Published

Engineering Innovation of a Length of Nearly 3300m large Diameter Pipeline Installed by HDD

DOI:

https://doi.org/10.15446/esrj.v20n1.54504Keywords:

Engineering Innovation, Long distance, Large diameter, Gas Pipeline, Horizontal Directional Drilling (HDD), Starting Velocity. (en)The Yangtze River Crossing Project, which is part of the Chinese gas pipeline trunk network and aims to transmit the natural gas to the Yangtze River Delta area, sets up a record for the length of Horizontal Directional Drilling (HDD) in the world. The term of pipeline installed is 3300m, and the diameter is 40in. Many technical difficulties have been inevitably encountered in a large diameter hole reaming in fine sand, the calculation of section scour depth which determines the minimum buried depth of the pipe, protection of outside coating and the method of long distance pilot hole drilling, such other challenges. In view of this, it was recommended that two pipelines of 711mm should be installed to replace the existing one of 1016mm in diameter and 1% flooding scour depth obtained by reliable statistical analysis. In period of installation, application glass fiber reinforced epoxy resin as a protective coating, executing the pilot hole by Intersect Method. As a result, this super project is finished successfully on May 21.2013. The experience can be applied to any pipeline engineering the installed by horizontal directional drilling or similar works.

https://doi.org/10.15446/esrj.v20n1.54504

Engineering Innovation of a Length of Nearly 3300m large Diameter Pipeline Installed by HDD

Li Guohui1, Ma Xiaocheng2, Yang Chunling3

1 Doctoral students/Vice chief engineer, Southwest Jiaotong University/China Petroleum Pipeline Engineering Corp. Email cppe_ligh@cnpc.com.cn

2 Manager of Crossing Department, China Petroleum Pipeline Engineering Corp. Email: maxiaocheng@cnpc.com.cn

3 Engineer, China Petroleum Pipeline Engineering Corp. Email: yang-chl@cnpc.com.cn.

Record

Manuscript received: 02/12/2015 Accepted for publication: 22/03/2016

How to cite item

Guohui, L., Xiaocheng, Ma, & Chunling, Y. (2016). Engineering Innovation of a Length of Nearly 3300mlarge Diameter Pipeline Installed by HDD. Earth Sciences Research Journal, 20(1), P1-P5. doi: https://doi.org/10.15446/esrj.v20n1.54504

ABSTRACT

The Yangtze River Crossing Project, which is part of the Chinese gas pipeline trunk network and aims to transmit the natural gas to the Yangtze River Delta area, sets up a record for the length of Horizontal Directional Drilling(HDD) in the world. The term of pipeline installed is 3300m, and the diameter is 40in. Many technical difficulties have been inevitably encountered in a large diameter hole reaming in fine sand, the calculation of section scour depth which determines the minimum buried depth of the pipe, protection of outside coating and the method of long distance pilot hole drilling, such other challenges. In view of this,it was recommended that two pipelines of 711mm should be installed to replace the existing one of 1016mm in diameter and 1% flooding scour depth obtained by reliable statistical analysis. In period of installation, application glass fiber reinforced epoxy resin as a protective coating, executing the pilot hole by Intersect Method.As a result, this super project is finished successfully on May 21.2013. The experience can be applied to any pipeline engineering the installed by horizontal directional drilling or similar works.

Keywords: Engineering Innovation, Long distance, Large diameter, Gas Pipeline, Horizontal Directional Drilling (HDD), Starting Velocity.

Introduction

To improve the energy instruction in the Yangtze River Delta area by using clean fuels instead of coal, China National Petroleum Corporation(CNPC)executes Jiangdu-Rudong gas pipeline project. This pipeline aims to transmit the natural gas of Jiangsu LNG Terminal to the Delta area where is home to one-third of China's population and generates an estimated 20% of the country's annual GDP (Carlin,etc.2014).Yangtze River Crossing is an essential part of the whole project,with the total length of 3300m,design pressure of 10.0MPa,the diameter of 1016 mm,pipe material of API 5L X70 and external coating of 3LPE.

The crossing point is located at the downstream of Yangtze River, and the topography is flat, which the feature land unit is over bank alluvial plain and new delta alluvial plain. The width of this location is about 3000m with active water transportation,and the average of water depth ranges between 20m to 30m..The stratumunder Quaternary overburden is Devonian, Carboniferous, Permian, Triassic, Jurassic and Cretaceous along with the time sequence.

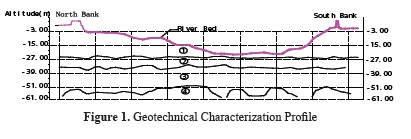

33 bores were drilled on both sides of crossing axis to make clear the geological condition. Relying on properties like geological time, source, lithology, physical and mechanical properties, the field stratum was divided into four parts from top to the bottom. Main properties are as follows:

Layer 1 is muddy, silty clay which contains a single thin layer of silt with a thickness of 2-5 mm. The silty clay was interbedded with silt locally.

Layer 2 is silty clay and the soil is uniform,containing little calcareous concretions with a diameter of 5-50mm, partially. This layer was exposed by all the borehole and it was found stable at the crossing site.

Layer 3is silty (dense). This layer was exposed by all the borehole,and it is evidenced stableat the crossing site. The buried depth on the roof is 10.70-43.70m and 28.40m on average.

Layer4 is medium sand, containinglittle like-round gravel particle and pebble. The overall diameter is 2-10mm and 20-40mm, individually.This layer was exposed to most of the borehole and distributed widely at the crossing site. The Geotechnical Characterization Profile (GCP) is shown in Figure 1.

CPPE (China Petroleum Pipeline Engineering Corp.), which is a branch company of CNPC, served as a design contractor. Engineers selected the scheme of installing by HDD rather than shield tunnel. However, it is a significant challenge: the crossing length is nearly 3300m, and the pipeline diameter is 40 inches. The critical problems of this project are 1) large diameter hole reaming in the fine sand; 2) the calculation of section scour depth, which determines the minimum buried depth of the pipe; 3) protection of outside coating, and 4) the method of long distance pilot hole drilling.

1. Two small diameter pipeline replace a large one avoiding to reach large diameter hole

Yangtze River is the longest river in China.There are rare HDD crossings in Yangtze River before this project. For example,Lanzhou-Zhengzhou-Changshan production oil pipeline project uses HDD crossing in Yangtze River, with a pipe diameter of 610mm, and a length of 2100m (Li Guohui, etc. 2012). The crossing construction confronted with many difficulties like bore collapse, drillpipe fracture,and finally it was finished after two difficult years..Other projects that adopt big diameter and long distance HDD crossing are also rare.In 2007, Hangzhou-Yongning pipeline project crossed Qiantang river,with a diameter of 813mm, crossing a distance of 2454m (Tan Mingxing, etc. 2008).In2008, Zhuhai-Zhongshan gas pipeline project crossed the Modaomen River,with a diameter of 660mmand a length of 2630m (Yin Gangqian,etc.2008). In the recent two years,pipe diameter enlarges continually. In 2011,China-Myanmar gas pipeline crossed at Irrawaddy River, using the HDD crossing method,with a pipe diameter of 1016mm, and a crossing length of 1760m. A final example is the second west-east natural gas pipeline crossingPengjiawan Sluice,with a pipe diameter of 1219mm, and a length of 1397m.

In others countries, the record-setting bore came during the drilling of a second 10,000-foot bore and pull-in of a 30-inch pipe near Al Jabayl for the Bern Causeway Pipeline project. A new global horizontal directional drill (HDD) undersea crossing record has been set regarding pipe diameter, pipe weight and length of crossing, in Saudi Arabia, in 2007 (Share, 2009). Southern Gas Networks (SGN) is currently reinforcing the gassupply infrastructure on the Isle of Wight, located off the south coast of England. Part of this process required the replacement of the pipelines supplying gas from the UK mainland to the island. Two 324mm-diameter steel pipelines were installed through separate holes some 50m below the bed of the Solent using horizontal directional drilling (HDD). Each 3,930m-long crossing is believed to be some 20% longer than any previously completed using HDD(Seamans,2011).

Analyzing the cases mentioned regarding pipe diameter, pipe weight and length of the crossing, the case of utilizing a 1016mm diameter,with 3300 lengths and a weight reaching 2096tons pipe cannot complete pullback. Take into consideration adopting two pipes of the same diameter as a replacement. Comparing different diameters ranging from 610mm to 914mm, the sectional area sum for two pipe are as followsin Table 1.

Concluding from the table 1,there is little difference between two pipes with a diameter of 711mm and one pipe with a diameterof1016mmconcerning the medium through capacity. As a consequence, adopting HDD crossing will reduce the difficulty in comparison with the use of a previous scheme.

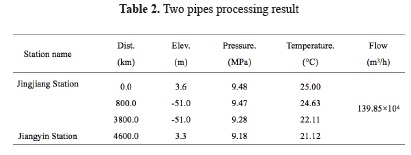

Meanwhile,set two pigging station at both sides, named Jingjiang Station and Jiangyin Station. It is required that the outlet temperature is no less than 20°Cand outlet pressure is no less than 8.8 MPa in Jiangyin station to satisfy the transmission to downstream. We should analyze processing influence for the new scheme, which includes two stations and two 711mm diameter pipelines. The analysis of the fundamental dataconsists oftwo pipes with a diameter of 711mm and pipe thickness of 19mm, the inlet pressure of 9.48 MPa, the rate of flow 139.85×104Nm3/h, 3PE reinforced protecting coating thickness of 3.8mm,no thermal insulation,no inner coating, earth temperature of 25°C. The total length of the pipe is 4600m.The two pipes processing result is shown in Table 2.

Through technology analysis,the pressure of transmission pigging station is 9.18 MPa, and the temperature is 21°C, having no influence on the feasibility ofdownstream and pipe.Hence,this scheme does not affect the whole design.

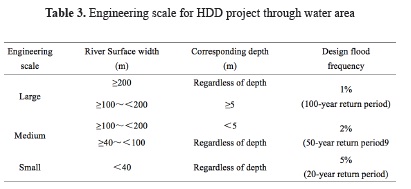

2. 1% flooding scour depth obtained by reliable statistical analysis

The Yangtze River scour primarily controls the depth of penetration because of the flood peak. According to code GB50423(China Petroleum Pipeline Engineering Co., Ltd., 2007), the minimum depth of penetration should not be less than 6m from the design flood scour line.The project is defined on a large scale, and we should choose 1% (100-year return period) flood frequency. The chosenrule is shown in Table 3. The design flood frequency of channel erosion calculation is 1%,and the peak flood is 108800 m3/s.

Since 1960, the crossing region varies relatively small.One main reason is that this project section is influenced by the dual role of runoff and tidal current, so the riverbed maintains a certain amplitude balance of erosion and deposition.The frontier waters riverbed of proposed construction suffers interactive effects of upstream inflow and reciprocating tidal current. The shoreline varies little and keeps relatively stable for years.Measures have to be taken to protect the shoreline of proposed project so that the scheme has strong anti-erosion features.On condition that Yangtze river regime does not change greatly,the riverbed condition can keep stable over the long run. The change of riverbed is shown in Figure 2.

Observing the 50 years scour condition,the river regime of pipe crossing region is stable;a deep groove(-15m) in the north bank varies a lot over the years, and the south bank keeps slightly stagnant.Also,the axis of the deep groove in the south bank and the deep groove itself(-20m)remains stable. The envelope line for depth scour of 50 years is shown in Figure 3.

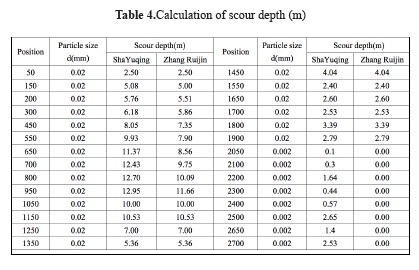

The commonly used methods for river scour depth calculations are Samov formula,Xie Jianheng formula,Zhang Ruijin formula and Sha Yuqing formula(Zhang Fengliang, etc. 2013).Consider Samov formula and Xie Jianheng formula are only adapted to coarse granular sediment which satisfied the condition d>0.15∼0.20mm, and they are not suited to fine sand and silty clay particles.As a consequence,scour calculation in this article uses Zhang Ruijin formula and Sha Yuqing formula which are adapted to fine cohesive sediment to figure out the starting velocity.

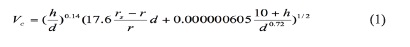

Zhang Ruijin starting velocity formula

Professor Zhang Ruijin from water conservancy and electric power institute Wuhan University started from rolling mode of sediment and gave the equilibrium equations of force,then derived the Zhang Ruijin starting velocity formula.

Where the units of depth h,diameter d are both m.Zhang Ruijin starting velocity formula is not only adapted to fine cohesive sediment but also the cohesionless coarse sediment.It is a general formula.

Sha Yuqing starting velocity formula

Where ε means porosity,stable data is 0.4; the units of d and h are mm and m,respectively;ucmeans starting velocity, and the unit is m/s.

The maximum scour depth always arises in the main channel.When the main channel velocity is larger than sand starting velocity,the riverbed stops scouring until the main channel velocity is smaller than starting velocity, and then the scouring process stops.

The maximum rate of flow per unit width multiples the maximum vertical average velocity can be derived according to the result of 2-D tidal flow mathematical model.

Then by the riverbed property,use the formula below to calculate the maximum depth after scouring.

If the riverbed consists of cohesive soil,the highest depth after scouring is:

Where uc' means the non-scouring velocity of cohesive soil in corresponding depth.

If the riverbed consists cohesionless soil,use the formula below to calculate the maximum depth:

Where Vc is the sediment starting velocity,which can be calculated by corresponding velocity formula.

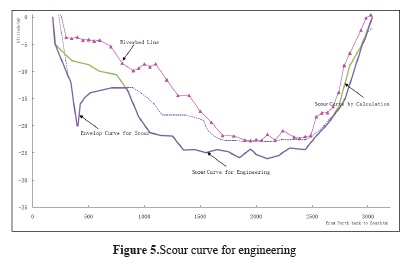

When the diameter satisfies the condition d<0.15mm,the sediment particle possesses certain viscosity,the starting velocity increases according to the d decreasing,the fine particle size should be replaced by the equivalent diameter in the same starting velocity or utilizing cohesive sediment starting velocity formula to calculate. The calculated result of scour depth by Sha Ruiqing formula and Zhang Ruijin formula is shown in Table 4.The scour curve by calculation is shown in Figure 4.

Superimpose previous monitoring envelop curve for scour line and scour line by calculation, obtaining scour line for engineering. The scour curve for engineering is shown in Figure 5.

Figure 5 implies that we should lay the pipeline in Layer 3 fine sand.

3. Application a new type protective coating

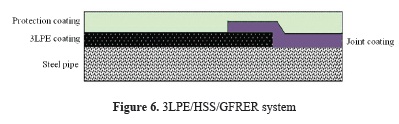

3LPE is the most commonly used as outside coating for long distance pipelines(J.D.hair,etc.2000). Strengthen 3LPE are coated on HDD pipes and dedicated filed joint coating system are used for 3LPE which consists of heat shrinkable sleeve (HSS) and another protective sleeve installed in the front end of the drilling direction, with 100mm overlap on HSS and 3LPE, respectively.

An uneven seam, or step, would be inevitably formed between HSS and 3LPE after the completion of field joint coating system installation, resulting HSS dragged off from the pipe during HDD pulling, even extensive damage of 3LPE coating in case of harsh geological conditions. This condition would consequently affect the integrity performance of coating due to lots of hole or damages. In a worst-case scenario, the HSS might slip off from the pipe causing sticking accidents and hence making the crossing fail.

CPPE' engineers applied a modified liquid solvent-free, glass fiber reinforced epoxy resin (GFRER) coating to protect the anticorrosion coating on HDD pipes. As showed in Figure 6, GFRER is coated outside completely encasing the 3LPE layer and its HSS field joint coating system, obtaining 3LPE/HSS/GFRER system with a smooth surface for the all HDD pipeline to favor pipe pullback.

GFRER protective coating was first applied to the HDD project. The coating thickness is 3.7mm. Using a glass fiber reinforced epoxy resin as an armoring coating over the corrosion coating preserve the integrity of the coating and minimize damage when installation. Figure 7 shows the glass fiber reinforced epoxy resin painting.

4. HDD design

Entry and exit point. It is same geotechnical for drilling effectiveness at south and north bank. So we should select the availability of workspace for pull section fabrication at the exit point. The north bank side is flatness and has enough length for pipeline welding before pulling. It is properly to clarify that the north side is exit point, and the south is the entry.

Input and output angle. HDD input and output angle should be determined based on crossing length, burial pipeline depth, diameter, elastic laying conditions, terrain conditions. Entry angle is limited by equipment capabilities and should be 8° ∼ 20°; the exit angle should be 4° ∼ 12°.Choose lower exit angle when pipeline diameter is large. According to the condition of surface and subsurface, in this case, the selected entry angle is 10°, and the exit is 8°.

Design radius of curvature. The curvature radius of HDD elastic laying section should not be less than 1500 times the diameter of the pipe to be installed, and must not be less than the 1200D. In this case,the radius is 1067m, which is 1500D.

The HDD crossing horizontal distance between Yangtze River buried and unearthed point is 3290m and actual length is 3300m. The HDD curve is shown in Figure 8.

5.Executing the pilot hole by Intersect Method

Magnetic signal submarine cable laying.In this project, prepare to lay armored cable used to provide artificial magnetic field strength in crossing area.Rent dedicated laying barge to bury the submarine cable while laying.Employ the dedicated submarine measurement company to measure the cable coordinate.

Parameters of measurement direction control.Calibrate guide hole crossing Paratrack II direction control system and mark direction control parameter.To ensure the accuracy of data,measure at different locations across the center line to compare and make a record.

Intersect area.Combine Paratrack II direction control system and magnetic signal cable,main rig drills along with the design crossing curve and the auxiliary rig drills at the same time.Two sets of rigs coordinate each other while drilling,reaching the intersect area simultaneously. In the intersect area,start axial magnet which is installed in the Assistant rig drill bit,leading drill bit of main rig drilling until two drill bits combined, that is drill bit of main rig drills into the guide hole of the auxiliary rig.Auxiliary rig pulls back the drill pipe, the main rig pushes on the drill pipe and ultimately unearths along with guide hole dug by the auxiliary.

Mud sensor, which is installed behind the main rig drill bit, will supervise the mud pressure in holes during the entire processing in pilot hole construction procedure.If the mud pressure increases unusually,pull back the drill bit and go on drilling after hole flushing.

Pilot holeworks last 20 days only, from March 22, 2013, to April12, 2013.

6. Result

Once the pilot hole was successfully completed, the following reaming operations were executed using new Φ168mm S-135 drill pipe:

Stage One: Φ610mm (24") barrel reamer pre-reaming;

Stage Two: Φ762mm (30") barrel reamer pre-reaming;

Stage Three: Φ924mm (36") barrel reamer pre-reaming;

Stage Four: Φ1,118mm (44") barrel reamer pre-reaming followed by washing of the hole.

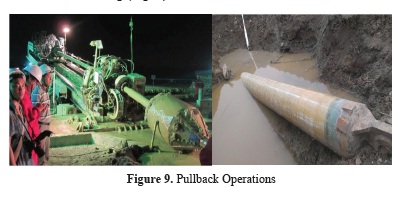

The pullback was the last step in the crossing process. The pullback was executed by Φ168mm drill pipe, a Φ1,067mm (42") barrel reamer, and 3,300m of steel pipeline. All drill parameters and fluid parameters were closely monitored to ensure the smooth pullback and avoid damage to the outside coating (Fig. 9).

The original project included 274 working days. The actual work was completed within this time frame. Overall, the drilling operations were successful at steering along the design profile.

7. Conclusion

The following conclusions were reached through the HDD project:

1. It is reasonable that two 711-mm-diameter pipelines replace one 1016-mm-diameter pipeline installation by HDD. This scheme is not only guaranteeing success installation but also reduce thedifficulty. No any contractor can finish the construction if we use one 1016-mm-diameter pipeline, and we should select the shield tunnel which is more expensive than HDD.

2. It is most important that confirm the depth of penetrationaccording to river scour depth analysis. In this project, we analyze the scour depthorganizing the 50 years river scour condition and calculation by Zhang Ruijin formula and Sha Yuqing formula.

3. The success of the crossing of Yangtze River has established a new record of diameter * length in oil and gas pipeline installation by HDD.

References

Carlin, M., Ariaratnam, S., Ma, B.S., and Zeng, C., 2014. "Record setting Yangtze river HDD crossing of three parallel pipelines over a length of nearly 3300m," Proc. 2014 NASTT No-Dig Conference, North American Soc. For Trenchless Technology, NY.

GB 50423-2007: Code for design of oil and gas transportation pipeline. (2008). China Plans to Press, Beijing, China.

J.D. Hair & Associates, Inc., 2000. "Coating Requirements for Pipelines Installed by Horizontal Directional Drilling and Slip Boring," Pipeline Research Council International, Inc., Houston, United States.

Li Guohui, Wei. Yang, Feng. Qian and XC. Ma, 2012. "High-Risk, 610mm Diameter, 2,090m HDD Project- A Case Study", ICPTT 2012, American Society of Civil Engineers (ASCE), Reston, United States.

Seamans, J., 2011. "HDD in record Solent crossing," World Tunnelling, 2011 (Jun.):46-49.

Share, J., 2009. "Challenging HDD Project Provides 10,000-Foot Record-Setting Crossing," Pipeline and Gas Journal, 2009, 236(5):40-42.

Tan, Mingxing., Liu, Yufeng, Yang Fan,. Zeng Qiang, Lei Jie, Xie Qishuai, 2008. "Design of HDD engineering in Qiantang Rover", Natural gas and oil, Natural gas and oil press, Chengdu, China.

Yin Gangqian., and Tang X.F., 2008. "The construction technology of horizontal directional drilling crossing in Modaomen River," Petroleum Engineering Construction Vol.34 (6), Petroleum Engineering Construction press, Tianjin, China.

Zhang Fengliang and Wang Xintao, 2013. "Discussion on the calculation of the scour depth in the flood impact assessment", China Flood & Drought Management, 2013(5), China Flood & Drought Management press, Beijing, China.

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

License

Earth Sciences Research Journal holds a Creative Commons Attribution license.

You are free to:

Share — copy and redistribute the material in any medium or format

Adapt — remix, transform, and build upon the material for any purpose, even commercially.

The licensor cannot revoke these freedoms as long as you follow the license terms.

The Earth Sciences Research Journal is the copyright holder for these license attributes.