Published

Evaluating the Use of Recycled Brick Powder as a Partial Replacement for Portland Cement in Concrete

Evaluación del uso del polvo reciclado de ladrillo como reemplazo parcial al cemento Portland en el hormigón

DOI:

https://doi.org/10.15446/ing.investig.107462Keywords:

workability, mechanical properties, physical properties, sustainability (en)trabajabilidad, propiedades mecánicas, propiedades físicas, sostenibilidad (es)

Downloads

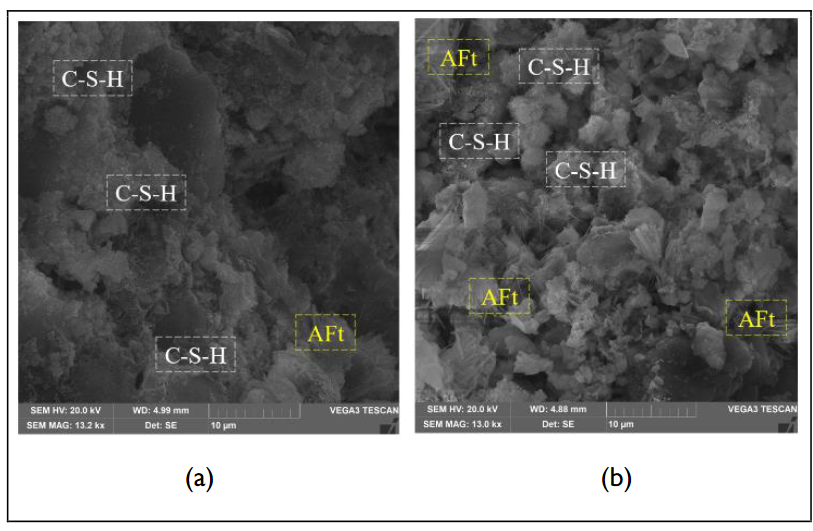

Portland cement is one of the most used construction materials. However, its production represents between 5 and 7% of the total CO2 emissions. On the other hand, during construction and demolition activities, different wastes are produced, including recycled brick powder (RBP), whose potential as a supplementary cementitious material (SCM) has been demonstrated in the literature. This research aims to evaluate RBP as a partial replacement for Portland cement in concrete. 5 to 10% of Portland cement was replaced with RBP in two strength designs (20 and 25 MPa) in order to propose concretes that meet the requirements for use in construction. Tests involving slump, compressive strength, tensile strength by diametrical compression, absorption, density, and void content were performed. The results show that a 5% RBP replacement does not affect workability in concrete mixes, as it maintains their mechanical resistance and slightly improves their physical properties. On the other hand, 10% RBP replacements adversely affect workability and reduce tensile strength. These results are attributed to pozzolanic activity and the physical effect caused by RBP, whose performance may be improved by reducing RBP particles and increasing their specific surface area (SSA). Using RBP as a replacement for Portland cement to produce concrete is a viable alternative with a sustainable approach.

El cemento Portland es uno de los materiales de construcción más utilizados. Sin embargo, su producción representa entre el 5 y el 7 % de las emisiones totales de CO2. Por otro lado, durante las actividades de construcción y demolición, se producen diferentes residuos, entre ellos el polvo de ladrillo reciclado (PLR), cuyo potencial como material cementante suplementario (MCS) ha sido demostrado en la literatura. El objetivo de la presente investigación es evaluar el PLR como reemplazo parcial del cemento Portland en el hormigón. Se sustituyó 5 y 10% de cemento Portland por PLR para dos resistencias de diseño (20 y 25 MPa), a fin de proponer concretos que cumplan con los requerimientos para ser utilizados en la construcción. Se realizaron ensayos de asentamiento, resistencia a la compresión, resistencia a la tracción por compresión diametral, absorción, densidad y contenido de vacíos. Los resultados muestran que la sustitución del 5% de PLR no afecta la trabajabilidad de las mezclas, pues mantiene las resistencias mecánicas y mejora levemente las propiedades físicas. Por otro lado, las sustituciones del 10% de PLR afectan negativamente la trabajabilidad y reducen la resistencia a la tracción. Estos resultados se atribuyen a la actividad puzolánica y al efecto físico del PLR, cuyo desempeño puede ser mejorado si se reducen las partículas de PLR y se incrementa el área superficial específica (ASE). El uso de PLR como reemplazo del cemento Portland para la elaboración de hormigón es una alternativa viable con enfoque sostenible.

References

Adamson, M., Razmjoo, A., and Poursaee, A. (2015). Durabil-ity of concrete incorporating crushed brick as coarse aggre-gate. Construction and Building Materials, 94, 426-432. https://doi.org/10.1016/j.conbuildmat.2015.07.056

American Society for Testing and Materials (2015a). ASTM C136-06. Standard test method for sieve analysis of fine and coarse aggregates. ASTM. https://doi.org/10.1520/C0136-06

American Society for Testing and Materials (2015b). ASTM C127-15. Standard test method for relative density (specific gravity) and absorption of coarse aggregate. ASTM. https://doi.org/10.1520/C0127-15

American Society for Testing and Materials (2015c). ASTM C128-15. Standard test method for relative density (specific gravity) and absorption of fine aggregate. ASTM. https://doi.org/10.1520/C0128-15

American Society for Testing and Materials (2019). ASTM C204. Standard test methods for fineness of hydraulic cement by air-permeability apparatus. ASTM. https://doi.org/10.1520/C0204-18E01

American Society for Testing and Materials (2021a). ASTM C595/C595M-21. standard specification for blended hydrau-lic cements. ASTM. https://doi.org/10.1520/C0595_C0595M-21

American Society for Testing and Materials (2021b). ASTM C39/C39M-21. Standard test method for compressive strength of cylindrical concrete specimens. ASTM. https://doi.org/10.1520/C0039_C0039M-21

American Society for Testing and Materials (2021c). ASTM C642-21. Standard test method for density, absorption, and voids in hardened concrete. ASTM. https://doi.org/10.1520/C0642-21

American Society for Testing and Materials (2022). ASTM C618-22. Standard specification for coal fly ash and raw or cal-cined natural pozzolan for use in concrete. ASTM: West Con-shohocken, PA, USA, 2022. https://doi.org/10.1520/C0618-22

Arif, R., Khitab, A., Kırgız, M. S., Khan, R. B. N., Tayyab, S., Khan, R. A., Tayyab, S., Akhtar Khan, R., Anwar, W., and Ar-shad, M. T. (2021). Experimental analysis on partial replace-ment of cement with brick powder in concrete. Case Studies in Construction Materials, 15, e00749. https://doi.org/10.1016/j.cscm.2021.e00749

Asociación Española de Normalización (2020). UNE-EN 12350-2: Ensayos de hormigón fresco. Parte 2: ensayo de asenta-miento. UNE.

Associação Brasileira de Normas Técnicas (2011). NBR 7222: Concreto e argamassa — Determinação da resistência à tração por compressão diametral de corpos de prova cilín-dricos. ABNT.

Borges, P. M., Schiavon, J. Z., da Silva, S. R., Rigo, E., Junior, A. N., Possan, E., and de Oliveira Andrade, J. J. (2023). Mor-tars with recycled aggregate of construction and demolition waste: Mechanical properties and carbon uptake. Construc-tion and Building Materials, 387, 131600. https://doi.org/10.1016/j.conbuildmat.2023.131600

Da Silva, S. R., and Andrade, J. J. D. O. (2022). A review on the effect of mechanical properties and durability of con-crete with construction and demolition waste (CDW) and fly ash in the production of new cement concrete. Sustainabi-lity, 14(11), 6740. https://doi.org/10.3390/su14116740

da Silva, S. R., Cimadon, F. N., Borges, P. M., Schiavon, J. Z., Possan, E., and de Oliveira Andrade, J. J. (2022). Relation-ship between the mechanical properties and carbonation of concretes with construction and demolition waste. Case Studies in Construction Materials, 16, e00860. https://doi.org/10.1016/j.cscm.2021.e00860

da Silva, S. R., de Brito, J., and de Oliveira Andrade, J. J. (2023). Synergic effect of recycled aggregate, fly ash, and hydrated lime in concrete production. Journal of Building Engineering, 70, 106370. https://doi.org/10.1016/j.jobe.2023.106370

Duan, Z., Hou, S., Xiao, J., and Li, B. (2020). Study on the es-sential properties of recycled powders from construction and demolition waste. Journal of Cleaner Production, 253, 119865. https://doi.org/10.1016/j.jclepro.2019.119865

Gao, T., Dai, T., Shen, L., and Jiang, L. (2021). Benefits of using steel slag in cement clinker production for environmental conservation and economic revenue generation. Journal Of Cleaner Production, 282, 124538. https://doi.org/10.1016/j.jclepro.2020.124538

Ge, P., Huang, W., Zhang, J., Quan, W., and Guo, Y. (2021). Mix proportion design method of recycled brick aggregate concrete based on aggregate skeleton theory. Construction and Building Materials, 304, 124584. https://doi.org/10.1016/j.conbuildmat.2021.124584

Ge, Z., Wang, Y., Sun, R., Wu, X., and Guan, Y. (2015). Influ-ence of ground waste clay brick on properties of fresh and hardened concrete. Construction and Building Materials, 98, 128-136. https://doi.org/10.1016/j.conbuildmat.2015.08.100

Habert, G., Miller, S. A., John, V. M., Provis, J. L., Favier, A., Horvath, A., and Scrivener, K. L. (2020). Environmental im-pacts and decarbonization strategies in the cement and concrete industries. Nature Reviews Earth & Environment, 1(11), 559-573. https://doi.org/10.1038/s43017-020-0093-3

He, Z., Shen, A., Wu, H., Wang, W., Wang, L., Yao, C., and Wu, J. (2021). Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materi-als. Construction and Building Materials, 274, 122113. https://doi.org/10.1016/j.conbuildmat.2020.122113

IBNORCA (1987). CBH 87: Código boliviano del hormigón. Instituto Boliviano de Normalización y Calidad.

ACI (1991). Standard practice for selecting proportions for normal, heavyweight and mass concrete (ACI 211.1-91). ACI.

Irki, I., Debieb, F., Ouzadid, S., Dilmi, H. L., Settari, C., and Boukhelkhel, D. (2018). Effect of Blaine fineness of recycling brick powder replacing cementitious materials in self com-pacting mortar. Journal of adhesion science and Technolo-gy, 32(9), 963-975. https://doi.org/10.1080/01694243.2017.1393202

Jiang, W., Li, X., Lv, Y., Jiang, D., Liu, Z., and He, C. (2020). Mechanical and hydration properties of low clinker cement containing high volume superfine blast furnace slag and nano silica. Construction and Building Materials, 238, 117683. https://doi.org/10.1016/j.conbuildmat.2019.117683

Jiang, X., Xiao, R., Bai, Y., Huang, B., and Ma, Y. (2022). Influ-ence of waste glass powder as a supplementary cementi-tious material (SCM) on physical and mechanical properties of cement paste under high temperatures. Journal of Clean-er Production, 340, 130778. https://doi.org/10.1016/j.jclepro.2022.130778

Juenger, M. C., and Siddique, R. (2015). Recent advances in understanding the role of supplementary cementitious mate-rials in concrete. Cement and Concrete Research, 78, 71-80. https://doi.org/10.1016/j.cemconres.2015.03.018

Juenger, M. C., Snellings, R., and Bernal, S. A. (2019). Supple-mentary cementitious materials: New sources, characteriza-tion, and performance insights. Cement and Concrete Re-search, 122, 257-273. https://doi.org/10.1016/j.cemconres.2019.05.008

Likes, L., Markandeya, A., Haider, M. M., Bollinger, D., McCloy, J. S., and Nassiri, S. (2022). Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. Journal of Cleaner Production, 364, 132651. https://doi.org/10.1016/j.jclepro.2022.132651

Likes, L., Markandeya, A., Haider, M. M., Bollinger, D., McCloy, J. S., and Nassiri, S. (2022). Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. Journal of Cleaner Production, 364, 132651. https://doi.org/10.1016/j.jclepro.2022.132651

Liu, Q., Li, B., Xiao, J., and Singh, A. (2020). Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Construction and Building Materials, 238, 117721. https://doi.org/10.1016/j.conbuildmat.2019.117721

Luo, X., Gao, J., Li, S., Xu, Z., and Chen, G. (2022). Experi-mental study on the early-age properties of cement pastes with recycled brick powder. Construction and Building Ma-terials, 347, 128584. https://doi.org/10.1016/j.conbuildmat.2022.128584

Ma, Z., Tang, Q., Wu, H., Xu, J., and Liang, C. (2020a). Me-chanical properties and water absorption of cement com-posites with various fineness and contents of waste brick powder from C&D waste. Cement and Concrete Compo-sites, 114, 103758. https://doi.org/10.1016/j.cemconcomp.2020.103758

Ma, Z., Liu, M., Duan, Z., Liang, C., and Wu, H. (2020b). Effects of active waste powder obtained from C&D waste on the microproperties and water permeability of concrete. Journal of Cleaner Production, 257, 120518. https://doi.org/10.1016/j.jclepro.2020.120518

Mohammed, T. U., Hasnat, A., Awal, M. A., and Bosunia, S. Z. (2015). Recycling of brick aggregate concrete as coarse aggregate. Journal of Materials in Civil Engineering, 27(7), B4014005. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001043

Naceri, A., and Hamina, M. C. (2009). Use of waste brick as a partial replacement of cement in mortar. Waste Manage-ment, 29(8), 2378-2384. https://doi.org/10.1016/j.wasman.2009.03.026

Nguyen, M. H., Trinh, S. H., and Ly, H. B. (2023). Toward im-proved prediction of recycled brick aggregate concrete compressive strength by designing ensemble machine learn-ing models. Construction and Building Materials, 369, 130613. https://doi.org/10.1016/j.conbuildmat.2023.130613

Ortega, J. M., Letelier, V., Solas, C., Moriconi, G., Climent, M. Á., and Sánchez, I. (2018). Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Construction and Building Materials, 182, 691-702. https://doi.org/10.1016/j.conbuildmat.2018.06.161

Panesar, D. K., and Zhang, R. (2020). Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials – A review. Con-struction and Building Materials, 251, 118866. https://doi.org/10.1016/j.conbuildmat.2020.118866

Reig, L., Tashima, M. M., Borrachero, M. V., Monzó, J., Cheeseman, C. R., and Payá, J. (2013). Properties and mi-crostructure of alkali-activated red clay brick waste. Con-struction and Building Materials, 43, 98-106. https://doi.org/10.1016/j.conbuildmat.2013.01.031

Rocha, J. H. A., Toledo Filho, R. D., and Cayo-Chileno, N. G. (2022). Sustainable alternatives to CO2 reduction in the ce-ment industry: A short review. Materials Today, Proceedings, 52(2), 436-439. https://doi.org/10.1016/j.matpr.2021.12.565

Schackow, A., Stringari, D., Senff, L., Correia, S. L., and Segadães, A. M. (2015). Influence of fired clay brick waste additions on the durability of mortars. Cement and Con-crete Composites, 62, 82-89. https://doi.org/10.1016/j.cemconcomp.2015.04.019

Shao, J., Gao, J., Zhao, Y., and Chen, X. (2019). Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Construction and Building Materials, 213, 209-215. https://doi.org/10.1016/j.conbuildmat.2019.03.307

Singh, N. B., and Middendorf, B. (2020). Geopolymers as an alternative to Portland cement: An overview. Construction and Building Materials, 237, 117455. https://doi.org/10.1016/j.conbuildmat.2019.117455

Sousa, V., and Bogas, J. A. (2021). Comparison of energy consumption and carbon emissions from clinker and recy-cled cement production. Journal of Cleaner Production, 306, 127277. https://doi.org/10.1016/j.jclepro.2021.127277

Tang, Q., Ma, Z., Wu, H., and Wang, W. (2020). The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cement and Con-crete Composites, 114, 103807. https://doi.org/10.1016/j.cemconcomp.2020.103807

Thomas, B. S., Yang, J., Bahurudeen, A., Abdalla, J. A., Hawileh, R. A., Hamada, H. M., Nazar, S., Jittin, V., and Ash-ish, D. K. (2021). Sugarcane bagasse ash as supplementary cementitious material in concrete–A review. Materials Today, Sustainability, 15, 100086. https://doi.org/10.1016/j.mtsust.2021.100086

Toledo Filho, R. D., Gonçalves, J. P., Americano, B. B., and Fairbairn, E. M. R. (2007). Potential for use of crushed waste calcined-clay brick as a supplementary cementitious materi-al in Brazil. Cement and Concrete Research, 37(9), 1357-1365. https://doi.org/10.1016/j.cemconres.2007.06.005

Tripathy, A., and Acharya, P. K. (2022). Characterization of bagasse ash and its sustainable use in concrete as a sup-plementary binder – A review. Construction and Building Materials, 322, 126391. https://doi.org/10.1016/j.conbuildmat.2022.126391

UN Environment, Scrivener, K. L., John, V. M., and Gartner, E. M. (2018). Eco-efficient cements: Potential economically via-ble solutions for a low-CO2 cement-based materials industry. Cement and Concrete Research, 114, 2-26. https://doi.org/10.1016/j.cemconres.2018.03.015

Vieira, C. S. (2020). Valorization of fine-grain construction and demolition (C&D) waste in geosynthetic reinforced structures. Waste and Biomass Valorization, 11(4), 1615-1626. https://doi.org/10.1007/s12649-018-0480-x

Wang, H., Wang, L., Qian, X., Cao, K., Xu, Y., Fang, Y., and Cui, L. (2022). Hydration, compressive strength and durability of eco-friendly cement mortars containing recycled brick powder and metakaolin. KSCE Journal of Civil Engineering, 26(9), 4023-4037. https://doi.org/10.1007/s12205-022-0035-3

Wong, C. L., Mo, K. H., Yap, S. P., Alengaram, U. J., and Ling, T. C. (2018). Potential use of brick waste as alternate con-crete-making materials: A review. Journal of Cleaner Pro-duction, 195, 226-239. https://doi.org/10.1016/j.jclepro.2018.05.193

Zhao, Y., Gao, J., Liu, C., Chen, X., and Xu, Z. (2020). The particle-size effect of waste clay brick powder on its poz-zolanic activity and properties of blended cement. Journal of Cleaner Production, 242, 118521. https://doi.org/10.1016/j.jclepro.2019.118521

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

CrossRef Cited-by

1. Mukhtar Ismail, Adams Balade Abubakar, Adamu Lawan, Ibrahim Aliyu, Ayman Sabry Shihata. (2025). Mechanical and sulfate resistance properties of ternary blended mortar composite incorporating rice husk ash and pulverized clay bricks. Innovative Infrastructure Solutions, 10(10) https://doi.org/10.1007/s41062-025-02292-4.

2. Yasin Onuralp Özkılıç, Memduh Karalar, Ali İhsan Çelik, Özer Zeybek, P. Jagadesh, Essam Althaqafi. (2025). Experimental and computational analyses of eco-friendly concrete using recycled crushed brick. REVIEWS ON ADVANCED MATERIALS SCIENCE, 64(1) https://doi.org/10.1515/rams-2025-0157.

3. Vitalii Kryzhanovskyi, Jeanette Orlowsky, Jan Skocek, Marina Macias Barrientos. (2025). Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties. Materials, 18(22), p.5120. https://doi.org/10.3390/ma18225120.

4. Hugo Nicolas Callao Corrales, Erick Alexander Torrez Real, Melissa Cindy Merino Llaves, Joel Gerson Peredo Villarroel, Joaquin Humberto Aquino Rocha. (2025). Recycled and waste materials in construction in Bolivia: a systematic literature review. Journal of Building Pathology and Rehabilitation, 10(2) https://doi.org/10.1007/s41024-025-00615-7.

Dimensions

PlumX

Article abstract page views

Downloads

License

Copyright (c) 2024 Joaquin Humberto Aquino Rocha, Boris Marcelo Morales Ruiz, Romildo Dias Toledo Filho

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors or holders of the copyright for each article hereby confer exclusive, limited and free authorization on the Universidad Nacional de Colombia's journal Ingeniería e Investigación concerning the aforementioned article which, once it has been evaluated and approved, will be submitted for publication, in line with the following items:

1. The version which has been corrected according to the evaluators' suggestions will be remitted and it will be made clear whether the aforementioned article is an unedited document regarding which the rights to be authorized are held and total responsibility will be assumed by the authors for the content of the work being submitted to Ingeniería e Investigación, the Universidad Nacional de Colombia and third-parties;

2. The authorization conferred on the journal will come into force from the date on which it is included in the respective volume and issue of Ingeniería e Investigación in the Open Journal Systems and on the journal's main page (https://revistas.unal.edu.co/index.php/ingeinv), as well as in different databases and indices in which the publication is indexed;

3. The authors authorize the Universidad Nacional de Colombia's journal Ingeniería e Investigación to publish the document in whatever required format (printed, digital, electronic or whatsoever known or yet to be discovered form) and authorize Ingeniería e Investigación to include the work in any indices and/or search engines deemed necessary for promoting its diffusion;

4. The authors accept that such authorization is given free of charge and they, therefore, waive any right to receive remuneration from the publication, distribution, public communication and any use whatsoever referred to in the terms of this authorization.