Optimization of castor seed oil extraction process using response surface methodology

Optimización del proceso de extracción de aceite de semillas de ricino utilizando la metodología de superficie de respuesta

DOI:

https://doi.org/10.15446/ing.investig.v36n3.55632Keywords:

Experiment design, mechanical extraction, Ricinus communis L. (en)Diseño de experimentos, extracción mecánica, Ricinus communis L. (es)

This work focuses on the study of the oil extraction yield from castor seed using three different seed conditions: whole, minced and bare endosperm. Taguchi design was used to determine the contribution of the following parameters: seed condition, seed load in the extractor, temperature, and pressure. It was proved that it is necessary to introduce the whole seed and that the presence of the pericarp increases the extraction yield. The contribution of the control factors has an extraction yield limit. After determining which factors contributed to the process, these were left at their optimum levels aiming to reduce the control factors to only two. The complete analysis was done using a surface response methodology giving the best parameter for temperature and pressure that allows a better yielding mechanical extraction. The oil extraction yield can be kept up to 35% of the seed.

Este trabajo se centra en el estudio de la extracción y la producción de aceite de semillas de ricino usando tres diferentes estados de semillas: entera, partida y sin testa. Se utilizó un diseño Taguchi para determinar la contribución de los siguientes parámetros: estado de las semillas, cantidad de semilla en el extractor, temperatura y presión. Se demostró que es necesario introducir la semilla entera para aumentar el rendimiento de la extracción. La contribución de los factores de control tiene un límite de extracción en la variable respuesta (rendimiento). Después de determinar cuáles factores contribuían altamente al proceso de extracción y cuáles no, se procedió a dejarlos en los niveles de mayor contribución con la finalidad de reducir el número de factores de control a dos. Posteriormente se utilizó la metodología de superficie de respuesta para la optimización del proceso, dando como resultado los niveles óptimos para los factores de control temperatura y presión. De acuerdo con las pruebas, el rendimiento de la extracción del aceite se puede mantener en un 35% de la semilla.

Optimization of castor seed oil extraction process

using response surface methodology

Optimización del proceso de extracción de aceite

de semillas de ricino utilizando la metodología

de superficie de respuesta

J.D. Mosquera-Artamonov1, J.F. Vasco-Leal2,

A.A. Acosta-Osorio3, I. Hernandez-Rios4, E.Ventura-Ramos5,

E. Gutiérrez-Cortez6, and M.E. Rodríguez-Garcia7

1 M.Sc in System Engineering, Universidad Autónoma de Nuevo León. M.I in Quality Engineering from Universidad Autónoma de Querétaro, México. Industrial Engineer by the Universidad Tecnológica de Pereira, Colombia. Affiliation: Ph.D Student in System Engineering, Universidad Autónoma de Nuevo León. México. Email: xoce15@ingenieros.com

2 M.Sc Sustainable Production of Bioenergy, Colegio de Postgraduados, Agroindustrial Engineer from the Universidad La Gran Colombia, Colombia. Affiliation: Ph.D Student in Technology and Innovation Management, Universidad Autónoma de Querétaro, México. E-mail: jose.vasco.leal@gmail.com

3 Ph.D in Engineering and M.Sc. in Instrumentation and Automatic Control, for the Universidad Autónoma de Querétaro, México. B.Sc in Mechanical Engineer by the Universidad Tecnológica de Pereira, Colombia. Affiliation: Conacyt Research fellow Instituto Tecnológico de Veracruz, Veracruz, México. E-mail: aandacos@gmail.com

4 Ph.D in Plant Physiology and Weed Science by New Mexico State University, USA; M.Sc. in Plant Nutrition by Colegio de Postgraduados, México; B.Sc. in Agronomy by Universidad Autónoma Chapingo, México. Current affiliation: Associate Professor-Researcher at Colegio de Postgraduados, Campus San Luis Potosí. Salinas de Hgo, SLP, México. E-mail: ismaelhr@colpos.mx

5 Ph.D in Soil Water Erosion in the Purdue University. USA. M.Sc. in Soil Physics for the Colegio de Postgraduados, México. Agronomic Engineering for the Universidad Autónoma Chapingo. México. Affiliation: Professor-Researcher at Universidad Autónoma de Querétaro, Querétaro, México. E-mail: eventura@uaq.mx

6 Ph.D in Engineering for the Universidad Autónoma de Querétaro. M.Sc. in Chemical Food Engineering for the Universidad Nacional Autónoma de México. México. Affiliation: Professor-Researcher at Universidad Nacional Autónoma de México, México. E-mail: elsaneqpm@yahoo.com.mx

7 Ph.D in Physics in the Centro de Investigación y Estudios Avanzados of Instituto Politécnico Nacional, México. M.Sc. in Physics of the Universidad Autónoma de San Luís Potosí, México. B.Sc in Physics of the Universidad del Quindío, Colombia, Affiliation: Researcher at Universidad Nacional Autónoma de México, Querétaro. México. E-mail: marioga@fata.unam.mx

How to cite: Mosquera-Artamonov, J. D., Vasco-Leal, J. F., Acosta-Osorio, A. A., Hernandez-Rios, I., Ventura-Ramos, E., Gutiérrez-Cortez, E., & Rodríguez-Garcia, M. E. (2016). Optimization of castor seed oil extraction process using response surface methodology. Ingeniería e Investigación, 36(3), 82−88. DOI: 10.15446/ing.investig.v36n3.55632

ABSTRACT

This work focuses on the study of the oil extraction yield from castor seed using three different seed conditions: whole, minced and bare endosperm. Taguchi design was used to determine the contribution of the following parameters: seed condition, seed load in the extractor, temperature, and pressure. It was proved that it is necessary to introduce the whole seed and that the presence of the pericarp increases the extraction yield. The contribution of the control factors has an extraction yield limit. After determining which factors contributed to the process, these were left at their optimum levels aiming to reduce the control factors to only two. The complete analysis was done using a surface response methodology giving the best parameter for temperature and pressure that allows a better yielding mechanical extraction. The oil extraction yield can be kept up to 35 % of the seed.

Keywords: Experiment design, mechanical extraction, Ricinus communis L.

RESUMEN

Este trabajo se centra en el estudio de la extracción y la producción de aceite de semillas de ricino usando tres diferentes estados de semillas: entera, partida y sin testa. Se utilizó un diseño Taguchi para determinar la contribución de los siguientes parámetros: estado de las semillas, cantidad de semilla en el extractor, temperatura y presión. Se demostró que es necesario introducir la semilla entera para aumentar el rendimiento de la extracción. La contribución de los factores de control tiene un límite de extracción en la variable respuesta (rendimiento). Después de determinar cuáles factores contribuían altamente al proceso de extracción y cuáles no, se procedió a dejarlos en los niveles de mayor contribución con la finalidad de reducir el número de factores de control a dos. Posteriormente se utilizó la metodología de superficie de respuesta para la optimización del proceso, dando como resultado los niveles óptimos para los factores de control temperatura y presión. De acuerdo con las pruebas, el rendimiento de la extracción del aceite se puede mantener en un 35 % de la semilla.

Palabras clave: Diseño de experimentos, extracción mecánica, Ricinus communis L.

Received: January 1st 2016

Accepted: August 31st 2016

Introduction

Castor bean (Ricinus communis L.) is a shrub that originates from Africa. Its seed is commonly known as ‘higuerilla’, ‘ricine’ or ‘mamona’ (Ali et al., 2008;Scholz & Da Silva 2008). The optimal growth conditions are loamy to sandy loam soils and temperatures ranging from 20 to 30 °C. In addition, the annual rainfall should be between 700 and 1500 mm (Valderrama et al., 1994; Ogunniyi, 2006) for the optimal development of the plant. Nevertheless, it adapts to tropical, subtropical, and semiarid conditions, tolerating extreme environmental stresses, including high temperatures and low water availability. At present, the oil extracted from its seeds has many different applications, which include but are not limited to: hydraulic oil, paint thinner, emulsifier, varnishes, pharmaceutical applications, organic fertilizers, biological pest control, manufacture of polymers, and dyes (Ogunniyi, 2006; Lorestani et al. 2012), with biodiesel production being another well-known use (Kılıç et al., 2013).

Oil from castor bean seeds may undergo changes according to the extraction procedure (Ortiz et al., 2003). A particularly noticeable change is the modification in the free fatty acid content when heat is used during extraction. Heating around 100 °C generates triricinoleine decomposition of ricinoleic acid and diricinoleine, resulting in increased oil acidity (Salimon et al. 2010).

The transesterified biodiesel obtained from Ricinus communis L. oil is a potential alternative for solving problems associated with biofuels produced from other sources (first-generation oil, used cooking oils, waste animal fats, etc.), which have shown difficulties in their cold flow properties and oxidative stability, generating storage problems (Perdomo et al., 2013).

Hincapié et al. (2011) used castor oil to produce biodiesel by transesterification, obtaining a conversion rate of 74,9 % when potassium carbonate was used as a catalyst, and 66,2 % when the catalyst was hemimorphite. On the other hand, Montoya et al. (2010) used the response surface method to optimize the ethanolysis process, achieving a transesterification rate of 93,63 %. These authors have focused their research mainly on the transesterification process, but have not considered the oil extraction procedure from seeds.

Rios et al. (2007) compared three procedures for oil extraction from cardamom seeds. Fontal (2007) worked on oil extraction by extrusion from coffee seeds, carrying out sensorial tests and the analysis of the volatile compounds in the oil, without considering the oil extraction process. Perdomo et al., (2013) characterized physically and chemically seeds of seven castor bean accessions from central Mexico; also, seed oil was extracted by three different methods (chemical solvent, cold pressing, and warm pressing).

Methods for vegetable oil extraction from seeds

Several processes can be used to obtain oil. The most common oil extraction procedures are classified as: expeller pressing, hydraulic pressing, and solvent-dependent extraction.

The expeller-pressing procedure is widely used in the food industry; raw materials are squeezed under high pressure, either in one step or in batches (Pradhan et al., 2011). The extraction is based on a screw that presses the raw materials against the walls of a metallic cylinder; oil is recovered through a mesh that do not allow the passage of solids (Evangelista 2009). The system is commonly equipped with a temperature control device to avoid any damage to the oil that may affect its properties.

Hydraulic pressing is somehow similar to the expeller pressing method, but it yields higher quality oil, and it is more economical at an industry level (Sriti et al., 2011); however, it works only for seed batch extraction. In this case, a hydraulic piston is used to press raw materials against a rigid surface with small openings to separate oil and solid residues. Extraction may be done at room temperature or under increased seed temperature; in the second case, oil yield is enhanced, but oil chemical properties may be altered (Perdomo et al. 2013).

Solvent-extraction methods are based on the addition of organic liquid chemicals to ground seeds, and the mixture is then filtered and subsequently heated to around 150 °C to remove solvents by evaporation (Qian et al., 2010). Due to the use of solvents and high temperature, this is a high-cost method, and it is used mostly at a laboratory level.

The aim of this research was to optimize the extraction process of oil from Ricinus communis L. using a hydraulic press, and the techniques of experimental designs.

Experimental procedure Material

The seed accession used in this study was collected in the State of Queretaro, Mexico, and named VQ-4 (Perdomo et al., 2013). In terms of experiment design, Figure 1a shows a complete seed (‘whole’) that defines one of the conditions used for the oil extraction; Figure 1b presents the second seed condition, defined as ‘minced’; and Figure 1c defines the third condition, designated as ‘bare endosperm’. These three conditions of the seed were used to feed the oil extractor.

(a)

(a)

(b)

(b)

(c)

(c)

Figure 1. a) Whole seed, b) broken, and c) bare endosperm Ricinus communis L.

Oil extraction equipment

Oil extraction was carried out with a temperature-controlled stainless steel prototype, with a maximum load capacity of 400 g. The extraction device has a cylinder to enclose the seeds and a plunger for pressure application. The prototype is assembled with a hydraulic press (Mikel, México), with a maximum pressure capacity of 68,65 MPa and a 150-mm piston. The system has a thermal casing with a commercial strength of 1000 W at 127 V, and a data logger connected to a k-type thermocouple for temperature-controlled oil extraction.

Oil extraction performance

Immediately after extractions, oil was centrifuged twice at 1300 rpm for 16 min to remove debris.

Kinetic Viscosity

Determination of the oil rheological behavior was done with a Rheomat viscometer (Mettler Toledo, USA). Samples were heated to 40 °C, and measurements were run in triplicate using the standard procedure D445 of the American Society of Testing and Materials (ASTM), designed to determine kinematic viscosity of transparent and opaque liquids.

Color

Oil color was measured with a Minolta colorimeter Model CR300 (Konica Minolta, Japan), according to ASTM D1500-12.

Turbidity

Turbidity was determined with a Hanna Instruments turbidimeter (Hanna, Italia) set with an infrared mode (Lau et al., 2000).

Statistical Analysis

Statistical analysis was performed from a Taguchi experimental design, with an orthogonal array of L9, with two replications (Taguchi, 1987; Miranda, 2009). Temperature values were: 20 °C, 40 °C, and 60 °C; pressure levels were 22,85 MPa, 34,32 MPa, and 45,80 MPa; seed materials used were 100 g, 200 g, and 300 g, for the three seed conditions: whole, minced, and bare endosperm (Figure 1). Analysis of variance (α = 0,05) was used to determine statistical significance of response variables. With the information collected through the Taguchi design, correlation and principal components analyses were performed (Esbense & Geladi, 2009).

The response surface methodology proposed for the analysis, is a central composite design (CCD) consisting of two factors with two blocks, three points central, three points axial cube, with two replications, run randomly (Montgomery, 2013). The central point is replicated several times to provide an independent estimate of the experimental error; α used for this design was 1,414. Temperature factor ranged from 40 °C to 60 °C, and pressure from 22,85 MPa to 45,80 MPa.

Results and discussion

Taguchi design

Table 1 shows the results for Taguchi design for turbidity, viscosity, color, and extraction yield. Regardless of the combination between pressure and temperature, no oil is extracted at all when bare endosperm is used, suggesting that seed coat is required for oil percolation to the collector within the extraction prototype.

Table 1. Results obtained from Taguchi design.

|

Run |

Temp |

Pressure |

Sample |

Seed |

Turbidity |

Viscosity |

Color |

Extraction |

|

8 |

20 |

22,85 |

100 |

1 |

188,250 |

0,330 |

9,55 |

20,44 |

|

4 |

20 |

34,32 |

200 |

2 |

212,500 |

0,360 |

10,37 |

13,62 |

|

1 |

20 |

45,8 |

300 |

3 |

0,000 |

0,000 |

0,00 |

0,00 |

|

9 |

40 |

22,85 |

200 |

3 |

0,000 |

0,000 |

0,00 |

0,00 |

|

3 |

40 |

34,32 |

300 |

1 |

194,400 |

0,340 |

12,26 |

30,69 |

|

5 |

40 |

45,8 |

100 |

2 |

204,500 |

0,350 |

11,70 |

30,65 |

|

7 |

60 |

22,85 |

300 |

2 |

228,000 |

0,370 |

16,25 |

31,95 |

|

2 |

60 |

34,32 |

100 |

3 |

0,000 |

0,000 |

0,00 |

0,00 |

|

6 |

60 |

45,8 |

200 |

1 |

191,600 |

0,330 |

14,52 |

35,55 |

Seed condition (1) Whole, (2) Minced, (3) Bare endosperm.

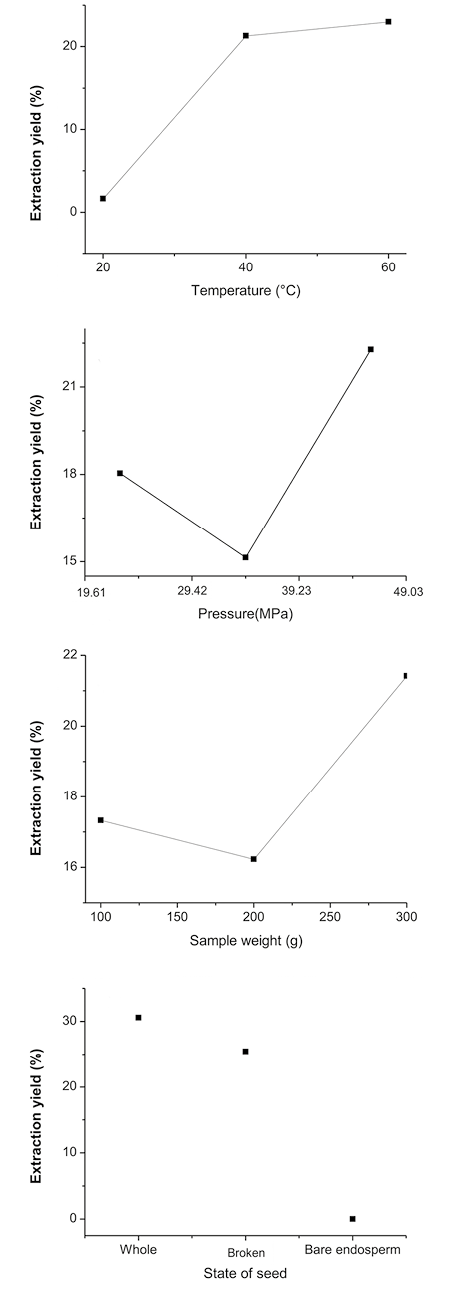

The effects of temperature (a), pressure (b), sample weight (c), and seed conditions (d) on extraction yield are presented in Figure 2. There is a slight increase in oil extraction (Figure 2a) when the temperature increases from 20 °C to 60 °C because temperature facilitates the breaking of fatty acids in the seed, allowing the exudation of oil. Figure 2b presents the extraction yield as a function of the pressure, showing an increase in the extraction yield (from 34,32 MPa to 45,80 MPa). Figure 2c shows that increasing the sample weight had just a little contribution to the extraction yield (6 % -100g to 300g). It can also be noticed a significant decrease in the extraction performance affected by the condition of the seed, with no oil extraction at all from bare endosperms Figure 2d; this leads to the inference that the seed coat is required for oil percolation from the top of the collector cylinder to the filter. As it happened with bare endosperm, minced seed (broken) also had a decrease in oil extraction yield, compared to the whole seed, which presented the higher extraction values. In terms of the industry, these results show that it is necessary to use the whole seed in order to increase the extraction yield, suggesting that the paths formed by the pericarp facilitates oil extraction.

Figure 2. Effects of extraction factors.

The contribution of each factor to oil extraction yield was as follows: seed condition (82 %), temperature (12 %), pressure (4 %) and seed amount in the container (2 %). The extraction of oil increases when the process involves the whole seed and also when the container temperature is increased.

Correlation and principal component analysis

The percentages of correlation between the response variables were: very high, with four iterations over 95 % (viscosity-turbidity, color, turbidity, color-performance, and color-viscosity), and two iterations being less than 90 % (oil extraction performance-turbidity, viscosity-yield) although over 85 %. Thus, raising the level of either variable will have a positive effect on the remaining three variables.

Table 2 shows the principal components for analysis; for the first component (PC1), variation is explained by 95,7 %, and the correlations of the variables are positive, although these are low. In the second component, variation is explained by 99,4 %, and the correlations changed significantly. Then, the experiment contains two major components.

Table 2. Principal component analysis.

|

Eigenvalue |

3,827 |

0,1500 |

0,022 |

0,000 |

|

Proportion |

0,957 |

0,0380 |

0,006 |

0,000 |

|

Accumulated |

0,957 |

0,9940 |

1,000 |

1,000 |

|

Variable |

PC1 |

PC2 |

PC3 |

PC4 |

|

Oil extraction |

0,487 |

0,765 |

-0,410 |

-0,093 |

|

Turbidity |

0,503 |

-0,456 |

-0,088 |

-0,729 |

|

Viscosity |

0,503 |

-0,430 |

-0,355 |

0,660 |

|

Color |

0,506 |

0,145 |

0,835 |

0,158 |

When considering two principal components, the correlation matrix shows that increasing the system performance could decrease oil turbidity and viscosity. This type of relationship has also been observed using a supercritical fluid process (Sheibani & Ghaziaskar 2008). Those decreased oil properties could affect the use of castor bean oil for biodiesel production, since low viscosity and acidity are recommended for that purpose (ASTM D6751).

Response surface methodology

For the implementation of the central composite design with two controllable factors, the ‘whole’ seed condition is used for the high contribution (82 %), and a load of 100 g of seeds, to increase oil extraction performance (Table 2).

The controllable factors are: temperature between 40 °C and 60 °C, and pressure from 22,85 MPa to 45,70 MPa. Table 3 presents the design used with data obtained for each performed run.

Using the average values for extraction showed in Table 3, and the Kolmogorov-Smirnov statistic test with 95 % confidence, it was shown that data collected for performance follows a normal distribution with a p-value of 0,090 (Izraelevitz et al., 2011). For standard deviation, Bonferroni confidence intervals of 95 % were performed for each level. Using the statistics proposed by Bartlett, values are greater than α = 0,05, stating that it does not have problems of heteroskedasticity.

Table 3. Experimental design runs for central composite design.

|

Experiment (rum) |

Temperature |

Pressure |

Average |

Average |

||

|

Encrypted units |

(°C) |

Encrypted units |

(MPa) |

|||

|

14 |

−1 |

40 |

−1 |

22,9 |

20,166 |

0,391 |

|

11 |

1 |

60 |

−1 |

22,9 |

27,849 |

0,481 |

|

9 |

−1 |

40 |

1 |

45,8 |

26408 |

0,473 |

|

10 |

1 |

60 |

1 |

45,8 |

33,611 |

0,511 |

|

12 |

0 |

50 |

0 |

34,3 |

31,210 |

0,479 |

|

13 |

0 |

50 |

0 |

34,3 |

31,210 |

0,462 |

|

8 |

0 |

50 |

0 |

34,3 |

31,219 |

0,466 |

|

7 |

−1,41 |

36 |

0 |

34,3 |

24,008 |

0,484 |

|

2 |

1,41 |

64 |

0 |

34,3 |

33,611 |

0,452 |

|

6 |

0 |

50 |

−1,41 |

18,1 |

20,166 |

0,46 |

|

5 |

0 |

50 |

1,41 |

50,6 |

32,65 |

0,456 |

|

4 |

0 |

50 |

0 |

34,3 |

29,769 |

0,468 |

|

3 |

0 |

50 |

0 |

34,3 |

31,210 |

0,529 |

|

1 |

0 |

50 |

0 |

34,3 |

28,809 |

0,466 |

Table 4 presents the iteration pressure*temperature, which had no significant effect on the response variable studied; therefore, it was excluded from the analysis. The response variable had a quadratic response (p-value 0,001), in which both pressure and temperature showed an effect, and had a quadratic relationship.

Table 4. ANOVA for central composite design.

|

Source |

Degree |

Adjusted sum |

Adjusted |

F ratio |

P value |

|

Regression |

5 |

253,64 |

20,067 |

39,78 |

0,000 |

|

Linear |

2 |

40,13 |

34,997 |

15,74 |

0,002 |

|

Pressure |

1 |

34,99 |

7,28 |

27,44 |

0,001 |

|

Temperature |

1 |

7,28 |

21,14 |

5,71 |

0,044 |

|

Square |

2 |

42,29 |

36,75 |

16,58 |

0,001 |

|

Pressure*Pressure |

1 |

36,76 |

7,81 |

28,82 |

0,001 |

|

Temperature*Temp |

1 |

7,81 |

1,27 |

6,12 |

0,038 |

|

Residual Error |

8 |

10,20 |

1,82 |

− |

− |

|

Lack-of-fit |

4 |

7,28 |

0,73 |

2,49 |

0,199 |

|

Pure error |

4 |

2,92 |

20,07 |

− |

− |

|

Total |

13 |

263,84 |

− |

− |

− |

S= 1,12929 R-sq. = 96,13 % R-sq.(adjusted) = 93,72%

Equation (1) represents the variation present in the bearing performance, as control variables are temperature and pressure:

Where: OEY is oil extraction yield, P is pressure, T is temperature, and ε is the absolute error  ; regression equation in units unencrypted.

; regression equation in units unencrypted.

According to the Equation (1) and Table 4, all the terms proposed are significant (p-value <0,05), opposed to the results obtained in a study conducted by Goswami et al., (2009). This research seeks to optimize bioconversion of castor bean oil into ricinoleic acid, finding an equation that characterizes that process. However, due to the lack of significances (p-value > 0,05) in several of the studied variables, these results cannot be conclusive on this pursuit.

The normality of the residuals (p-value = 0,109 Anderson Darling test) is supported by the results and the model presented.

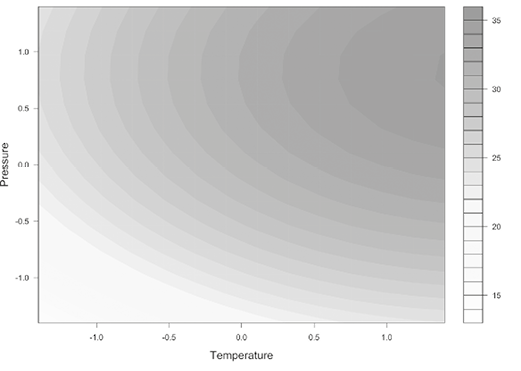

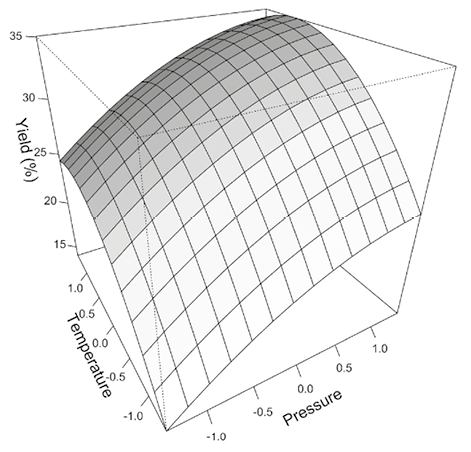

Figure 3 shows the contours produced for increasing the yield in oil extraction. Oil yield increases when levels of both controllable factors are raised.

Figure 3. Contour plots for pressure and temperature.

Looking at the response surface for oil extraction yield (Figure 4), the optimization point to get the greatest oil yield performance (35,07 %) was observed at a pressure of 50,31 MPa (0,8403 units unencrypted), and a temperature of 64 °C (1,41 units unencrypted). On the other hand, the control factors had a significant increase in performance (Figure 3), but this significance tends to have a limit, where the control factors did not increase oil yield (Figure 4). This outcome could be due to a high compression of the seed within the extraction device, resulting in a lack of paths for oil flowing to the collector component.

Figure 4.

Scenario analysis

Scenario analysis was developed using optimization techniques (Derringer & Suich, 1980). Three scenarios are detected (Table 5) to determine the optimal levels for the extraction process, taking into account oil yield and viscosity. Table 5 shows the variation related to the possibility of changing pressure and temperature for the extraction process, depending on the importance given to either oil yield or viscosity.

Table 5. Analysis of scenarios to determine the best combination, between variables extraction yield and viscosity.

|

Scenario |

Control |

Response |

Target |

Value |

Desirability |

|

1 |

Pressure |

Max |

49,380 |

0,668 |

|

|

Temperature |

Min |

40,830 |

|||

|

Extraction yield |

Max |

28,161 |

|||

|

Viscosity |

Min |

0,471 |

|||

|

2 |

Pressure |

Min |

30,870 |

0,651 |

|

|

Temperature |

Max |

64,000 |

|||

|

Extraction yield |

Max |

30,180 |

|||

|

Viscosity |

Min |

0,477 |

|||

|

3 |

Pressure |

Min |

50,310 |

0,894 |

|

|

Temperature |

Max |

63,030 |

|||

|

Extraction yield |

Max |

34,546 |

|||

|

Viscosity |

Min |

0,470 |

Confirmation runs following the recommended settings

In order to test the results of the analysis developed, two seed oil extraction runs were performed using the optimal setting values obtained (Table 6). According to these tests, oil yield can be increased by 35 % or even more just by controlling those factors that generate higher variability during the extraction process.

Table 6. Confirmation runs.

|

Experiment |

Seed |

Pressure |

Temperature |

Extraction |

|

1 |

Whole |

50,31 |

64 |

36,01 |

|

2 |

50,31 |

64 |

34,81 |

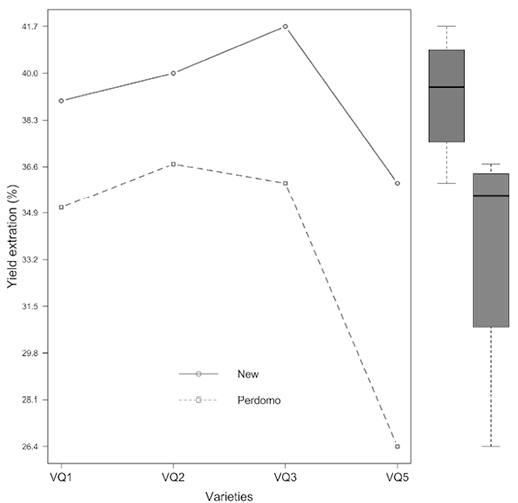

Figure 5 illustrates the extraction yield percent of both process, that one carried out in this work (new), and that performed by Perdomo et al. (2013) in four castor seeds varieties. The new extraction process showed an oil yield enhancement in all the seed varieties compared to the extraction yield obtained by Perdomo et al. (2013). In addition, the new process decreases the deviation by 12 % ± 5% to 7 % ± 2 %, obtaining an improvement of 54 % in comparison with Perdomo et al,(2013).

Figure 5.

Conclusions

The condition of the seed has a high contribution to the performance of the oil extraction process (82 %), while the amount of the material load has no effect on the process. Extraction yield, turbidity, viscosity, and color are highly correlated (> 85 %). These variables presented two main components: extraction yield and viscosity, coupled with turbidity. The contribution of the control factors has a yield extraction limit. Increasing pressure (> 50,31 MPa) has no effect on extracting performance, which is due to a high compaction of the seed within the device.

Acknowledgments

This work was partially supported by Dirección de Vinculación Tecnológica y Proyectos Especiales UAQ. J.D. Mosquera-Artamanov and J.F. Vasco-Leal were supported by a scholarship from the CONACYT.

References

Ali, R.M., Elfeky, S.S., & Abbas, H. (2008). Response of salt stressed Ricinus commnunis L. to exogenous application of glycerol and/or aspartic acid. Journal of Biological Science, 8 (1), 171–175. DOI: 10.3923/jbs.2008.171.175

Derringer, G., & Suich, R. (1980). Simultaneous optimization of several response variables. Journal of Quality Technology, 12(4), 214-219.

Esbensen, K.H., & Geladi, P. (2009). Principal component analysis: Concept, Geometrical Interpretation, Mathematical Background, Algorithms, History, Practice. Comprehensive Chemometrics, 2, 11-226.

Evangelista, R. (2009). Oil extraction from lesquerella seeds by dry extrusion and expelling. Industrial Crops and Products, 29(1), 189-196. DOI: 10.1016/j.indcrop.2008.04.024.

Fontal, L.M.E. (2007). Extracting oil from coffee. Ingeniería e Investigación, 27(1), 25-31.

Goswami, D., Sen, R. Kumar, J.B., & De S. (2009). Maximization of bioconversion of castor oil into ricinoleic acid by response surface methodology. Bioresource Technology, 100 (18), 4067-4073. DOI: 10.1016/j.biortech.2008.11.040.

Hincapié Triviño, G. M., Moreno Lopera, J. A., & López López, D. P. (2011). Transesterificación de aceite de higuerilla crudo utilizando catalizadores heterogéneos-estudio preliminares. DYNA, 78(169) (2011), 176-181.

Izraelevitz, A.M., Anderson-Cook, C.M., & Hamada, M.S. (2011). Illustrating the Use of Statistical Experimental Design and Analysis for Multiresponse Prediction and optimization. Quality Engineering, 23(3), 265-277. DOI: 10.1080/08982112.2011.575499.

Kılıç, M., Uzun, B. B., Pütün, E., & Pütün, A. E. (2013). Optimization of biodiesel production from castor oil using factorial design. Fuel Processing Technology, 111, 105-110. DOI: 10.1016/j.fuproc.2012.05.032.

Lau, M., Tang, J., & Paulson, A. (2000). Texture profile and turbidity of gellan/gelatin mixed gels. Food Research International, 33(8), 665-671. DOI: 10.1016/S0963-9969(00)00111-3.

Lorestani, A. N., Jaliliantabar, F., & Gholami, R. (2012). Physical and mechanical properties of castor seed. Quality Assurance and Safety of Crops & Foods, 4(5), e29-e32. DOI: 10.1111/qas.12002

Miranda, V. (2009) Product design: techniques for reliability, robustness and optimization. Toluca: Tecnológico de Monterrey.

Montgomery, D.C. (2013.). Design and Analysis of Experiments 8th ed. Wiley: New York.

Montoya, J., Benjumea, P., & Pashova, V. (2011). Optimization of the basic ethanolysis of ricin oil using the response surface methodology. DYNA, 78(168), 90-97.

Ogunniyi, D.S. (2006). Castor oil: A vital industrial raw material. Bioresource Technology, 97, 1086–1091. DOI: 10.1016/j.biortech.2005.03.028.

Ortiz, M.A., Dorantes, L., Galíndez, J., & Guzmán, R.I. (2003). Effect of Different Extraction Methods on Fatty Acids, Volatile Compounds, and Physical and Chemical Properties of Avocado (Persea americana Mill.) Oil. Journal of Agricultural and Food Chemistry, 51(8), 2216-2221. DOI: 10.1021/jf0207934.

Perdomo, F.A., Acosta-Osorio, A.A., Herrera G, Vasco-Leal, J.F., Mosquera-Artamonov, J.D., Millan-Malo, B., & Rodriguez-Garcia, M.E. (2013). Physicochemical characterization of seven Mexican Ricinus communis L. seeds and oil contents. Biomass and Bioenergy, 48, 17-24. DOI:10.1016/j.biombioe.2012.10.020.

Pradhan, R. C., Mishara, S., Naik, S. N., Bhatnagar, N., & Vijay, V. K. (2011). Oil expression from Jatropha seeds using a screw press expeller. Biosystems Engineering, 109(2), 158-166. DOI: 10.1016/j.biosystemseng.2011.02.012.

Qian, J., Shi, H., & Yun, Z. (2010). Preparation of biodiesel from Jatropha curcas L. oil produced by two-phase solvent extraction. Bioresource Technology, 101(18), 025-7031. DOI: 10.1016/j.biortech.2010.04.018.

Ríos, L., Lopera, G., Caicedo, R., Granda, F., Montoya, A., Restrepo, G., & Suárez, R. (2008). Extracción y caracterización de aceite de cardamomo (Elettaria cardamomum). DYNA, 74(151), 47-52. Retrieved from: http://revistas.unal.edu.co/index.php/dyna/article/view/891

Salimon. J., Aleemanohdnoor, D., Nazrizawati, A. T., & Mohdnoor, M.Y. (2010). Fatty acid composition and physicochemical properties of Malaysian castor bean Ricinus communis L. Seed Oil. Science of Malaysian, 39(5), 761-761.

Scholz, V., & Da Silva, J. N. (2008). Prospects and risks of the use of castor oil as fuel. Biomass and Bioenergy, 32, 95–100. DOI: 10.1016/j.biombioe.2007.08.004.

Sheibani, A., & Ghaziaskar, H. S. (2008). Pressurized fluid extraction of pistachio oil using a modified supercritical fluid extractor and factorial design for optimization. LWT - Food Science and Technology, 41(8), 1472-1477. DOI: 10.1016/j.lwt.2007.09.002.

Sriti, J., Talou, T., Faye, M., Vilarem, G., & Marzouk, B. (2011). Oil extraction from coriander fruits by extrusion and comparison with solvent extraction processes. Industrial Crops and Products, 33(3), 659-664. DOI: 10.1016/j.indcrop.2011.01.005.

Taguchi, G. (1987). System of Experimental Desing, Vol 1, Unipub/Kraus International. White Plains, New York.

Valderrama, J.C., Mery, A., & Aravena, F. (1994). La Higuerilla y su principal producto, el aceite de ricino. Parte I. Aspectos principales. Información Tecnológica, 5(1), 87-90.

Attribution 4.0 International (CC BY 4.0) Share - Adapt

References

Ali, R.M., Elfeky, S.S., & Abbas, H. (2008). Response of salt stressed Ricinus commnunis L. to exogenous application of glycerol and/or aspartic acid. Journal of Biological Science, 8 (1), 171–175. DOI: 10.3923/jbs.2008.171.175

Derringer, G., & Suich, R. (1980). Simultaneous optimization of several response variables. Journal of Quality Technology, 12(4), 214-219.

Esbensen, K.H., & Geladi, P. (2009). Principal component analysis: Concept, Geometrical Interpretation, Mathematical Background, Algorithms, History, Practice. Comprehensive Chemometrics, 2, 11-226.

Evangelista, R. (2009). Oil extraction from lesquerella seeds by dry extrusion and expelling. Industrial Crops and Products, 29(1), 189-196. DOI: 10.1016/j.indcrop.2008.04.024.

Fontal, L.M.E. (2007). Extracting oil from coffee. Ingeniería e Investigación, 27(1), 25-31.

Goswami, D., Sen, R. Kumar, J.B., & De S. (2009). Maximization of bioconversion of castor oil into ricinoleic acid by response surface methodology. Bioresource Technology, 100 (18), 4067-4073. DOI: 10.1016/j.biortech.2008.11.040.

Hincapié Triviño, G. M., Moreno Lopera, J. A., & López López, D. P. (2011). Transesterificación de aceite de higuerilla crudo utilizando catalizadores heterogéneos-estudio preliminares. DYNA, 78(169) (2011), 176-181.

Izraelevitz, A.M., Anderson-Cook, C.M., & Hamada, M.S. (2011). Illustrating the Use of Statistical Experimental Design and Analysis for Multiresponse Prediction and optimization. Quality Engineering, 23(3), 265-277. DOI: 10.1080/08982112.2011.575499.

Kılıç, M., Uzun, B. B., Pütün, E., & Pütün, A. E. (2013). Optimization of biodiesel production from castor oil using factorial design. Fuel Processing Technology, 111, 105-110. DOI: 10.1016/j.fuproc.2012.05.032.

Lau, M., Tang, J., & Paulson, A. (2000). Texture profile and turbidity of gellan/gelatin mixed gels. Food Research International, 33(8), 665-671. DOI: 10.1016/S0963-9969(00)00111-3.

Lorestani, A. N., Jaliliantabar, F., & Gholami, R. (2012). Physical and mechanical properties of castor seed. Quality Assurance and Safety of Crops & Foods, 4(5), e29-e32. DOI: 10.1111/qas.12002

Miranda, V. (2009) Product design: techniques for reliability, robustness and optimization. Toluca: Tecnológico de Monterrey.

Montgomery, D.C. (2013.). Design and Analysis of Experiments 8th ed. Wiley: New York.

Montoya, J., Benjumea, P., & Pashova, V. (2011). Optimization of the basic ethanolysis of ricin oil using the response surface methodology. DYNA, 78(168), 90-97.

Ogunniyi, D.S. (2006). Castor oil: A vital industrial raw material. Bioresource Technology, 97, 1086–1091. DOI: 10.1016/j.biortech.2005.03.028.

Ortiz, M.A., Dorantes, L., Galíndez, J., & Guzmán, R.I. (2003). Effect of Different Extraction Methods on Fatty Acids, Volatile Compounds, and Physical and Chemical Properties of Avocado (Persea americana Mill.) Oil. Journal of Agricultural and Food Chemistry, 51(8), 2216-2221. DOI: 10.1021/jf0207934.

Perdomo, F.A., Acosta-Osorio, A.A., Herrera G, Vasco-Leal, J.F., Mosquera-Artamonov, J.D., Millan-Malo, B., & Rodriguez-Garcia, M.E. (2013). Physicochemical characterization of seven Mexican Ricinus communis L. seeds and oil contents. Biomass and Bioenergy, 48, 17-24 DOI:10.1016/j.biombioe.2012.10.020.

Pradhan, R. C., Mishara, S., Naik, S. N., Bhatnagar, N., & Vijay, V. K. (2011). Oil expression from Jatropha seeds using a screw press expeller. Biosystems Engineering, 109(2), 158- 166. DOI: 10.1016/j.biosystemseng.2011.02.012.

Qian, J., Shi, H., & Yun, Z. (2010). Preparation of biodiesel from Jatropha curcas L. oil produced by two-phase solvent extraction. Bioresource Technology, 101(18), 025-7031. DOI: 10.1016/j.biortech.2010.04.018.

Ríos, L., Lopera, G., Caicedo, R., Granda, F., Montoya, A., Restrepo, G., & Suárez, R. (2008). Extracción y caracterización de aceite de cardamomo (Elettaria cardamomum). DYNA, 74(151), 47-52. Retrieved from: http://revistas.unal.edu.co/index.php/dyna/article/view/891

Salimon. J., Aleemanohdnoor, D., Nazrizawati, A. T., & Mohdnoor, M.Y. (2010). Fatty acid composition and physicochemical properties of Malaysian castor bean Ricinus communis L. Seed Oil. Science of Malaysian, 39(5), 761-761.

Scholz, V., & Da Silva, J. N. (2008). Prospects and risks of the use of castor oil as fuel. Biomass and Bioenergy, 32, 95–100. DOI: 10.1016/j.biombioe.2007.08.004.

Sheibani, A., & Ghaziaskar, H. S. (2008). Pressurized fluid extraction of pistachio oil using a modified supercritical fluid extractor and factorial design for optimization. LWT - Food Science and Technology, 41(8), 1472-1477. DOI: 10.1016/j.lwt.2007.09.002.

Sriti, J., Talou, T., Faye, M., Vilarem, G., & Marzouk, B. (2011). Oil extraction from coriander fruits by extrusion and comparison with solvent extraction processes. Industrial Crops and Products, 33(3), 659-664. DOI: 10.1016/j.indcrop.2011.01.005.

Taguchi, G. (1987). System of Experimental Desing, Vol 1, Unipub/Kraus International. White Plains, New York.

Valderrama, J.C., Mery, A., & Aravena, F. (1994). La Higuerilla y su principal producto, el aceite de ricino. Parte I. Aspectos principales. Información Tecnológica, 5(1), 87-90.

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

CrossRef Cited-by

1. Hossein Ahangari, Jerry W. King, Ali Ehsani, Mohammad Yousefi. (2021). Supercritical fluid extraction of seed oils – A short review of current trends. Trends in Food Science & Technology, 111, p.249. https://doi.org/10.1016/j.tifs.2021.02.066.

2. Maria Guadalupe Villarreal-Marroquin, Jose Daniel Mosquera-Artamonov, Celso E. Cruz, Jose M. Castro. (2020). A sequential surrogate-based multiobjective optimization method: effect of initial data set. Wireless Networks, 26(8), p.5727. https://doi.org/10.1007/s11276-019-02212-2.

3. Zoran B. Todorović, Petar M. Mitrović, Vesna Zlatković, Nada L. Grahovac, Ivana B. Banković-Ilić, Dragan Z. Troter, Ana M. Marjanović-Jeromela, Vlada B. Veljković. (2024). Optimization of oil recovery from oilseed rape by cold pressing using statistical modeling. Journal of Food Measurement and Characterization, 18(1), p.474. https://doi.org/10.1007/s11694-023-02138-6.

4. Francisco Maciel Monticeli, Sergio Roberto Montoro, Herman Jacobus Cornelis Voorwald, Maria Odila Hilário Cioffi. (2020). Porosity Characterization of Carbon Fiber/Epoxy Composite Using Hg Porosimetry and Other Techniques. Polymer Engineering & Science, 60(4), p.841. https://doi.org/10.1002/pen.25343.

5. Ayodeji OMOTEHİNSE, Godwin OVUWORİE. (2021). Optimization of Small Castor Seed (Ricinus Communis) Oil Extraction Yield Using Response Surface Methodology. International Journal of Agriculture Environment and Food Sciences, 5(3), p.294. https://doi.org/10.31015/jaefs.2021.3.6.

6. José F. Vasco-Leal, M. Liceth Cuellar-Nuñez, Ivan Luzardo-Ocampo, Eusebio Ventura-Ramos, G. Loarca-Piña, M. E. Rodriguez-García. (2021). Valorization of Mexican Ricinus communis L. Leaves as a Source of Minerals and Antioxidant Compounds. Waste and Biomass Valorization, 12(4), p.2071. https://doi.org/10.1007/s12649-020-01164-5.

7. Liu Yang, Huan Chen, Miao Hu, Shaoyun Song, Yonglin Zhang. (2022). Optimization of Mechanical Extraction by Response Surface Methodology and Oil Yield Characterization from Single‐Grain Castor Seed. European Journal of Lipid Science and Technology, 124(9) https://doi.org/10.1002/ejlt.202200016.

8. T H Tran, P T N Nguyen, V T T Ho, T H N Le, L G Bach, T D Nguyen. (2019). Using soft computing approaches for orange (Citrus nobilis Lour. var. nobilis) oils extraction process. IOP Conference Series: Materials Science and Engineering, 479, p.012015. https://doi.org/10.1088/1757-899X/479/1/012015.

9. Is Fatimah, Suresh Sagadevan, Baranya Murugan, Oki Muraza. (2022). Biorefinery of Oil Producing Plants for Value‐Added Products. , p.51. https://doi.org/10.1002/9783527830756.ch4.

10. Jelena M. Avramovic, Ana M. Marjanović Jeromela, Miljana S. Krstić, Biljana M. Kiprovski, Ana V. Veličković, Dragana D. Rajković, Vlada B. Veljković. (2025). Castor Oil Extraction: Methods and Impacts. Separation & Purification Reviews, 54(1), p.60. https://doi.org/10.1080/15422119.2024.2361674.

11. Kartikkumar Thakkar, Surendra Singh Kachhwaha, Pravin Kodgire. (2023). Enhanced castor seed oil extraction assisted by the synergistic effect of ultrasound and microwave: Impact on extraction effectiveness and oil quality. Chemical Engineering and Processing - Process Intensification, 185, p.109307. https://doi.org/10.1016/j.cep.2023.109307.

12. Kenneth Kennedy Adama, Osikemekha Anthony Anani. (2023). Experimental and theoretical assessment of phenomena linked with separation and purification of biodiesel from Ricinus communis seed oil. Heliyon, 9(6), p.e16536. https://doi.org/10.1016/j.heliyon.2023.e16536.

13. Eduardo Valdés, J. D Mosquera‐Artamonov, Celso Cruz‐Gonzalez, Jose Jaime Taha‐Tijerina. (2021). Multiobjective optimization on adhesive bonding of aluminum‐carbon fiber laminate. Computational Intelligence, 37(1), p.621. https://doi.org/10.1111/coin.12432.

14. Jose Daniel Mosquera, Jose Fernando Vasco-Leal, Ismael Hernandez-Rios, Santiago De Jesus Mendez-Gallegos, Maria De Jesus Perea-Flores, Juan Manuel Peña-Aguilar, Mario Enrique Rodriguez-Garcia. (2018). Physicochemical characteristics of seeds from wild and cultivated castor bean plants (Ricinus communis L.). Ingeniería e Investigación, 38(1), p.24. https://doi.org/10.15446/ing.investig.v38n1.63453.

Dimensions

PlumX

Article abstract page views

Downloads

License

Copyright (c) 2016 J. D. Mosquera-Artamonov, J. F. Vasco-Leal, A. A. Acosta-Osorio, I. Hernandez-Rios, E. Ventura-Ramos, E. Gutiérrez-Cortez, M. E. Rodríguez-Garcia

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors or holders of the copyright for each article hereby confer exclusive, limited and free authorization on the Universidad Nacional de Colombia's journal Ingeniería e Investigación concerning the aforementioned article which, once it has been evaluated and approved, will be submitted for publication, in line with the following items:

1. The version which has been corrected according to the evaluators' suggestions will be remitted and it will be made clear whether the aforementioned article is an unedited document regarding which the rights to be authorized are held and total responsibility will be assumed by the authors for the content of the work being submitted to Ingeniería e Investigación, the Universidad Nacional de Colombia and third-parties;

2. The authorization conferred on the journal will come into force from the date on which it is included in the respective volume and issue of Ingeniería e Investigación in the Open Journal Systems and on the journal's main page (https://revistas.unal.edu.co/index.php/ingeinv), as well as in different databases and indices in which the publication is indexed;

3. The authors authorize the Universidad Nacional de Colombia's journal Ingeniería e Investigación to publish the document in whatever required format (printed, digital, electronic or whatsoever known or yet to be discovered form) and authorize Ingeniería e Investigación to include the work in any indices and/or search engines deemed necessary for promoting its diffusion;

4. The authors accept that such authorization is given free of charge and they, therefore, waive any right to receive remuneration from the publication, distribution, public communication and any use whatsoever referred to in the terms of this authorization.