The influence of drying on the physiological quality of cape gooseberry (Physalis peruviana L.) fruits added with active components

DOI:

https://doi.org/10.15446/acag.v66n4.59507Palabras clave:

Functional foods, calcium, vacuum impregnation, dehydrated products, vitamins (en)Functional foods, calcium, vacuum impregnation, dehydrated products, vitamins (es)

Descargas

Dehydrated products added with active components (AC) represent a healthy alternative for modern consumer. The aim of this research was to evaluate the influence of drying process conditions on the physiological quality attributes of cape gooseberry (Physalis peruviana L.) impregnated under vacuum with AC and dehydrated. A factorial design was performed with two independent variables, 2 levels per variable (temperature: 50 and 60ºC, air velocity: 2.0 and 3.0 m.s-1) and three replicates per drying condition. In fact, cape gooseberry fruits were previously impregnated under vacuum with an emulsion containing calcium and vitamins B9, C, D3 and E, which were subjected to dehydration until a water activity of approximately 0.6. In addition, drying rate curves presented in all cases two periods of decreasing speed. An increase of drying temperature decreases the processing time, presenting a greater AC degradation, while the air velocity offers a non-significant effect. The treatment which have allowed an AC better retention and low processing times was 60° C and 2 m.s-1, reaching levels of 204.8 ± 10.5 mg, 137.0 ± 34.7 μg, 13.6 ± 0.9 mg, 2.2± 0.6 μg, 7.0±1.2 mg for calcium and vitamins B9, C, D3 and E, respectively per 50 g serving of dehydrated cape gooseberry. An integration of the vacuum impregnation process with conventional air-drying, represents an effective technological alternative, which confers a higher added value to cape gooseberry fruit.

Recibido: 8 de septiembre de 2016; Aceptado: 3 de mayo de 2017

Abstract

Dehydrated products added with active components (AC) represent a healthy alternative for modern consumer. The aim of this research was to evaluate the influence of drying process conditions on the physiological quality attributes of cape gooseberry (Physalis peruviana L.) impregnated under vacuum with AC and dehydrated. A factorial design was performed with two independent variables, 2 levels per variable (temperature: 50 and 60ºC, air velocity: 2.0 and 3.0 m.s-1) and three replicates per drying condition. In fact, cape gooseberry fruits were previously impregnated under vacuum with an emulsion containing calcium and vitamins B9, C, D3 and E, which were subjected to dehydration until a water activity of approximately 0.6. In addition, drying rate curves presented in all cases two periods of decreasing speed. An increase of drying temperature decreases the processing time, presenting a greater AC degradation, while the air velocity offers a non-significant effect. The treatment which have allowed an AC better retention and low processing times was 60° C and 2 m.s-1, reaching levels of 204.8 ± 10.5 mg, 137.0 ± 34.7 μg, 13.6 ± 0.9 mg, 2.2± 0.6 μg, 7.0±1.2 mg for calcium and vitamins B9, C, D3 and E, respectively per 50 g serving of dehydrated cape gooseberry. An integration of the vacuum impregnation process with conventional air-drying, represents an effective technological alternative, which confers a higher added value to cape gooseberry fruit.

Keywords:

Functional foods, calcium, vacuum impregnation, dehydrated products, vitamins.Resumen

Los productos deshidratados adicionados con componentes activos (CA) representan una alternativa saludable para el consumidor moderno. El objetivo de la investigación fue evaluar la influencia de las condiciones del proceso de secado sobre Los atributos de la calidad fisiológica de la uchuva (Physalis peruviana L.) impregnada al vacío con CA y deshidratada. Se utilizó un diseño factorial con dos variables independientes, 2 niveles por variable (temperatura: 50 y 60ºC; velocidad del aire: 2.0 y 3.0 m.s-1) y 3 réplicas por condición de secado. Los frutos de uchuva fueron previamente impregnados al vacío con una emulsión que contenía calcio y vitaminas B9, C, D3 y E, además se sometieron a una deshidratación hasta una actividad de agua aproximada de 0.6. En adición a lo anterior, las curvas de velocidad de secado presentaron en todos los casos dos periodos de velocidad decreciente. El aumento de la temperatura de secado disminuye el tiempo de proceso, presentándose mayor degradación de los CA, mientras que la velocidad del aire ofrece un efecto no significativo. El tratamiento que permitió una mejor retención de los CA y bajos tiempos de proceso fue 60°C y 2 m.s-1, alcanzando niveles de 204.8(10.5 mg, 137.0(34.7 (g, 13.6(0.9 mg, 2.2(0.6 (g, 7.0(1.2 mg para calcio y vitaminas B9, C, D3 y E, respectivamente por porción de 50 g de uchuva deshidratada. La integración del proceso de impregnación al vacío y secado por aire convencional representa una alternativa tecnológica efectiva que confiere un mayor valor agregado al fruto de uchuva.

Palabras clave:

Alimentos funcionales, calcio, impregnación a vacío, productos deshidratados, vitaminas.Introduction

Cape gooseberry is an exotic fruit with very positive effects for human health, highlighting medicinal properties as antispasmodic, diuretic, antiseptic, sedative, analgesic, in addition, it helps to strengthen the optic nerve, relieves throat problems and eliminates intestinal parasites and amoebas (Puente, Pinto-Muñoz, Castro, & Cortés, 2011). Currently, is cultivated in diverse tropical, subtropical high hills and even temperate countries, being Colombia the major producer. The fruit contains β-carotene (provitamin A), phosphorus, iron, potassium, zinc, calcium, fatty acids (linoleic, oleic, palmitic and stearic acids), vitamin C (ascorbic acid) and polyphenols, the latter confer antioxidant activity (Ocampo, Caro, Rivera & Franco, 2017; Puente, Pinto-Muñoz, Castro & Cortés, 2011).

In Colombia, the fruit is considered promissory for export, reason why is looked for technological alternatives which could generate an added value. In this sense, during the last years, a vacuum impregnation process had achieved an application to incorporate active components (AC) in porous foods (Castagnini, Betoret, Betoret & Fito, 2015), which consists of gas exchange and/or liquid occluded in a intercellular space by an external solution, which is promoted by a pressure gradient imposed by the process IV (De Lima et al., 2016).

The integration of process IV and hot air drying (HAD) process, contributes to improve the food composition and its stability due to water activity (Wa) reduction, where water evaporation generally occurs by a forced convection (Chen et al., 2015). In convective dryers, a required heat is transferred into the food by a stream of hot air, where is initially used for surface water evaporation, keeping the temperature close to wet bulb of the drying air. Subsequently, the heat penetrates mainly by conduction towards the interior of the food, while the moisture exits through it, a temperature gradient becomes contrary to the moisture gradient.

In the food dehydration processes, the relationship between the process conditions and the product properties is very complex, producing physical, chemical, sensorial and nutritional changes which influence the final product quality as a consequence of thermal and water stress from which a vegetable tissue is subjected during the process. The aim of this research was to evaluate the influence of the drying process conditions on the cape gooseberry (Physalis peruviana L.) quality attributes impregnated under vacuum with AC and dehydrated.

Materials and methods

Source materials

Fresh cape gooseberry (FCG) (Colombian ecotype) were used in commercial maturity stage, weighing between 5 and 7g. The impregnation emulsion (IE), used the AC, chloride and calcium fumarate, vitamins B9 (folic acid), C (ascorbic acid), D3 (Colecalciferol) and E (DL-α-tocopherol acetate). In addition, an isolation from soy (Glycine max (L.) Merr.) protein, sucralose, Tween 80 & Span 60 (tm).

Vacuum impregnation process

IE, was prepared using an Ultraturrax homogenizer (UTL 50 INLINE Janke & Kunkel IKA- Labortechnik(tm)) to 10000 rpm during 10 min. In fact, FCG were subjected to process IV by initially applying a vacuum pressure (4.1 kPa) during 5 min and then to local barometric pressure (85.3 kPa) during 5 more min.

Hot air dehydration

For the production of impregnated cape gooseberry fruits under vacuum and dried by hot air (ICGDHA) process, a tunnel dryer (Centricol S.A. (tm)) was used, which was conformed as follows: fan, a heating resistor system (1.6 x 10-2.m-3), drying chamber with three trays in perforated mesh (load volume of 6.5 x 10-4. m-3 per tray), balance, anemometer, thermo hygrometers and an integrated data acquisition system, respectively.

The ICGDHA quality was evaluated with a Wa ( 0.6, in function of the process conditions: temperature (50 and 60°C) and air velocity (AV) (2.0 and 3.0 m.s-1).

Analytical determination of CAs

Samples of 7g, were homogenized in an Ultraturrax (IKA(r) T25 digital) homogenizer to 10000 rpm during 5 min. The extraction of vitamins B9 and C were carried out by the methodologies proposed by Arcot & Shrestha (2005) and Gutiérrez, Hoyos & Páez (2007), respectively. Whereas, vitamins D3 and according to the methodology described in: Cortés, Herrera & Gil (2016). Vitamins quantification was performed by a high performance of liquid chromatography (Shimadzu, serie 204 Prominence 20Å), detector UV/VIS with diode array, column C18 RP-5 µm 4.0 mm x 250 mm with a flow rate =1.0 mL.min-1.

The quantification of vitamins B9 and C, was evaluated in the aqueous extract using a mobile phase of ortho-phosphoric acid (85%, 0.02M, pH=3.0), oven temperature 35°C, detection to 283 and 244 nm, respectively.

In fact, for vitamins D3 and E in the oily extract with a mobile phase of acetonitrile: methanol (25:75), oven temperature 45°C and detection to 264 and 285 nm, respectively. Calcium was determined by flame atomic absorption.

Characterization of properties

The moisture content was determined by the thermo-gravimetric method and Wa with a dew point hygrometer at 25°C (AquaLAB Decagon serie 3TE). The color was determined on a spectrophotometer X-Rite SP64, illuminant D65, 10° observer and observation window of 4 mm; obtaining the coordinates CIE-L*a*b* from the spectra of reflection.

Where L*: luminosity, a*: green chromaticity (-) to red (+) and b*: blue chromaticity (-) to yellow (+).The texture was performed by penetration tests on a texturometer TA.XT2 (Stable Micro Systems (tm)) determining the maximum force (Fmax) and the slope (N.mm-1). In addition, was used a load cell of 50 kg, metal plunger diameter of 2 mm, velocity of 1 mm.s-1, penetration distance 70% of sample height.

Experimental design and data analysis

A factorial design was carried out with two independent variables (temperature and air velocity), two levels per variable and three replicates per drying condition. The results were analyzed using the least significant differences method, with a confidence level of 95% (α=0.05). The statistical package Statgraphics Plus(r) versión 5.1, was used.

Results

ICGDHA, reached the evaluated conditions with Wa = 0.576±0.017, where there is a growth inhibition of most microorganisms, improving the safety conditions, which have allowed the product to be classified as a low moisture food. In addition, the solid phase has a greater proportion with respect to the liquid phase, thus limiting the water availability. In fact, drying curves for ICGDHA to different temperature and the analyzed AV conditions, showed a humidity decreasing with time since 4.2±0.1 to 0.3±0.0 kgh2O.kgSS-1 (Figure 1).

Figure 1: Hot air drying curves for ICGDHA

In addition, for a same temperature curves, had achieved a trend to approach with time, which indicates that at low moisture contents, an internal resistance to mass transfer is similar, regardless of the AV used.

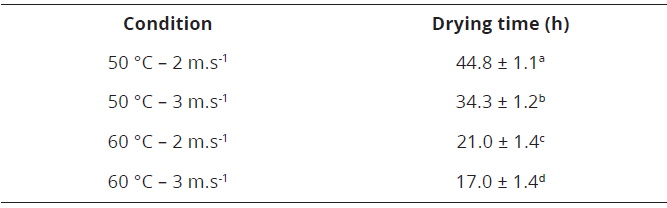

Table 1, shows drying times for the evaluated conditions, which have allowed to observe a significant effect (p <0.05) of drying time with respect to the evaluated factors, a previously reported stage by some authors (Nadian et al., 2015; Wang et al., 2007).

Table 1: Drying times for ICGDHA

The drying rate curves (Figure 2) showed a period of constant drying rate (CDR) very short and mainly at AV=2 m.s-1 (Figure 2).Therefore, at AV=3 m.s-1, the process starts with a decreasing drying velocity (DDV).

Figure 2: Hot air drying velocity curves for ICGDHA

Conversely, notice the presence of a first point at 2 m.s-1 in 3.5±0.0 and 2.9±0.1 kgh2O.kgSS-1 for 50 and 60°C, respectively.

As the moisture content in ICGDHA continues to decrease, the influence of external conditions becomes less effective due to a greater internal resistance for mass transfer through the peduncle area. In fact, would increase a new critical point or second DVC period of 0.7±0.0; 0.8±0.0; 0.5±0.0 and 0.6±0.0 kgh2O.kgSS-1 for 50°C-2 m.s-1, 50°C-3 m.s-1, 60°C-2 m.s-1 and 60°C-3 m.s-1, respectively.

Levels reached by ACs in process IV were as follows: 203.7±3.3 µg; 23.7±9.2 mg; 2.3±0.4 µg; 7.3±0.9 mg and 210.5±2.0 mg for vitamins B9, C, D3, E and calcium, respectively in a portion of 200 g UF.

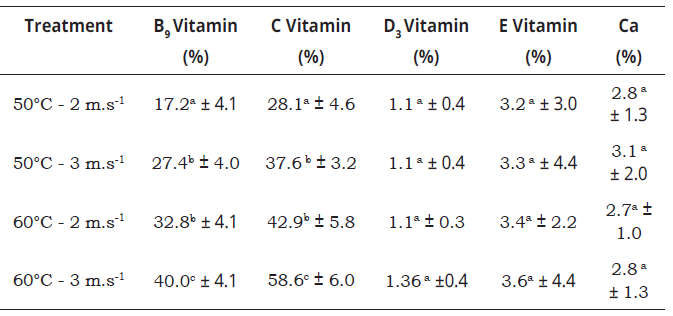

Table 2, shows the mean values plus the standard deviation of the AC loss percentages in ICGDHA due to the employed drying treatments.

Table 2: Effect of hot air drying on the AC loss in ICGDHA

Therefore, ANOVA did not present significant differences (p> 0.05) in the calcium and fat-soluble contents, vitamins D3 and E. In fact, if there were significant differences (p <0.05) with respect to the soluble vitamins B9 and C, these become more sensitive to the drying process due to its thermo labile characteristics.

The AC levels reached in ICGDHA were as follows: 203.7±3.3µg; 23.7±9.2mg; 2.3±0.4µg; 7.3±0.9mg and 210.5±2.0mg.200gUF-1, for vitamins B9, C, D3, E and calcium, respectively, which demonstrates the process IV effectiveness, guaranteeing at the beginning of the drying process, level higher than 20% CDR in the AC.

Nevertheless, a process condition was considered at 60°C and 2 m.s-1, which is the most appropriate for the ICGDHA drying process. It was observed that in a time of 21.0±1.4 h and levels in vitamins B9, C, D3, E and calcium of 137.0±34.7 µg, 13.6±0.9 mg, 2.2±0.6 µg, 7.0±1.2 mg and 204.8±10.5 mg, respectively, it was reached in a portion of 50 g of ICGDHA.

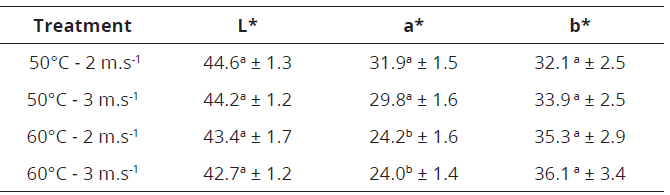

Table 3, presents the mean values plus the standard deviation of the color parameters as a function of the drying treatments.

Table 3: Optical characterization of ICGDHA

The results identify a greater influence on the color changes mainly due to the effect of the process temperature, which provides a lower stability of the pigments with their increase. In fact, ANOVA analysis did not show significant differences (p> 0.05) in the color parameters L * and b * with respect to the treatment factor, although it can be shown that L * has a tendency to decrease (darker and brown) and b * to increase (More yellow-brown) for ICGDHA treated at 60°C and 3 m.s-1 speed. The chromaticity a*, presented significant differences (p<0.05), which hve allowed to conform two homogeneous groups, one for each temperature, identifying a greater decreasing of the red chromaticity (a * <<) in the fruits subjected to 60°C.

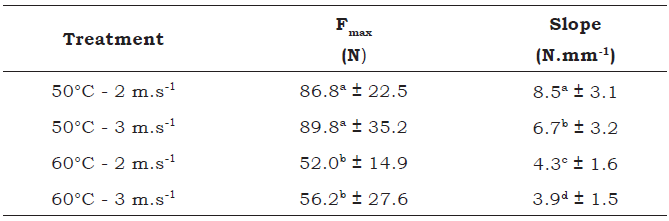

Table 4, shows rupture Fmax and the slope of force-distance ICGDHA graphic in function of the process condition.

Table 4: Mechanical characterization of ICGDHA

ANOVA analysis presented significant differences (p <0.05) in the texture parameters with respect to the process conditions, allowing to show that the firmness is affected to a greater extent by the temperature, which requires less force for its rupture and penetration in the treatments of higher temperature with their minimum values being 60°C.

Discussion

Drying process

The dehydration kinetics of the ICGDHA have allowed an analysis of the moisture variation over time, in which both the material characteristics and the external conditions to which a subjected food, was influenced. In fact, the moisture loss did not present a constant or linear behavior with time, indicating that not only the conditions of the medium influence the process, but also its physical and structural characteristics, being able to limit the water output in the surface film of the cape gooseberry fruits, and therefore, slow down the process.

The results of drying times show a raising air temperature, which had achieved a flow constant; 53.1 and 50.4% reduce the time for AV of 2 and 3 ms-1, respectively, due to a direct relationship between temperature and the water diffusivity processes from the interior of the product (Onwude, Hashim & Chen, 2016). Therefore, a decreasing time with an increasing AV, can be observed maintaining a constant temperature (23.4 and 19.1% for 50 and 60°C, respectively).

During the drying of some biological materials, the induction or latency zone as well as the CDR period do not appear (Ratti, 2009). It should be taken into account that in CDR period, water is in free state, the wet surface and the surface temperature in equilibrium with vapor concentration (Arcot & Shrestha, 2005; Yiotis, Tsimpanogiannis, Stubos & Yortsos, 2006; Castells, 2011). For instance, AV=2 m.s-1, water evaporation rate in the ICGDHA is constant and controlled by external variables, which in the case of pure convection are AV, temperature and relative humidity of drying air process. On the other hand, time depends on the heat and mass transfer coefficients, the surface area, sample geometry and temperature and humidity difference between the air and the wet surface of the solid phase. In addition, any decrease in the circulating airflow decreases the evaporation rate due to a decreasing of the convective effects in the velocity of heat and mass transfer.

The first critical point represents a condition, where water cannot serve as a solvent for biochemical reactions, which implies a conformational change of cellular polymers and under which, requires more energy to be eliminated, reason why the velocity of drying process diminishes in a significant way.

This provides more accurate and reliable estimates of ICGDHA surface area, which has a semipermeable surface waxy film ((95%) and negatively influences the mass transfer during the process of obtaining ICGDHA. As a result, it has long been thought that these removals of the evaporated water occurs mainly through the porous space constituted in the ICGDHA by a peduncle area (( 5% of total surface areas).

Due to short periods of CDR (AV=2 m.s-1) or non-existence (AV=3 m.s-1), a higher water evaporation is experienced by ICGDHA during the first period of DDV. In fact, higher temperature profiles inside the cape gooseberry fruits, carries out the evaporation front at the interface greater due to a greater vapor or liquid diffusion from the center of the solid phase throughout the interface, which is also increased when the flow is greater (Fito, Andrés, Barat & Albor, 2001).

On the other hand, dry areas appear on the material surface, which make it difficult to remove water due to shrinkage and surface hardening as a result of the evaporation front throughout the center of the product, which reduces the liquid or steam migration rate, and therefore, the vapor pressure on the material surface. This situation generates a small amount of water, which is eliminated or evaporated in longer periods of time, due to a fraction of the thermal energy of drying air, which is used for evaporation and had achieved a lower energy efficiency and a higher specific energy consumption (Ratti, 2009).

Given these concerns, in the second period of VSD, is considered that physically occurs a greater material contraction, where the energy is used for the removal of bound water in capillaries, while the product temperature approaches the dried bulb of the air decreasing. A possible explanation for this is the impeller thermal force while drying process takes place. In this way, the moisture content tends to asymptotically reach an equilibrium corresponding to a relative air humidity on the adsorption isotherm of the material (Ratti, 2009).

In general, is observed that the slope of the ICGDHA drying rate curves increases with an increasing temperature, which indicates at higher temperature and a higher kinetic energy of the water molecules. Likewise, a greater inclination can be observed for the second period of decreasing velocity, which indicates the process at this stage is performed more rapidly. These results are comparable in variability to the report by Wang et al. (2007), during apple drying process.

Effect of drying processes on the cape gooseberry quality

Process IV demonstrated its effectiveness at the beginning of drying process, levels higher than 20% of VDR in AC. However, it was observed that cape gooseberry fruits can be overcome a post-process IV relaxation, which produces a minimal way out of impregnating liquid containing the ACs of interest.

The drying process plays an important role in the stability of the ACs present or added in the matrix of cape gooseberry fruits. Conversely, this losses are enhanced when operating at high temperature and air velocity. In fact, fat-soluble vitamins due to their hydrophobic character and chemical forms used, presented low losses due to the drying process, considering there is a protection of the collapsed matrix, which encapsulates the AC inside. Calcium is maintained in the structure, enhancing its fixation to the matrix throughout interactions with a pectic content of fruit cell walls (Gras, Vidal, Betoret, Chiralt & Fito, 2003).

Vitamin D3 is quite stable and unaffected by air exposure, although slight losses may occur from light exposure and even from heat treatment. Vitamin E can present losses due to its degradation by effects of light, heating, pH, presence of metals and free radicals. Vitamins B9 and C reported the highest percentages of loss due to their water-soluble condition, since the degradation is directly influenced by the process temperature and the product moisture. Accordingly, the collected data among the added ACs, vitamin C proves to be the most thermosensitive compound under the evaluated conditions to which cape gooseberry fruits were dehydrated, thus reporting higher losses by process (Mendoza-Corvis, Hernández & Ruiz, 2015).

The loss of vitamin B9 may result from the combination of thermal degradation (predominant) and the liquid impregnation liquid during its relaxation, previously discussed.

The losses level of other vitamins may be influenced by environmental factors, the duration of thermal processes and the water ratio in the product, while the presence of reducing agents may increase their retention (Lešková et al., 2006). Vitamin C is a quality indicator in cape gooseberry fruits, since is the most sensitive nutrients to the heat applied treatment, its retention ensures that other components remain unaltered during the process. It is important to note that loss can be explained mainly by enzymatic degradation due to a long exposure time of the fruit to high moisture contents, as well as a reduction in oxide reactions, which convert it to dehydroascorbic acid (Sánchez-Chávez, Cortez-Arredondo, Solano-Cornejo & Vidaurre-Ruiz, 2015). The obtained ICGDHA at 60°C and AV=2 m.s-1 have allowed and identification of ICGDHA with the following descriptor: "Excellent source of vitamins B9, C, D3, E and calcium" in a portion of 50 g of ICGDHA by containing 34.2(2.6; 22.6(2.9; 22.3(2.09; 23.4(3.8 and 20.5(0.4% VDR, respectively.

The ICGDHA color parameters compared with the impregnated cape gooseberry fruits (L*=46.1±3.1, a*=15.5±2.1 and b*=39.2±4.9), showed significant statistical differences (p <0.05) in the chromaticity a * with respect to the type of process. Therefore, these differences are predominantly attributed to the carotenoid pigments degradation, which are mostly sensitive to heat induction. The variation of b * is mainly observed at low temperatures and may be caused by the development of some brown pigments related to non-enzymatic reactions activated during the drying process (Vega-Gálvez et al., 2008), while changes in L * parameters, are observed mainly at low temperatures and air velocities, which had achieved an enzymatic browning of the food matrix.

Nevertheless, mechanical behavior of the ICGDHA shows a decrease in the Fmax at higher temperature, which could be attributed to several factors as follows: a possible fracturability of the waxy film, the collapse of the structure and cellular compaction (from the outside to the inside of the sample), which generates drier external layers that fix the volume, a crisp, vitreous bark is present, which does not plasticize by the moisture flow throughout and within a gummy structure.

Conclusions

The integration of vacuum impregnation and conventional hot air drying process, represent an effective technological alternatives, which contribute to an added value generation in cape gooseberry fruits, giving to the dehydrated product levels of AC higher than 20% of the VDR (34.2(2.6; 22.6(2.9; 22.3(2.1; 23.4(3.8 and 20.5(0.4% VDR of vitamins B9, C, D3, E and calcium.50gICGDHA-1, respectively).

Given these concerns, during the drying process, temperature was the independent variable, which had achieved the most notable effects on the response or dependent variables, being 60ºC and airflow velocity of 2 ms-1, the process conditions, which have allowed obtaining an acceptable color product, gummy texture and with greater retention of AC. In addition, this product can be labeled according to Colombian regulations with the following descriptor: "Excellent source of calcium and vitamins B9, C, D3 and E in a portion of 50 g ICGDHA".

References

Recibido: 8 de septiembre de 2016; Aceptado: 3 de mayo de 2017

Abstract

Dehydrated products added with active components (AC) represent a healthy alternative for modern consumer. The aim of this research was to evaluate the influence of drying process conditions on the physiological quality attributes of cape gooseberry (Physalis peruviana L.) impregnated under vacuum with AC and dehydrated. A factorial design was performed with two independent variables, 2 levels per variable (temperature: 50 and 60ºC, air velocity: 2.0 and 3.0 m.s-1) and three replicates per drying condition. In fact, cape gooseberry fruits were previously impregnated under vacuum with an emulsion containing calcium and vitamins B9, C, D3 and E, which were subjected to dehydration until a water activity of approximately 0.6. In addition, drying rate curves presented in all cases two periods of decreasing speed. An increase of drying temperature decreases the processing time, presenting a greater AC degradation, while the air velocity offers a non-significant effect. The treatment which have allowed an AC better retention and low processing times was 60° C and 2 m.s-1, reaching levels of 204.8 ± 10.5 mg, 137.0 ± 34.7 μg, 13.6 ± 0.9 mg, 2.2± 0.6 μg, 7.0±1.2 mg for calcium and vitamins B9, C, D3 and E, respectively per 50 g serving of dehydrated cape gooseberry. An integration of the vacuum impregnation process with conventional air-drying, represents an effective technological alternative, which confers a higher added value to cape gooseberry fruit.

Keywords:

Functional foods, calcium, vacuum impregnation, dehydrated products, vitamins.Resumen

Los productos deshidratados adicionados con componentes activos (CA) representan una alternativa saludable para el consumidor moderno. El objetivo de la investigación fue evaluar la influencia de las condiciones del proceso de secado sobre Los atributos de la calidad fisiológica de la uchuva (Physalis peruviana L.) impregnada al vacío con CA y deshidratada. Se utilizó un diseño factorial con dos variables independientes, 2 niveles por variable (temperatura: 50 y 60ºC; velocidad del aire: 2.0 y 3.0 m.s-1) y 3 réplicas por condición de secado. Los frutos de uchuva fueron previamente impregnados al vacío con una emulsión que contenía calcio y vitaminas B9, C, D3 y E, además se sometieron a una deshidratación hasta una actividad de agua aproximada de 0.6. En adición a lo anterior, las curvas de velocidad de secado presentaron en todos los casos dos periodos de velocidad decreciente. El aumento de la temperatura de secado disminuye el tiempo de proceso, presentándose mayor degradación de los CA, mientras que la velocidad del aire ofrece un efecto no significativo. El tratamiento que permitió una mejor retención de los CA y bajos tiempos de proceso fue 60°C y 2 m.s-1, alcanzando niveles de 204.8(10.5 mg, 137.0(34.7 (g, 13.6(0.9 mg, 2.2(0.6 (g, 7.0(1.2 mg para calcio y vitaminas B9, C, D3 y E, respectivamente por porción de 50 g de uchuva deshidratada. La integración del proceso de impregnación al vacío y secado por aire convencional representa una alternativa tecnológica efectiva que confiere un mayor valor agregado al fruto de uchuva.

Palabras clave:

Alimentos funcionales, calcio, impregnación a vacío, productos deshidratados, vitaminas.Introduction

Cape gooseberry is an exotic fruit with very positive effects for human health, highlighting medicinal properties as antispasmodic, diuretic, antiseptic, sedative, analgesic, in addition, it helps to strengthen the optic nerve, relieves throat problems and eliminates intestinal parasites and amoebas (Puente, Pinto-Muñoz, Castro, & Cortés, 2011). Currently, is cultivated in diverse tropical, subtropical high hills and even temperate countries, being Colombia the major producer. The fruit contains β-carotene (provitamin A), phosphorus, iron, potassium, zinc, calcium, fatty acids (linoleic, oleic, palmitic and stearic acids), vitamin C (ascorbic acid) and polyphenols, the latter confer antioxidant activity (Ocampo, Caro, Rivera & Franco, 2017; Puente, Pinto-Muñoz, Castro & Cortés, 2011).

In Colombia, the fruit is considered promissory for export, reason why is looked for technological alternatives which could generate an added value. In this sense, during the last years, a vacuum impregnation process had achieved an application to incorporate active components (AC) in porous foods (Castagnini, Betoret, Betoret & Fito, 2015), which consists of gas exchange and/or liquid occluded in a intercellular space by an external solution, which is promoted by a pressure gradient imposed by the process IV (De Lima et al., 2016).

The integration of process IV and hot air drying (HAD) process, contributes to improve the food composition and its stability due to water activity (Wa) reduction, where water evaporation generally occurs by a forced convection (Chen et al., 2015). In convective dryers, a required heat is transferred into the food by a stream of hot air, where is initially used for surface water evaporation, keeping the temperature close to wet bulb of the drying air. Subsequently, the heat penetrates mainly by conduction towards the interior of the food, while the moisture exits through it, a temperature gradient becomes contrary to the moisture gradient.

In the food dehydration processes, the relationship between the process conditions and the product properties is very complex, producing physical, chemical, sensorial and nutritional changes which influence the final product quality as a consequence of thermal and water stress from which a vegetable tissue is subjected during the process. The aim of this research was to evaluate the influence of the drying process conditions on the cape gooseberry (Physalis peruviana L.) quality attributes impregnated under vacuum with AC and dehydrated.

Materials and methods

Source materials

Fresh cape gooseberry (FCG) (Colombian ecotype) were used in commercial maturity stage, weighing between 5 and 7g. The impregnation emulsion (IE), used the AC, chloride and calcium fumarate, vitamins B9 (folic acid), C (ascorbic acid), D3 (Colecalciferol) and E (DL-α-tocopherol acetate). In addition, an isolation from soy (Glycine max (L.) Merr.) protein, sucralose, Tween 80 & Span 60 (tm).

Vacuum impregnation process

IE, was prepared using an Ultraturrax homogenizer (UTL 50 INLINE Janke & Kunkel IKA- Labortechnik(tm)) to 10000 rpm during 10 min. In fact, FCG were subjected to process IV by initially applying a vacuum pressure (4.1 kPa) during 5 min and then to local barometric pressure (85.3 kPa) during 5 more min.

Hot air dehydration

For the production of impregnated cape gooseberry fruits under vacuum and dried by hot air (ICGDHA) process, a tunnel dryer (Centricol S.A. (tm)) was used, which was conformed as follows: fan, a heating resistor system (1.6 x 10-2.m-3), drying chamber with three trays in perforated mesh (load volume of 6.5 x 10-4. m-3 per tray), balance, anemometer, thermo hygrometers and an integrated data acquisition system, respectively.

The ICGDHA quality was evaluated with a Wa ( 0.6, in function of the process conditions: temperature (50 and 60°C) and air velocity (AV) (2.0 and 3.0 m.s-1).

Analytical determination of CAs

Samples of 7g, were homogenized in an Ultraturrax (IKA(r) T25 digital) homogenizer to 10000 rpm during 5 min. The extraction of vitamins B9 and C were carried out by the methodologies proposed by Arcot & Shrestha (2005) and Gutiérrez, Hoyos & Páez (2007), respectively. Whereas, vitamins D3 and according to the methodology described in: Cortés, Herrera & Gil (2016). Vitamins quantification was performed by a high performance of liquid chromatography (Shimadzu, serie 204 Prominence 20Å), detector UV/VIS with diode array, column C18 RP-5 µm 4.0 mm x 250 mm with a flow rate =1.0 mL.min-1.

The quantification of vitamins B9 and C, was evaluated in the aqueous extract using a mobile phase of ortho-phosphoric acid (85%, 0.02M, pH=3.0), oven temperature 35°C, detection to 283 and 244 nm, respectively.

In fact, for vitamins D3 and E in the oily extract with a mobile phase of acetonitrile: methanol (25:75), oven temperature 45°C and detection to 264 and 285 nm, respectively. Calcium was determined by flame atomic absorption.

Characterization of properties

The moisture content was determined by the thermo-gravimetric method and Wa with a dew point hygrometer at 25°C (AquaLAB Decagon serie 3TE). The color was determined on a spectrophotometer X-Rite SP64, illuminant D65, 10° observer and observation window of 4 mm; obtaining the coordinates CIE-L*a*b* from the spectra of reflection.

Where L*: luminosity, a*: green chromaticity (-) to red (+) and b*: blue chromaticity (-) to yellow (+).The texture was performed by penetration tests on a texturometer TA.XT2 (Stable Micro Systems (tm)) determining the maximum force (Fmax) and the slope (N.mm-1). In addition, was used a load cell of 50 kg, metal plunger diameter of 2 mm, velocity of 1 mm.s-1, penetration distance 70% of sample height.

Experimental design and data analysis

A factorial design was carried out with two independent variables (temperature and air velocity), two levels per variable and three replicates per drying condition. The results were analyzed using the least significant differences method, with a confidence level of 95% (α=0.05). The statistical package Statgraphics Plus(r) versión 5.1, was used.

Results

ICGDHA, reached the evaluated conditions with Wa = 0.576±0.017, where there is a growth inhibition of most microorganisms, improving the safety conditions, which have allowed the product to be classified as a low moisture food. In addition, the solid phase has a greater proportion with respect to the liquid phase, thus limiting the water availability. In fact, drying curves for ICGDHA to different temperature and the analyzed AV conditions, showed a humidity decreasing with time since 4.2±0.1 to 0.3±0.0 kgh2O.kgSS-1 (Figure 1).

Figure 1: Hot air drying curves for ICGDHA

In addition, for a same temperature curves, had achieved a trend to approach with time, which indicates that at low moisture contents, an internal resistance to mass transfer is similar, regardless of the AV used.

Table 1, shows drying times for the evaluated conditions, which have allowed to observe a significant effect (p <0.05) of drying time with respect to the evaluated factors, a previously reported stage by some authors (Nadian et al., 2015; Wang et al., 2007).

Table 1: Drying times for ICGDHA

The drying rate curves (Figure 2) showed a period of constant drying rate (CDR) very short and mainly at AV=2 m.s-1 (Figure 2).Therefore, at AV=3 m.s-1, the process starts with a decreasing drying velocity (DDV).

Figure 2: Hot air drying velocity curves for ICGDHA

Conversely, notice the presence of a first point at 2 m.s-1 in 3.5±0.0 and 2.9±0.1 kgh2O.kgSS-1 for 50 and 60°C, respectively.

As the moisture content in ICGDHA continues to decrease, the influence of external conditions becomes less effective due to a greater internal resistance for mass transfer through the peduncle area. In fact, would increase a new critical point or second DVC period of 0.7±0.0; 0.8±0.0; 0.5±0.0 and 0.6±0.0 kgh2O.kgSS-1 for 50°C-2 m.s-1, 50°C-3 m.s-1, 60°C-2 m.s-1 and 60°C-3 m.s-1, respectively.

Levels reached by ACs in process IV were as follows: 203.7±3.3 µg; 23.7±9.2 mg; 2.3±0.4 µg; 7.3±0.9 mg and 210.5±2.0 mg for vitamins B9, C, D3, E and calcium, respectively in a portion of 200 g UF.

Table 2, shows the mean values plus the standard deviation of the AC loss percentages in ICGDHA due to the employed drying treatments.

Table 2: Effect of hot air drying on the AC loss in ICGDHA

Therefore, ANOVA did not present significant differences (p> 0.05) in the calcium and fat-soluble contents, vitamins D3 and E. In fact, if there were significant differences (p <0.05) with respect to the soluble vitamins B9 and C, these become more sensitive to the drying process due to its thermo labile characteristics.

The AC levels reached in ICGDHA were as follows: 203.7±3.3µg; 23.7±9.2mg; 2.3±0.4µg; 7.3±0.9mg and 210.5±2.0mg.200gUF-1, for vitamins B9, C, D3, E and calcium, respectively, which demonstrates the process IV effectiveness, guaranteeing at the beginning of the drying process, level higher than 20% CDR in the AC.

Nevertheless, a process condition was considered at 60°C and 2 m.s-1, which is the most appropriate for the ICGDHA drying process. It was observed that in a time of 21.0±1.4 h and levels in vitamins B9, C, D3, E and calcium of 137.0±34.7 µg, 13.6±0.9 mg, 2.2±0.6 µg, 7.0±1.2 mg and 204.8±10.5 mg, respectively, it was reached in a portion of 50 g of ICGDHA.

Table 3, presents the mean values plus the standard deviation of the color parameters as a function of the drying treatments.

Table 3: Optical characterization of ICGDHA

The results identify a greater influence on the color changes mainly due to the effect of the process temperature, which provides a lower stability of the pigments with their increase. In fact, ANOVA analysis did not show significant differences (p> 0.05) in the color parameters L * and b * with respect to the treatment factor, although it can be shown that L * has a tendency to decrease (darker and brown) and b * to increase (More yellow-brown) for ICGDHA treated at 60°C and 3 m.s-1 speed. The chromaticity a*, presented significant differences (p<0.05), which hve allowed to conform two homogeneous groups, one for each temperature, identifying a greater decreasing of the red chromaticity (a * <<) in the fruits subjected to 60°C.

Table 4, shows rupture Fmax and the slope of force-distance ICGDHA graphic in function of the process condition.

Table 4: Mechanical characterization of ICGDHA

ANOVA analysis presented significant differences (p <0.05) in the texture parameters with respect to the process conditions, allowing to show that the firmness is affected to a greater extent by the temperature, which requires less force for its rupture and penetration in the treatments of higher temperature with their minimum values being 60°C.

Discussion

Drying process

The dehydration kinetics of the ICGDHA have allowed an analysis of the moisture variation over time, in which both the material characteristics and the external conditions to which a subjected food, was influenced. In fact, the moisture loss did not present a constant or linear behavior with time, indicating that not only the conditions of the medium influence the process, but also its physical and structural characteristics, being able to limit the water output in the surface film of the cape gooseberry fruits, and therefore, slow down the process.

The results of drying times show a raising air temperature, which had achieved a flow constant; 53.1 and 50.4% reduce the time for AV of 2 and 3 ms-1, respectively, due to a direct relationship between temperature and the water diffusivity processes from the interior of the product (Onwude, Hashim & Chen, 2016). Therefore, a decreasing time with an increasing AV, can be observed maintaining a constant temperature (23.4 and 19.1% for 50 and 60°C, respectively).

During the drying of some biological materials, the induction or latency zone as well as the CDR period do not appear (Ratti, 2009). It should be taken into account that in CDR period, water is in free state, the wet surface and the surface temperature in equilibrium with vapor concentration (Arcot & Shrestha, 2005; Yiotis, Tsimpanogiannis, Stubos & Yortsos, 2006; Castells, 2011). For instance, AV=2 m.s-1, water evaporation rate in the ICGDHA is constant and controlled by external variables, which in the case of pure convection are AV, temperature and relative humidity of drying air process. On the other hand, time depends on the heat and mass transfer coefficients, the surface area, sample geometry and temperature and humidity difference between the air and the wet surface of the solid phase. In addition, any decrease in the circulating airflow decreases the evaporation rate due to a decreasing of the convective effects in the velocity of heat and mass transfer.

The first critical point represents a condition, where water cannot serve as a solvent for biochemical reactions, which implies a conformational change of cellular polymers and under which, requires more energy to be eliminated, reason why the velocity of drying process diminishes in a significant way.

This provides more accurate and reliable estimates of ICGDHA surface area, which has a semipermeable surface waxy film ((95%) and negatively influences the mass transfer during the process of obtaining ICGDHA. As a result, it has long been thought that these removals of the evaporated water occurs mainly through the porous space constituted in the ICGDHA by a peduncle area (( 5% of total surface areas).

Due to short periods of CDR (AV=2 m.s-1) or non-existence (AV=3 m.s-1), a higher water evaporation is experienced by ICGDHA during the first period of DDV. In fact, higher temperature profiles inside the cape gooseberry fruits, carries out the evaporation front at the interface greater due to a greater vapor or liquid diffusion from the center of the solid phase throughout the interface, which is also increased when the flow is greater (Fito, Andrés, Barat & Albor, 2001).

On the other hand, dry areas appear on the material surface, which make it difficult to remove water due to shrinkage and surface hardening as a result of the evaporation front throughout the center of the product, which reduces the liquid or steam migration rate, and therefore, the vapor pressure on the material surface. This situation generates a small amount of water, which is eliminated or evaporated in longer periods of time, due to a fraction of the thermal energy of drying air, which is used for evaporation and had achieved a lower energy efficiency and a higher specific energy consumption (Ratti, 2009).

Given these concerns, in the second period of VSD, is considered that physically occurs a greater material contraction, where the energy is used for the removal of bound water in capillaries, while the product temperature approaches the dried bulb of the air decreasing. A possible explanation for this is the impeller thermal force while drying process takes place. In this way, the moisture content tends to asymptotically reach an equilibrium corresponding to a relative air humidity on the adsorption isotherm of the material (Ratti, 2009).

In general, is observed that the slope of the ICGDHA drying rate curves increases with an increasing temperature, which indicates at higher temperature and a higher kinetic energy of the water molecules. Likewise, a greater inclination can be observed for the second period of decreasing velocity, which indicates the process at this stage is performed more rapidly. These results are comparable in variability to the report by Wang et al. (2007), during apple drying process.

Effect of drying processes on the cape gooseberry quality

Process IV demonstrated its effectiveness at the beginning of drying process, levels higher than 20% of VDR in AC. However, it was observed that cape gooseberry fruits can be overcome a post-process IV relaxation, which produces a minimal way out of impregnating liquid containing the ACs of interest.

The drying process plays an important role in the stability of the ACs present or added in the matrix of cape gooseberry fruits. Conversely, this losses are enhanced when operating at high temperature and air velocity. In fact, fat-soluble vitamins due to their hydrophobic character and chemical forms used, presented low losses due to the drying process, considering there is a protection of the collapsed matrix, which encapsulates the AC inside. Calcium is maintained in the structure, enhancing its fixation to the matrix throughout interactions with a pectic content of fruit cell walls (Gras, Vidal, Betoret, Chiralt & Fito, 2003).

Vitamin D3 is quite stable and unaffected by air exposure, although slight losses may occur from light exposure and even from heat treatment. Vitamin E can present losses due to its degradation by effects of light, heating, pH, presence of metals and free radicals. Vitamins B9 and C reported the highest percentages of loss due to their water-soluble condition, since the degradation is directly influenced by the process temperature and the product moisture. Accordingly, the collected data among the added ACs, vitamin C proves to be the most thermosensitive compound under the evaluated conditions to which cape gooseberry fruits were dehydrated, thus reporting higher losses by process (Mendoza-Corvis, Hernández & Ruiz, 2015).

The loss of vitamin B9 may result from the combination of thermal degradation (predominant) and the liquid impregnation liquid during its relaxation, previously discussed.

The losses level of other vitamins may be influenced by environmental factors, the duration of thermal processes and the water ratio in the product, while the presence of reducing agents may increase their retention (Lešková et al., 2006). Vitamin C is a quality indicator in cape gooseberry fruits, since is the most sensitive nutrients to the heat applied treatment, its retention ensures that other components remain unaltered during the process. It is important to note that loss can be explained mainly by enzymatic degradation due to a long exposure time of the fruit to high moisture contents, as well as a reduction in oxide reactions, which convert it to dehydroascorbic acid (Sánchez-Chávez, Cortez-Arredondo, Solano-Cornejo & Vidaurre-Ruiz, 2015). The obtained ICGDHA at 60°C and AV=2 m.s-1 have allowed and identification of ICGDHA with the following descriptor: "Excellent source of vitamins B9, C, D3, E and calcium" in a portion of 50 g of ICGDHA by containing 34.2(2.6; 22.6(2.9; 22.3(2.09; 23.4(3.8 and 20.5(0.4% VDR, respectively.

The ICGDHA color parameters compared with the impregnated cape gooseberry fruits (L*=46.1±3.1, a*=15.5±2.1 and b*=39.2±4.9), showed significant statistical differences (p <0.05) in the chromaticity a * with respect to the type of process. Therefore, these differences are predominantly attributed to the carotenoid pigments degradation, which are mostly sensitive to heat induction. The variation of b * is mainly observed at low temperatures and may be caused by the development of some brown pigments related to non-enzymatic reactions activated during the drying process (Vega-Gálvez et al., 2008), while changes in L * parameters, are observed mainly at low temperatures and air velocities, which had achieved an enzymatic browning of the food matrix.

Nevertheless, mechanical behavior of the ICGDHA shows a decrease in the Fmax at higher temperature, which could be attributed to several factors as follows: a possible fracturability of the waxy film, the collapse of the structure and cellular compaction (from the outside to the inside of the sample), which generates drier external layers that fix the volume, a crisp, vitreous bark is present, which does not plasticize by the moisture flow throughout and within a gummy structure.

Conclusions

The integration of vacuum impregnation and conventional hot air drying process, represent an effective technological alternatives, which contribute to an added value generation in cape gooseberry fruits, giving to the dehydrated product levels of AC higher than 20% of the VDR (34.2(2.6; 22.6(2.9; 22.3(2.1; 23.4(3.8 and 20.5(0.4% VDR of vitamins B9, C, D3, E and calcium.50gICGDHA-1, respectively).

Given these concerns, during the drying process, temperature was the independent variable, which had achieved the most notable effects on the response or dependent variables, being 60ºC and airflow velocity of 2 ms-1, the process conditions, which have allowed obtaining an acceptable color product, gummy texture and with greater retention of AC. In addition, this product can be labeled according to Colombian regulations with the following descriptor: "Excellent source of calcium and vitamins B9, C, D3 and E in a portion of 50 g ICGDHA".

References

Referencias

Arcot, J. & Shrestha, A. (2005). Folate: Methods of analysis. Trends Food Sci Tech, 16(6-7), 253–266. https://doi.org/10.1016/j.tifs.2005.03.013

Castagnini, J. M., Betoret, N., Betoret, E. & Fito, P. (2015). Vacuum impregnation and air drying temperature effect on individual anthocyanins and antiradical capacity of blueberry juice included into an apple matrix. LWT - Food Sci Tech, 64(2), 1289–1296. https://doi.org/10.1016/j.lwt.2015.06.044

Castells, X. (2012). Sistemas de tratamiento térmico. Procesos a baja temperatura: secado: Tratamiento y valorizacion energética de residuos. Díaz de Santos(Eds.). Madrid, España. 1256p.

Chen, Q., Bi, J., Wu, X., Yi, J., Zhou, L. & Zhou, Y. (2015). Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short- and medium-wave infrared radiation. LWT - Food Sci Tech, 64(2), 759–766. https://doi.org/10.1016/j.lwt.2015.06.071

Cortés, M., Herrera, E. & Gil, J.H. (2016). Impregnación de uchuva (Physalis peruviana L.) de forma semiesférica con una emulsión fortificante. Biotecnología en el Sector Agropecuario y Agroindustrial, 14(1), 27- 36. https://doi.org/10.18684/BSAA(14)27-36

De Lima, M. M., Tribuzi, G., De Souza, J. A. R., De Souza, I. G., Laurindo, J. B. & Carciofi, B. A. M. (2016). Vacuum impregnation and drying of calcium-fortified pineapple snacks. LWT - Food Sci Tech, 72, 501–509. https://doi.org/10.1016/j.lwt.2016.05.016

Fito, P., Andrés, A.M., Barat, J.M. & Albor, A.M. (2001). Introducción al secado de alimentos por aire caliente. UPV, Universidad Politécnica de Valencia (Eds.). Valencia, España. 211p.

Gras, M. L., Vidal, D., Betoret, N., Chiralt, A. & Fito, P. (2003). Calcium fortification of vegetables by vacuum impregnation: Interactions with cellular matrix. J Food Eng, 56(2-3), 279–284. https://doi.org/10.1016/S0260-8774(02)00269-8

Gutiérrez, T., Hoyos, O. & Páez, M. (2007). Determinación de contenido de ácido ascórbico en uchuva (Physalis peruviana L.) por cromatografía liquida de alta resolución (CLAR). Biotecnología en el Sector Agropecuario y Agroindustrial, 5(1), 70-79.

Lešková, E., Kubíková, J., Kováčiková, E., Košická, M., Porubská, J., & Holčíková, K. (2006). Vitamin losses: Retention during heat treatment and continual changes expressed by mathematical models. J Food Compos Anal, 19(4), 252–276. https://doi.org/10.1016/j.jfca.2005.04.014

Mendoza-Corvis, F., Hernández, E. & Ruiz. L. (2015). Efecto del escaldado sobre el color y cinética de degradación térmica de la vitamina c de la pulpa de mango de hilacha (Mangifera indica var. magdalena river). Inf Tecnol, 26(3), 9-16. http://dx.doi.org/10.4067/S0718-07642015000300003

Nadian, M., Rafiee, S., Aghbashlo, M., Hosseinpour, S. & Mohtasebi, S. (2015). Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food Bioprod Process, 94, 263–274. https://doi.org/10.1016/j.fbp.2014.03.005

Ocampo, Y., Caro, D., Rivera, D. & Franco, L. (2017). Safety of sucrose esters from Physalis peruviana L. in a 28-day repeated-dose study in mice. Biomed Pharmacother, 90, 850–862. https://doi.org/10.1016/j.biopha.2017.04.046

Onwude, D., Hashim, N. & Chen, G. (2016). Recent advances of novel thermal combined hot air drying of agricultural crops. Trends Food Sci Tech, 57(Part A), 132 – 145. https://doi.org/10.1016/j.tifs.2016.09.012

Puente, L. A., Pinto-Muñoz, C. A., Castro, E. S. & Cortés, M. (2011). Physalis peruviana Linnaeus, the multiple properties of a highly functional fruit: A review. Food Res Int, 44(7), 1733–1740. https://doi.org/10.1016/j.foodres.2010.09.034

Ratti, C. (2009). Advances in food dehydration (CRC Press. Eds.). Contemporary Food Series. Engineering 467 p.

Sánchez-Chávez, W., Cortez-Arredondo, J., Solano-Cornejo, M. & Vidaurre-Ruiz, J. (2015). Cinética de degradación térmica de betacianinas, betaxantinas y vitamina C en una bebida a base de jugo de remolacha (Betavulgaris L.) y miel de abeja. Scientia Agropecuaria, 6(2), 111 – 118. http://dx.doi.org/10.17268/sci.agropecu.2015.02.03

Vega-Gálvez, A., Lemus-Mondaca, R., Bilbao-Sáinz, C., Fito, P. & Andrés, A. (2008). Effect of air drying temperature on the quality of rehydrated dried red bell pepper (var. Lamuyo). J Food Eng, 85, 42–50. http://dx.doi.org/10.1016/j.jfoodeng.2007.06.032

Wang, Z., Sun, J., Liao, X., Chen, F., Zhao, G., Wu, J., & Hu, X. (2007). Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int, 40(1), 39–46. http://dx.doi.org/10.1016/j.foodres.2006.07.017

Yiotis, A. G., Tsimpanogiannis, I. N., Stubos, A. K. & Yortsos, Y. C. (2006). Pore-network study of the characteristic periods in the drying of porous materials. J Colloid Interf Sci, 297(2), 738–748. http://dx.doi.org/10.1016/j.jcis.2005.11.043

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

CrossRef Cited-by

1. Alexis Pasten, Luis S. Gomez-Perez, Antonio Vega-Galvez, Elsa Uribe, Luis Puente. (2024). Handbook of Goldenberry (Physalis Peruviana). , p.351. https://doi.org/10.1016/B978-0-443-15433-1.00034-0.

2. Manuela Gallón Bedoya, Soany Karola Eraso Grisales, Misael Cortés Rodríguez. (2021). Avances tecnológicos en el proceso de transformación de la uchuva: una revisión. Revista Facultad de Ciencias Básicas, 16(1), p.7. https://doi.org/10.18359/rfcb.5019.

3. Valentina Ossa Montoya, Maritza Gil, Misael Cortés. (2023). Impregnación al vacío y sus parámetros operativos: una revisión. TecnoLógicas, 26(56), p.e2605. https://doi.org/10.22430/22565337.2605.

4. Jose Luis Cháves-Gómez, Laura Marcela Becerra-Mutis, Cristhian Camilo Chávez-Arias, Hermann Restrepo-Díaz, Sandra Gómez-Caro. (2020). Screening of Different Physalis Genotypes as Potential Rootstocks or Parents Against Vascular Wilt Using Physiological Markers. Frontiers in Plant Science, 11 https://doi.org/10.3389/fpls.2020.00806.

5. Luis Puente-Díaz, Oliver Spolmann, Diego Nocetti, Liliana Zura-Bravo, Roberto Lemus-Mondaca. (2020). Effects of Infrared-Assisted Refractance Window™ Drying on the Drying Kinetics, Microstructure, and Color of Physalis Fruit Purée. Foods, 9(3), p.343. https://doi.org/10.3390/foods9030343.

6. Katherine Pere, Kenneth Mburu, Edward K. Muge, John Maina Wagacha, Evans N. Nyaboga. (2023). Molecular Discrimination and Phylogenetic Relationships of Physalis Species Based on ITS2 and rbcL DNA Barcode Sequence. Crops, 3(4), p.302. https://doi.org/10.3390/crops3040027.

7. T. Chuquizuta, W. Castro, M. Castro-Giraldez, P.J. Fito. (2026). Thermodynamic model and infrared thermography monitoring system for convective drying of goldenberry (Physalis peruviana). Journal of Food Engineering, 404, p.112773. https://doi.org/10.1016/j.jfoodeng.2025.112773.

Dimensions

PlumX

Visitas a la página del resumen del artículo

Descargas

Licencia

Derechos de autor 2017 Acta Agronómica

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Política sobre Derechos de autor:Los autores que publican en la revista se acogen al código de licencia creative commons 4.0 de atribución, no comercial, sin derivados.

Es decir, que aún siendo la Revista Acta Agronómica de acceso libre, los usuarios pueden descargar la información contenida en ella, pero deben darle atribución o reconocimiento de propiedad intelectual, deben usarlo tal como está, sin derivación alguna y no debe ser usado con fines comerciales.