Physical-chemical characteristics determination of potato (Solanum phureja Juz. & Bukasov) starch

DOI:

https://doi.org/10.15446/acag.v66n3.52419Palabras clave:

Functional properties, gelatinization, native potato, starch gelatinization transition, thermal characteristics (en)Functional properties, gelatinization, native potato, starch gelatinization transition, thermal characteristics. (es)

Descargas

The aim of this research was to evaluate the functional properties of the native potato (Solanum phureja Juz. & Bukasov) starch in the food and non-food industry for which a thermal analysis was conducted, including thermogravimetric (TGA) analysis, differential scanning calorimetry (DSC) analysis, X-ray diffraction (XRD) analysis, morphologic analysis via scanning electron microscopy (SEM), and rapid viscoamylograph analysis (RVA). The RVA analysis showed that gelatinization temperature was 63.95 °C, the maximum viscosity was 1087 cP and ease of cooking was 7 min. The thermogravimetric (TGA) analysis revealed three stages: in the first, the product had weight loss of 9.51%; in the second, a weight loss of 53.88%; and in the third, a weight loss of 37.91%. The differential scanning calorimetry (DSC) analysis found that heat flux initiates at 50.97 °C, where the starch gelatinization transition starts, ending at 71.25 °C with enthalpy of 2.11 J.g-1. Evaluation of the native potato starch demonstrated that this product is an excellent alternative in the elaboration of different products which need a thickener in cooking processes, given that its behavior at high temperatures, which have allowed to maintain its structure.

Recibido: 10 de agosto de 2015; Aceptado: 16 de febrero de 2016

Abstract

The aim of this research was to evaluate the functional properties of the native potato (Solanum phureja Juz. & Bukasov) starch in the food and non-food industry for which a thermal analysis was conducted, including thermogravimetric (TGA) analysis, differential scanning calorimetry (DSC) analysis, X-ray diffraction (XRD) analysis, morphologic analysis via scanning electron microscopy (SEM), and rapid viscoamylograph analysis (RVA). The RVA analysis showed that gelatinization temperature was 63.95 °C, the maximum viscosity was 1087 cP and ease of cooking was 7 min. The thermogravimetric (TGA) analysis revealed three stages: in the first, the product had weight loss of 9.51%; in the second, a weight loss of 53.88%; and in the third, a weight loss of 37.91%. The differential scanning calorimetry (DSC) analysis found that heat flux initiates at 50.97 °C, where the starch gelatinization transition starts, ending at 71.25 °C with enthalpy of 2.11 J.g-1. Evaluation of the native potato starch demonstrated that this product is an excellent alternative in the elaboration of different products which need a thickener in cooking processes, given that its behavior at high temperatures, which have allowed to maintain its structure.

Keywords:

Functional properties, gelatinization, native potato, starch gelatinization transition, thermal characteristics.Resumen

El objetivo de esta investigación fue evaluar las propiedades funcionales del almidón de papa nativa (Solanum phureja Juz. & Bukasov) en la industria alimentaria y no alimentaria para la cual se realizó un análisis térmico, incluyendo análisis termo gravimétrico (TGA), análisis de calorimetría diferencial de barrido (DSC), Análisis de difracción de rayos X (XRD), análisis morfológico a través de microscopía electrónica de barrido (SEM) y análisis rápido de viscoamilografía (RVA). El análisis RVA mostró que la temperatura de gelatinización era de 63.95ºC; La viscosidad máxima fue de 1087 cP y la facilidad de cocción fue de 7 min. El análisis termo gravimétrico (TGA) reveló tres etapas: En la primera, el producto tenía una pérdida de peso del 9.51%; En la segunda, una pérdida de peso del 53.88%; y en la tercera, una pérdida de peso del 37.91%. El análisis de calorimetría diferencial de barrido (DSC) encontró que el flujo de calor comienza a 50.97 ° C, donde inicia la transición de gelatinización del almidón, terminando a 71.25 ° C con entalpía de 2.11J.g-1. La evaluación del almidón de papa nativa, demostró que este producto es una excelente alternativa en la elaboración de diferentes productos que necesitan un espesante en los procesos de cocción, dado que su comportamiento a altas temperaturas han permitido mantener su estructura.

Palabras clave:

Características térmicas, gelatinización, papa nativa, propiedades funcionales, transición de gelatinización de almidón.Introduction

Currently, diverse products are found in the market that use flour and starch from as raw material. It is common to find a large amount of products elaborated from wheat and corn flour, given that their characteristics and behavior are known, while flours from other non-conventional sources are not as well known. Flours and starches existing in the market are used to elaborate bakery products, instant soups, meal, and are used as thickeners, for breading, frying, and in confectionery, among others (Lucas et al., 2013).

Corn starch is used most widely at industrial and household levels, given its high extraction yield and because of many hybrids exist and permit obtaining starches with different thermal and functional characteristics. In recent years, much research has been conducted to produce information about the behavior of starches extracted from non-commercialized sources (Chao-Q, et al., 2015).

The native potato (Solanum Phureja Juz. & Bukasov ) is a diploid tuber, meaning it has two equal or homologous chromosomes and that it can reproduce sexually, whose advantages are that if a parental has flaws in its DNA, the other can compensate. This plant tends to perpetuate because of the support from said diploid is cultivated in Colombia, mainly in the departments of Nariño, Boyacá, and Cundinamarca. It corresponds to 10% of the potatoes cultivated in Colombia. It is commonly used in the soups preparation, fried products, and purees due to its high starch content, ranging between 70 and 85% in dry weight. Compared to cereals, potato has a higher amount of protein (2.8 -14.6% in dry matter), with high content of essential amino acids (lysine, methionine, tryptophan). It also has a high content of micronutrients, such as vitamins (C and B complex), minerals (potassium, magnesium, calcium, phosphorus, and iron), colorants (anthocyanin and carotenoids), and phenolic antioxidants (Eun-Jung Kim & Hyun-Seok Kim, 2015).

A study conducted by the Colombian Federation of Potato Producers (Giraldo, 2009), shows for 2006, the production of native potato in the Cundinamarca and Boyacá plateau was 13 t per ha. In Nariño, it was 15 t and in Antioquia, 13 t. For 2007, the production in the Cundinamarca and Boyacá plateau, dropped to 12 t per ha, while in Nariño department increased to 18 t and in Antioquia department maintained the production at 13 t.

Starch from other potatoes, like that extracted from Solanum tuberosum L., has been reported by other authors (Rajarathnam, 2011) due to its functional and physical-chemical characteristics, like low gelatinization temperature, low tendency to retrograde, low in waxy solids, slight cereal flavor, high viscosity, high swelling ability and high solubility.

The aim of this research was to evaluate thermal and functional characteristics of the flour and starch from native potato (Solanum phureja Juz. & Bukasov).

Materials and methods

Raw material preparation

The native potato was obtained at a local market in the city of Armenia-Quindio, Colombia, which is located at 1640 m. a. s. l. The material was washed, weighed, peeled and sliced into 1-mm thick portions. The slices were weighed before drying them and then placed in an air recirculation-drying oven (Memmert UL40) at 45 °C during 48 h. For starch extraction, the traditional method was used, which consisted in adding water to the banana slices in a 1:1 ratio, prior to blending at 6000 rpm during 1 min and passed through a 100-μm mesh, with addition of abundant distilled water. The mixture was centrifuged at 10000 rpm during 1 min at 25 ºC. The precipitate was filtered through a membrane with 100-μm pore size and the filtrate containing the starch was dried in a recirculation stove (Memmert UL40, Germany) at 40 ºC for 48 h (Dufour et al., 2009).

Proximal Analysis

Humidity content was determined via Official Method AOAC 925.10 (2005); ash content was obtained by following Official Method AOAC 923.03 (2005); fiber for the flour was determined through Official Method AOAC 991.42 (2005) and Official Method AOAC 985.29 (2005), was used for starch. Fat was quantified throughout Official Method AOAC 922.06 (2005), and proteins amount via Official Method AOAC 960.52 (2005) (Lucas et al., 2013).

Physical and Thermal Characterization

Differential scanning calorimetry (DSC). Temperature determination [Tp(°C)] and gelatinization enthalpy [(Hp(J.g-1)] was carried out in TA Instruments DSC-Q100 equipment in samples of 10.00 ± 0.50 mg with 80% humidity content for a heating rate of 5°C.min-1, from room temperature to 100°C, in nitrogen atmosphere (Pineda-Gómez et al., 2011).

Thermogravimetric analysis (TGA). This analysis was performed on TA Instruments TGA Q500 equipment in presence of nitrogen atmosphere for a range from ambient temperature to 800 °C, with a heating rate of 5°C.min-1 in samples of 6 ± 0.50 mg (Pineda-Gómez et al., 2011).

X-ray diffraction. The samples were reduced to a fine dust and passed throughout a mesh with pore size of 150 µm. Thereafter, they were densely packed in an aluminum container. X-ray diffraction patterns were obtained using a Bruker D8 advance diffractometer, with radiation line Cu Kα (l=1.5 5418 Å), with a potential difference of 30 kV and current density of 20 mA. The samples were placed in the equipment with a 0.050 angular step between 5 and 40 degrees (2θ) and 15s count time per angular step. The material was placed on a 30-mm X 30-mm aluminum sample kept at room temperature and low humidity (Pineda-Gómez et al., 2011).

Scanning electron microscopy (SEM). Morphology was determined with a scanning electron microscope (JEOL, Model JSM-6060LV, Japan) with high vacuum and 5-nm resolution in high-voltage mode. Analyses were performed at 20 kV accelerated electron voltage and 12-20 Pa chamber pressure on samples, obtaining images on fracture surfaces with the secondary electron signal (Lucas et al., 2013).

Rapid viscosity analysis (RVA). A solution was prepared at 7% starch without α amylase inhibitor. An RVA-4 rapid visco-analyzer (Newport, Australia) was used. The solution was heated from 50 to 90°C with constant agitation and a heating rate of 6 °C/min, after this, temperature was maintained at 90 °C during 5 min and, finally, it was cooled to 50°C at a rate of 6°C.min-1(Lucas et al., 2013).

All the procedures were conducted in triplicate and unilateral variance analysis at 95% confidence to process the obtained data.

Results and discussion

Proximal Analysis

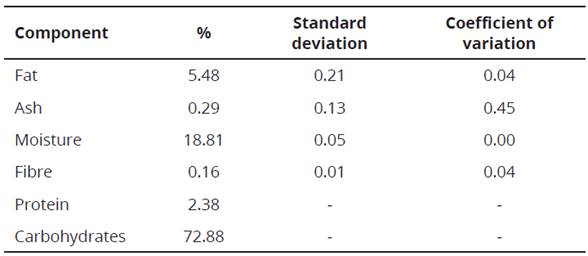

Table 1, shows the physical-chemical composition of the native potato starch.

Upon comparing the proximal analysis results of the native potato starch to results from a research of cassava starch conducted by Alvis et al. (2008), differences were found in all the tests performed, with significant differences in humidity, fat, and protein tests. The values reported by the authors (humidity 8.47; fat 0.31; protein 0.60) are lower than those found in this research.

Table 1: Physicochemical properties of potato starch (Solanum phureja)

Another study conducted by Alvis et al. (2009), in wheat starch, which was compared to the native potato starch, found that differences exist in the humidity, protein, and fat percentages, but said differences are not as big as those of the cassava starch.

Morphologic analysis

The SEM micrographs of the native potato starch (Figure 1), show granule agglomeration by sections, similar to the starch structure. These micrographs were taken from two different locations. Those on the left column are equatorial perspective micrographs, while those on the right column are of transversal perspective, which permits observing the starch granules from different points to have a clearer idea of their morphology in general.

Figure 1: Potato (Solanum phureja) starch micrographs

The granule shape of the native potato starch and its distribution are quite different with respect to that reported for amaranth starch (Yadav et al., 2006), which has an irregular granule shape but with a spherical shaped distribution. In another study, arracacha (Arracacia xanthorrhiza Bancr.) starch (Rodríguez et al., 2005), being another tuber, differs in all its morphology from the native potato starch.

In studies on starches where SEM analysis is used, great similarity can be seen in the starch granules from native potato with respect to the native potato starch in which the morphologic characteristics reported by Yadav (2006), and Lee (2015), indicate this big similarity for these two tubers.

Previous studies, evaluating the behavior of flours throughout X-ray diffraction analysis, show the results difference of this analysis applied to flours from cereals, like wheat, reported by Saiah et al. (2009). Note that the behavior of diffractogram is type A, with different peaks and intensity with respect to the results for native potato, thus, elucidating the differences they have with respect to compounds between the tubers and cereals.

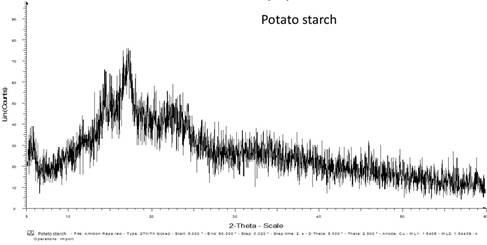

X-ray diffraction analysis

Figure 2, presents the native potato starch diffractogram, which shows type B shape. The diffractogram (Figure 2), shows a semi-crystalline structure with peaks at 17°, 19°, and 22° approximately, according to Dündar et al. (2009), and Lee (2015), who report a diffractogram for potato starch (Solanum tuberosum L.), revealing important similarities with respect to the native potato starch, thus, establishing the same properties could be present in these two starches.

Figure 2: Potato starch diffractogram

A study conducted by Konishi et al. (2006), on amaranth starch reports a diffractogram which presents an approximation of potato starch results. Thus, by comparing the XRD results for a starch from a tuber, like native potato, with another tuber, like potato (Solanum tuberosum L.), and a cereal, like amaranth (Amaranthus mantegazzianus Pass.), which show great similarity in their crystallinity, it could be said the starch obtained from these three elements could have equal properties.

In addition, by comparing the flour and native potato starch diffractograms, which have peaks in nearby positions, varying only the peak intensity, which is why similarity is observed between the flour and starch samples. This could be explained as the majority presence of starch in the flour sample, given the other elements which comprise it do not have these marked crystalline characteristics (Konishi et al., 2006; Dündar et al., 2009).

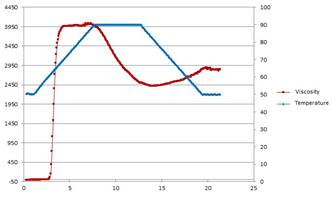

Rapid viscoamylograph analysis (RVA)

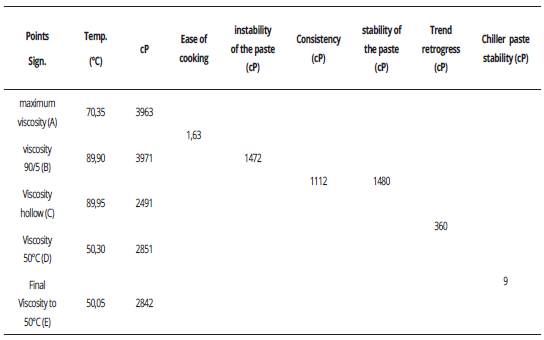

Table 2, shows the results for the RVA test (Figure 3) performed on native potato starch. For the starch, time and temperature of gelatinization start was 2.76 min and 60.59°C; the maximum viscosity was 3963 cP, at 70.35°C, reached at approximately 4.39 min, with this being a big opposing force of the starch paste, which corroborates the thickening sample capacity, as previously mentioned.

Table 2: RVA analysis data of potato starch (S. phureja).

A study of different starches conducted by Alvis et al. (2008), reports very low values of different starches from tubers compared to those obtained for native potato starch, thus, yielding the idea of the great thickening capacity of the native potato starch.

Paste viscosity was 3971 cP, at 89.90°C and time close to 8 min, thereby, necessitating very little time between phases, losing a bit of its viscosity, which translates into free swelling of its granules in the paste by being composed mainly of starch.

With relation to ease of cooking, with 1.63 min in said parameter, it does not permit industrial use in foods that need to be sterilized, without it losing its characteristics, given that its starch granules can solubilize more rapidly and alter their consistency.

Instability of the gel for the starch is quite high due to the large amount of amylose molecules, which make its leaching process and most of the granules break, thus, lowering its viscosity. For the native potato starch the value was 1472 cP, which translates into major swelling ability of the granule and high fragility when breaking when its viscosity drops.

A research conducted by Messager & Despre (2004), on wheat starch reports that when compared to native potato starch it presents very low results in all the RVA analysis phases, differences due to the sample nature, understanding their different uses. The native potato starch showed that viscosity at the end of the first maintenance period was 2491 cP, at 89.95°C, in 12.70 min. The drop in viscosity is due to the rupture of the starch granules, because of their swelling, permitting their solubilization after the rupture due to release of water in the paste.

Stability of the paste during cooking was 1480 cP due to the solubility of the granules in the paste, given that after its rupture, its water permits the granules to be oriented in the same direction the paste is being agitated, demonstrating its fragility to mechanical action and to the applied thermal action. Viscosity of the paste of the native potato starch cooked and cooled was 2851 cP, at 50.30 °C, in 19 min, approximately. The low viscosity is because the starch granules, although their retrogression capacity was at 360 cP, are not all capable of returning to their natural state due to their rapid destruction. Also noted is the high consistency at 1112 cP, which represents loss, during the cooking and cooling process, of viscosity that starch granules do not manage to recover.

Viscosity at the end of the second maintenance period was at 2845 cP at 50.05 °C in 21 min, showing another slight decrease in viscosity. By evaluating the stability of the paste during this maintenance period, which was at 9 cP, it indicates that after all the analysis phases starch is more stable after cooking when maintained at 50°C. Comparing the results obtained for the flour and native potato starch samples, the difference can be observed between the viscosities given for each sample (Table 3), representing the freedom of the starch granules, given that they are not found with other compounds and can swell freely.

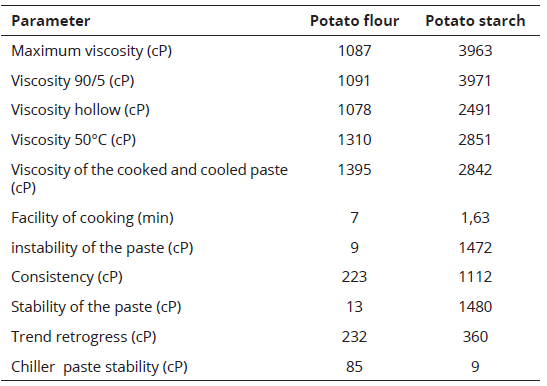

Table 3: Comparison of the results of the RVA analysis for flour and potato starch (S. phureja)

The tendency for flour to retrograde with respect to starch is quite low, but considering that in flour there is little separation of the granules, it has a large capacity for said granules to return to their natural state. In starch, most of these granules do not have the capacity to re-associate due to their rupture after water absorption (Yadav, 2006).

The times and temperatures of gelatinization initiation are similar (63.95 °C and 3.33 min for flour and 60.59°C and 2.76 min for starch), indicating that the starch present in the flour has the same behavior as the isolate.

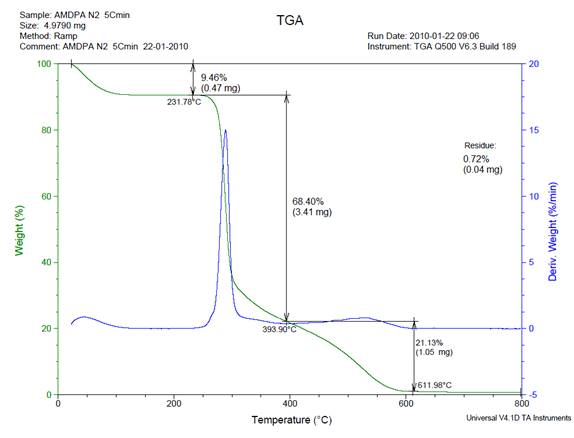

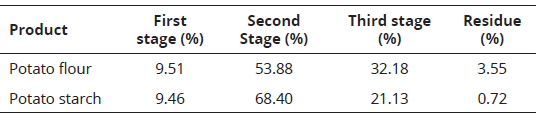

Thermogravimetric analysis

Figure 4, is the thermogram for the native potato starch, which shows a more stable degradation behavior than the native potato flour. Starch behaves similar to the analysis performed for the native potato flour (Figure 4).

Figure 4: TGA graphics

The first stage, shows elimination of water contained by sample, which is 9.46% (0.47 mg) increased at room temperature of the sample to 231.78°C. The second stage, shows the degradation of a large percentage of the sample, 68.40% (3.41 mg), between the temperature intervals from 231.78 to 393.90°C, an interval in which most of the starch is degraded. The third stage, is where combustion of the other components, 21.13% (1.05 mg), takes place recombined with the inorganic part (fat, protein), in increased temperature from 393.90 to 611.98 °C. The residue at 0.72% (0.04 mg) indicates sample purity, which means that it is mostly starch.

Studies on corn starch by Dries et al. (2014), present a thermogram which evidences the big similarity in loss percentage, discerning considerably from the rate of loss, with the native potato starch being higher than the rate of loss of corn starch.

Another study conducted on potato starch by Hongjia et al. (2013), reports a thermogram with a similar behavior with respect to the loss percentages and a rate of loss lower than the native potato starch. A study shows a cassava starch thermogram (Yaoqi, 2011) in which the difference between the loss percentages and the rate of loss are not significant to those of the native potato. Hence, we may say they behave similarly.

By comparing the thermograms of the different starches, agreement is noticed based on the starch components, given that the percentages of loss are quite similar. Therefore, it could be said that they would have similar behaviors for their use in the different uses of the starches. (Dries et al., 2014; Hongjia et al., 2013; Yaoqi et al., 2011). In addition, with these being so similar with respect to their components, the same cannot be said for their stability, given that the loss rates are quite different except for the starches from cassava and native potato, which would limit the use of some of these starches, depending on the temperature to which they will be subjected during their utilization process.

Comparison of the flour and native potato starch (Table 4), shows similarity in water retention capacity of starch and native potato flour, the difference between carbohydrate degradation - given its higher presence in starch, which translates into a higher loss percentage in starch than in flour, and the purity of the native potato starch sample, compared to that of native potato flour - given that the starch residue is less than 1%.

Table 4: Mass loss percentages for flour and potato starch, calculated by TGA

Figure 4, also presents the rate of weight loss, with that of starch (15%/min) being three times faster than that of flour (4.80%.min-1) due to the presence of a higher amount of carbohydrates which degrade during the second stage of the analysis, although flour shows another peak of high rate of loss of 2.50%.min-1, where other types of compounds (inorganic) present in the sample would be eliminated.

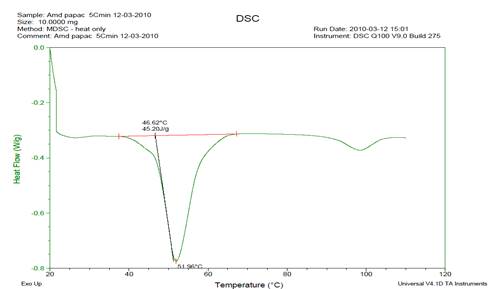

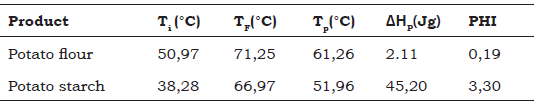

Differential scanning calorimetry analysis

Figure 5, shows the thermogram of differential scanning calorimetry test for the native potato starch.

Figure 5: DSC thermogram for potato starch (S. phureja)

This thermogram reveals the behavior of the sample receiving heat, evidencing an endothermic peak with a minimum at 51.96 °C and enthalpy of 45.20 J.g-1, which occurred in the temperature interval of 28.69°C. The mean temperature where the gelatinization transition starts is at 46.62°C. Starch purity can be seen through these results, given that much energy was needed for the gelatinization process. In studies by Sandhu & Singh (2007), of different types of corn starch temperatures are significantly above those in this research, while the obtained enthalpy for native potato is nearly four times above those reported for corn starch from different varieties.

The maximum peak index is similar to that reported by Sandhu & Singh (2007), given that the differences among the related data enthalpy and the temperature interval are big, thus, equating the differences and giving a similar PHI within a gelatinization temperature range of 39.68°C, while the ranges reported in the prior study are almost four times lower.

A study on amaranth starch (Konishi et al., 2006), reports temperatures above those obtained for native potato starch, but enthalpy is much lower; hence, the maximum peak index for amaranth starch is much lower than native potato starch in a significantly lower temperature range.

Another study conducted by Le Corre et al. (2012), reports the DSC results for cassava starch; the peak temperature (118°C) and enthalpy (488.90 J.g-1) are higher than those obtained for native potato starch, thus, the cassava starch had higher ease of gelatinization.

Comparison of the results of the DSC analysis of the flour and native potato starch amongst each other, bearing in mind that the starch gelatinization transition depends on time and temperature to which the sample is subjected, responds to the amount of starch present in the sample. This is why the native potato flour needs more time and temperature for starch gelatinization, requiring much lower energy for this process and, thereby, a lower starch gelatinization index than the native potato starch (Table 5). (Dufour et al., 2009).

Table 5: Comparison of DSC results flour and starch potato (Solanum phureja)

Conclusion

Evaluation of the native potato starch demonstrated that this product is an excellent alternative in the elaboration of different products that need a thickener in cooking processes because its behavior at high temperatures allows it to maintain its structure. This is confirmed by viscosity analyses (RVA), TGA, and DSC, given its low water absorption during heating processes, important water retention capacity, and knowing that it needs more time and temperature to undergo the phase change of the native potato starch. The native potato starch, according to data obtained in this research, could be used as an additive in different industries, like the meat industry, given its semi-crystalline structure with a diffraction pattern similar to soluble starches, corroborated via the high water retention capacity of this starch. In addition, this starch may be used as a biodegradable polymer for packing, given its low water absorption

References

Referencias

Alvis, A., Vélez, C., Villada, H., & Rada-Mendoza, M. (2008). Análisis físico-químico y morfológico de almidones de ñame, yuca y papa y determinación de la viscosidad de las pastas. Información tecnológica, 19(1) ,19-28.

Chao-Q, Li X, Ji N, Yang- Q, Qingjie S. & Xiong, L. (2015). Rheological properties and microstructure characterization of normal and waxy corn starch dry heated with soy protein isolate. Food Hydrocolloids, 48, 1-7. http://dx.doi.org/10.1016/j.foodhyd.2015.01.030

Dries, D.M., Gomand, S.V., Goderis, B., & Delcour, J.A. (2014). Structural and thermal transitions during the conversion from native to granular cold-water swelling maize starch. Carbohyd Polym, 114(19), 196-205. http://dx.doi.org/10.1016/j.carbpol.2014.07.066

Dufour, D., Gibert, O., Giraldo, A., Sánchez, T., Reynes, M., Pain, J.P., González, A., Fernández, A., & Díaz, A. (2009). Differentiation between cooking bananas and dessert bananas. 2. Thermal and functional characterization of cultivated Colombian Musaceae (Musa sp.). J Agric Food Chem, 57(17), 7870 - 7876. http://dx.doi.org/10.1021/jf900235a

Dündar, E., Yusuf, T., & Blaurock, A. (2009). Large scale structure of wheat, rice and potato starch revealed by ultra-small angle X-ray diffraction.

Int J Biol Macromol, 45(2), 206-212.

http://dx.doi.org/10.1016/j.ijbiomac.2009.05.002

Eun-Jung, K., & Hyun-Seok, K. (2015). Physicochemical properties of dehydrated potato parenchyma cells with ungelatinized and gelatinized starches. Carbohyd Polym, 117, 845-852. http://dx.doi.org/10.1016/j.carbpol.2014.10.038

Giraldo, C. M. (2009). Estudio de prefactibilidad para el montaje de una planta procesadora de papa criolla de carácter mixto en el departamento de Cundinamarca.

Hongjia, L., Yu- G, Longhui, Z. & Xiong, L. (2013). Morphological, crystalline, thermal and physicochemical properties of cellulose nanocrystals obtained from sweet potato residue. Food Res Int, 50(1), 121-128. http://dx.doi.org/10.1016/j.foodres.2012.10.013

Lee, J. C. & Tae- Wha, M. (2015). Structural characteristics of slowly digestible starch and resistant starch isolated from heat–moisture treated waxy potato starch. Carbohyd Polym, 125, 200-205. http://dx.doi.org/10.1016/j.carbpol.2015.02.035

Konishi, Y., Arnao, I. & Calixto, R. (2006). Caracterización del almidón de Amaranthus caudatus por barrido calorimétrico diferencial. Rev Soc Quím Perú, 72(1), 12-18.

LeCorre, D., Bras, J. & Dufresne, A. (2012). Influence of native starch's properties on starch nanocrystals thermal properties. Carbohyd Polym, 87(1), 658-666. http://dx.doi.org/10.1016/j.carbpol.2011.08.042

Lucas-Aguirre, J., Quintero-Castaño, V. D. & Cárdenas- Valencia, C. A. (2013). Caracterización de harina y almidón obtenidos a partir de plátano guineo AAAea (Musa sapientum L.). Acta Agron, 62(2), 83 - 96.

Messager, A. & Despre, D. (2004). Harinas y almidones con muy alto contenido en amilopectina, sus procedimientos de preparación y sus aplicaciones. Certificado de Patente. ES 2 202 084 T3. pp. 25. http://www.espatentes.com/pdf/2202084_t3.pdf.

Pineda - Gómez, P., Coral, D. F., Ramos - Rivera, D., Rosales - Rivera, A. & Rodríguez - García, M. E. (2011). Thermo-alkaline treatment. A process that changes the thermal properties of corn starch. Procedia Food Sci, 1, 370–378. http://dx.doi.org/10.1016/j.profoo.2011.09.057

Rajarathnam, E. & Narpinder, S. (2011). Use of potato flour in bread and flat bread, chapter 23. In: flour and breads and their fortification in health and disease prevention. pp. 247-259. http://dx.doi.org/10.1016/b978-0-12-380886-8.10023-6

Rodríguez, D., Espitia, M., Caicedo, Y., Córdoba, Y., Baena, Y. & Mora, C. (2005). Caracterización de algunas propiedades fisicoquímicas y farmacotécnicas del almidón de arracacha (Arracacia xanthorriza). Rev Colomb Cienc Quím Farm, 34(2), 140-146.

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Anusha, Baishali Das, Nirmal Mazumder. (2024). Advanced Research in Starch. , p.185. https://doi.org/10.1007/978-981-99-9527-1_6.

2. Preiti Deol, Mitali Madhumita, Piyush Verma, Amit Kumar, Ravinder Kaushik, Chin Wei Lai. (2025). Recent Advances in Polysaccharide‐Based Edible Films Using Natural Extracts and Their Potential Food Applications. Journal of Food Science, 90(12) https://doi.org/10.1111/1750-3841.70737.

3. Stephano Tambo Tene, Julie Mathilde Klang, Serge Cyrille Ndomou Houketchang, Gires Teboukeu Boungo, Hilaire Macaire Womeni. (2019). Characterization of corn, cassava, and commercial flours: Use of amylase‐rich flours of germinated corn and sweet potato in the reduction of the consistency of the gruels made from these flours—Influence on the nutritional and energy value. Food Science & Nutrition, 7(4), p.1190. https://doi.org/10.1002/fsn3.902.

4. Guillermo Arrazola. (2020). Propiedades fisicoquímicas y funcionales del almidón obtenido de dos variedades de batata (Ipomoea batatas). Biotecnología en el Sector Agropecuario y Agroindustrial, 19(1), p.117. https://doi.org/10.18684/BSAA(19)117-127.

5. Hafiz Usama Noor, Muhammad Tauseef Sultan, Muhammad Usman Khalid, Muhammad Hamdan Rashid, Shahzaib Noor, Muhammad Abrar, Ahmad Raza. (2026). Comparative Evaluation of Modified Mango Kernel Starch Properties Using Principal Component Analysis. Starch - Stärke, 78(2) https://doi.org/10.1002/star.70178.

6. Amanda Cantos Lopes, Juliano Tadeu Vilela de Resende, José Machado, Edson Perez Guerra, Nathalia Vilela Resende. (2018). Alcohol production from sweet potato (Ipomoea batatas (L.) Lam.) genotypes in fermentative medium. Acta Agronómica, 67(2), p.231. https://doi.org/10.15446/acag.v67n2.65321.

7. Yajnadutta Swain, Sushanta Kumar Badamali. (2020). Microwave assisted synthesis and spectroscopic characterisation of diphenyl carbonate functionalised nanoporous starch. Journal of Polymer Research, 27(10) https://doi.org/10.1007/s10965-020-02277-0.

8. Diana Melisa Chaves-Morillo, Diego Fernando Mejía-España. (2022). Physicochemical and Technofunctional Comparison of Starch from Varieties of Native Potato (Solanum Phureja) with Commercial Starches. TecnoLógicas, 26(56), p.e2455. https://doi.org/10.22430/22565337.2455.

9. Mary L. Parker, Peter Ryden, Peter J. Wilde, Cathrina H. Edwards. (2021). A Simple and Effective Method for Observing Starch in Whole Plant Cells and in Raw and Processed Food Ingredients. Starch - Stärke, 73(3-4) https://doi.org/10.1002/star.202000056.

10. Wilson Daniel Caicedo Chacon, Yessica Alexandra Rodriguez Gaviria, Ana Paula Zapelini de Melo, Silvani Verruck, Alcilene Rodrigues Monteiro, Germán Ayala Valencia. (2024). Physicochemical Properties and Potential Food Applications of Starches Isolated from Unconventional Seeds: A Review. Starch - Stärke, 76(1-2) https://doi.org/10.1002/star.202200228.

11. María‐Alejandra Beltrán‐Penagos, Andrea del Pilar Sánchez‐Camargo, Carlos‐Eduardo Narváez‐Cuenca. (2020). Proximal composition, bioactive compounds and biorefinery approach in potato tubers of Solanum tuberosum Group Phureja: a review. International Journal of Food Science & Technology, 55(6), p.2282. https://doi.org/10.1111/ijfs.14461.

12. Abebaw Teshome Tiruneh, Abebaw Ayele Negatu, Neela Satheesh, Ahmed Al-Alawi. (2021). Effect of Anchote (Coccinia abyssinica) and Potato Starch Addition on Colloidal Stability of Pineapple Juice. International Journal of Food Science, 2021, p.1. https://doi.org/10.1155/2021/6615273.

13. Leysan Azatovna Mingazova, Elena Vyacheslavovna Kryakunova, Aigul Rafikovna Galieva, Zosya Albertovna Kanarskaya, Albert Vladimirovich Kanarsky , Ekaterina Vasilievna Belkina . (2024). INFLUENCE OF CULTIVATION CONDITIONS ON CELLULASE AND XYLANASE ACTIVITY OF RHIZOPUS ORYZAE F-1030. chemistry of plant raw material, (1), p.301. https://doi.org/10.14258/jcprm.20240112909.

14. David Choque-Quispe, Sandro Froehner, Carlos A. Ligarda-Samanez, Betsy S. Ramos-Pacheco, Henry Palomino-Rincón, Yudith Choque-Quispe, Aydeé M. Solano-Reynoso, Fredy Taipe-Pardo, Lourdes Magaly Zamalloa-Puma, Miriam Calla-Florez, Miriam E. Obregón-Yupanqui, Miluska M. Zamalloa-Puma, Antonieta Mojo-Quisani. (2021). Preparation and Chemical and Physical Characteristics of an Edible Film Based on Native Potato Starch and Nopal Mucilage. Polymers, 13(21), p.3719. https://doi.org/10.3390/polym13213719.

15. Mohammad Ubaid, Mukhtar Ahmed, Mohd Aaqib Sheikh, Tawseefa Jan, Imran Sheikh, Naseer Ahmed, Krishan Kumar, Arvind Kumar, Aseem Vashisht. (2026). Potato starch as a next-generation biopolymer: Functionality, modification, sustainability, and industrial perspectives. Food Physics, 3, p.100082. https://doi.org/10.1016/j.foodp.2026.100082.

16. Juan Carlos Lucas-Aguirre, Víctor Dumar Quintero-Castaño, Johan Sebastián Henao-Ossa, Oscar Yael Barrón-García, Mario Enrique Rodríguez-García. (2025). Influence of Germination Time on the Morphological, Structural, Vibrational, Thermal and Pasting Properties of Potato Starch from Solanum tuberosum Phureja Group. Potato Research, 68(2), p.1375. https://doi.org/10.1007/s11540-024-09784-3.

17. Olga Mileti, Noemi Baldino, Francesco Filice, Francesca R. Lupi, Maria Stefania Sinicropi, Domenico Gabriele. (2023). Formulation Study on Edible Film from Waste Grape and Red Cabbage. Foods, 12(14), p.2804. https://doi.org/10.3390/foods12142804.

18. Tesfa Nega Gesese, Desalegn Abera Mersha, Asmare Tezera Admase, Ejigayehu Dealegn Asrade, Alelgn Anmaw Getahun, Atrsaw Jejaw Bezie, Behailu Bisenebt Mosse, Alebel Abebaw Teshager. (2025). Sustainable Development Research in Materials and Renewable Energy Engineering. Green Energy and Technology. , p.83. https://doi.org/10.1007/978-3-031-81730-4_7.

19. Nedim Gürler, Salih Paşa, M. Hakkı Alma, Hamdi Temel. (2020). The fabrication of bilayer polylactic acid films from cross-linked starch as eco-friendly biodegradable materials: Synthesis, characterization, mechanical and physical properties. European Polymer Journal, 127, p.109588. https://doi.org/10.1016/j.eurpolymj.2020.109588.

20. Berenice González-Torres, Miguel Ángel Robles-García, Melesio Gutiérrez-Lomelí, J. Jesús Padilla-Frausto, Claudia Luz Navarro-Villarruel, Carmen Lizette Del-Toro-Sánchez, Francisco Rodríguez-Félix, Arturo Barrera-Rodríguez, Mireya Zoila Reyna-Villela, María Guadalupe Avila-Novoa, Francisco Javier Reynoso-Marín. (2021). Combination of Sorbitol and Glycerol, as Plasticizers, and Oxidized Starch Improves the Physicochemical Characteristics of Films for Food Preservation. Polymers, 13(19), p.3356. https://doi.org/10.3390/polym13193356.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2017 Acta Agronómica

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Política sobre Derechos de autor:Los autores que publican en la revista se acogen al código de licencia creative commons 4.0 de atribución, no comercial, sin derivados.

Es decir, que aún siendo la Revista Acta Agronómica de acceso libre, los usuarios pueden descargar la información contenida en ella, pero deben darle atribución o reconocimiento de propiedad intelectual, deben usarlo tal como está, sin derivación alguna y no debe ser usado con fines comerciales.