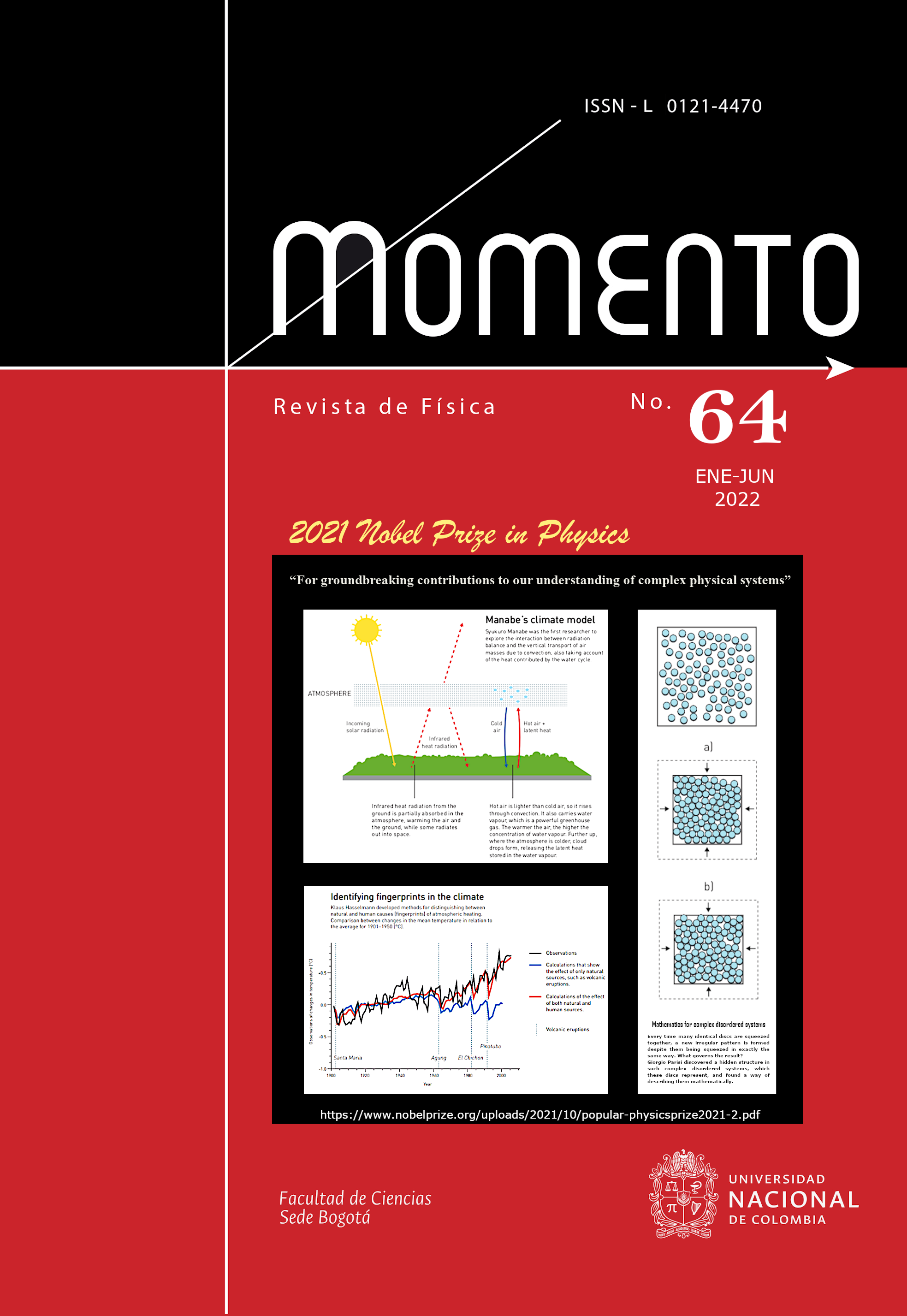

Effect of kaolin waste annealing on the structural and thermal behavior of poly(ε−caprolactone)

Efecto del recocido de residuos de caolín sobre el comportamiento estructural y térmico de poli(ε−caprolactona)

DOI:

https://doi.org/10.15446/mo.n64.99725Keywords:

kaolin waste, reuse, heat treatment, composites, poly(ε-caprolactone) (en)residuo de caolín, reutilizar, tratamiento térmico, compuestos, poli (ε-caprolactona) (es)

Downloads

The heat treatment effect on kaolin waste from mining was evaluated on the structural and thermal behavior of poly(ε-caprolactone) (PCL). The PCL/KW (kaolin waste) and PCL/HTKW (heat-treated kaolin waste) composites were processed in an internal mixer and subsequently characterized by X-ray diffraction (XRD) and differential scanning calorimetry (DSC). The kaolin waste showed kaolinite and quartz in its composition, while the heat treatment at 1200°C modified it to mullite, quartz and silica-rich amorphous phase. By XRD, there was an increase in the intensity of the peak 2θ = 23.9° of the PCL/KW composites compared to neat PCL. In contrast, PCL/HTKW composites tended to reduce the intensity of the peak 2θ = 23.9°, especially at 5% HTKW. The crystalline melting temperature and the degree of crystallinity of PCL/KW and PCL/HTKW composites were practically unchanged, compared to PCL. However, the crystallization process was more effective with the kaolin waste (KW) without heat treatment, indicating that the HTKW amorphous phase inhibited crystallization. The PCL/KW development promoted an increase in crystallization temperature, relative crystallinity, and crystallization rate, surpassing PCL and the PCL/HTKW system. In view of this, kaolin waste has the potential to accelerate the PCL crystallization process, contributing to add value to a material that would otherwise be discarded and minimizing environmental impacts.

Se evaluó el efecto del tratamiento térmico en los desechos de caolín de la minería sobre el comportamiento estructural y térmico de la poli (ε-caprolactona) (PCL). Los compuestos PCL/DC (desechos de caolín) y PCL/DCT (desechos de caolín tratados térmicamente) se procesaron en un mezclador interno y luego se caracterizaron por difracción de rayos X (DRX) y calorimetría de barrido diferencial (DSC). El residuo de caolín tenía caolinita y cuarzo en su composición, mientras que el tratamiento térmico a 1200 °C lo cambió a mullita, cuarzo y fase amorfa rica en sílice. Por XRD, hubo un aumento en la intensidad del pico 2θ = 23,9° de los compuestos PCL/DC, en comparación con el PCL puro. Por el contrario, los compuestos PCL/DCT tendieron a reducir la intensidad máxima 2θ = 23,9°, especialmente con el 5% de DCT. La temperatura de fusión cristalina y el grado de cristalinidad de los compuestos PCL/DC y PCL/DCT se mantuvieron prácticamente sin cambios, en relación al PCL. Sin embargo, el proceso de cristalización fue más eficiente con residuo de caolín (DC) sin tratamiento térmico, lo que indica que la fase amorfa del DCT inhibió la cristalización. El desarrollo de los PCL/DC promovió un aumento en la temperatura de cristalización, cristalinidad relativa y velocidad de cristalización, superando a la PCL y al sistema de los PCL/ DCT. Como resultado, el residuo de caolín tiene el potencial de acelerar el proceso de cristalización de la PCL, contribuyendo a agregar valor a un material que de otra manera sería descartado y minimizando los impactos ambientales.

References

Z. Han, A. Golev, and M. Edraki, Minerals 11, 701 (2021).

W. B. B. Lima, H. L. Lira, and G. A. Neves, Revista Eletrónica de Materiais e Processos 11, 89 (2016).

F. F. Carmo, A. O. Lanchotti, and L. H. Kamino, Sustainability 12, 8466 (2020).

C. M. Anjos and G. A. Neves, Revista Eletrónica de Materiais e Processos 6, 91 (2011).

P. Boonphayak, S. Khansumled, and C. Yatongchai, Materials Letters 283, 128759 (2021).

A. M. Rodrigues and et al., Sustainability 13, 11395 (2021).

R. Menezes and et al., Cerámica 53, 388 (2007).

M. L. S. Rezende and et al., REM: Rev. Esc. Minas 61 (2008).

M. R. Nascimento and et al., Revista Principia - Divulgação Científica e Tecnológica do IFPB 23, 77 (2015).

[D. M. Zago and et al., Journal of Science and Technology 9, 19 (2017).

A. Akpinar Borazan and G. Adiguzel, Journal of Engineering Research and Applied Sciences 7, 937 (2018).

J. X. Chan and et al., Polymer Composite 41, 395 (2020).

M. Brebu, Polymers 12, 166 (2020).

W. A. da Silva and et al., J. Polym. Environ. 29, 2932–2951 (2021).

T. R. Rigolin and et al., J. Polym. Environ. 27, 1096 (2019).

T. El Assimi and et al., J. Polym. Environ. 28, 2078 (2020).

M. Dadras and et al., J. Polym. Environ. 28, 1252 (2020).

G. Medeiros and et al., J. Polym. Environ. 28, 331 (2020).

C. B. B. Luna and et al., Mater. Res. Express 6, 125317 (2019).

C. B. B. Luna and et al., MOMENTO 62, 1 (2021).

M. Rojas, D. Solera, C. Herrera, and J. Vega, MOMENTO 60, 67 (2020).

L. A. Reul, L. H. Carvalho, and E. L. Canedo, Revista Eletrónica de Materiais e Processos 12, 174 (2017).

D. Siqueira and et al., Journal of Materials Research and Technology 9, 9691 (2020).

I. Janigová, D. Jochec, and I. Chodák, Aip. Conf. Proc. 1255, 287 (2010).

M. Lanfranconi, V. A. Alvarez, and L. N. Ludueña, J. Therm. Anal. Calorim. 126, 1273 (2016).

D. D. Siqueira and et al., Mat. Res. 22 (2019).

M. Paula and et al., Polímeros 29 (2019).

K. M. Seven, J. M. Cogen, and J. F. Gilchrist, Polymer Engineering and Science 56, 541 (2016).

D. D. Siqueira and et al., Mater. Res. Express 6, 095335 (2019).

L. Lima and et al., Revista Eletrónica de Materiais e Processos 13, 163 (2018).

A. L. Silva and et al., Sustainability 12, 10159 (2020).

E. A. S. Filho and et al., Polymer Composites 42, 6182 (2021).

N. Vogelsanger and et al., Mat. Res. 6, 359 (2003).

C. B. B. Luna and et al., J. Elastom. Plast. 53, 1045 (2021).

E. S. B. Ferreira and et al., Sustainability 13, 12157 (2021).

A. Barros and et al., Materials 13 (2020).

R. Hoffmann and et al., Composites Part A: Applied Science and Manufacturing 124, 105472 (2019).

J. Azevedo and et al., Matéria (Rio J.) 21, 391 (2016).

A. P. F. Albers and et al., Cerámica 48, 34 (2002).

S. G. Brena and et al., MOMENTO 61, 24–36 (2020).

J. Shichun and et al., Polymer 42, 3901 (2001).

M. Abubakar and et al., Materials 13, 1872 (2020).

A. L. Silva and et al., Cerámica 64, 69 (2018).

A. L. Silva and et al., Res. Soc. Dev. 10, e283101220653 (2021).

A. Spinelli and et al., Cerámica Industrial 8, 46 (2003).

D. Kumar, G. Babu, and S. Krishnan, Polímeros 29, e2019024 (2019).

L. Siqueira and et al., Polímeros 29, e2019005 (2019).

M. Rabello, Aditivacao de polímeros (2000) pp. 159–171.

C. Barreto and et al., Mater. Res. Express 6, 125367 (2020).

G. M. X. Carvalho and et al., Polímeros 17, 98 (2007).

J. C. C. Lima and et al., Revista Eletrónica de Materiais e Processos 11, 10 (2016).

J. C. de Sousa, J. C. Lima, S. A. Arruda, E. L. Canedo, and Y. M. B. Almeida, 4º. Encontro Nordeste de Ciencia e Tecnologia de Polímeros , 1 (2018).

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

CrossRef Cited-by

1. Carlos Bruno Barreto Luna, Eduardo da Silva Barbosa Ferreira, Danilo Diniz Siqueira, Edcleide Maria Araújo, Emanuel Pereira do Nascimento, Eliton Souto Medeiros, Tomás Jeferson Alves de Mélo. (2022). Electrical nanocomposites of PA6/ABS/ABS‐MA reinforced with carbon nanotubes (MWCNTf) for antistatic packaging. Polymer Composites, 43(6), p.3639. https://doi.org/10.1002/pc.26643.

2. Asmaa N. Alkassfarity, Mohamed A. Yassin, Mona H. Abdel Rehim, Lipeng Liu, Ziyue Jiao, Bo Wang, Zhiyong Wei. (2024). Modified cellulose nanocrystals enhanced polycaprolactone multifunctional films with barrier, UV-blocking and antimicrobial properties for food packaging. International Journal of Biological Macromolecules, 261, p.129871. https://doi.org/10.1016/j.ijbiomac.2024.129871.

3. Carlos Bruno Barreto Luna, Edson Antonio dos Santos Filho, Danilo Diniz Siqueira, Edcleide Maria Araújo, Emanuel Pereira do Nascimento, Tomás Jeferson Alves de Mélo. (2022). Influence of Small Amounts of ABS and ABS-MA on PA6 Properties: Evaluation of Torque Rheometry, Mechanical, Thermomechanical, Thermal, Morphological, and Water Absorption Kinetics Characteristics. Materials, 15(7), p.2502. https://doi.org/10.3390/ma15072502.

4. Aleksandra Jeżo, Faksawat Poohphajai, Rene Herrera Diaz, Grzegorz Kowaluk. (2024). Incorporation of Nano-Zinc Oxide as a Strategy to Improve the Barrier Properties of Biopolymer–Suberinic Acid Residues Films: A Preliminary Study. Materials, 17(15), p.3868. https://doi.org/10.3390/ma17153868.

5. Betül Gürbüz, Erkan Türker Baran, Aydın Tahmasebifar, Bengi Yilmaz. (2024). Construction of Aligned Polycaprolactone/Poly(Glycerol Sebacate)/Polysulfone Nanofibrous Scaffolds for Tissue Engineering of the Ventricularis Layer of Heart Valves. Polymers for Advanced Technologies, 35(11) https://doi.org/10.1002/pat.6629.

6. Jessika Andrade dos Santos Nogueira, Carlos Bruno Barreto Luna, Adriano Lima da Silva, Ana Cristina Figueiredo de Melo Costa, João Baptista da Costa Agra de Melo, Renate Maria Ramos Wellen, Edcleide Maria Araújo. (2023). Turning residues of coconut flour in bioadditive: an alternative to accelerate PCL biodegradation. Journal of Polymer Research, 30(9) https://doi.org/10.1007/s10965-023-03711-9.

7. Pilar Astrid Ramos Casas, Andres Felipe Rubiano-Navarrete, Yolanda Torres-Perez, Edwin Yesid Gomez-Pachon. (2025). Effect of Diatomite Content in a Ceramic Paste for Additive Manufacturing. Ceramics, 8(3), p.96. https://doi.org/10.3390/ceramics8030096.

8. Carlos B. B. Luna, Eduardo S. B. Ferreira, Fernanda M. Sousa, Emanuel P. Nascimento, Edcleide M. Araújo, Dayanne D. Souza, Elieber B. Bezerra, Renate M. R. Wellen. (2022). DETERMINATION OF THE VISCOSITY TEMPERATURE COEFFICIENT (β) AND PSEUDOPLASTIC INDEX (n) OF POLY(LACTID ACID) (PLA). MOMENTO, (65), p.25. https://doi.org/10.15446/mo.n65.102254.

9. Carlos Bruno Barreto Luna, Edson Antonio dos Santos Filho, Danilo Diniz Siqueira, Dayanne Diniz de Souza, Renate Maria Ramos Wellen, Edcleide Maria Araújo. (2022). Jatobá wood flour: An alternative for the production of ecological and sustainable PCL biocomposites. Journal of Composite Materials, 56(25), p.3835. https://doi.org/10.1177/00219983221123940.

10. Carlos Bruno Barreto Luna, Eduardo da Silva Barbosa Ferreira, Adriano Lima da Silva, Edcleide Maria Araújo, Ana Cristina Figueiredo de Melo Costa, Renate Maria Ramos Wellen. (2022). Tuning the performance of PA6/EPDM‐MA nanocomposites reinforced with Ni0.5Zn0.5Fe2O4. Effect of the mixing protocol on mechanical, thermal, thermomechanical, magnetic, and morphological behavior. Polymer Composites, 43(7), p.4447. https://doi.org/10.1002/pc.26704.

11. Dayanne Diniz de Souza Morais, Carlos Bruno Barreto Luna, Elieber Barros Bezerra, Danyelle Campos de França, Edcleide Maria Araújo, Emanuel Pereira do Nascimento, Amanda Dantas de Oliveira, Tomás Jefferson Alves de Mélo. (2022). Performance of Poly(caprolactone) (PCL) as an Impact Modifier for Polystyrene (PS): Effect of Functionalized Compatibilizers with Maleic Anhydride and Glycidyl Methacrylate. Sustainability, 14(15), p.9254. https://doi.org/10.3390/su14159254.

Dimensions

PlumX

Article abstract page views

Downloads

License

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Those authors who have publications with this journal, accept the following terms:

a. The authors will retain their copyright and will guarantee the publication of the first publication of their work, which will be subject to the Attribution-SinDerivar 4.0 International Creative Commons Attribution License that permits redistribution, commercial or non-commercial, As long as the Work circulates intact and unchanged, where it indicates its author and its first publication in this magazine.

b. Authors are encouraged to disseminate their work through the Internet (eg in institutional telematic files or on their website) before and during the sending process, which can produce interesting exchanges and increase appointments of the published work.