Published

Effect of Convective Drying and Far-Infrared Radiation on the Physical Properties and Microstructure of Yacón Chips (Smallanthus sonchifolius)

Efecto del secado convectivo y radiación infrarroja lejana sobre las propiedades físicas y microestructura de hojuelas de yacón (Smallanthus sonchifolius)

DOI:

https://doi.org/10.15446/ing.investig.104346Keywords:

heat transfer, internal structure, micropores, drying, hot air, infrared (en)transferencia de calor, estructura interna, microporos, secado, aire caliente, infrarrojo (es)

Downloads

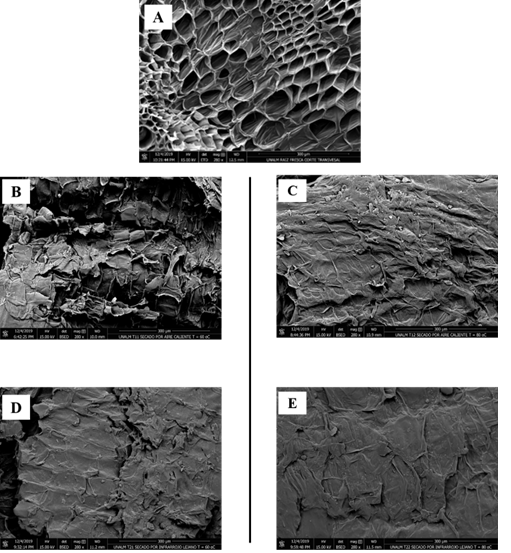

Convective drying is widely used in the food industry due to its simplicity and versatility, as it allows for better temperature control and heat distribution, which is essential for maintaining product quality. However, this method can be slower compared to infrared drying. The aim of this research was to evaluate the effect of convective and infrared drying on the physical properties and microstructure of yacón chips. An infrared dryer and a convection dryer were used to this effect, setting temperatures of 60, 70, and 80 °C for both methods. The color and texture properties, as well as the microstructure, changed with the increase in temperature. The greatest color variation in the yacón samples was reported by infrared drying at a temperature of 80 ° C. Regarding texture, there were no differences between the two methods. The microstructure of the yacón samples dried by hot air exhibited more significant cell damage, especially at 60 °C, in comparison with infrared drying, which showed a more microporous and compact structure. The results indicate that the method used impacted shrinkage: infrared drying produced a higher level of shrinkage when compared to convective drying. It is important to note that this is a significant physical change that can adversely affect the quality of dehydrated food. Infrared drying produced greater rehydration in comparison with convective drying. Similarly, improved rehydration was observed at a temperature of 70 ºC. In conclusion, the infrared drying method, coupled with appropriate drying conditions, constitutes a good alternative for drying yacón chips.

El secado convectivo es ampliamente utilizado en la industria alimentaria debido a su simplicidad y versatilidad, ya que permite un mejor control de la temperatura y distribución del calor, lo cual es esencial para mantener la calidad del producto. Sin embargo, este método puede ser más lento en comparación con el secado por infrarrojos. El objetivo de esta investigación fue evaluar el efecto del secado convectivo y por infrarrojos en las propiedades físicas y la microestructura de las rodajas de yacón. Para ello, se utilizaron un secador por infrarrojos y un secador de convección, estableciendo temperaturas de 60, 70 y 80 °C para ambos métodos. Las propiedades de color y textura, así como la microestructura, cambiaron con el aumento de la temperatura. La mayor variación de color en las muestras de yacón correspondió al secado por infrarrojos a una temperatura de 80 °C. En cuanto a la textura, no hubo diferencias entre los dos métodos. La microestructura de las muestras de yacón secadas con aire caliente mostró un daño celular más significativo, especialmente a 60 °C, en comparación con el secado por infrarrojos, que mostró una estructura más microporosa y compacta. Los resultados indican que el método utilizado impactó en la contracción: el secado por infrarrojos produjo un nivel de contracción más alto en comparación con el secado convectivo. Es importante señalar que este es un cambio físico significativo que puede afectar negativamente la calidad de los alimentos deshidratados. El secado por infrarrojos produjo una mayor rehidratación en comparación con el secado convectivo. De manera similar, se observó una mejor rehidratación a una temperatura de 70 ºC. En conclusión, el método de secado por infrarrojos, en combinación con condiciones de secado adecuadas, constituye una buena alternativa para el secado de rodajas de yacón.

References

Bernstein, A., and Noreña, C. P. Z. (2014). Study of thermody-namic, structural, and quality properties of yacon (Smallan-thus sonchifolius) during drying. Food and Bioprocess Technol-ogy, 7(1), 148-160. https://doi.org/10.1007/s11947-012-1027-y

Campos, D., Aguilar-Galvez, A., and Pedreschi, R. (2016). Stabil-ity of fructooligosaccharides, sugars and colour of yacon (Smallanthus sonchifolius) roots during blanching and drying. International Journal of Food Science and Technology, 51(5), 1177-1185. https://doi.org/10.1111/ijfs.13074

Choque Delgado, G. T., da Silva Cunha Tamashiro, W. M., Ma-róstica Junior, M. R., and Pastore, G. M. (2013). Yacon (Smal-lanthus sonchifolius): A functional food. Plant Foods for Human Nutrition, 68(3), 222-228. https://doi.org/10.1007/s11130-013-0362-0

Corrêa, J. L. G., Lopes, F. J., de Mello Junior, R. E., de Jesus Junqueira, J. R., de Angelis Pereira, M. C., and Salvio, L. G. A. (2021). Dried yacon with high fructooligosaccharide content. Journal of Food Process Engineering, 44(12), 13884. https://doi.org/10.1111/jfpe.13884

de Jesus Junqueira, J. R., Corrêa, J. L. G., de Mendonça, K. S., de Mello Júnior, R. E., and de Souza, A. U. (2018). Pulsed vac-uum osmotic dehydration of beetroot, carrot and eggplant slices: Effect of vacuum pressure on the quality parameters. Food and Bioprocess Technology, 11(10), 1863-1875. https://doi.org/10.1007/s11947-018-2147-9

Egea, M. B., Borsato, D., Silva, R. S. dos S. F. da, and Yamashita, F. (2012). Osmo-dehydrated functional product containing fructo-oligosaccharides: Physical, chemical and sensorial characteristics. Brazilian Archives of Biology and Technology, 55(6), 927-936. https://doi.org/10.1590/S1516-89132012000600017

El-Mesery, H. S., and Mwithiga, G. (2015). Performance of a convective, infrared and combined infrared-convective heated conveyor-belt dryer. Journal of Food Science and Technology, 52(5), 2721-2730. https://doi.org/10.1007/s13197-014-1347-1

Franco, T. S., Perussello, C. A., Ellendersen, L. N., and Masson, M. L. (2016). Effects of foam mat drying on physicochemical and microstructural properties of yacon juice powder. LWT - Food Science and Technology, 66, 503-513. https://doi.org/10.1016/j.lwt.2015.11.009

Huang, D., Yang, P., Tang, X., Luo, L., and Sunden, B. (2021). Application of infrared radiation in the drying of food prod-ucts. Trends in Food Science and Technology, 110, 765-777. https://doi.org/10.1016/j.tifs.2021.02.039

Huang, X., Li, W., Wang, Y., and Wan, F. (2021). Drying charac-teristics and quality of Stevia rebaudiana leaves by far-infrared radiation. LWT, 140, 110638. https://doi.org/10.1016/j.lwt.2020.110638

Jiang, Y., Lawrence, M., Ansell, M. P., and Hussain, A. (2018). Cell wall microstructure, pore size distribution and absolute density of hemp shiv. Royal Society Open Science, 5(4), 171945. https://doi.org/10.1098/rsos.171945

Khajehei, F., Hartung, J., and Graeff-Hönninger, S. (2018). Total phenolic content and antioxidant activity of yacon (Smallan-thus sonchifolius poepp. and endl.) chips: Effect of cultivar, pre-treatment and drying. Agriculture, 8(12), 183. https://doi.org/10.3390/agriculture8120183

Marques, B., Perré, P., Casalinho, J., Tadini, C. C., Plana-Fattori, A., and Almeida, G. (2023). Evidence of iso-volume defor-mation during convective drying of yacón: An extended van Meel model adapted to large volume reduction. Journal of Food Engineering, 341, 111311. https://doi.org/10.1016/j.jfoodeng.2022.111311

Mugodo, K., and Workneh, T. S. (2021). The kinetics of thin-layer drying and modelling for mango slices and the influence of differing hot-air drying methods on quality. Heliyon, 7(6), e07182. https://doi.org/10.1016/j.heliyon.2021.e07182

Naseri, M., Movagharnejad, K., and Nanvakenari, S. (2023). Comparison of the dried properties of Ganoderma lucidum produced by the convective dryer and infrared dryer. Scien-tific Reports, 13(1), 12636. https://doi.org/10.1038/s41598-023-39883-z

Nathakaranakule, A., Jaiboon, P., and Soponronnarit, S. (2010). Far-infrared radiation assisted drying of longan fruit. Journal of Food Engineering, 100(4), 662-668. https://doi.org/10.1016/j.jfoodeng.2010.05.016

Ning, X., Lee, J., and Han, C. (2015). Drying characteristics and quality of red ginseng using far-infrared rays. Journal of Gin-seng Research, 39(4), 371-375. https://doi.org/10.1016/j.jgr.2015.04.001

Nowak, D., and Lewicki, P. P. (2005). Quality of infrared dried apple slices. Drying Technology, 23(4), 831-846. https://doi.org/10.1080/DRT-200054206

Perussello, C. A., Kumar, C., De Castilhos, F., and Karim, M. A. (2014). Heat and mass transfer modeling of the osmo-convective drying of yacon roots (Smallanthus sonchifolius). Applied Thermal Engineering, 63(1), 23-32. https://doi.org/10.1016/j.applthermaleng.2013.10.020

Pham, N. D., Martens, W., Karim, M. A., and Joardder, M. U. H. (2018). Nutritional quality of heat-sensitive food materials in intermittent microwave convective drying. Food & Nutrition Research, 62, 1-11. https://doi.org/10.29219/fnr.v62.1292

Puente-Díaz, L., Spolmann, O., Nocetti, D., Zura-Bravo, L., and Lemus-Mondaca, R. (2020). Effects of infrared-assisted re-fractance windowTM drying on the drying kinetics, microstruc-ture, and colour of Physalis fruit purée. Foods, 9(3), 343. https://doi.org/10.3390/foods9030343

Qi, L.-L., Zhang, M., Mujumdar, A. S., Meng, X.-Y., and Chen, H.-Z. (2014). Comparison of drying characteristics and quality of shiitake mushrooms (Lentinus edodes) using different drying methods. Drying Technology, 32(15), 1751-1761. https://doi.org/10.1080/07373937.2014.929588

Reis, Felipe R., Lenzi, M. K., and Masson, M. L. (2012). Effect of vacuum drying conditions on the quality of yacon (Smallan-thus sonchifolius) slices: Process optimization toward colour quality. Journal of Food Processing and Preservation, 36(1), 67-73. https://doi.org/10.1111/j.1745-4549.2011.00555.x

Reis, F. R., Lenzi, M. K., de Muñiz, G. I. B., Nisgoski, S., and Mas-son, M. L. (2012). Vacuum drying kinetics of yacon (Smallan-thus sonchifolius) and the effect of process conditions on fractal dimension and rehydration capacity. Drying Technolo-gy, 30(1), 13-19. https://doi.org/10.1080/07373937.2011.611307

Sadeghi, E., Haghighi Asl, A., and Movagharnejad, K. (2020). Optimization and quality evaluation of infrared‐dried kiwifruit slices. Food Science & Nutrition, 8(2), 720-734. https://doi.org/10.1002/fsn3.1253

Senadeera, W., Adiletta, G., Önal, B., Di Matteo, M., and Russo, P. (2020). Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods, 9(1), 101. https://doi.org/10.3390/foods9010101

Shi, Q., Zheng, Y., and Zhao, Y. (2013). Mathematical modeling on thin-layer heat pump drying of yacon (Smallanthus sonchi-folius) slices. Energy Conversion and Management, 71, 208-216. https://doi.org/10.1016/j.enconman.2013.03.032

Valentová, K., and Ulrichová, J. (2003). Smallanthus sonchifolius and Lepidium meyenii - Prospective Andean crops for the prevention of chronic diseases. Biomedical Papers, 147(2), 119-130. https://doi.org/10.5507/bp.2003.017

Yang, R.-L., Li, Q., and Hu, Q.-P. (2020). Physicochemical prop-erties, microstructures, nutritional components, and free ami-no acids of Pleurotus eryngii as affected by different drying methods. Scientific Reports, 10(1), 121. https://doi.org/10.1038/s41598-019-56901-1

Yao, L., Fan, L., and Duan, Z. (2020). Effect of different pre-treatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and micro-structure of mango slices. Food Chemistry, 305, 125477. https://doi.org/10.1016/j.foodchem.2019.125477

Zeng, Y., Liu, Y., Zhang, J., Xi, H., and Duan, X. (2019). Effects of far-infrared radiation temperature on drying characteristics, water status, microstructure and quality of kiwifruit slices. Journal of Food Measurement and Characterization, 13(4), 3086-3096. https://doi.org/10.1007/s11694-019-00231-3

Žiarovská, J., Padilla-González, G. F., Viehmannová, I., and Fernández, E. (2019). Genetic and chemical diversity among yacon [Smallanthus sonchifolius (Poepp. et Endl.) H. Robinson] accessions based on iPBS markers and metabolomic finger-printing. Plant Physiology and Biochemistry, 14, 183-192. https://doi.org/10.1016/j.plaphy.2019.05.020

Zhu, J., Liu, Y., Zhu, C., and Wei, M. (2022). Effects of different drying methods on the physical properties and sensory char-acteristics of apple chip snacks. LWT, 154, 112829. https://doi.org/10.1016/j.lwt.2021.112829

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

CrossRef Cited-by

1. Edwin O. Baldeón, Lizbeth R. Mamani-Olgado, Bernardo O. Yépez Silva-Santisteban, Gabriela C. Chire-Fajardo, Nubia C. Martínez-Guerrero, Milber O. Ureña-Peralta. (2025). Impact of hot-air and infrared-assisted solar drying on the drying characteristics and physicochemical properties of cacao beans (Theobroma cacao L.). Frontiers in Sustainable Food Systems, 9 https://doi.org/10.3389/fsufs.2025.1596519.

Dimensions

PlumX

Article abstract page views

Downloads

License

Copyright (c) 2024 Edwin O. Baldeón, Álvaro Bracamonte-Herrera, Andrés Soto-Torres, Walter F. Salas-Valerio, Julio Mauricio Vidaurre-Ruiz

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors or holders of the copyright for each article hereby confer exclusive, limited and free authorization on the Universidad Nacional de Colombia's journal Ingeniería e Investigación concerning the aforementioned article which, once it has been evaluated and approved, will be submitted for publication, in line with the following items:

1. The version which has been corrected according to the evaluators' suggestions will be remitted and it will be made clear whether the aforementioned article is an unedited document regarding which the rights to be authorized are held and total responsibility will be assumed by the authors for the content of the work being submitted to Ingeniería e Investigación, the Universidad Nacional de Colombia and third-parties;

2. The authorization conferred on the journal will come into force from the date on which it is included in the respective volume and issue of Ingeniería e Investigación in the Open Journal Systems and on the journal's main page (https://revistas.unal.edu.co/index.php/ingeinv), as well as in different databases and indices in which the publication is indexed;

3. The authors authorize the Universidad Nacional de Colombia's journal Ingeniería e Investigación to publish the document in whatever required format (printed, digital, electronic or whatsoever known or yet to be discovered form) and authorize Ingeniería e Investigación to include the work in any indices and/or search engines deemed necessary for promoting its diffusion;

4. The authors accept that such authorization is given free of charge and they, therefore, waive any right to receive remuneration from the publication, distribution, public communication and any use whatsoever referred to in the terms of this authorization.