Rheological, fat bloom, and sensory acceptability effects of mango kernel fat and palm olein blends on chocolate-flavored coatings

DOI:

https://doi.org/10.15446/acag.v66n4.56219Palabras clave:

Accelerated bloom, Casson viscosity, Casson yield stress, chocolate coatings, CBE, general acceptability, rheology (en)Accelerated bloom, Casson viscosity, Casson yield stress, chocolate coatings, CBE, general acceptability, rheology (es)

Descargas

The effects of replacing cocoa butter with different percentages and proportions of a mango kernel fat/palm olein (MKF/POL) blend, are reported. Samples were prepared by melting together mango kernel fat, palm olein, cocoa butter and cocoa mass and powdered sugar combinated. The samples were milled, conched, tempered, and molded to obtain three sets of seven samples as follows: one control omitting mango kernel fat and palm olein, and six samples with cocoa butter replacement of 15 and 22.5% and MKF/POL ratios of 2.3, 4.0, and 9.0. Casson viscosity, Casson yield stress, fat bloom and sensory acceptability were all measured. In fact, all samples had achieved a low Casson viscosity (ηCA) and Casson yield stress (τ_oCA), which indicates molding and enrobing as appropriate uses. In addition, some significant differences (p ≤ 0.05) were found among samples. Fat bloom was accelerated in the samples relative to control, but high MKF proportions tended to retard appearance of fat bloom. No differences were observed in organoleptic properties between samples and control.

Recibido: 16 de marzo de 2016; Aceptado: 3 de diciembre de 2016

Abstract

The effects of replacing cocoa butter with different percentages and proportions of a mango kernel fat/palm olein (MKF/POL) blend, are reported. Samples were prepared by melting together mango kernel fat, palm olein, cocoa butter and cocoa mass and powdered sugar combinated. The samples were milled, conched, tempered, and molded to obtain three sets of seven samples as follows: one control omitting mango kernel fat and palm olein, and six samples with cocoa butter replacement of 15 and 22.5% and MKF/POL ratios of 2.3, 4.0, and 9.0. Casson viscosity, Casson yield stress, fat bloom and sensory acceptability were all measured. In fact, all samples had achieved a low Casson viscosity (ηCA) and Casson yield stress ( τ oCA ), which indicates molding and enrobing as appropriate uses. In addition, some significant differences (p ≤ 0.05) were found among samples. Fat bloom was accelerated in the samples relative to control, but high MKF proportions tended to retard appearance of fat bloom. No differences were observed in organoleptic properties between samples and control.

Key words:

Accelerated bloom, Casson viscosity, Casson yield stress, chocolate coatings, CBE, general acceptability, rheology.Resumen

Se reporta los efectos de la sustitución de manteca de cacao con diferentes porcentajes y proporciones de mezclas de grasa de almendra de mango/oleína de palma (GAM/ODP). Las muestras fueron preparadas fundiendo la grasa de almendra de mango, la oleína de palma, la manteca de cacao y pasta de cacao; se mezclaron con el azúcar en polvo. Las muestras se molieron, concharon, atemperaron y moldearon para obtener tres grupos de siete muestras: un testigo sin sustitución de manteca de cacao y seis muestras con reemplazos de manteca de cacao de 15 y 22.5% y con proporciones GAM/ODP de 2.3, 4.0 y 9.0. Se midieron la viscosidad de Casson, valor mínimo de fluencia, eflorescencia de grasa y aceptabilidad general. Todas las muestras tuvieron bajos valores de viscosidad de Casson (ηCA) y valor mínimo de fluencia ( 𝜏 𝑜𝐶𝐴 ), lo que indica su uso apropiado para moldeo o cobertura; se hallaron algunas diferencias significativas (p ≤ 0.05) entre las muestras. La aparición de eflorescencia de grasa fue acelerada en las muestras, con relación al control, pero las proporciones altas de GAM tendieron a retardar la aparición de la eflorescencia. No se observaron diferencias entre las propiedades organolépticas de las muestras y del control.

Palabras clave:

Aceptabilidad general, cobertura chocolate, eflorescencia acelerada, MCE, reología, valor mínimo de Casson, viscosidad de Casson.Introduction

Cocoa butter is an important binder of key ingredients (cocoa powder, sugar, etc.) in chocolate coatings, which presents a major impact on their emergent sensory and physical properties (Kaphueakngam et al., 2009). Cocoa butter is comprised of 35.9 mol% oleic acid (O), 30.7 mol% stearic acid (S) and 27.7 mol% palmitic acid (P), which combine to predominantly form monounsaturated triglycerides as follows: POP, POS and SOS, respectively (Kaphueakngam et al., 2009).

Cocoa butter is the most expensive ingredient in a chocolate formulation (Stauffer, 2005). Numerous factors such as uncertainties in supply and demand, variable quality and high cost compared to other fats have driven a search for alternatives to cocoa butter as well as regulations as to what may be added to chocolate coatings. For this reason, Cocoa Butter Equivalents (CBE), or blends of different vegetable fats producing the appropriate ratio of POP, POS and SOS, which had achieved for many years to mimic the physical and sensory properties of cocoa butter (Beckett, 2008). Conventionally, CBE are produced by blending Palm Mid Fraction (PMF) with one or more types of approved fats which are high in SOS content such as sal (Shorearobusta), shea (Butyrospermumparkii), and Borneo tallow (Shoreaspp). In addition, blending mango kernel fat (MKF) and PMF or palm olein (POL), all permitted by the European Directive, could be used as CBE, but this has not been researched thoroughly.

Using CBE to prepare chocolate flavored coatings requires optimizing triglyceride ratios so the product has desirable physical and organoleptic characteristics. Rheological properties such as Casson viscosity (IOCCC, 2000) can be modified by changing triglyceride ratios in chocolate products. In addition, preparation of products that are resistant to fat bloom is desirable. Fat bloom is a phenomenon which forms a whitish haze, white spots, and/or a dusty appearance on chocolate surface (Beckett, 2008) and is caused by the light scattering of fat crystals (more than 5 µm), which slowly form on the chocolate surface (Hartel, 1999). Bloom is the result from bad tempering, improper preparation temperature, storage conditions, incorrect cooling methods, and/or fats crystallization, which are incompatible with cocoa butter. (Hartel, 1999; Kinta & Hartel, 2010; Lonchampt & Hartel, 2006). In this sense, changing the triglyceride ratios in chocolate products may also influence organoleptic properties such as mouth feel and taste.

In the present work, we study the effect of substituting cocoa butter with different amounts and ratios of MKF and POL on the rheological properties, fat bloom, and general sensory acceptability of chocolate-flavored coatings.

Materials and methods

Materials

Mango kernel fat, palm olein, cocoa mass and cocoa butter, soy lecithin, and sugar were obtained from Dr. Adorable, India; Palmas, Espino, Peru; ROMEX, Peru; MONTANA S. A., Peru; and Universal S. A., Peru, respectively.

Production of chocolate-flavored coating

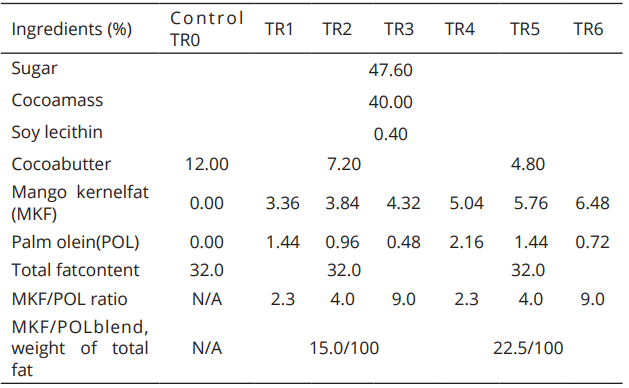

A set of six treatments (TR1-6) and one CBE-free control (TR0) were formulated according to Table 1. The cocoa butter was replaced at two levels: 4.8 and 7.2% of finished product mass, and the MKF/POL ratio was 2.3, 4.0 or 9.0.

Table 1: Test sample formulation

For each formulation, the mango kernel fat, palm olein, cocoa mass and part of the cocoa butter were melted together and mixed with sugar at 40°C for one hour (using stand mixer model TH-350P, Thomas). This mixture was refined to less than 30 µm particle size using five passes in a motor-operated grinder. The blend was then conched at 50°C for 4 h using a mixer, the rest of the cocoa butter and the soy lecithin were added during the conching at the third hour to give the chocolate-flavored mix the desired flow characteristics. The chocolate coating was then tempered (Beckett, 2009), poured into 30 x 30 x 15 mm chocolate molds, cooled at 12 °C (refrigerator Bosch), unmolded from the forms when solid.

Assessment of chocolate-flavored coatings

Rheological properties

Casson viscosity and Casson shear stress of chocolate-flavored coatings were measured using established procedure (IOCCC, 2000). Briefly, 100 g of sample was melted at 50 ºC for 75 minutes. A 15 g aliquot at 40 °C was added to a coaxial cylinder RVDV-III+ Brookfield rheometer, with Spindle 27 and 13RP chamber with a thermostatic water jacket. Shear stresses at rates from 0.34 to 17.0 s-1 were measured and fitted to the Casson-Steiner equation.

Fat bloom

An accelerated bloom study was conducted by exposing test samples to a daily temperature cycle (30 ± 1ºC for 8 hours and 20 ± 1ºC for 16 hours, Memmert Incubator) at 86% relative humidity (using a desiccator with saturated potassium chromate solution) for up to 20 days. Color was measured using The HunterLab color model (L*, a*, b*) prior to the test and every other day during temperature cycling using a Konica Minolta CR-400 colorimeter (Zarringhalami, Sahari, Barzegar & Hamidi-Esfehani, 2010). The whiteness index (WI) was calculated from the color model (Lohman & Hartel, 1994).

Sensory evaluation

Sensory acceptability of chocolate-flavored coatings was evaluated using a 9-point hedonic scale by 40 untrained judges (Anzaldúa-Morales, 2005), selected from undergraduate students of the of the Food Science program, Universidad Privada Antenor Orrego, Trujillo-Peru.

Statistic analysis

Experimental rheological and fat bloom data were subjected analysis of variance (ANOVA) and Duncan´s multiple range test. Friedman and Wilcoxon tests were applied to sensory data. Statistical analysis was performed with the support of SPSS version 20.0 for Windows(r). All measurements and experiments were conducted in triplicate.

Results

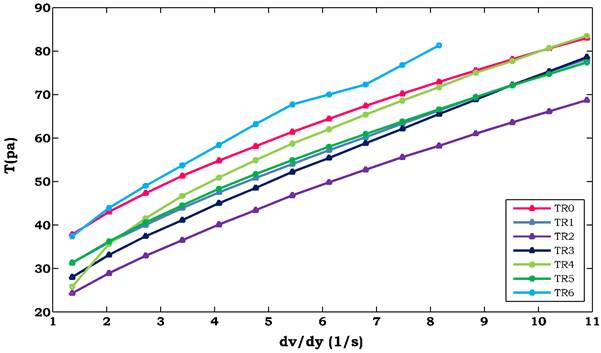

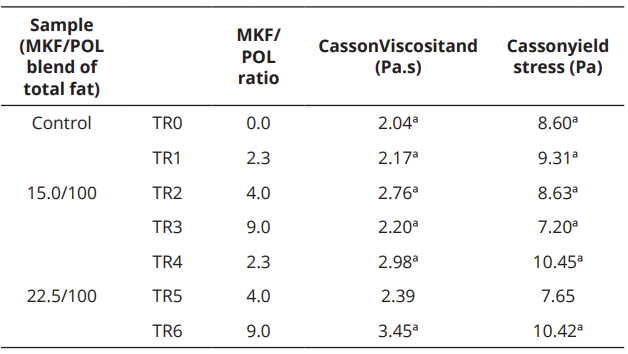

Table 2, summarizes the Casson viscosity and yield stress calculated from the data presented in Figure 1.

ª Average of three measurementsTable 2: Casson viscosity and yield stress on chocolate-flavored coatings

Figure 1: Rheograms of chocolate-flavored coatings.

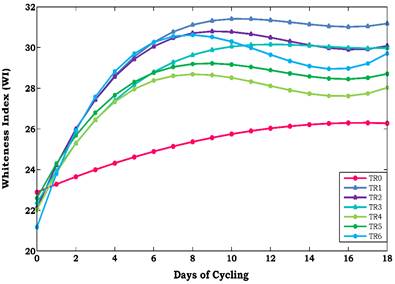

Figure 2, shows how whiteness index (WI) changes during the accelerated bloom study, for all samples, WI increased over time, but the initial rate was variable.

Figure 2: Whiteness index of chocolate-flavored coatings according to storage time.

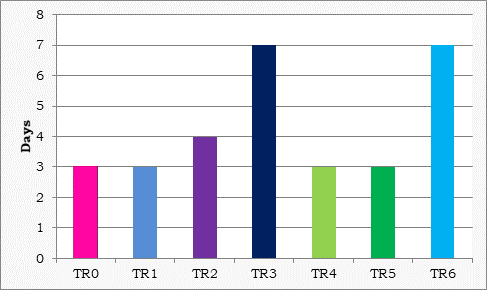

Figure 3, shows the day we observe the first appearance of fat bloom in the test samples.

Figure 3: Days before the first appearance of fat bloom on chocolate- flavored coatings.

Figure 4, shows four areas of possible application of chocolate-flavored coatings, according to their rheological characteristics: molding, enrobing, hand-dipping and chocolate chips.

Figure 4: Casson viscosity and Casson yield stress related to application usage in chocolate confectionery industry.

Discussion

Chocolate rheology

We observe an increase in shear stress as shear rate increases for all samples with very similar slopes. In addition, extrapolating the curves gives a nonzero shear stress at a shear rate of zero (Figure 1). This yield value is a measure of the shear stress necessary to start flow and is typical of Bingham plastics. Low yield values will provide thin coatings while high yield values are more appropriate for chocolate drops.

The first derivative of the curves in Figure 1, is a measurement of the plastic viscosity of the samples, or the shear stress necessary to maintain a constant flow (Table 2). An inspection of the slopes indicates a decrease in viscosity as shear increases, which supports the model that chocolate is a suspension of particles in a fat phase (Stauffer, 2005; Beckett, 2009). The viscosity determines how well the chocolate will flow into a mold. Significantly lower viscosity decreases the flow resistance such as in chocolate mixing and pumping (Beckett, 2009).

Each value of Casson viscosity and yield stress is an average of 3 independent tests. Casson viscosity ranged from 2.17 to 3.45 Pa.s (Table 2), which is within the 1.51-5.56 Pa.s range for eight CBE commercial dark chocolate coatings measured previously (Visotto et al., 1999). Therefore, the coatings tested here could be transported by pipes and pumps already in use for other coatings without optimization.

Samples TR0 and TR1 had the lowest, while TR4 and TR6 had the highest Casson viscosities. TR4 and TR6 contained the highest cocoa butter replacement (22.5%) as well as higher MKF content of 5.04% (TR4) and 6.48% (TR6), as compared to the other 15% cocoa butter replacement treatments. From these observations, it seems that the MKF content is weakly correlated with the Casson viscosity value for chocolate-flavored coatings.

Experimental Casson yield stress (Pa) values ranged from 7.20 to 10.45 Pa, which agrees well with the CBE commercial dark chocolate coating range of 7.11 to 15.26 Pa measured by Visotto et al.(1999). This parameter is affected by particle-particle interaction, specific surface area, amount of particles, emulsifiers and moisture content (Afoakwa, Paterson, Fowler & Ryan, 2007). Samples TR3 and TR5 had the lowest and TR4 and TR6 had the highest yield values as compared to other treatments.

A two-factor ANOVA was performed in order to study if replacing cocoa butter with MKF/POL or whether the MKF/POL ratio had an effect on Casson viscosity and Casson yield stress. ANOVA results indicated that the two factors and their interactions have a significant effect (95% confidence level) on the Casson viscosity and Casson yield stress of chocolate coating. We observe three separate groupings of samples in which we were unable to see statistical significance, but between which we saw differences: group 1 (TR3, TR5 and TR2), group 2 (TR5, TR2 and TR1) and group 3 (TR2, TR1, TR6 and TR4).

Fat bloom

We observe that sample TR0 had achieved the lowest WI on day 18 of storage, with 26.27 WI; while TR1 and TR2 treatments showed the highest values, with 31.17 WI and 30.07 WI. A 30.00 WI at 75% RH usually denotes an unpleasant appearance (Lonchampt & Hartel, 2006). Such values near the end of the study indicate that only some of the coatings chocolate tested in this work, will only have an unpleasant appearances after exposure to extreme conditions (Figure 2). However, WI was lower in the 100% cocoa butter formulation after day 2. In fact, a WI increased for test samples could be explained by crystallization of incompatible fats.

Sonwai, Kaphueakngam & Flood (2014), observed that WI of freshly-tempered cocoa butter and a 95:4:1 CBE mixture of cocoa butter: MKF: PMF, were not significantly different. During a period of four months of incubation at 25°C, WI of the mixture, increased continuously before reaching a stationary phase. However, WI of the cocoa butter remained approximately the same for the first four months and then increased slowly but continuously for the remaining two months. In contrast, we observe that WI increased for all samples during our experiment without going through a latent phase, which may be due to our storage conditions, which strongly favor a rapid bloom. Samples TR1-6 had steeper WI versus time slopes, which means a fat bloom was accelerated compared to the sample of pure cocoa butter (Figure 2).

Ali, Seltman, Che, & Suria (2001), investigated the effect of storage temperature on texture, polymorphic structure, sensory attributes and bloom formation of filled dark chocolate. No bloom was observed when the samples were stored at 18°C. However, bloom was observed after one week at 30°C. The bloom was found to be due to recrystallization of the PMF, coconut and cocoa butter triglycerides mixture (Laustsen, 1991).PMF crystallizes out as form III or β'-2 because it is usually contaminated with PPO and other unsaturated glycerides from palm olein (Kheiri, 1982). Likewise, POL was used in this work could have promoted bloom due to its similar characteristics. TR1, TR2, and TR3 had the highest WI at the end of the experimental run, indicating that their formulations best promoted fat bloom. The highest WI was measured for TR1, which has a high POL to MKF proportion.

The first appearance of fat bloom in test samples, was defined as the first day with a significant difference in whiteness index for treatments with respect to whiteness index Day 0 of TR0 (Dunnett's test). It was observed that comparing Figure 3 and Table 1, makes it clear an increasing in cocoa butter substitution, which tends to decrease the number of days before fat bloom is observed. In addition, decreasing the amount of POL in the samples tends to increase the time to fat bloom in both addition groups (TR1-3 and TR4-6). TR3 and TR6 treatments had the appearance of fat bloom on the seventh day, while the TR1, TR4, TR5 and treatment TR0 at the third day.

Beckett (2008), mentioned that triglycerides containing two molecules of oleic acid are primarily liquid at room temperature. The POL used in this experiment has a minimum iodine value of 59. These results are comparable in variability to the report by Gunstone (2011), who affirm that palm olein present an iodine value, which is comprised to 30.2% of POO triglyceride. Given these concerns, fats had achieved a low compatibility with cocoa butter and an increasing proportions of POL in the product, which can promote an earlier bloom. Owing to its high and evident comparison between TR1, TR2 and TR3, respectively (3, 4 and 7 days without fat bloom). Under these extreme conditions, can be inferred that mango kernel fat (MKF) behaves like anti fat bloom agent by delaying fat bloom for up to four days.

Duncan´s multiple range test results indicated a significant differences among samples for fat bloom, which represented as whiteness index, between TR0 (control) and the other treatments (TR2, TR3 and TR6, respectively).

Sensory evaluation

All of the test samples not show significant differences in their sensory properties or general acceptability when compared to TR0. Also, all blends did not show any solid content at 32-35°C. Therefore, chocolate coatings had desirable melt-in-the-mouth characteristics.

Possible application in the chocolate confectionery industry of chocolate-flavored coatings

According to their rheological characteristics, which are as follows: molding, enrobing, hand-dipping and chocolate chips, respectively (Bloomer, 2015). Of the seven experimental samples, the control and six of them, are located in two areas of low Casson viscosity, low minimum yield stress. In fact, treatment TR6 (sky blue dot), does not appear in any of the mentioned application areas.

From a practical perspective, CBE applications based on rheological properties, TR1 is very similar to TR0 and both, are appropriate for molding and enrobing. In addition, TR2 and TR4, produce chocolate-flavored coatings appropriate for enrobing and TR3 and TR5 may be useful for molding applications.

Conclusions

We report a rheological, fat bloom and sensory acceptability analysis of six different chocolate coating preparations with different substitutions amounts and ratios of MKF and POL. It was observed that sensory acceptability was not statistically different among samples and all samples had achieved a desirable melt-in-mouth characteristics.

Conversely, the tested samples had achieved a relatively low Casson viscosities and yield stress, which have allowed a most appropriate for molding and enrobing. In addition, MKF content tends to increase viscosity. Although viscosities and yield stress were similar, there were statistically significant results among sample groups.

Degree and rate of fat bloom in test samples was increased, as WI for the 100% cocoa butter formulation was always lower after day 2 of fat bloom study. CBE are thought to contribute an increasing in fat bloom due to introduction of incompatible fats which crystalize on the sample surface. However, appearance of fat bloom may be retarded by addition of more MKF to the blend under certain circumstances.

Acknowledgments

We would like to thank Palmas del Espino for provided palm olein, Universidad Privada Antenor Orrego (UPAO), Peru for allowing the use of laboratory instruments and Dr. Kevin Andrew Wilkinson (UPAO) for scientific and grammatical input on this article

References

Referencias

Afoakwa, E., Paterson, A., Fowler M., & Ryan, A. (2007). Factor influencing rheological and textural qualities in chocolate – a review. Trends Food Sci Tech, 18(6), 290-298. https://doi.org/10.1016/j.tifs.2007.02.002

Ali, A., Selmat, J., Che-Man, Y.B. & Suria, A. M. (2001). Effect of storage temperature on texture, polymorphic structure, bloom formation and sensory attributes of filled dark chocolate. Food Chem, 72(4), 491-497. https://doi.org/10.1016/S0308-8146(00)00271-5

Anzaldúa-Morales, A. (2005). La evaluación sensorial de los alimentos en la teoría y en la práctica. Acribia, S.A. (Eds.) 2nd edition. Zaragoza, España. 220p.

Beckett, ST. (2008). The science of chocolate. The Royal Society of Chemistry (Eds.). Cambridge, England. 240p.

https://doi.org/10.1039/9781847558053

Beckett, ST. (2009). Industrial chocolate manufacture and use. Wiley-Blackwell (Eds.). 4th edition. York, United Kingdom.720p.

Blommer. (2015). Chocolate viscosity. Fact sheet.

http://www.blommer.com/_documents/Fact%20Sheet_Viscosity.pdf

Gunstone, F. (2011). Vegetable oils in food technology: Composition. Properties and uses. John Wiley & Sons (Eds.) 2nd Edition. Oxford, UK. 352p.

Hartel, R.W. (1999). Chocolate: fat bloom during storage. The influence of structural elements. The Manufacturing Confectioner, 79(5), 89-99.

IOCCC. International Office of Cocoa, Chocolate and Sugar Confectionery. (2000). Viscosity of chocolate and chocolate products. Analytical method. CABISCO (Eds.). Brussels, Belgium. 152p.

Kaphueakngam, P., Flood, A., & Sonway, S. (2009). Production of cocoa butter equivalent from mango seed almond fat and palm oil mid-fraction. As J Food Ag-Ind, 2(4), 441-447.

Kheiri, M. (1982). Formulation, evaluation and marketing of cocoa butter replacer fats [palm oil products for chocolate based products]. Malaysia, 4, 1-53.

Kinta, Y., & Hartel, R.W. (2010). Bloom formation on poorly-tempered chocolate and effects of seed addition. J Am Oil Chem Soc, 87(1), 19-27. https://doi.org/10.1007/s11746-009-1473-5

Laustsen, E. (1991). The nature of fat bloom in molded compound coating. The Confectionery Manufacturing, 71, 134-144. http://europe.ioiloders.com/images/papers/The_Nature_of_Fat_Bloom_on_Lauric_Compound_Coatings_tcm40-3654.pdf

Lohman, M., & Hartel, RW. (1994). Effect of milk fat fractions on fat bloom in dark chocolate. J Am Oil Chem Soc, 71(3), 267-276. https://doi.org/10.1007/BF02638052

Lonchampt, P. & Hartel, R. W. (2006). Surface bloom on improperly tempered chocolate. Eur J Lipid Sci Tech, 108(2), 159-168. https://doi.org/ 10.1002/ejlt.200500260

Sonwai, S., Kaphueakngam, P. & Flood, A. (2014). Blending of mango kernel fat and palm oil mid-fraction to obtain cocoa butter equivalent. J Food Sci Technol, 51 (10), 237-245. https://doi.org/10.1007/s13197-012-0808-7

Stauffer, M. (2005). Selection of coatings for moulding application. 59th PMCA Production Conference. 32-39. http://www.blommer.com/_documents/coating-for-moulding-application-article.pdf.

Vissotto, F., Luccas, V., Bragagnolo, N., Turatti, J., Grimaldi, R., & Figuereido, M. (1999). Caracterização fisico-quimica e reologica de chocolates comerciais tipo cobertura elaborados com gorduras alternativas. Braz J Food Technol Campinas, 2(1), 139-148.

Zarringhalami, S., Sahari, M. A., Barzegar, M., & Hamidi-Esfehani, Z. (2010). Enzymatically modified tea seed oil as cocoa butter replacer in dark chocolate. Int J Food Sci Tech, 45(3), 540–545.

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Aroldo Daza-La Plata, Gabriela Cristina Chire-Fajardo, Milber Oswaldo Ureña-Peralta. (2020). Cinética de eflorescencia grasa en muestras de chocolate oscuro comercial en Perú. Acta Agronómica, 69(2), p.81. https://doi.org/10.15446/acag.v69n2.79782.

2. Franco Centurion, Srinivas Mettu, Md. Arifur Rahim. (2023). Polymer-Based Nanoscale Materials for Surface Coatings. , p.195. https://doi.org/10.1016/B978-0-32-390778-1.00017-7.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2017 Acta Agronómica

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Política sobre Derechos de autor:Los autores que publican en la revista se acogen al código de licencia creative commons 4.0 de atribución, no comercial, sin derivados.

Es decir, que aún siendo la Revista Acta Agronómica de acceso libre, los usuarios pueden descargar la información contenida en ella, pero deben darle atribución o reconocimiento de propiedad intelectual, deben usarlo tal como está, sin derivación alguna y no debe ser usado con fines comerciales.