Publicado

Adaptative comfort modeling for a typical non-centrifugal cane sugar processing facility

Modelamiento de confort adaptativo para un trapiche panelero

DOI:

https://doi.org/10.15446/dyna.v91n232.112625Palabras clave:

thermal stress; computer simulation; natural ventilation; thermal load; panela (en)estrés térmico; simulación computacional; ventilación natural; carga térmica; panela (es)

Descargas

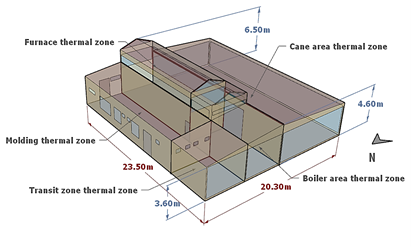

The production of non-centrifuged cane sugar in Colombia takes place in post-harvest facilities that generate significant heat and steam resulting from the evaporation of cane juices during the process. This study aimed to improve the comfort conditions of a facility of this type in the municipality of Pacho, Cundinamarca, Colombia, through bioclimatic simulation, where the enclosure on the walls and the lantern window were modified. The evaluation of adaptative thermal comfort revealed that configurations with open perimeter and lantern window demonstrated the best bioclimatic behavior. This is attributed to the increased ventilation area and chimney effect, which optimizes the transfer of heat and mass. Likewise, it was observed that there is a generalized behavior of thermal discomfort for workers in the thermal zone of the oven, due to the high emissions of heat and steam in this specific area.

La producción de azúcar de caña no centrifugada, en Colombia se realiza en instalaciones de poscosecha que generan alta cantidad de calor y vapor, producto de la evaporación de los jugos de caña del proceso. Este estudio tuvo como objetivo mejorar las condiciones de confort de una instalación de este tipo en el municipio de Pacho, Cundinamarca, Colombia, a través de simulación bioclimática, donde se modificó el cerramiento en las paredes y en la ventana cenital. Se evalúo el confort térmico adaptativo, donde el mejor comportamiento bioclimático se presentó en las configuraciones con perímetro abierto y ventana cenital, esto debido a que una mayor área de ventilación y efecto chimenea optimizan la transferencia de calor y masa; así mismo, se observó que hay un comportamiento generalizado de incomodidad térmica para los trabajadores en la zona térmica hornilla, debido a las altas emisiones de calor y vapor en esta zona.

Referencias

Jaffé, W.R., Nutritional and functional components of non centrifugal cane sugar: a compilation of the data from the analytical literature, Journal of Food Composition and Analysis, 43, pp. 194–202, 2015. DOI: https://doi.org/10.1016/j.jfca.2015.06.007. DOI: https://doi.org/10.1016/j.jfca.2015.06.007

García, J.M., Narváez, P.C., Heredia, F.J., Orjuela, Á., and Osorio, C., Physicochemical and sensory (aroma and colour) characterisation of a non-centrifugal cane sugar (“panela”) beverage, Food Chemistry, 228, pp. 7–13, 2017. DOI: https://doi.org/10.1016/j.foodchem.2017.01.134. DOI: https://doi.org/10.1016/j.foodchem.2017.01.134

Gutiérrez-Mosquera, L.F., Arias-Giraldo, S., and Ceballos-Peñaloza, A.M., Energy and productivity yield assessment of a traditional furnace for noncentrifugal brown sugar (panela) production, International Journal of Chemical Engineering, 2018, art. 6841975, 2018. DOI: https://doi.org/10.1155/2018/6841975. DOI: https://doi.org/10.1155/2018/6841975

Ramírez-Gil, J.G., Characterization of traditional production systems of sugarcane for panela and some prospects for improving their sustainability, Revista Facultad Nacional de Agronomia Medellin, 70(1), pp. 8045–8055, 2017. DOI: https://doi.org/10.15446/rfna.v70n1.61763. DOI: https://doi.org/10.15446/rfna.v70n1.61763

Volverás-Mambuscay, B., González-Chavarro, C.F., Huertas, B., Kopp-Sanabria, E., and Ramírez-Durán, J., Effect of the organic and mineral fertilizer on the performance of sugarcane yield in Nariño, Colombia, Agronomy Mesoamerican, 31(3), pp. 547–565, 2020. DOI: https://doi.org/10.15517/AM.V31I3.37334. DOI: https://doi.org/10.15517/am.v31i3.37334

Alarcón, A.L., Palacios, L.M., Osorio, C., César Narváez, P., Heredia, F.J., Orjuela, A., and Hernanz, D., Chemical characteristics and colorimetric properties of non-centrifugal cane sugar (“panela”) obtained via different processing technologies, Food Chemistry, 340(August 2020), art. 128183, 2021. DOI: https://doi.org/10.1016/j.foodchem.2020.128183. DOI: https://doi.org/10.1016/j.foodchem.2020.128183

Andrade, M., Johanna, M., Torres, G., y Nelson, E., La panela del Catatumbo, una alternativa agroindustrial con perfil Internacional, Revista Espacios [Online]. 41(25), pp. 159–170, 2020. [date of reference December 15th of 2021]. Available at: http://sistemasblandosxd.revistaespacios.com/a20v41n25/a20v41n25p13.pdf

Duarte-Muñoz, M., Torres-González, M.J., Salazar-Beleño, A.M., Carreño-Castaño, L.A., and Pacheco-Valderrama, M.M., Análisis de la situación actual de la industria de transformación de la caña de azúcar en Santander, CITECSA [Online]. 14(23), pp. 31–51, 2022. [date of reference May 08th of 2023]. Available at: https://revistas.unipaz.edu.co/index.php/revcitecsa/article/view/313

Ministerio de la Protección Social de Colombia – MinSalud. Resolución Numero 779 de 2006, del 17 de marzo. Por la cual se establece el reglamento técnico sobre los requisitos sanitarios que se deben cumplir en la producción y comercialización de la panela para consumo humano y se dictan otras disposiciones. Diario Oficial de la República de Colombia N° 46.223 del 17 de marzo de 2006, 2006.

Torres, H.A. y Osorio, R., Evaluación de las condiciones de secado del bagazo usado como combustible en trapiche panelero en el municipio de Nocaima Cundinamarca, en: Congreso Colombiano de Estudiantes de Ingeniería Agrícola CEIA 2020 - Innovación y desarrollo avanzando hacia una agricultura sostenible Bogotá, Colombia, 2020, 28 P.

Amaro, A.L.N., Junior, T.Y., Yanagi, S. de N.M., Ferraz, G.A.E.S., and Campos, A.T., Climate change and rural workers thermal comfort: historical and future impacts, Engenharia Agricola, 38(2), pp. 173–179, 2018. DOI: https://doi.org/10.1590/1809-4430-Eng.Agric.v38n2p173-179/2018. DOI: https://doi.org/10.1590/1809-4430-eng.agric.v38n2p173-179/2018

Habib, R.R., El-Haddad, N.W., Halwani, D.A., Elzein, K., and Hojeij, S., Heat stress-related symptoms among bakery workers in Lebanon: a national cross-sectional study, Inquiry (United States), 58, 2021. DOI: https://doi.org/10.1177/0046958021990517. DOI: https://doi.org/10.1177/0046958021990517

Occupational Safety and Health Administration – OSHA, Overview: working in outdoor and indoor heat environments [Online], 2021. [date of reference January 25th of 2022]. Available at: https://www.osha.gov/heat-exposure

Bolghanabadi, S., Ganjali, A., and Ghalehaskar, S., Investigation of thermal exposure in traditional neyshabur bakeries using heat strain and physiological indices, MethodsX, 6(February), pp. 355–359, 2019. DOI: https://doi.org/10.1016/j.mex.2019.02.003. DOI: https://doi.org/10.1016/j.mex.2019.02.003

Instituto Sindical de Trabajo Ambiente y Salud de España – ISTA, Exposición laboral a estrés térmico por calor y sus efectos en la salud. ¿Qué hay que saber? [Online], QAR Comunicación SA, 2019. [date of reference January 25th of 2022]. Available at: https://istas.net/sites/default/files/2019-04/Guia%20EstresTermico%20por%20exposicion%20a%20calor_0.pdf

Roelofs, C., Without warning: worker deaths from heat 2014–2016, New Solutions, 28(2), pp. 344–357, 2018. DOI: https://doi.org/10.1177/1048291118777874. DOI: https://doi.org/10.1177/1048291118777874

Dacanal, C., Luz, S.doN., Turco, S.H.N., and Vasconcelos, O.C.d.M., Diagnosis and recommendations for the bioclimatic design of grape packing houses in hot and dry climate, Engenharia Agricola, 38(1), pp. 1–6, 2018. DOI: https://doi.org/10.1590/1809-4430-Eng.Agric.v38n1p1-6/2018. DOI: https://doi.org/10.1590/1809-4430-eng.agric.v38n1p1-6/2018

Chen-Austin, M., Castillo, M., De Mendes Da Silva, Á., and Mora, D., Numerical assessment of bioclimatic architecture strategies for buildings design in tropical climates: a case of study in Panama, E3S Web of Conferences, 197, pp. 1–10, 2020. DOI: https://doi.org/10.1051/e3sconf/202019702006. DOI: https://doi.org/10.1051/e3sconf/202019702006

Chong, A., Gu, Y., and Jia, H. Calibrating building energy simulation models: A review of the basics to guide future work, Energy and Buildings, 253, art. 111533, 2021. DOI: https://doi.org/10.1016/j.enbuild.2021.111533. DOI: https://doi.org/10.1016/j.enbuild.2021.111533

Banihashemi, F., Weber, M., and Lang, W., Model order reduction of building energy simulation models using a convolutional neural network autoencoder, Building and Environment, 207(PB), art. 108498, 2022. DOI: https://doi.org/10.1016/j.buildenv.2021.108498. DOI: https://doi.org/10.1016/j.buildenv.2021.108498

Osorio, R.H., Tinôco, I.deF.F., Carlo, J.C., Saraz, J.A.O., and Torres, I.D.A., Bioclimatic analysis of three buildings for wet processing of coffee in Colombia, Revista Facultad Nacional de Agronomia Medellin, 71(3), pp. 8609–8616, 2018. DOI: https://doi.org/10.15446/rfnam.v71n3.64566. DOI: https://doi.org/10.15446/rfnam.v71n3.64566

Gao, N., Shao, W., Rahaman, M.S., Zhai, J., David, K., and Salim, F.D., Transfer learning for thermal comfort prediction in multiple cities, Building and Environment, 195(November 2020), art. 107725, 2021. DOI: https://doi.org/10.1016/j.buildenv.2021.107725. DOI: https://doi.org/10.1016/j.buildenv.2021.107725

Geng, Y., Ji, W., Lin, B., and Zhu, Y., The impact of thermal environment on occupant IEQ perception and productivity, Building and Environment, 121, pp. 158–167, 2017. DOI: https://doi.org/10.1016/j.buildenv.2017.05.022. DOI: https://doi.org/10.1016/j.buildenv.2017.05.022

Ma, N., Aviv, D., Guo, H., and Braham, W.W., Measuring the right factors: a review of variables and models for thermal comfort and indoor air quality, Renewable and Sustainable Energy Reviews, 135(August 2020), art. 110436, 2021. DOI: https://doi.org/10.1016/j.rser.2020.110436. DOI: https://doi.org/10.1016/j.rser.2020.110436

Zhang, S. and Lin, Z., Standard effective temperature based adaptive-rational thermal comfort model, Applied Energy, 264(February), art. 114723, 2020. DOI: https://doi.org/10.1016/j.apenergy.2020.114723. DOI: https://doi.org/10.1016/j.apenergy.2020.114723

Hong, T., Kim, J., and Lee, M., Integrated task performance score for the building occupants based on the CO2 concentration and indoor climate factors changes, Applied Energy, 228(April), pp. 1707–1713, 2018. DOI: https://doi.org/10.1016/j.apenergy.2018.07.063. DOI: https://doi.org/10.1016/j.apenergy.2018.07.063

ASHRAE. Definitions. Section 3. In: Standard 55 Thermal Environmental Conditions for Human Occupancy. Atlanta, Ga American Society of Heating Refrigerating, and Air Conditioning Engineers, Inc. 2017.

Humphreys, M.A. and Fergus, N.J., Principles of adaptive thermal comfort, in: Sustainable houses and living in the hot-humid climates of Asia, Kubota, T., Rijal, H.B., and Takaguchi, H., Eds., Singapore: Springer Singapore, 2018, pp. 103–113. DOI: https://doi.org/10.1007/978-981-10-8465-2_10. DOI: https://doi.org/10.1007/978-981-10-8465-2_10

Bienvenido-Huertas, D., Pulido-Arcas, J.A., Rubio-Bellido, C., and Pérez-Fargallo, A., Influence of future climate changes scenarios on the feasibility of the adaptive comfort model in Japan, Sustainable Cities and Society, 61(June), art. 102303, 2020. DOI: https://doi.org/10.1016/j.scs.2020.102303. DOI: https://doi.org/10.1016/j.scs.2020.102303

De Dear, R.J., Xiong, J., Kim, J., and Cao, B., A review of adaptive thermal comfort research since 1998, Energy and Buildings, 214, art. 109893, 2020. DOI: https://doi.org/10.1016/j.enbuild.2020.109893. DOI: https://doi.org/10.1016/j.enbuild.2020.109893

Hellwig, R.T., Teli, D., Schweiker, M., Choi, J.H., Lee, M.C.J., Mora, R., Rawal, R., Wang, Z., and Al-Atrash, F., A framework for adopting adaptive thermal comfort principles in design and operation of buildings, Energy and Buildings, 205, art. 109476, 2019. DOI: https://doi.org/10.1016/j.enbuild.2019.109476. DOI: https://doi.org/10.1016/j.enbuild.2019.109476

Ferrari, S. and Zanotto, V., Adaptive comfort: analysis and application of the main indices, Building and Environment, 49(1), pp. 25–32, 2012. DOI: https://doi.org/10.1016/j.buildenv.2011.08.022. DOI: https://doi.org/10.1016/j.buildenv.2011.08.022

Ministerio de Trabajo y Seguridad Social de Colombia. Resolución 2400 de 1979. Por el cual se establecen disposiciones sobre vivienda, higiene y seguridad industrial en los establecimientos de trabajo [Online], 1979 [date of reference October 15th of 2021]. Available at: https://www.alcaldiabogota.gov.co/sisjur/normas/Norma1.jsp?i=53565

IDEAM Atlas Climatológico de Colombia. [Online]. [date of reference June 15th of 2021]. Available at: http://atlas.ideam.gov.co/visorAtlasClimatologico.html

Instituto Nacional de Metrologia Qualidade e Tecnologia - anexo Geral V - Catálogo de Propriedades Térmicas de Paredes, Coberturas e Vidros - Portaria no. 50, de 01 de Fevereiro de 2013 [Online], 2013 [date of reference May 15th of 2021]. Available at: https://www.inmetro.gov.br/consumidor/produtospbe/regulamentos/anexov.pdf

Osorio, R.H., Guerra, L.M.G., Tinôco, I.deF.F., Saraz, J.A.O., and Aristizábal, I.D.T., Simulation of a thermal environment in two buildings for the wet processing of coffee, DYNA, 82(194), pp. 214–220, 2015. DOI: https://doi.org/10.15446/dyna.v82n194.49526. DOI: https://doi.org/10.15446/dyna.v82n194.49526

Associação Brasileira de Normas Técnicas – ABNT, Desempenho térmico de edificações - parte 2: métodos de cálculo da transmitância térmica, da capacidade térmica, do atraso térmico e do fator de calor solar de elementos e componentes de edificações. NBR15220-2, 2005.

Laboratório de Eficiência Energética em Edificações – LabEEE, Florianópolis Universidade Fed. St. Catarina Sd Homepage Laboratório Pesqui. [Online]. 2021. [date of reference May 25th of 2021]. Available: http://www.labeee.ufsc.br

Lamberts, R., and Dutra, L., Eficiência Energética na Arquitetura, 3rd ed. ELETROBRAS/PROCEL, Brazil, 2014.

Abreu, P.G.de, Abreu, V.M.N., Franciscon, L., Coldebella, A., and Amaral, A.G., Estimativa da temperatura de globo negro a partir da temperatura de bulbo seco, Revista Engenharia na Agricultura, 19(6), pp. 557–563, 2011. DOI: https://doi.org/10.13083/reveng.v19i6.273. DOI: https://doi.org/10.13083/1414-3984.v19n06a08

Williamson, T., and Daniel, L., A new adaptive thermal comfort model for homes in temperate climates of Australia, Energy and Buildings, 210, art. 109728, 2020. DOI: https://doi.org/10.1016/j.enbuild.2019.109728. DOI: https://doi.org/10.1016/j.enbuild.2019.109728

ASTM, American Society for Testing and Materials, Standard Guide for Statistical Evaluation of Indoor Air Quality Models (D5157-91) [Online]. 2002. [date of reference December 15th of 2021]. Available at: http://sistemasblandosxd.revistaespacios.com/a20v41n25/a20v41n25p13.pdf

Baêta, F.C. and Souza, C.F., Ambiência em edificações rurais, 2nd ed. Editora UFV, 2010.

Guerra-García, L.M., Ferreira-Tinôco, I.deF., Osorio-Saraz, J.A., and Osorio-Hernández, R., Thermal comfort in buildings for wet processing of coffee, Revista de Arquitectura (Bogotá), 21(1), pp. 101–111, 2019. DOI: https://doi.org/https://doi.org/10.14718/RevArq.2019.21.2.2597. DOI: https://doi.org/10.14718/RevArq.2019.21.2.2597

Almoosa, A., Asal, A., Atif, M., and Ayachit, S., Occupational eye injury: the neglected role of eye protection, Bahrain Medical Bulletin, 39(2), pp. 82–84, 2017. DOI: https://doi.org/10.12816/0047525. DOI: https://doi.org/10.12816/0047525

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Licencia

Derechos de autor 2024 DYNA

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

El autor o autores de un artículo aceptado para publicación en cualquiera de las revistas editadas por la facultad de Minas cederán la totalidad de los derechos patrimoniales a la Universidad Nacional de Colombia de manera gratuita, dentro de los cuáles se incluyen: el derecho a editar, publicar, reproducir y distribuir tanto en medios impresos como digitales, además de incluir en artículo en índices internacionales y/o bases de datos, de igual manera, se faculta a la editorial para utilizar las imágenes, tablas y/o cualquier material gráfico presentado en el artículo para el diseño de carátulas o posters de la misma revista.