PELÍCULAS GRUESAS DE YBCO POR EL MÉTODO QUÍMICO SUAVE FUNDIDO-RECOCIDO

Palabras clave:

método fundido-recocido, películas gruesas superconductoras. (es)YBCO THICK FILMS BY SOFT CHEMICAL MELT-ANNEALING METHOD

PELÍCULAS GRUESAS DE YBCO POR EL MÉTODO QUÍMICO SUAVE FUNDIDO-RECOCIDO

YBCO THICK FILMS PELO MÉTODO DE QUÍMICA SOFT FUNDIDO - RECOZIMENTO

Paula A. Garcés1, Alvaro Marino2

1 Departamento de Química, Facultad de Ciencias, Universidad Nacional de Colombia, sede Bogotá, Bogotá, D. C., Colombia

2 Departamento de Física, Facultad de Ciencias, Universidad Nacional de Colombia, sede Bogotá, Bogotá, D. C., Colombia. Autor para correspondencia: amarinoca@unal.edu.co

Recibido: 30/04/09 - Aceptado: 07/09/09

ABSTRACT

Thick films (≥ 1 μm) of YBa2Cu3O7-δ were deposited by the dip-coating method on MgO (100) substrates at room temperature. After that, superconducting films were obtained by using the melt-annealing method with different thermal treatments. These films showed both different crystalline orientations and critical current densities (Jc). Additionally the thick films displayed superconducting transitions (Tc) around 89.5 K and critical current densities ≥ 2x104 A/cm2 at 77 K and 0t. The highest Tc and Jc values achieved were attributed mainly to the higher oxygen content and the growth of larger grain sizes as determined by XRD and SEM analysis respectively.

Key words: melt-annealing method, superconducting thick films.

RESUMEN

Películas gruesas (≥ 1 μtm) de YBa2Cu3 O7-δ se depositaron por el método dip-coating a temperatura ambiente en sustratos de MgO (100). Con el fin de obtener películas superconductoras se utilizó luego el método de fundido-recocido con diferentes tratamientos térmicos. Las películas obtenidas así, mostraron diferentes orientaciones cristalinas y diferentes densidades de corriente crítica (Jc). Las películas presentaron además, transiciones superconductoras (Tc) de aproximadamente 89,5 K y densidades de corriente crítica ≥ 2x104 A/cm2 a 77 K y 0t. Los valores más altos de Tc y Jc logrados se atribuyeron principalmente al alto contenido de oxígeno y al crecimiento de granos grandes, como se determinó por los métodos de análisis XRD y SEM respectivamente.

Palabras clave: método fundido-recocido, películas gruesas superconductoras.

RESUMO

Filmes espessos de YBa2Cu3O7-δ (≥ 1mícron) foram depositados por dip-coating de revestimento na temperatura ambiente em substratos de MgO (100). Então, a fim de obter supercondutores filmes, utilizou-se a derreter-annealing método com diferentes tratamentos térmicos. Os filmes obtidos apresentaram orientações de cristal um pouco diferentes, e densidade de corrente crítica (Jc). Os filmes mostraram transições supercondutoras (Tc) de 89,5 K e densidades de corrente crítica (Jc) ≥ 2x104 A/cm2 a 77 K e 0t. Valores de Tc e Jc obtidos foram atribuídas principalmente ao elevado conteúdo de oxígano e crescimento de grãos grande, determinada por DRX e MEV, respectivamente.

Palavras-chave: derreter-annealing método, filmes supercondutores de espessura.

INTRODUCTION

At present many methods have been used for the preparation of high temperature superconducting films. They can be divided in two basic groups: physical vapor deposition (PVD) methods such as sputtering, laser ablation, molecular beam epitaxy and thermal evaporation, and chemical vapor deposition (CVD) methods such as spin coating, spray pyrolysis, Metal organic chemical vapor deposition (MOCVD), metal organic deposition (MOD) and others like oxide powder in tube (OPIT) and melting - quenching - annealing (MQA) (1). In the last time trifluoroacetate (TFA-Based) solution deposition for YBa2Cu3O7-δ (YBCO) thin films has been widely adapted to pilot scale production (2, 3), but the incorporation of-fluorine in this process has several drawbacks. The removal of effluent HF gas from the reaction between the fluorides with water vapor during heat treatment limits YBCO growth (4).

On the other side, enormous efforts have been focused on the use of High-temperature superconductors (HTS) in many electrical applications. Prototype kilometers long transmission lines have been produced by using Bi-compounds BiSrCaCuO (2223), with critical current densities of 1000 A/cm2 at 77 K. However, these conductors have basic properties that hinder their applications, such as the presence of weak pinning and difficulties to achieve a proper biaxial growth, as observed in the fabrication of tapes by the powder in tube method. However the YBCO coated conductors (Second generation coated conductors) offer attractive alternatives mainly because they present a better behavior under applied magnetic fields and moreover, can be produced with a high degree of biaxial texture (5, 6). Bi-axially textured YBCO coated conductors (CC) are very promising for their applications such as superconducting cables, motors, transformers, fault current limiters, and generators (7, 8, 9). In this work we present the results of electric properties of YBCO superconducting thick films obtained by the melt - annealing method as a function of different preparation parameters like melting time and temperature. The obtained YBCO superconducting thick films were also structurally characterized by X-ray diffraction and SEM techniques. Because of the relative ease of this preparation method, a goal of this work is to search out more information about the role played by these parameters on the superconducting properties of YBCO thick films, and to find out how to improve them.

EXPERIMENTAL

The precursor superconductor material was prepared by the solid state reaction method using high purity oxides Y2O3 (Fluka 99.98% purity), BaO (Fluka 99.97% purity) and CuO (Fluka 99.0% purity) according to the reaction formula:

Three series ofthick YBCO superconductor films ≥ 1 /xm were prepared by the meltannealing method. The thick films were deposited from the precursor superconducting material by the dipcoating method at room temperature on MgO (100) substrates.

Different thermal treatments were used as shown in table 1: the films of series 1 were melted at 950 °C during different times between 0.1 hour and 5 hours, for series 2 the melting temperatures were changed between 880 °C and 950 °C during 0.5 hour and for series 3 the films were melted at 900 °C during different times from 0.1 hour to 5 hours. The annealing temperature and time were identical for all the films (500 °C and 3.5 h respectively). Finally, a film of Au - Pd of ~ 50 nm was deposited on the top of the films.

The samples were also characterized electrically by resistive methods and structural and morphological by X-ray diffraction (Philips PW 1710 with CuKα λ = 1,54056 C radiation) and scanning electronic microscopy (SEM-FEI QUANTA) respectively.

RESULTS AND DISCUSSION

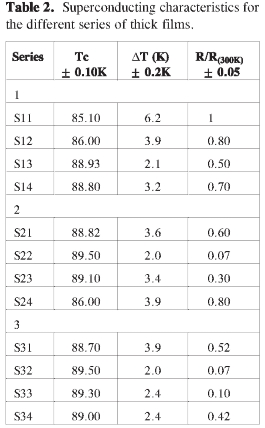

Figures 1 (a) (b) and (c) display the curves of normalized resistance as a function of temperature (R/R(300) vs. T) for all the samples, determined by the four points resistive method. All the films presented superconductor transition. A metallic behavior in the measured range of temperature was observed with exception of the sample S11, which was attributed to oxygen deficiencies. The Tc's determined from the maximum of dR/dT vs. T curves and the transition widths ΔT (FWHG) are shown in table 2.

As illustrated, the higher Tc's (89.5 ± 0.1K) and the lower transition widths (ΔT= 2 ± 0.2K) were obtained in samples melted at 900°C during 0.5h. The other samples showed lower Tc's and larger transition widths, which has been attributed mainly to oxygen deficiencies. These results correlate well with those obtained by X-ray diffraction. It is known that O2 deficiencies produce a decrease of Tc's, broadening of the superconducting transitions and an increase of the residual resistance because of a reduction of charge concentration and an enhancement of impurity formation (10, 11).

It is important to note that in series 3, the samples with Tc's > 89K showed a smaller c-axis parameter as determined by X-ray diffraction, which has been correlated with a higher oxygen content (10). Additionally, the sample S31 displayed a higher porosity as shown in the morphological analysis by SEM.

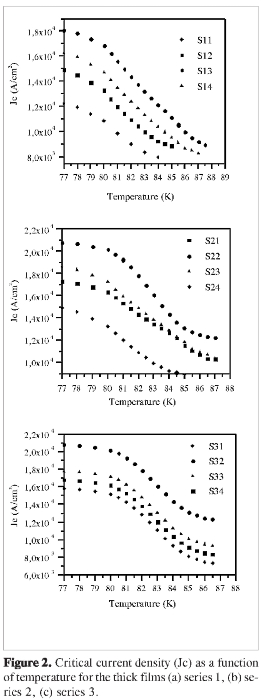

Figure 2 shows the behavior of the critical current densities as a function of temperature for the different series of films. The values of the critical current densities at 77K and B = 0 (table 3) determined by resistive methods using the 10 juY criterion, decreased markedly for the films with less oxygen content which, correlate well with the observed superconducting characteristics of these samples, (higher transition widths and higher residual resistances).

It is worth to not that samples with Tc's around 89K, (S32, S33 and S34), however showed differences in the critical current densities. These can be attributed to other factors than oxygen content, like grain sizes and porosity, as observed by SEM analysis (table 3).

On the order hand the Jc decreased by the application of magnetic fields perpendicular to the sample's surface, which indicates the presence of weak links (12). The highest Jc reduction was observed in samples with less oxygen content and smaller grain sizes between 6 and 8 um.

Figure 3 displays a typical result of scanning electron microscopy of a thick film (S22). It is evident the granular character of the sample, however some differences relating with grain sizes and porosity were observed in the films as a function of both melting time and temperature. Additionally the samples with higher oxygen content exhibited larger grain sizes (~ 9 μm) and a more compact surface (less porosity), which correlate well with their higher critical current densities.

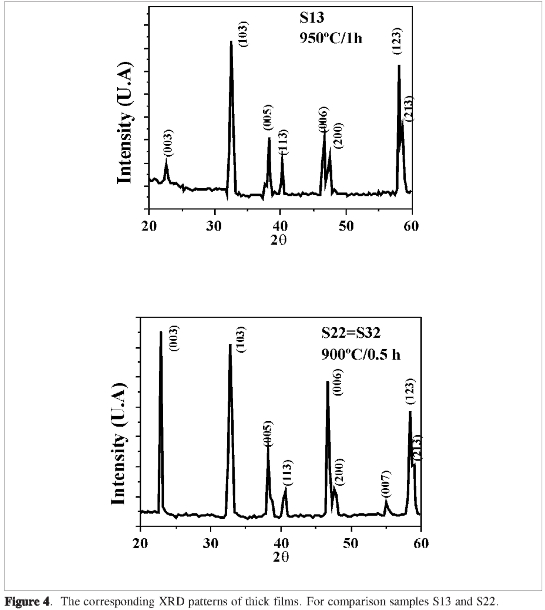

The corresponding X-ray diffraction patterns of samples S13 and S22 (S22 = S32) are shown in figure 4. All of them exhibit the characteristic reflection peaks of the YBCO (123) without a visible presence of impurities like Ba2CuO3,BaCuO2, Y2Cu2O5,Y2BaO4 and other oxides.

As show, the samples with higher oxygen content exhibit also higher orientation along the 00l direction.

The c lattice parameters, determined by using the program DRXWIN 2.2 (see table 3), are smaller for samples of series 3. A decreasing of c lattice parameter has been associated with an increase of the oxygen content (10, 13). The c decrease correlates well with the superconducting properties of these samples.

CONCLUSIONS

Three series of YBCO superconductor thick films (≥ 1 μm) were prepared with different thermal treatments by the melt -annealing method. The thick films were deposited at first from the precursor stoi-chiometry material (YBa2Cu3O7-á) by the dip-coating method at room temperature on MgO (100) substrates.

All the thick films presented superconductor transition in the measured range of temperature. The higher Tc's (89.5 ± 0.1K) and the lower transition widths (ΔT = 2 ± 0.2K) were obtained in samples melted at 900 °C during 0.5 h. These values are comparable with high quality YBCO thin films prepared by other methods.

The samples with higher Tc's displayed the highest Jc values (~2.00 x 104 A/cm2). Small differences observed in the critical current densities of these films can be attributed to other factors such as grain sizes and porosity as observed by SEM analysis. Nevertheless the relative ease method of preparation, the achieved Jc values are similar to those obtained using more sophisticated methods (1, 2, 9, 12).

REFERENCES

1. Jergel, M. Synthesis of high-Tc superconducting films by deposition from an aerosol. Supercond. Sci. Technol.1995. 8: 67-78.

2. Malozemoff, A. P.; Fleshler, S.; Rupich, M.; Thieme, C.; Li, X.; Zhang, W.;Otto,A.; Maguire,J.; Folts,D.; Yuan, J.; Kaemer, H.-P.; Schmidt, W.; Wohlfart, M.; Neumueller, H.-W. Progress in high temperature superconductor coated conductors and their applications. Supercond. Sci. Technol. 2008. 21:7.

3. Izumi, T.; Fujia, H.; Aokia, Y.; Teranishia, R.; Matsuda, J.; Nakaoka, K.; Kitoha, Y.; Nomotoa, S.; Yamadab, Y.; Yajimac, A.; Saitoh, T.; Shiohara, Y. R&D for long tapes with high Ic by advanced TFA-MOD process. Physica C.2006. 445-448: 533.

4. Patta, Y. R.; Wesolowski, D. E.; Cima, M. J. Aqueous polymer-nitrate solution deposition of YBCO films. Physica C. 2009 . 469: 129-134.

5. VanDriessche, I.; Schoofs, B.; Penneman, G.; Bruneel, E.; Hoste, S. Review of the application of high temperature superconductors in coated conductor development and the measurement of their properties.Measurement Science Review. 2005.5:19-29.

6. Matsushita, T.; Kiuchi, M.; Kimura, K.; Takayama, S.; Yamada, Y.; Shiohara, Y.; Fujikami, J.; Hayashi, K.; Sato, K. Critical current properties in high-temperature superconducting wires and tapes. Physica C. 2007 463-465:686-691.

7. Zhang, W.; Rupich, M. W.; Schoop, U.; Verebelyi, D. T.; Thieme, C. L. H.; Li, X.; Kodenkandath, T.; Huang, Y.; Siegal, E.; Buczek, D.; Carter, W.; Nguyen, N.; Schreiber, J.; Prasova, M.; Lynch, J.; Tucker, D.; Fleshler, S. Progress in AMSC scale-up of second generation HTS wire. Physica C. 2007. 463-465: 505.

8. Shiohara, Y.; Kitoh, Y.; Izumi, T. Highlights in R&D for coated conductors in Japan. Physica C. 2006. 445-448:496.

9. Shin, G.; Ko, M. K. P.; Song, K. J.; Moon, S. H.; Yoo, S. I. High-Ic YBCO films fabricated by the MOD process.Physica C. 2008 . 468: 1567-1570.

10. Cogollo, R P.; Marino, A C.; Sánchez, H M. Transport properties of YBCO superconducting films at different oxygen concentration. IEEE. 2003. 13: 2789-2791.

11. Garcés, P.; Marino, A. Películas gruesas superconductoras de YBCO para conductores recubiertos. Momento Revista de Física. 2005.31:45-54.

12. Chen, J.; Spagnola, P.; Bhattacharya, N.; Zhifeng, R. Preparation ofhigh Jc YBCO coated conductors on non-magnetic Ni-W substrates. Phys. D. Appl. 2004. 37: 1685-1689.

13. Ye, J.; Nakamura, K. Quantitative structure analyses of YBa2Cu3O7-alpha thin films: Determination of oxygen content from x-ray-diffraction patterns. Physical Review B. 1993. 48: 7554.

Cómo citar

IEEE

ACM

ACS

APA

ABNT

Chicago

Harvard

MLA

Turabian

Vancouver

Descargar cita

Visitas a la página del resumen del artículo

Descargas

Licencia

Los autores/as conservarán sus derechos de autor y garantizarán a la revista el derecho de primera publicación de su obra, el cuál estará simultáneamente sujeto a la Licencia de reconocimiento de Creative Commons (CC. Atribución 4.0) que permite a terceros compartir la obra siempre que se indique su autor y su primera publicación en esta revista.

Los autores/as podrán adoptar otros acuerdos de licencia no exclusiva de distribución de la versión de la obra publicada (p. ej.: depositarla en un archivo telemático institucional o publicarla en un volumen monográfico) siempre que se indique la publicación inicial en esta revista.

Se permite y recomienda a los autores/as difundir su obra a través de Internet (p. ej.: en archivos telemáticos institucionales o en su página web) antes y durante el proceso de envío, lo cual puede producir intercambios interesantes y aumentar las citas de la obra publicada. (Véase El efecto del acceso abierto).