant reduction was observed between the day weight gain of the birds kept in the thermal environments MHS, AHS and SHS, compared to LHS and CT. Broilers kept on LHS treatment obtained better final weight gain (WG) and daily weight gain (DWG), however, the broilers kept in the LHS and CT treatment presented higher weight gain than those maintained in moderate and severe heat stress throughout the experimental period, as already observed by Medeiros et al. (2005) and Oliveira et al. (2006).

The birds kept at the environmental temperatures of CT, LHS, during the fourth, fifth and sixth weeks of life, respectively, presented higher feed intake (FI), whereas the opposite occurred in MHS, AHS and SHS treatments, with had reduction in feed intake. The reduction of the feed intake of the broilers kept in the treatments MHS, AHS and SHS is in agreement with the one exposed by Olanrewaju et al. (2010) and Cardoso (2016), who observed a reduction in the feed intake of broilers kept at high ambient temperature in relation to those kept in comfort at 42 days of age.

It can be observed that all birds maintained at MHS, AHS and SHS, presented worse feed conversion (FC) compared to those maintained in CT and LHS during the whole experimental period. It can be inferred, within the temperature ranges tested, that the ambient temperature above 31 °C for 12 hours per day is sufficient to compromise the feed conversion of the broilers, compared to those maintained under conditions of 28 °C, treatment LHS and 25 °C, treatment CT.

The worst broilers viability results occurred for the AHS and SHS treatment, where they only survived the thermal stress (temperatures above 30 °C) for two weeks reaching a mortality of 100% at 35 days of life.

Carcass yield evaluation and viscera of broilers slaughtered at 42 days of age

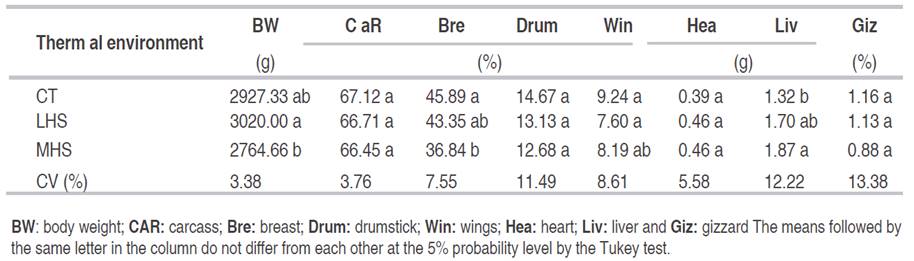

As can be seen in Table 3, significant differences were found between the treatments for the parameters body weight (BW), breast weight (Bre) and liver weight (Liv) for broilers at 42 days old. For the means carcass weight parameters CAR, drumstick (Drum), wing (Win), heart (Hea) and gizzard (Giz) no significant differences were found for none of the treatments (CT, LHS and MHS). For AHS and SHS treatments, data on carcass yield evaluation at 42 days of age are not presented, since these treatments reached 100% mortality at 35 days of age, these results coincide with the findings by Oliveira et al. (2006).

Table 3: Carcass yield evaluation of broilers slaughtered at 42 days of age.

Muller et al. (2013) found that when the broilers were submitted to different levels of heat stress (27 - and 32 °C), the animals in the first week of life showed no adaptation to heat capable of increasing production and carcass characteristics when submitted to chronic heat stress during the final rearing period, results that are according that was found in this research, mainly with the MHS treatment.

CONCLUSIONS

Considering the influence of different levels of thermal stress used in this research, it can concluded that agree with the zootechnical and physiological results found, it is feasible to increase of 3 °C in the ambient temperature of the poultry facilities in relation to the currently used (25 °C), by Brazilian literature and agribusiness, as well as by tropical and subtropical countries. Therefore, temperature ranges between 25 and 28 °C, it could lead to an improvement in the productive indexes of broiler chickens during the final phase of poultry farming.

ACKNOWLEDGMENTS

The authors thank the Brazilian governmental agencies FAPEMIG and CNPq, and the Federal University of Viçosa (UFV - Brazil).

REFERENCES

References

Buzati W, De Paula J, Da Silva T and Da C. 2011. Rendimento de carcaças de frango de corte semicaipira criados em diferentes tipos de cama e densidade. pp 1-10. Em: Memorias 4ed Congresso de Iniciação Científica. Cáceres/MT, Brasil.

Cândido M, Tinôco I, Pinto F, Santos N and Roberti R. 2016. Determination of thermal comfort zone for early-stage broilers. Engenharia Agrícola 36(5): 760-767. doi: 10.1590/1809-4430-Eng. Agric.v36n5p760-767/2016

Cardoso N. 2016. Desempenho, descrição do crescimento e produção de calor de frangos de corte de três linhagens comerciais. Tese Doutor em Ciência Animal. Pós-Graduação Em Ciência Animal. Universidade Federal Do Piauí. Brazil. 111 p.

Cassuce D, Tinôco I, Baêta F, Zolnier S, Cecon P and Vieira M. 2013. Thermal comfort temperature update for broiler chickens up to 21 days of age. Engenharia Agrícola 33(1): 28-36. doi: 10.1590/ S0100-69162013000100004

Cobb Vantress. 2012. Manual de manejo de fragos de corte. Em: Cobb Vantress. Suplemento de desempenho e nutrição para frangos de corte, http://wp.ufpel.edu.br/avicultura/files/2012/04/ Cobb-Manual-Frango-Corte-BR.pdf. 13 p.; consulta: diciembre 2015.

Medeiros C, Baêta F, Miranda R, Tinôco I, Albino L and Cecon P. 2005. Efeitos de temperatura, unidade relativa e velocidade do ar em frangos de corte. Revista Engenharia na Agricultura 9(4): 277- 286.

Menegali I, Tinoco I, Carvalho C, Souza C and Martins J. 2013. Comportamento de variáveis climáticas em sistemas de ventilação mínima para produção de pintos de corte. Revista Brasileira de Engenharia Agrícola e Ambiental 17(1): 106-113. doi: 10.1590/ S1415-43662013000100015

Müller J, Boareto L, Thaísa E, Burin A, Marques F and Gruchouskei L. 2013. Thermal conditioning during the first week on performance, heart morphology and carcass yield of broilers submitted to heat stress. Acta Scientiarum. Animal Sciences 35(3): 311-319. doi: 10.4025/actascianimsci.v35i3.18707

Nazareno A, Pandorfi H, Guiselini C, Vigoderis R and Pedrosa E. 2011. Bem-estarna produção de frangos de corte em diferentes sistemas de criação. Engenharia Agrícola 31(1): 13-22. doi: 10.1590/ S0100-69162011000100002

Olanrewaju H, Purswell J, Collier S and Branton S. 2010. Effect of ambient temperature and light intensity on growth performance and carcass characteristics of heavy broiler chickens at 56 days of age. International Journal of Poultry Science 9(8): 720-725. doi: 10.3923/ijps.2010.720.725

Oliveira R, Donzele J, Abreu M, Ferreira R, Vaza R and Cella P. 2006. Efeitos da temperatura e da umidade relativa sobre o desempenho e o rendimento de cortes nobres de frangos de corte de 1 a 49 dias de idade. Revista Brasileira de Zootecnia 35(3): 797- 803. doi: 10.1590/S1516-35982006000300023

Oliveira Neto A, Oliveira R, Donzele J, Rostagno H, FerreiraR, Maximiano H and Gasparino E. 2000. Efeito da temperatura ambiente sobre o desempenho e características de carcaça de frangos de corte alimentados com dietas controladas e dois níveis de energia metabolizável. Revista Brasileira de Zootecnia 29(1): 183-190. doi: 10.1590/S1516-35982000000100025

Souza M, Tinôco I, Amaral A, Inoue K, Barreto L, Savastano Junior H, Souza C and Paula M. 2016. Thermal comfort zones for starter meat-type quails. Brazilian Journal of Poultry Science 16(3):265-272. doi: 10.1590/1516-635x1603265-272

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

CrossRef Cited-by

1. Wellington Luis Reis Costa, Emília Turlande Sêneca Ribeiro dos Santos, Moara de Santana Martins Rodgers, Lia Muniz Barretto Fernandes, Elmiro Rosendo do Nascimento. (2023). Salmonella spp. in non-edible animal products: a burden on the broiler industry. Brazilian Journal of Food Technology, 26 https://doi.org/10.1590/1981-6723.14622.

2. Yangyang Hu, Weiyun Zhang, Ke Yang, Xi Lin, Hsiao-Ching Liu, Jack Odle, Miles Todd See, Xiaoyan Cui, Tingting Li, Shengchen Wang, Xiudong Liao, Liyang Zhang, Sufen Li, Yun Hu, Xugang Luo. (2024). Dietary Zn proteinate with moderate chelation strength alleviates heat stress-induced intestinal barrier function damage by promoting expression of tight junction proteins via the A20/NF-κB p65/MMP-2 pathway in the jejunum of broilers. Journal of Animal Science and Biotechnology, 15(1) https://doi.org/10.1186/s40104-024-01075-8.

3. Lucas Henrique Pedrozo Abreu, Tadayuki Yanagi Junior, Marcelo Bahuti, Renato Ribeiro De Lima, Dian Lourençoni, Édison José Fassani. (2019). Performance of broilers submitted to different intensities and duration of thermal stress. DYNA, 86(211), p.131. https://doi.org/10.15446/dyna.v86n211.79465.

4. Sara Lamari. (2023). Evaluation of the zootechnical performance of broiler chicken at the level of different types of breeding in Algeria. Algerian Journal of Biosciences, 4(1), p.021. https://doi.org/10.57056/ajb.v4i1.107.

Dimensions

PlumX

Article abstract page views

Downloads

License

Copyright (c) 2018 Revista Facultad Nacional de Agronomía Medellín

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The journal allows the author(s) to maintain the exploitation rights (copyright) of their articles without restrictions. The author(s) accept the distribution of their articles on the web and in paper support (25 copies per issue) under open access at local, regional, and international levels. The full paper will be included and disseminated through the Portal of Journals and Institutional Repository of the Universidad Nacional de Colombia, and in all the specialized databases that the journal considers pertinent for its indexation, to provide visibility and positioning to the article. All articles must comply with Colombian and international legislation, related to copyright.

Author Commitments

The author(s) undertake to assign the rights of printing and reprinting of the material published to the journal Revista Facultad Nacional de Agronomía Medellín. Any quotation of the articles published in the journal should be made given the respective credits to the journal and its content. In case content duplication of the journal or its partial or total publication in another language, there must be written permission of the Director.

Content Responsibility

The Faculty of Agricultural Sciences and the journal are not necessarily responsible or in solidarity with the concepts issued in the published articles, whose responsibility will be entirely the author or the authors.